Abstract

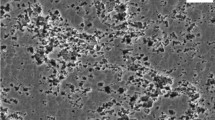

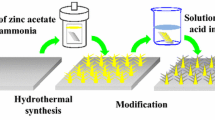

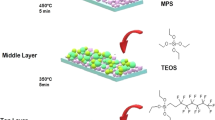

Inspired by lotus-effect, superhydrophobicity has attracted considerable interest in various areas such as self-cleaning, antifouling and liquid transportation, and so on. Superhydrophobic surfaces can be prepared mostly by altering the surface with creating micro/nanoscale structures or with chemically modifying by materials of low surface energy. In this study, the electrochemically fabricated nanoporous alumina is deposited with poly(dimethylsiloxane) via a one-step thermal treatment to achieve ultra-water repellent or superhydrophobic surfaces. Nanoporous anodic alumina substrates with varying pore diameters were used for the poly(dimethylsiloxane) deposition, and their morphological characterization is carried out using the field emission scanning electron microscope. Energy-dispersive X-ray spectroscopy, Fourier transform infrared spectroscopy inferred the chemical composition, while contact angle measurements using a commercial contact angle measurement system is exploited to probe the water spreading behaviour on the fabricated substrates. The substrates also exhibit high repellence behaviour towards ethylene glycol. The superhydrophobic behaviour of the fabricated substrates is investigated while the substrate is immersed in organic solvents like decane, hexane and toluene. In addition, the super repellence behaviour of the substrates against the corrosive chemicals such as aqua regia and saturated sodium hydroxide is investigated and the substrate was found to retain its super repellence behaviour against corrosive solutions. Further, the self-cleaning properties and antifouling behaviour of the fabricated substrates were also demonstrated.

Similar content being viewed by others

References

George J E, Unnikrishnan V, Mathur D, Chidangil S and George S D 2018 Sens. Actuators B Chem.272 485

George S D, Chidangil S and Mathur D 2018 Langmuir35 10139

Bixler G D and Bhushan B 2013 Adv. Funct. Mater.23 4507

Blossey R 2003 Nat. Mater.2 301

Daniello R J, Waterhouse N E and Rothstein J P 2009 Phys. Fluids21 085103

Ionov L, Houbenov N, Sidorenko A, Stamm M and Minko S 2006 Adv. Funct. Mater.16 1153

Miljkovic N, Enright R and Wang E N 2012 ACS Nano6 1776

Nishimoto S and Bhushan B 2013 RSC Adv.3 671

Wang C, Yao T, Wu J, Ma C, Fan Z, Wang Z et al 2009 ACS Appl. Mater. Interfaces1 2613

Xia F and Jiang L 2008 Adv. Mater.20 2842

Zhao L, Liu Q, Gao R, Wang J, Yang W and Liu L 2014 Corros. Sci.80 177

Zhou X, Zhang Z, Xu X, Guo F, Zhu X, Men X et al 2013 ACS Appl. Mater. Interfaces5 7208

Jiao Y, Lv X, Zhang Y, Li C, Li J, Wu H et al 2019 Nanoscale11 1370

Yuan S, Zhang X, Lin D, Xu F, Li Y and Wang H 2020 Prog. Org. Coat.142 105563

Barthlott W and Neinhuis C 1997 Planta202 1

Liu X, Liang Y, Zhou F and Liu W 2012 Soft Matter8 2070

Ghasemlou M, Daver F, Ivanova E P and Adhikari B 2019 J. Mater. Chem. A7 16643

Wang S, Liu K, Yao X and Jiang L 2015 Chem. Rev.115 8230

Su X, Li H, Lai X, Zhang L, Wang J, Liao X and Zeng X 2017 ACS Appl. Mater. Inter.9 28089

Liu K, Du J, Wu J and Jiang L 2012 Nanoscale4 768

Zhang Y, Qu S, Cheng X, Gao X and Guo X 2016 J. Bionic Eng.13 132

Wang D, Zhao A, Sun H, Chen P and He Q 2018 Colloids Surf. A. Physicochem. Eng. Asp.538 262

Li J, Ueda E, Paulssen D and Levkin P A 2019 Adv. Funct. Mater.29 1802317

Liu Y, Tian Y, Chen J, Gu H, Liu J, Wang R et al 2020 Colloids Surf. A Physicochem. Eng. Asp.588 124384

Sola L, Álvarez J, Cretich M, Swann M J, Chiari M and Hill D 2015 J. Membr. Sci.476 128

Su S, Zhou Q, Zeng Z, Hu D, Wang X, Jin M et al 2018 ACS Appl. Mater. Interfaces10 8026

Law C S, Lim S Y and Santos A 2018 Sci. Rep.8 4642

Schiavi P G, Altimari P, Rubino A and Pagnanelli F 2018 Electrochimica Acta259 711

Zhao H, Wang C, Vellacheri R, Zhou M, Xu Y, Fu Q et al 2014 Adv. Mater.26 7654

Chen Y, Santos A, Wang Y, Kumeria T, Ho D, Li J et al 2015 Sci. Rep.5 12893

Gorokh G G, Pashechko M I, Borc J T, Lozovenko A A, Kashko I A and Latos A I 2018 Appl. Surf. Sci.433 829

Khoobi A, Salavati-Niasari M, Ghani M, Ghoreishi S M and Gholami A 2019 Food Chem.288 39

Choudhari K, Hebbar D, Kulkarni S D, Santhosh C and George S D 2019 Ceram. Int.45 12130

Norek M, Putkonen M, Zaleszczyk W, Budner B and Bojar Z 2018 Mater. Charact.136 52

Politidis C, Alexandris S, Sakellariou G, Steinhart M and Floudas G 2019 Macromolecules52 4185

Choudhari K, Kulkarni S D, Santhosh C and George S D 2018 ECS J. Solid State Sci. Technol.7 R175

Choudhari K, Kulkarni S D, Unnikrishnan V, Sinha R K, Santhosh C and George S D 2019 Nano-Struct. Nano-Objects19 100354

Choudhari K S, Jidesh P, Sudheendra P and Kulkarni S D 2013 Microsc. Microanal.19 1061

Choudhari K S, Kulkarni S D, Santhosh C and George S D 2018 Microporous Mesoporous Mater.271 138

Guo C, Wang X-W and Yuan Z-H 2013 J. Porous Mater.20 673

Feng L, Zhang H, Mao P, Wang Y and Ge Y 2011 Appl. Surf. Sci.257 3959

Wang X, Song W, Li Z and Cong Q 2012 Chinese Sci. Bull.57 4635

Saleema N, Sarkar D K, Gallant D, Paynter R W and Chen X-G 2011 ACS Appl. Mater. Interfaces3 4775

Tanardi C R, Pinheiro A F, Nijmeijer A and Winnubst L 2014 J. Membr. Sci.469 471

Long M, Peng S, Yang X, Deng W, Wen N, Miao K et al 2017 ACS Appl. Mater. Interfaces9 15857

Choudhari K S, Jidesh P and Udayashankar N 2012 Synth. React. Inorg. M42 369

Choudhari K S, Sudheendra P and Udayashankar N 2012 J. Porous Mater.19 1053

Acknowledgements

SDG acknowledges the Manipal Academy of Higher Education for his Dr TMA Pai Endowment Chair in Applied Nanosciences and Department of Science and Technology, Government of India, for the financial assistance through the TDT Division project with sanction No. IDP/BDTD/20/2019.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Supplementary material 1 (m4v 1682 KB)

Supplementary material 2 (mp4 961 KB)

Supplementary material 3 (m4v 5530 KB)

Supplementary material 4 (m4v 1251 KB)

Supplementary material 5 (m4v 1713 KB)

Supplementary material 6 (m4v 2209 KB)

Supplementary material 7 (m4v 4232 KB)

Supplementary material 8 (m4v 7699 KB)

Supplementary material 9 (m4v 2503 KB)

Supplementary material 10 (m4v 1983 KB)

Supplementary material 11 (m4v 1127 KB)

Supplementary material 12 (m4v 5487 KB)

Supplementary material 13 (m4v 2286 KB)

Supplementary material 14 (m4v 1017 KB)

Supplementary material 15 (m4v 1723 KB)

Supplementary material 16 (m4v 1282 KB)

Supplementary material 17 (m4v 4194 KB)

Supplementary material 18 (m4v 928 KB)

Rights and permissions

About this article

Cite this article

Choudhari, K.S., Kulkarni, S.D., Chidangil, S. et al. Facile one-step fabrication of super-repellent nanoporous anodic alumina using a non-fluorinated approach. Bull Mater Sci 43, 193 (2020). https://doi.org/10.1007/s12034-020-02129-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-020-02129-z