Abstract

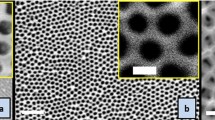

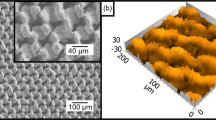

Conventional lithographic printing processes using porous alumina for offset applications generally use “wet” routes. Recently “dry” processes have been developed which are based on a heat-induced hydrophilic/oleophilic conversion of one or more layers of the coating so that a stronger affinity towards ink or water fountain is created at the exposed areas with respect to the surface of the unexposed coating. Treatments involving rf plasma-enhanced fluorination (PEF) constitute exceptional tools for modifying the surface properties of materials. Many advantages of these techniques can be indeed outlined, when compared to more conventional methods: room-temperature reactions, chemical modifications limited to surface only without changing the bulk properties, possible non-equilibrium reactions. The influence of PEF treatments on porous alumina layer used in printing plates has been tested with various fluorinated gases (CF4, C3F8 and C4F8) and characterized by XPS. The hydrophobic properties of the fluorinated layer have been deduced from contact angle measurements. Using C4F8 rf-PEF treatment, the outmost surface of the hydrophilic alumina substrate used for lithographic printing is hydrophobized, or in other words, the hydrophilic substrate is converted into a support with hydrophobic properties. Once being hydrophobized, the surface layer may be rendered hydrophilic using a heat pulse, thus giving rise to switchable hydrophobic-hydrophilic properties of the material.

Similar content being viewed by others

References

Cardinaud C, Tressaud A. Surface modification of inorganic materials by fluorination. In: Nakajima T, Tressaud A, Žemva B, eds. Advanced Inorganic Fluorides. Amsterdam: Elsevier, 2000. 437–492

Nansé G, Papirer E, Fioux P, et al. Fluorination of carbon blacks, Carbon 35. Amsterdam: Pergamon-Elsevier, 1997. 175–194, 371–388 and 515–528

Tressaud A, Durand E, Labrugère C. Plasma-enhanced fluorination of nitrile butadiene elastomer: an XPS study. In: d’Agostino R, Favia P, eds. Plasma Processes & Polymers. Weinheim: Wiley-VCH, 2005

Tressaud A, Durand E, Labrugère C. Surface modification of carbon-based materials: comparison between CF4 rf cold plasma and direct F2-gas fluorination routes. J Fluorine Chem, 2004, 125: 1639–1648

Rodriguez L M, Alcaraz J, Hernandez M, et al. Alkylation of benzene with propylene catalyzed by fluorinated alumina. Appl Catal A: General, 1998, 169: 15–27

Babel D, Tressaud A. Crystal chemistry of fluorides. In: Hagenmuller P, ed. Inorganic Solid Fluorides, Chap. 3. New York: Academic Press, 1985

Andriessen H, Brigouleix C, Tressaud A. Processless lithographic printing plate. European Patent EP 1 640 175 A1, Agfa-Gevaert, March 2006

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tressaud, A., Labrugère, C., Durand, E. et al. Switchable hydrophobic-hydrophilic layer obtained onto porous alumina by plasma-enhanced fluorination. Sci. China Ser. E-Technol. Sci. 52, 104–110 (2009). https://doi.org/10.1007/s11431-008-0328-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-008-0328-x