Abstract

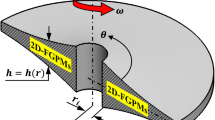

In this paper, we propose a model for the electrical responses of a soft cylindrical structure with shear deformations using piezoelectric sensors. Specifically, to analyze the cylindrical structure during movement, we assumed that a shear force was applied to the flat surface on the top of the structure. Using this force, we established a model using the Euler–Bernoulli beam theory and estimated the electrical responses of the sensors generated by its deformation. To validate the theoretical analysis, a soft cylindrical structure was fabricated using silicone containing piezoelectric sensors. Moreover, a series of tests were performed by applying a tensile testing machine and vibration exciter to the soft structure. During the experiments, we observed the sensor outputs while generating vibrations in the form of triangular and sinusoidal waves. The experimental outputs demonstrate that the sensors can distinguish the displacements and directions of the structural deformations, similar to our predictive model, through the voltage outputs and phase variations of the sensors. Moreover, parametric studies were performed to investigate the sensor responses under structural deformations affected by four parameters related to the material and external forces: the Young’s modulus, radius, mass density, and frequency of the sinusoidal shear force.

Similar content being viewed by others

References

Whitesides GM (2018) Soft robotics. Angew Chem Int Ed 57(16):4258–4273

Lipson H (2014) Challenges and opportunities for design, simulation, and fabrication of soft robots. Soft Rob 1(1):21–27

Trivedi D, Rahn CD, Kier WM, Walker ID (2008) Soft robotics: biological inspiration, state of the art, and future research. Appl Bionics Biomech 5(3):99–117

Youn JH, Mun H, Kyung KU (2021) A wearable soft tactile actuator with high output force for fingertip interaction. IEEE Access 9:30206–30215

Fras J, Noh Y, Macias M, Wurdemann H, Althoefer K (2018) Bio-inspired octopus robot based on novel soft fluidic actuator. In: 2018 IEEE international conference on robotics and automation (ICRA), pp 1583–1588

Xie Z, Domel AG, An N, Green C, Gong Z, Wang T, Knubben EM, Weaver JC, Bertoldi K, Wen L (2020) Octopus arm-inspired tapered soft actuators with suckers for improved grasping. Soft Rob 7(5):639–648

Sol JAHP, Peeketi AR, Vyas N, Schenning APHJ, Annabattula RK, Debije MG (2019) Butterfly proboscis-inspired tight rolling tapered soft actuators. Chem Commun 55(12):1726–1729

Katzschmann RK, Marchese AD, Rus D (2015) Autonomous object manipulation using a soft planar grasping manipulator. Soft Rob 2(4):155–164

Marchese AD, Komorowski K, Onal CD, Rus D (2014) Design and control of a soft and continuously deformable 2D robotic manipulation system. In: 2014 IEEE international conference on robotics and automation (ICRA), pp 2189–2196

Lee YM, Choi HR, Koo JC (2022) Analytical approach to deformation of a soft rotary actuator with double curvature shell shape. J Korea Rob Soc 17(1):68–75

Hashem R, Stommel M, Cheng LK, Xu W (2021) Design and characterization of a bellows-driven soft pneumatic actuator. IEEE ASME Trans Mechatron 26(5):2327–2338

Martinez RV, Fish CR, Chen X, Whitesides GM (2012) Elastomeric origami: programmable paper-elastomer composites as pneumatic actuators. Adv Func Mater 22(7):1376–1384

Ranzani T, Gerboni G, Cianchetti M, Menciassi A (2015) A bioinspired soft manipulator for minimally invasive surgery. Bioinspir Biomim 10(3):035008

Dawood AB, Fras J, Aljaber F, Mintz Y, Arezzo A, Godaba H, Althoefer K (2021) Fusing dexterity and perception for soft robot-assisted minimally invasive surgery: what we learnt from STIFF-FLOP. Appl Sci 11(14):6586

Gul JZ, Yang YJ, Su KY, Choi KH (2017) Omni directional multimaterial soft cylindrical actuator and its application as a steerable catheter. Soft Rob 4(3):224–240

Pfeil S, Henke M, Katzer K, Zimmermann M, Gerlach G (2020) A worm-like biomimetic crawling robot based on cylindrical dielectric elastomer actuators. Front Robot AI 7:9

Elgeneidy K, Lohse N, Jackson M (2018) Bending angle prediction and control of soft pneumatic actuators with embedded flex sensors—a data-driven approach. Mechatronics 50:234–247

Elgeneidy K, Neumann G, Jackson M, Lohse N (2018) Directly printable flexible strain sensors for bending and contact feedback of soft actuators. Front Robot AI 5:2

Costa JC, Spina F, Lugoda P, Garcia-Garcia L, Roggen D, Münzenrieder N (2019) Flexible sensors-from materials to applications. Technologies 7(2):35

Wurdemann HA, Sareh S, Shafti A, Noh Y, Faragasso A, Chathuranga DS, Liu H, Hirai S, Althoefer K (2015) Embedded electro-conductive yarn for shape sensing of soft robotic manipulators. In: 2015 37th Annual international conference of the IEEE engineering in medicine and biology society (EMBC), pp 8026–8029

Chhetry A, Das PS, Yoon H, Park JY (2018) A sandpaper-inspired flexible and stretchable resistive sensor for pressure and strain measurement. Org Electron 62:581–590

Matsuzaki R, Todoroki A (2007) Wireless flexible capacitive sensor based on ultra-flexible epoxy resin for strain measurement of automobile tires. Sens Actuators A 140(1):32–42

Fujimoto KT, Watkins JK, Phero T, Litteken D, Tsai K, Bingham T, Ranganatha KL, Johnson BC, Deng Z, Jaques B, Estrada D (2020) Aerosol jet printed capacitive strain gauge for soft structural materials. Npj Flex Electron 4:32

Galloway KC, Chen Y, Templeton E, Rife B, Godage IS, Barth EJ (2019) Fiber optic shape sensing for soft robotics. Soft Rob 6(5):671–684

Youn JH, Mun H, Jang SY, Kyung KU (2021) Highly stretchable-compressible coiled polymer sensor for soft continuum manipulator. Smart Mater Struct 31(1):015043

Ji Z, Zhang M (2022) Highly sensitive and stretchable piezoelectric strain sensor enabled wearable devices for real-time monitoring of respiratory and heartbeat simultaneously. Nanotechnol Precis Eng 5:013002

Gariya N, Kumar P, Prasad B, Singh T (2023) Soft pneumatic actuator with an embedded flexible polymeric piezoelectric membrane for sensing bending deformation. Mater Today Commun 35:105910

Shapiro Y, Wolf A, Kósa G (2013) Piezoelectric deflection sensor for a bi-bellows actuator. IEEE ASME Trans Mechatron 18(3):1226–1230

Shapiro Y, Kósa G, Wolf A (2014) Shape tracking of planar hyper-flexible beams via embedded PVDF deflection sensors. IEEE ASME Trans Mechatron 19(4):1260–1267

Vinogradov A, Holloway F (1999) Electro-mechanical properties of the piezoelectric polymer PVDF. Ferroelectrics 226(1):169–181

Thuruthel TG, Falotico E, Renda F, Laschi C (2017) Learning dynamic models for open loop predictive control of soft robotic manipulators. Bioinspir Biomim 12(6):066003

Rodrigue H, Wang W, Kim DR, Ahn SH (2017) Curved shape memory alloy-based soft actuators and application to soft gripper. Compos Struct 176:398–406

Jin H, Ouyang Y, Chen H, Kong J, Li W, Zhang S (2022) Modeling and motion control of a soft SMA planar actuator. IEEE ASME Trans Mechatron 27(2):916–927

He G (2019) Motion planning and control for endoscopic operations of continuum manipulators. Intel Serv Robot 12:159–166

Mehrkish A, Janabi-Sharifi F, Goharimanesh M, Norouzi-Ghazbi S (2023) Multiple aspects grasp quality evaluation in underactuated grasp of tendon-driven continuum robots. Intel Serv Robot 16:33–48

Abdarrhim MA, Abdussalam MR (2021) Euler–Bernoulli and Timoshenko Beam theories analytical and numerical comprehensive revision. Eur J Eng Technol Res 6(7):20–32

Jessica LS, Nicholas AV, Krysten EK, Benjamin L, Martin LT, Phillip AS, Karen S, Teresa ACK (2015) Use of silicone materials to simulate tissue biomechanics as related to deep tissue injury. Adv Skin Wound Care 28(2):59–68

Cowper GR (1966) The shear coefficient in Timoshenko’s beam theory. J Appl Mech 33(2):335–340

Chen WR, Chang H (2017) Closed-form solutions for free vibration frequencies of functionally graded Euler–Bernoulli beams. Mech Compos Mater 53:79–98

Chesne S, Pezerat C (2011) Distributed piezoelectric sensors for boundary force measurements in Euler–Bernoulli beams. Smart Mater Struct 20(7):075009

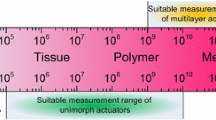

Marechal L, Balland P, Lindenroth L, Petrou F, Kontovounisios C, Bello F (2021) Toward a common framework and database of materials for soft robotics. Soft Rob 8(3):284–297

Lee CK, Moon FC (1989) Laminated piezopolymer plates for torsion and bending sensors and actuators. J Acoust Soc Am 85(6):2432–2439

Kim H, Lim M, Cha Y (2019) Cross-shaped piezoelectric beam for torsion sensing. Smart Mater Struct 29(1):015023

Cha Y, You H (2019) Parameter study on piezoelectric length to harvesting power in torsional loads. IEEE ASME Trans Mechatron 24(3):1220–1227

Caliò R, Rongala UB, Camboni D, Milazzo M, Stefanini C, De Petris G, Oddo CM (2014) Piezoelectric energy harvesting solutions. Sensors 14(3):4755–4790

Howells CA (2009) Piezoelectric energy harvesting. Energy Convers Manag 50:1847–1850

Cha Y (2017) Energy harvesting using flexible piezoelectric materials from human walking motion: theoretical analysis. J Intell Mater Syst Struct 28(20):3006–3015

Erturk A, Tarazaga PA, Farmer JR, Inman DJ (2009) Effect of strain nodes and electrode configuration on piezoelectric energy harvesting from cantilevered beams. J Vib Acoust 131(1):011010

Kipnis N (2009) A law of physics in the classroom: the case of Ohm’s law. Sci Educ 18:349–382

Cha Y, Seo J, Kim JS, Park JM (2017) Human-computer interface glove using flexible piezoelectric sensors. Smart Mater Struct 26(5):057002

Cha Y, Hong J, Lee J, Park JM, Kim K (2016) Flexible piezoelectric energy harvesting from mouse click motions. Sensors 16(7):1045

Li W, Wang WT, Sun WH, Wang WY, Zhu NH (2014) Generation of triangular waveforms based on a microwave photonic filter with negative coefficient. Opt Express 22(12):14993–15001

Kim H, Lee K, Jo G, Kim JS, Lim MT, Cha Y (2021) Tendon-inspired piezoelectric sensor for biometric application. IEEE ASME Trans Mechatron 26(5):2538–2547

Kim B, Lee SB, Lee J, Cho S, Park H, Yeom S, Park SH (2012) A comparison among Neo–Hookean model, Mooney–Rivlin model, and Ogden model for chloroprene rubber. Int J Precis Eng Manuf 13(5):759–764

Eshaghi M, Ghasemi M, Khorshidi K (2021) Design, manufacturing and applications of small-scale magnetic soft robots. Extreme Mech Lett 44:101268

Yu M, Cheng X, Peng S, Cao Y, Lu Y, Li B, Feng X, Zhang Y, Wang H, Jiao Z, Wang P, Zhao L (2022) A self-sensing soft pneumatic actuator with closed-Loop control for haptic feedback wearable devices. Mater Des 223:111149

Gabardi M, Solazzi M, Leonardis D, Frisoli A (2016) A new wearable fingertip haptic interface for the rendering of virtual shapes and surface features. In: 2016 IEEE haptics symposium (HAPTICS), pp 140–146

Kim SJ, Choi JY, Moon HP, Choi HR, Koo JC (2016) Development of polymer slip tactile sensor using relative displacement of separation layer. J Korea Robot Soc 11(2):100–107

Acknowledgements

The authors would like to thank Kyung Min Lee for his help with drawing schematics. This work is supported by the National Research Foundation of Korea (NRF) Grant funded by the Korea Ministry of Science and ICT (MSIT) (No. 2022M3C1A3098746).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors declare that they have no conflict of interest

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Min, J., Kim, H. & Cha, Y. Detecting deformation of a soft cylindrical structure using piezoelectric sensors. Intel Serv Robotics 17, 85–94 (2024). https://doi.org/10.1007/s11370-023-00484-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11370-023-00484-4