Abstract

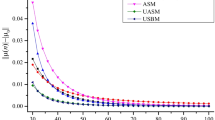

Chatter suppression during milling operations is of great significant for tool life, surface quality, and cutting efficiency. Based on the Hamming and Simpson methods, a Hamming–Simpson–based method is presented in this paper for accurately and efficiently determining the milling stability. The milling dynamic model with consideration of the regeneration effect is expressed by delay differential equations (DDEs) with time-periodic coefficients. After separating the tooth-passing period into two different phases, the two linear multistep methods are simultaneously adopted to estimate the state term by discretizing the forced vibration phase into time intervals of equal length. Subsequently, the state transition matrix can be determined over one period and the chatter-free borderline can be searched according to the Floquet theory. On this basis, the precision and efficiency of the Hamming–Simpson–based method are analyzed in detail through comparing with the three benchmark methods. Analysis results indicate that the Hamming method is required to convert variables which may affect the prediction accuracy. To overcome this shortcoming and promote the computational accuracy, a three-step implicit multistep exponential fitting method is applied to predict chatter stability; meanwhile, the Simpson method is responsible for the correction of the prediction. The effectiveness of the proposed method has been comparatively analyzed through two benchmark examples. Numerical simulations illustrate that the proposed method exhibits better prediction accuracy and computational efficiency.

Similar content being viewed by others

References

Altintas Y (2012) Manufacturing automation: metal cutting, mechanics, machine tool vibrations, and CNC design. Cambridge University Press, New York

Siddhpura M, Paurobally R (2012) A review of chatter vibration research in turning. Int J Mach Tools Manuf 61(10):27–47

Altintas Y, Stepan G, Merdol D, Dombovari Z (2008) Chatter stability of milling in frequency and discrete time domain. CIRP J Manuf Sci Technol 1(1):35–44

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376

Wiercigroch M, Budak E (2001) Sources of nonlinearities, chatter generation and suppression in metal cutting. Philos Trans R Soc Lond A 359(1781):663–693

Faassen RPH, Van De Wouw N, Oosterling JAJ, Nijmeijer H (2003) Prediction of regenerative chatter by modeling and analysis of high-speed milling. Int J Mach Tools Manuf 43(14):1437–1446

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann 53(2):619–642

Ding H, Ding Y, Zhu LM (2012) On time-domain methods for milling stability analysis. Chin Sci Bull 57(33):4336–4345

Altintas Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann 44(1):357–362

Budak E, Altintas Y (1998) Analytical prediction of chatter stability in milling—part II: application of the general formulation to common milling systems. ASME J Dyn Syst Meas Control 120(1):31–36

Merdol SD, Altintas Y (2004) Multi frequency solution of chatter stability for low immersion milling. J Manuf Sci Eng 126(3):459–466

Balachandran B (2001) Nonlinear dynamics of milling processes. Philos Trans R Soc A 359(1781):793–819

Balachandran B, Zhao MX (2000) A mechanics based model for study of dynamics of milling operations. Meccanica 35(2):89–109

Long X, Balachandran B (2007) Stability analysis for milling process. Nonlinear Dyn 49(3):349–359

Bayly PV, Halley JE, Mann BP, Davies MA (2003) Stability of interrupted cutting by temporal finite element analysis. J Manuf Sci Eng 125(2):220–225

Butcher EA, Bobrenkov OA, Bueler E, Nindujarla P (2009) Analysis of milling stability by the Chebyshev collocation method: algorithm and optimal stable immersion levels. J Comput Nonlinear Dyn 4(3):031003

Yan Z, Liu Z, Wang X, Liu B, Luo Z, Wang D (2016) Stability prediction of thin-walled workpiece made of Al7075 in milling based on shifted Chebyshev polynomials. Int J Adv Manuf Technol 1–10

Insperger T, Stépán G (2004) Updated semi-discretization method for periodic delay-differential equations with discrete delay. Int J Numer Methods Biomed Eng 61(1):117–141

Insperger T, Stépán G, Turi J (2008) On the higher-order semi-discretizations for periodic delayed systems. J Sound Vib 313(1–2):334–341

Insperger T (2010) Full-discretization and semi-discretization for milling stability prediction: some comments. Int J Mach Tools Manuf 50(7):658–662

Jiang SL, Sun YW, Yuan XL, Liu WR (2017) A second-order semi-discretization method for the efficient and accurate stability prediction of milling process. Int J Adv Manuf Technol 92(1–4):583–595

Ding Y, Zhu LM, Zhang XJ, Ding H (2010a) A full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 50(5):502–509

Ding Y, Zhu LM, Zhang XJ, Ding H (2010b) Second-order full discretization method for milling stability prediction. Int J Mach Tools Manuf 50(10):926–932

Quo Q, Sun YW, Jiang Y (2012) On the accurate calculation of milling stability limits using third-order full-discretization method. Int J Mach Tools Manuf 62:61–66

Ozoegwu CG, Omenyi SN, Ofochebe SM (2015) Hyper-third order full-discretization methods in milling stability prediction. Int J Mach Tools Manuf 92:1–9

Liu YL, Zhang DH, Wu BH (2012) An efficient full-discretization method for prediction of milling stability. Int J Mach Tools Manuf 63:44–48

Ji YJ, Wang XB, Liu ZB, Wang HJ, Yan ZH (2018) An updated full-discretization milling stability prediction method based on the higher-order Hermite-Newton interpolation polynomial. Int J Adv Manuf Technol 95(5–8):2227–2242

Tang X, Peng F, Yan R, Gong Y, Li Y, Jiang L (2017) Accurate and efficient prediction of milling stability with updated full discretization method. Int J Adv Manuf Technol 88(9–12):2357–2368

Yan Z, Wang X, Liu Z, Wang D, Jiao L, Ji Y (2017) Third-order updated full-discretization method for milling stability prediction. Int J Adv Manuf Technol 92(5–8):2299–2309

Li MZ, Zhang GJ, Huang Y (2013) Complete discretization scheme for milling stability prediction. Nonlinear Dyn 71:187–199

Xie QZ (2016) Milling stability prediction using an improved complete discretization method. Int J Adv Manuf Technol 83(5–8):815–821

Li ZQ, Yang ZK, Peng YR, Zhu F, Ming XZ (2016) Prediction of chatter stability for milling process using Runge-Kutta-based complete discretization method. Int J Adv Manuf Technol 86(1–4):943–952

Niu JB, Ding Y, Zhu LM, Ding H (2014) Runge–Kutta methods for a semi-analytical prediction of milling stability. Nonlinear Dyn 76(1):289–304

Dai Y, Li H, Xing X, Hao B (2018) Prediction of chatter stability for milling process using precise integration method. Precis Eng 52:152–157

Dai Y, Li H, Hao B (2018) An improved full-discretization method for chatter stability prediction. Int J Adv Manuf Technol 96(9–12):3503–3510

Li H, Dai Y, Fan Z (2019) Improved precise integration method for chatter stability prediction of two-DOF milling system. Int J Adv Manuf Technol 101(5–8):1235–1246

Ding Y, Zhu LM, Zhang XJ, Ding H (2011) Numerical integration method for prediction of milling stability. J Manuf Sci Eng 133(3):031005

Ding Y, Zhu LM, Zhang XJ, Ding H (2013) Stability analysis of milling via the differential quadrature method. J Manuf Sci Eng 135:044502

Zhang Z, Li HG, Meng G, Liu C (2015) A novel approach for the prediction of the milling stability based on the Simpson method. Int J Mach Tools Manuf 99:43–47

Zhang X, Xiong C, Ding Y, Ding H (2017) Prediction of chatter stability in high speed milling using the numerical differentiation method. Int J Adv Manuf Technol 89(9–12):2535–2544

Qin CJ, Tao JF, Li L, Liu CL (2017) An Adams-Moulton-based method for stability prediction of milling processes. Int J Adv Manuf Technol 89(9–12):3049–3058

Tao JF, Qin CJ, Liu CL (2017) Milling stability prediction with multiple delays via the extended Adams-Moulton-based method. Math Probl Eng 2017:1–15

Qin CJ, Tao JF, Liu CL (2017) Stability analysis for milling operations using an Adams-Simpson-based method. Int J Adv Manuf Technol 92(1–4):969–979

Tang C, Yan HQ, Zhang H, Chen ZQ, Liu M, Zhang GM (2005) The arbitrary order implicit multistep schemes of exponential fitting and their applications. J Comput Appl Math 173(1):155–168

Tang C, Wang WP, Yan HQ, Chen ZQ (2006) High-order predictor corrector of exponential fitting for the N-body problems. J Comput Phys 214(2):505–520

Funding

This work was partially supported by the Natural Science Foundation of Jiangsu Province Outstanding Youth Fund (Grant No. BK20160084) and the Fundamental Research Funds for the Central Universities (Grant No. NS2016056).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, Y., You, Y. & Jiang, J. A stability prediction method research for milling processes based on implicit multistep schemes. Int J Adv Manuf Technol 105, 3271–3288 (2019). https://doi.org/10.1007/s00170-019-04487-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-04487-3