Abstract

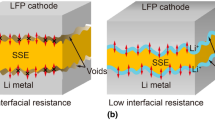

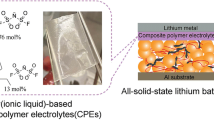

The solid-state electrolyte (SSE) has promising applications in next-generation lithium (Li) metal batteries (LMBs) because of its significantly enhanced safety and more compatible interface characteristics than flammable traditional liquid electrolytes. However, only a few attempts have achieved high-performance high-voltage LMBs, which is attributed to the fact that both high ionic conductivity and good compatibility with electrodes can hardly be achieved simultaneously. Herein, a composite solid-state electrolyte (CSE) based on star-shaped siloxane-based polymer electrolyte coupled with Li6.75La3Zr1.75Ta0.25O12 (LLZTO) ceramic fillers is designed and prepared through a facile in-situ polymerization method. The obtained CSE exhibits high ionic conductivity (i.e., 1.68 × 10−4 S cm−1 at a temperature of 60 °C), superior anodic stability, and high Li-ion transference number (i.e., 0.53) because of the multifunctional synergistic effect of the polymer electrolyte with LLZTO ceramic fillers. Moreover, the as-developed CSE shows excellent compatibility with Li anodes. As a result, the as-developed CSE enables the development of long-life 4.4-V-class solid-state LMBs with a LiCoO2 cathode, with 79.7% capacity retention and 99.74% average Coulombic efficiency after 500 cycles at a 0.5 C rate. Postmortem analysis of cycled batteries confirms that such superior battery performance can be mainly ascribed to the formation of a compatible electrode/electrolyte interface. Furthermore, excellent safety features can be observed in LiCoO2/Li pouch batteries. This work provides an important guide for the rational design of SSEs for high-voltage LMBs.

Similar content being viewed by others

References

Jiao S, Ren X, Cao R, Engelhard MH, Liu Y, Hu D, Mei D, Zheng J, Zhao W, Li Q, Liu N, Adams BD, Ma C, Liu J, Zhang JG, Xu W. Nat Energy, 2018, 3: 739–746

Zhao CZ, Duan H, Huang JQ, Zhang J, Zhang Q, Guo YG, Wan LJ. Sci China Chem, 2019, 62: 1286–1299

Xiao Y, Xu R, Yan C, Liang Y, Ding JF, Huang JQ. Sci Bull, 2020, 65: 909–916

Lv Z, Zhou Q, Zhang S, Dong S, Wang Q, Huang L, Chen K, Cui G. Energy Storage Mater, 2021, 37: 215–223

Han X, Gong Y, Fu KK, He X, Hitz GT, Dai J, Pearse A, Liu B, Wang H, Rubloff G, Mo Y, Thangadurai V, Wachsman ED, Hu L. Nat Mater, 2017, 16: 572–579

Zeng XX, Yin YX, Li NW, Du WC, Guo YG, Wan LJ. J Am Chem Soc, 2016, 138: 15825–15828

Tan SJ, Zeng XX, Ma Q, Wu XW, Guo YG. Electrochem Energy Rev, 2018, 1: 113–138

Zhao CZ, Zhang XQ, Cheng XB, Zhang R, Xu R, Chen PY, Peng HJ, Huang JQ, Zhang Q. Proc Natl Acad Sci USA, 2017, 114: 11069–11074

Huo H, Chen Y, Luo J, Yang X, Guo X, Sun X. Adv Energy Mater, 2019, 9: 1804004

Bae J, Li Y, Zhang J, Zhou X, Zhao F, Shi Y, Goodenough JB, Yu G. Angew Chem Int Ed, 2018, 57: 2096–2100

Huo H, Zhao N, Sun J, Du F, Li Y, Guo X. J Power Sources, 2017, 372: 1–7

Wang Q, Zhang H, Cui Z, Zhou Q, Shangguan X, Tian S, Zhou X, Cui G. Energy Storage Mater, 2019, 23: 466–490

Dong Z, Wei J, Yue H, Zhang K, Wang L, Li X, Zhang Z, Yang W, Yang S. J Colloid Interface Sci, 2021, 595: 35–42

Xue Z, He D, Xie X. J Mater Chem A, 2015, 3: 19218–19253

Zhou D, He YB, Liu R, Liu M, Du H, Li B, Cai Q, Yang QH, Kang F. Adv Energy Mater, 2015, 5: 1500353

Zhou D, Tkacheva A, Tang X, Sun B, Shanmukaraj D, Li P, Zhang F, Armand M, Wang G. Angew Chem Int Ed, 2019, 58: 6001–6006

Zhao Q, Liu X, Stalin S, Khan K, Archer LA. Nat Energy, 2019, 4: 365–373

Wang Y, Ju J, Dong S, Yan Y, Jiang F, Cui L, Wang Q, Han X, Cui G. Adv Funct Mater, 2021, 31: 2101523

Yan Y, Ju J, Dong S, Wang Y, Huang L, Cui L, Jiang F, Wang Q, Zhang Y, Cui G. Adv Sci, 2021, 8: 2003887

Quartarone E, Mustarelli P. Chem Soc Rev, 2011, 40: 2525–2540

Aldalur I, Martinez-Ibañez M, Piszcz M, Rodriguez-Martinez LM, Zhang H, Armand M. J Power Sources, 2018, 383: 144–149

Liu W, Liu N, Sun J, Hsu PC, Li Y, Lee HW, Cui Y. Nano Lett, 2015, 15: 2740–2745

Zhang J, Zhao N, Zhang M, Li Y, Chu PK, Guo X, Di Z, Wang X, Li H. Nano Energy, 2016, 28: 447–454

Zhou Q, Ma J, Dong S, Li X, Cui G. Adv Mater, 2019, 31: 1902029

Park C, Kim DW, Prakash J, Sun YK. Solid State Ion, 2003, 159:111–119

Liu W, Lin D, Sun J, Zhou G, Cui Y. ACS Nano, 2016, 10: 11407–11413

Han JG, Lee JB, Cha A, Lee TK, Cho W, Chae S, Kang SJ, Kwak SK, Cho J, Hong SY, Choi NS. Energy Environ Sci, 2018, 11: 1552–1562

Eshetu GG, Diemant T, Grugeon S, Behm RJ, Laruelle S, Armand M, Passerini S. ACS Appl Mater Interfaces, 2016, 8: 16087–16100

Liang JY, Zhang XD, Zeng XX, Yan M, Yin YX, Xin S, Wang WP, Wu XW, Shi JL, Wan LJ, Guo YG. Angew Chem Int Ed, 2020, 59: 6585–6589

Feng X, Ren D, He X, Ouyang M. Joule, 2020, 4: 743–770

Acknowledgements

This work was supported by the Strategic Priority Research Program of the Chinese Academy of Sciences (XDA21070304), the National Natural Science Foundation of China (51502319, 51803230, 52003285, 21901248), the Natural Science Foundation of Shandong Province (ZR2021QE039, ZR2021QE149, ZR2020MB082), the Key Scientific and Technological Innovation Project of Shandong (2020CXGC010401), and the Taishan Scholars of Shandong Province (ts201511063).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest The authors declare no conflict of interest.

Additional information

Supporting information The supporting information is available online at http://chem.scichina.com and http://link.springer.com/journal/11426. The supporting materials are published as submitted, without typesetting or editing. The responsibility for scientific accuracy and content remains entirely with the authors.

Rights and permissions

About this article

Cite this article

Wang, Q., Dong, T., Zhou, Q. et al. An in-situ generated composite solid-state electrolyte towards high-voltage lithium metal batteries. Sci. China Chem. 65, 934–942 (2022). https://doi.org/10.1007/s11426-022-1221-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11426-022-1221-4