Abstract

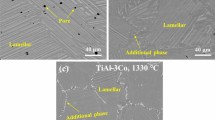

The isothermal oxidation behavior at 900–1300°C for 20 h in air of bulk Ti3AlC2 with 2.8 wt% TiC sintered by means of hot pressing was investigated in the work. The isothermal oxidation behavior generally followed a parabolic rate law. The parabolic rate constants increased from 1.39×10−10 kg2·m−4·s−1 at 900°C to 5.56×10−9 kg2·m−4·s−1 at 1300°C. The calculated activation energy was 136.45 kJ/mol. It was demonstrated that Ti3AlC2 had excellent oxidation resistance due to the continuous, dense and adhesive protect scales consisted of a mass of α-Al2O3 and a little of TiO2 and/or Al2TiO5. In principle, the oxide scale was grown by the inward diffusion of O2− and the outward diffusion of Ti4+ and Al3+. The rapid outward diffusion of cations usually resulted in the formation of cracks, gaps, and holes.

Similar content being viewed by others

References

Barsoum M W, El-Raghy T. Synthesis and characterization of a remarkable ceramic: Ti3SiC2. J Am Ceram Soc, 1996, 79(7): 1953–1956

Barsoum M W, Yaroschuck G, Tyagi S. Fabrication and characterization of M2SnC (M=Ti, Zr, Hf and Nb). Scr Mater, 1997, 10: 1583–1591

Procopio A T, Barsoum M W, El-Raghy T. Characterization of Ti4AlN3. Matall Mater Trans, 2000, 31A(12): 333–337

Sun Z M, Yan S L, Hashimoto H. Ti3SiC2 powder synthesis. Ceram Inter, 2004, 30: 1873–1877

Barsoum M W. The MN+1AXN phases: A new class of solids; thermodynamically stable nanolaminates. Prog Solid St Chem, 2000, 28: 201–281

Wang X H, Zhou Y C. Oxidation behavior of TiC-containing Ti3AlC2 based material at 500–900°C in air. Mat Res Innovat, 2003, 7: 381–390

Wang X H, Zhou Y C. Oxidation behavior of Ti3AlC2 at 1000–1400°C in air. Corrosion Science, 2003, 45: 891–907

Wang X H, Zhou Y C. Oxidation behavior of Ti3AlC2 powders in flowing air. J Mate Chem, 2002, 12(9): 2781–2785

Barsoum M W. Oxidation of Ti n+1AlXn where n=1−3 and X is C, N, part I: Model. J Electrochem Soc, 2001, 148(8): 544–550

Barsoum M W. Oxidation of Ti n+1AlXn where n=1–3 and X is C, N, partII: Experimental Results. J Electrochem Soc, 2001, 148(8): 551–562

Zhu J Q, Mei B C, Xu X W, et al., Synthesis of high-purity Ti3SiC2 and Ti3AlC2 by HP. J Mater Sci Lett, 2003, 22(15): 1111–1112

Zhu J Q, Mei B C, Xu X W, et al. Effect of aluminum on the reaction synthesis of ternary carbide Ti3SiC2. Scr Mater, 2003, 49: 693–697

Ikeda J A, Chiang Y M. Space charge segregation at grain boundaries in titanium dioxide: I, relationship between lattice defect chemistry and space charge potential. J Am Ceram Soc, 1993, 76: 2437–2446

Ikeda J A, Chiang Y M. Space charge segregation at grain boundaries in titanium dioxide: II, model experiments, J Am Ceram Soc, 1993, 76: 2447–2454

Haul R, Dumbgen G. Sauerstoff-selbstdiffusion in rutilkristallen. J Phys Chem Solids, 1965, 26(1): 1–10

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, X., Li, Y., Mei, B. et al. Study on the isothermal oxidation behavior in air of Ti3AlC2 sintered by hot pressing. SCI CHINA SER E 49, 513–520 (2006). https://doi.org/10.1007/s11431-006-0513-8

Received:

Accepted:

Issue Date:

DOI: https://doi.org/10.1007/s11431-006-0513-8