Abstract

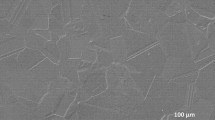

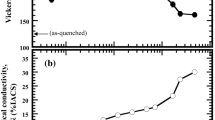

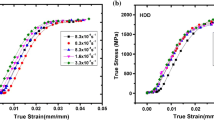

The microstructure and mechanical properties of Cu-12wt%Al alloy wires which are composed of continuous columnar crystals after dieless drawing forming at drawing speed of 1.0–1.4 mm/s and deformation temperature of 600–900°C were analyzed, and deformation behavior of the alloy during dieless drawing forming was experimentally investigated. The results showed that in the above-mentioned conditions, recrystallization phenomenon was not found during dieless drawing forming. When a drawing speed of 1.0 mm/s was used, the grain boundaries were out of straight gradually with increasing deformation temperature from 600°C to 900°C, and tensile strength of the dieless drawn Cu-12wt%Al alloy wires increased while elongations decreased with increasing deformation temperature. At drawing speed of 1.1–1.2 mm/s and deformation temperature of 600°C, the effect of dieless drawing forming process on the microstructure of the alloy was inconspicuous, and when drawing speed was up to 1.3–1.4 mm/s, the grain boundaries of continuous columnar crystals became zigzag while there was little effect of drawing speed of 1.1–1.4 mm/s on the elongation and tensile strength of the alloy wires.

Similar content being viewed by others

References

Gao L L, Cheng X H. Microstructure and dry sliding wear behavior of Cu-10%Al–4%Fe alloy produced by equal channel angular extrusion. Wear, 2008, 265: 986–991

Kudashov D V, Zauter R, Müller H R. Spray-formed high-aluminium bronzes. Mater Sci Eng A, 2008, 477: 43–49

Ji D P, Liu X F, Xie J X, et al. Preparation of Cu-12%Al albronze wires by continuous unidirectional solidification (in Chinese). Acta Metall Sin, 2006, 42: 1243–1247

Zhang H, Xie J X, Wang Z D. Fabrication of pure copper rods containing continuous columnar crystals by continuous unidirectional solidification technology. J Univ Sci Technol Beijing, 2004, 11: 240–244

Li Y G, Nathaniel R Q, Aravinda K. Dieless laser drawing of fine metal wires. J Mater Process Tech, 2002, 123: 451–458

Furushima T, Manabe K. Experimental study on multi-pass dieless drawing process of superplastic Zn-22%Al alloy microtubes. J Mater Process Tech, 2007, 187: 236–240

Wang Z T, Zhang S H, Xu Y, et al. Experiment study on the variation of wall thickness during dieless drawing of stainless steel tube. J Mater Process Tech, 2002, 120: 90–93

Carolan R, Tiernau P, Commerford P. The dieless drawing of high carbon steel. Mater Sci Forum, 2004, 447–448: 513–520

Furushima T, Manabe K. FE analysis of size effect on deformation and heat transfer behavior in microtube dieless drawing. J Mater Process Tech, 2008, 201: 123–127

Naughton M D, Tiernan P. Requirements of a dieless wire drawing system. J Mater Process Tech, 2007, 191: 310–313

Li Y G, Nathaniel R Q, Aravinda K. Structural evolution and drawability in laser dieless drawing of fine nickel wires. Mater Sci Eng A, 2003, 358: 59–70

Tiernan P, Hillery M T. Dieless wire drawing—an experimental and numerical analysis. J Mater Process Tech, 2004, 155–156: 1178–1183

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the National Basic Research Program of China (Grant No. 2006CB605200), the National High Technology Research and Development Program of China (Grant No. 2006AA03Z506), the National Natural Science Foundation of China (Grant Nos. 50674008 and 50634010) and the Program for New Century Excellent Talents in University of China (Grant No. NCET-06-0083)

Rights and permissions

About this article

Cite this article

Liu, X., Wu, Y. & Xie, J. Deformation behavior of Cu-12wt%Al alloy wires with continuous columnar crystals in dieless drawing process. Sci. China Ser. E-Technol. Sci. 52, 2232–2236 (2009). https://doi.org/10.1007/s11431-009-0236-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-009-0236-8