Abstract

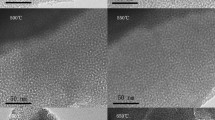

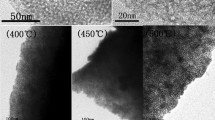

Spherical mesoporous ZrO2-Al2O3 composites containing different zirconia content have been synthesized by an oil-column sol-gel method. A mixed alumina-zirconia hydrosol and hexamethylenetetramine solution were mixed together and added dropwise into a hot oil column. Due to the surface tension, spherical gel particles were formed in the oil column. The spherical gel particles were then aged and washed by deionized water and dried at 120 °C for 12 h and then calcined at 600 °C for 8 h, 960 °C for 8 h or 1200 °C for 12 h. X-ray diffraction and nitrogen adsorption-desorption measurements indicated that the presence of zirconia prevents the sintering of alumina and the obtained ZrO2-Al2O3 composites have much larger surface areas than pure alumina. Temperature-programmed desorption of ammonia results illustrated that the addition of zirconia leads to an increase in the number of strong acid sites and the total number of acid sites compared with pure alumina. Thus, the spherical mesoporous ZrO2-Al2O3 composites prepared in this way were shown to be suitable for high temperature catalytic processes as a catalyst support.

Similar content being viewed by others

References

Lopez-Suarez FE, Bueno-Lopez A, Illan-Gomez MJ. Cu/Al2O3 catalysts for soot oxidation: Copper loading effect. Appl Catal B: Environ, 2008, 84: 651–658

Bikramjit B, Jozef V, Omer Van DB. ZrO2-Al2O3 composites with tailored toughness. J Alloys Compds, 2004, 372: 278–284

Kannisto H, Harelind, HI, Skoglundh M. Ag-Al2O3 catalysts for lean NOx reduction—Influence of preparation method and reductant. J Mol Catal A: Chem, 2009, 302: 86–89

Lu CY, Tseng HH, Wey MY, Liu LY, Kuo JH, Chuang KH. Al2O3-supported Cu-Co bimetallic catalysts prepared with polyol process for removal of BTEX and PAH in the incineration flue gas. Fuel, 2009, 88: 340–347

Zhang LZ, Wang XQ, Tan B, Ozkan US. Effect of preparation method on structural characteristics and propane steam reforming performance of Ni-Al2O3 catalysts. J Mol Catal A: Chem, 2009, 297: 26–34

Sundaramurthy V, Dalai AK, Adjaye J. Tetraalkylthiomolybdates-derived Co(Ni)Mo/γ-Al2O3 sulfide catalysts for gas oil hydrotreating. J Mol Catal A: Chem, 2008, 294: 20–26

Sue-min C, Ruey-an D. Interband transitions in sol-gel-derived ZrO2 films under different calcination conditions. Chem Mater, 2007, 19: 4804–4810

Kaspar J, Fornasiero PJ. Interaction of molecular hydrogen with three-way catalyst model of Pt/Ce0.6Zr0.4O2/Al2O3 type. J Mol Catal A: Chem, 2003, 204: 683–691

Bo L, Ga Z, Hanlin L, Christian Coddet, Ding CX. Friction and wear behavior of ZrO2-Al2O3 composite coatings deposited by air plasma spraying: Correlation with physical and mechanical properties. Surface & Coatings Technology, 2009, 203: 3235–3242

Hao YX, Li JS, Yang XJ, Wang X, Lu LD. Preparation of ZrO2-Al2O3 composite membranes by sol-gel process and their characterization. Materials Science and Engineering A, 2004, 367: 243–247

Meyer A, Michaelisdonn St, Noweck K, US Patent, 4 542 113, Sep. 17th, 1985

Liu PC, Feng JT, Zhang XM, Lin YJ, Evans DG, Li DQ. J Phys Chem Solids, 2008, 69: 799–804

Li H, Lu HX, Wang S, Jia JF, Sun HW, Hu X. Preparation of a nano-sized α-Al2O3 powder from a supersaturated sodium aluminate solution. Ceram Int, 2009, 35: 901–904

Wang H, Guan HB, Duan LY, Xie YC. Dispersion of MgO on Pt/γ-Al2O3 and the threshold effect in NOx storage. Catal Commun, 2006, 7: 802–806

Ram S, Thomas RW, Camden RH, Burtron HD. sulfated zirconia catalysts. the crystal phases and their transformations. Chem Mater, 1995, 7: 725–730

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, Siemicniewska T. Pure Appl Chem, 1985, 57: 603–619

Yan CX, Wang CQ, Yao JF, Zhang LX, Liu XQ. Adsorption of methylene blue on mesoporous carbons prepared using acid- and alkaline-treated zeolite X as the template. Colloids Surf A, 2009, 333: 115–119

Maria DH, Ana RA, Jacob AM Guido M. Identification of the role of surface acidity in the deactivation of TiO2 in the selective photo-oxidation of cyclohexane. Catalysis Today, 2009, 143: 326–333

Hosseinpour N, Khodadadi AA, Mortazavi Y, Bazyari A. Nanoceria-zirconia promoter effects on enhanced coke combustion and oxidation of CO formed in regeneration of silica-alumina coked during cracking of triisopropylbenzene. Appl Catal A: Gen, 2009, 353: 271–281

Tanabe K, Sumiyoshi T, Shibata K, Kiyoura T, Kitagawa J. A new hypothesis regarding the surface acidity of binary metal oxides. Bull Chem Soc Jpn, 1974, 47: 1064–1066

Ohring M. Engineering Materials Science. Elsevier Science and Technology Books, 1995

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Feng, J. & Li, D. Preparation and characterization of spherical mesoporous ZrO2-Al2O3 composites with high thermal stability. Sci. China Chem. 54, 1032–1038 (2011). https://doi.org/10.1007/s11426-011-4282-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11426-011-4282-2