Abstract

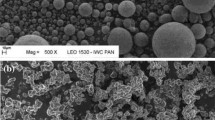

By means of transient plastic phase process, the Al2O3-SiC-Me composites were produced throungh adding metal aluminium and silicon-powder to Al2O3-SiC materials. Under the condition of the same content of silicon and aluminium mixed-powder, the effect of silicon powder addition on properties of Al2O3-SiC-Me composites was studied by means of XRD and EPMA analyses in the temperature range of 300°–1600°C. The results indicated that the content of metal phase in the sample at 1600°C increases with increasing silicon powder content. At the same time, when the temperature is lower than 1100°C, the strength of samples gradually increases with increasing temperature. However when the temperature is higher than 1100°C, the strength of samples gradually decreases with increasing temperature, and this change is very small. The results also indicated that at the same sintering temperature, the sample with 6% silicon powder has the maximum strength.

Similar content being viewed by others

References

Barsoum M W, Houng B. Transient plastic phase processing of titanium-boron-carbon composites. J Am Ceram Soc, 1993, 76(6): 1445–1451

Barsoum M W. Methods for densifying and strengthening ceramic-ceramic composites by transient plastic phase processing. Ceram Eng & Sci Pro, 1994, 15(4): 121–124

Hong Y R, Sun J L, Wang X T, et al. Non-oxide Composite Refractories. Beijing: Metallurgical Industry Publishing House, 2003. 1–120

Yue W D, Nie H B, Zhong X C, et al. Thermo mechanical properties and microstructure of Al-Si metal contained unfired Al2O3-C slide plate. Nai Huo Cai Liao, 2006, 40(3): 177–180

Ruan G Z, Li N, Zhang Z H. Effect of heat treatment temperature on structure and property of Al2O3-SiC-Al composite. Nai Huo Cai Liao, 2006, 40(3): 169–172

Eitan M. Microstructure evolution of SiC/Al2O3/Al-alloy composite produced by melt oxidation. J Am Ceram Soc, 1993, 76(7): 1777–1787

Li Y W, Wang A J, Jin S L. Influence of heat treatment temperature on properties of unburned Al2O3-C slide plate bonded with silicon resin. Nai Huo Cai Liao, 2005, 39(5): 321–325

Ernest M L, Howard F M. Phase Diagrams for Ceramists 1975 Supplement. Westerville: The American Ceramic Society, 1975

Author information

Authors and Affiliations

Corresponding author

Additional information

Supported by the Chen Yunbo Academician Fund (Grant No. 2007CY021)

Rights and permissions

About this article

Cite this article

Zhang, Z., Ruan, G. & Chen, Y. Effect of the silicon powder content on the properties of Al2O3-SiC-Me composites. Sci. China Ser. E-Technol. Sci. 52, 193–197 (2009). https://doi.org/10.1007/s11431-009-0021-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-009-0021-8