Abstract

Purpose

The degrading impacts of livestock production on the environment are well acknowledged. Although ruminants are much studied due to their large contribution to climate change impact, monogastrics are also known to carry a significant load, and mitigation options need investigation. Here, the climate change impact and water scarcity impact of Finnish pork production was investigated using the life cycle assessment approach.

Methods

As the importance of communicating reliable environmental information has been acknowledged in the EU, methods and guidance for this purpose have been developed. Product Environmental Footprint Category Rules have also been published for several food product categories, although not yet for meat. Here, the life cycle assessment methods were used based on PEFCR guidance and the draft version of red meat PEFCR guidance to achieve a reliable, transparent and comparable assessment.

Results

Finnish pork production resulted in a climate change impact of 3.6 kg CO2 eq. kgCW−1 and a water scarcity impact of 0.69 m3 eq. kgCW−1. The largest contribution to the climate change impact came from feed crop production, with an impact of 43%. Land-use changes were included, and their contribution to the Finnish pork climate change impact was 3%. Similarly, in the water scarcity impact, feed crop production was a major contributor, with 41% from fattening pig feed production. Significant contributions to both categories also came from piglet production, including feed crop production, and to the climate change impact from manure storage.

Conclusions

Finnish production was seen to already largely utilise sidestreams and domestic feed ingredients, although, e.g. soybean is still used. Based on the results, in mitigating the environmental impacts of Finnish pork production, attention should especially be paid to the resource-efficient production of domestic feed crops and reduced use of organic soils. As current assessment models are unable to grasp the impacts of regenerative farming techniques, the development of LCA methods is also required. Water scarcity impact was seen to be largely affected by the utilisation of feed crops originating from water-scarce countries. As a mitigation measure, the procurement of these feed crops and ingredients should therefore be directed to water-abundant areas and from production which does not depend on irrigation water or the extensive use of synthetic inputs.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

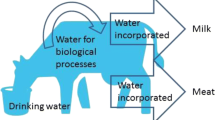

Livestock production is acknowledged to have large degrading impacts on the environment. It has been stated that current food production is responsible for as much as 29–33% of anthropogenic climate impacts (Vermeulen et al. 2012; Clark and Tilman 2017). Springmann et al. (2018) estimated that livestock production was responsible for 72–78% of total agricultural emissions. According to Gerber et al. (2013), pig production is the second largest contributor to climate impacts after cattle-based production, with a 9.5% share of the livestock sector’s total emissions. The majority of the livestock sector’s greenhouse gas emissions are acknowledged to be generated as methane from the enteric fermentation of ruminants. Other significant sources of greenhouse gas emissions in livestock production are feed crop cultivation and manure storing and handling. The demand for an increase in food production and cultivation in areas suffering from drought has increased the use of production inputs and cultivation in areas depending on irrigation. These are directly reflected in the water scarcity impacts of agricultural products (Boulay et al. 2018). According to FAO statistics, the harvested irrigated crop area expanded between 1998 and 2018 from 174 to 369 million ha, with an increasing trend (FAO 2021). More than 70% of freshwater withdrawals are conducted for agricultural use (FAO 2011, 2017). Unsustainable water use is causing local challenges to food production, livelihoods and ecosystems as aquatic habitats degrade. As the livestock sector is understood to generate a significant burden on the environment, there is increasing demand to find ways to mitigate emissions.

In Finland, pork production is the largest of the three most important meat production chains, accounting for about 43% of total meat production. According to the official statistics for meat production in Finland, Finnish meat production accounted for approximately 411 million kg in the peak year of 2021, with more than 7% growth in 10 years (Natural Resources Institute Finland, 2022a). Although the trend in consumption is towards less red meat, pork remains the largest category in Finnish consumption, with 38% (Natural Resources Institute Finland, 2022a, b).

To assess environmental performance, life cycle assessment is a well-adapted method for quantifying impacts per produced product or service. Livestock production has been widely studied for its life cycle impacts, especially for the climate impact. The environmental impacts of European and Nordic pork production have been previously assessed in several studies (Dorca-Preda et al. 2021; González-García et al. 2015; Lamnatou et al. 2016; Noya et al. 2016; Reckmann et al. 2013). However, for Finland, only rough estimates have been published for the sustainability of pork as part of meal portions (Virtanen et al. 2011, Saarinen et al. 2011), while other meat products have recently been assessed using LCA (Hietala et al. 2021; Usva et al. 2023). Typically, pork production LCAs have been conducted with system boundaries from cradle to farmgate or slaughterhouse gate. However, depending on the scope of the study, variation can be seen in setting the system boundaries and selection of methods. Due to these differences in LCA methods, the comparability of the achieved LCA results can be impaired.

To achieve more reliable and consistent LCA results, the European Commission has released harmonised guidance for LCA of product groups — a ‘Product Environmental Footprint’, PEF method (European Commission 2013, 2018a, 2021). The overall aim in developing it has been to reduce various unverified green claims conducted with a variable level of method accuracy. For meat products, finalised PEFCR is still lacking, although a well-developed pilot phase draft for red meat, compiled by the Technical Secretariat of the Red Meat pilot, has been available (European Commission, 2018b).

This study’s objective was to assess current Finnish pork production global warming potential and water scarcity with the life cycle assessment approach. For the life cycle assessment, the European Commission’s Product Environmental Footprint (PEF) method was utilised in the assessment of the selected impact categories (climate change impact and water use).

2 Material and methods

2.1 Finnish pork production

Finnish pork production data were partly collected from major meat-producing companies in Finland (Atria Ltd, HKScan Finland Ltd), whose market share of total production was estimated as 60–80% of total Finnish national production in 2016–2018. Pork production in Finland is mainly concentrated in the western and southwestern regions of Finland near the major slaughterhouses.

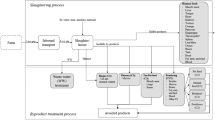

Data acquisition from slaughterhouses included data from farms supplying each slaughterhouse on the slaughter weights and numbers of slaughtered fattening pigs and sows. Slaughterhouse data accounted for a 3-year annual average of 98 million kg carcass weight. The slaughterhouse data were supplemented with data collected from farms supplying the slaughterhouses. The farm data included several fattening pigs, sows, gilts, boars, piglets and weaned piglets with a period length in each phase. Data on feed consumption and feed composition were collected from farms for each pig type. The characteristics of the farm data are presented in Table 1. In Finland, pork production is based either on specialised fattening pig or combined production. In specialised production, farms produce piglets, which are exported to fattening farms after reaching a weight of approx. 30 kg. In combined production, piglets are grown on the same farm as fattening pigs, i.e. from farrow to finish. The study’s system boundary is presented in Fig. 1. Farm activity data were collected for electricity use, heating, water use and the cultivation of feed crops, including fertiliser use and crop yields. Manure management systems were also collected directly from farms.

2.2 Life cycle assessment methods

The environmental life cycle assessment (LCA) of selected impact categories of pork production was conducted following the IPCC and European Commission’s Product Environmental Footprint (PEF) guidelines. As there is currently no Product Environmental Footprint Category Rules (PEFCR) for meat products, we have applied the draft version of the PEFCR for red meat, with the general PEFCR guidance, which was valid when this study was conducted (European Commission, 2018a, b). The feed PEFCR was followed regarding feed compound production (European Commission, 2018c) while feed crop LCA was conducted as described in Hietala et al. (2022). The general PEFCR guidance was followed in sampling and allocation (European Commission 2018a, European Commission 2021, Annex I, Table 18.).

For global warming potential (GWP), the IPCC 5th assessment report was followed with characterisation factor of 1 for CO2, 298 for N2O with climate carbon feedback and 34 for biogenic CH4 in accordance with PEFCR guidance (IPCC 2013; Joos et al. 2013).

LCA was conducted using Simapro software (Pré Sustainability 2022). Microsoft Excel was utilised in data management and calculating diet compositions and nitrogen balances.

Water scarcity (WS) was assessed following the AWARE method as suggested in PEFCR guidance (Boulay et al. 2018). Aggregated annual unknown characterisation factors and spatially aggregated instead of watershed level factors were applied because they were supported by Simapro. Most inputs of animal production were known by their origin country, but in the case of upstream processes, the origin information was not always available. Country- or region-specific characterization factors were applied when the origin country or region was known, otherwise global characterisation factors.

2.3 Manure management and emissions from animals

To assess dinitrogen oxide emissions from manure management, mass and nitrogen balances were defined for pork-producing farms. For the LCA of individual farm’s pork production, balances were defined separately for each farm. For Finnish pork production, nitrogen balance was determined as the average based on the farm data. Balances included masses and nitrogen amount in animals, feed and manure and were assessed to determine nitrogen excretion as presented in Eq. 1. In this study, the focus was on pork-producing systems and 1 year period. Thus, nitrogen balance and excretion were determined for the different age groups of animals, present on each farm during a 1-year period, according to primary data collection from separate farms.

Farm data on compound feed and feed crop use in diets of different animal types (sows, boars, piglets, weaned piglets, fattening pigs) formed a basis for determining the nitrogen content of diets. The nutritional content of diets was determined according to the share of ingredients and feed crop nutritional details according to feed tables (Natural Resources Institute Finland 2021).

Nitrogen excretion was determined with Eq. 1:

where Nexrection is the excreted total nitrogen (kg), Nfeed is the nitrogen content of feed portion (kg), and Nretention is determined according to species specific equations. For adult pigs, the Nfeed was determined based on ingredients in the feed portion. For piglets, excretion was determined based on the net energy intake estimate. The milk intake of weaning piglets was estimated based on the net energy demand and net energy content of the given feed supplements for the weaning piglets. Nitrogen retention was determined according to the method applied in the National Greenhouse Gas Inventory Report of Finland, for each animal type separately (Eq. 2, Statistics Finland 2021):

where a is the nitrogen retention factor for fattening pigs (0.026), and b is the nitrogen retention factor for piglets (0.025; Sevón-Aimonen 2002). The weights in the equation are given as live weight, so mfinal is slaughter weight, c is the conversion factor for live weight from slaughter weight (0.745 was used for fattening pigs as the constant), and mintial is the live weight at the beginning of the period.

The greenhouse gas emissions generated in animal production were assessed with farm data and utilising the IPCC methodology (IPCC 2006, 2019) and National Inventory Report methods (NIR, Statistics Finland 2021). When a country-specific method was available in the NIR, it was used; otherwise, the IPCC 2019 method and Tier recommended by the red meat PEFCR guidance draft were used. Direct N2O emissions from manure storage were determined according to IPCC 2019 Tier 2, based on total excreted nitrogen and for each manure management system separately. Indirect N2O emissions were similarly determined according to IPCC 2019 Tier 2. Methane (CH4) emissions from manure storage and animals due to feed digestion were determined according to NIR and IPCC 2019 Tier 2, including the manure management system. For slurry, 10% was used as MCF, which corresponded to the average storage time of approximately 5 months. For those pig farms which had their own biogas production, N2O emissions from storage between excretion and anaerobic digestion were calculated according to IPCC 2019. CH4 from anaerobic digestion was taken into account according to IPCC 2019, with an assumption of low leakage and an MMS factor of 1.41%. Manure methane was determined with IPCC 2019 (Eq. 3):

where Vs is the amount of volatile solids in manure according to the NIR, T is the period length in days, and Bo and MCF are the IPCC factors according to conditions.

2.4 Functional unit, system boundaries and allocation

For pork production, the functional unit (FU) was determined as kg carcass weight, while piglet production impacts were assessed for one 30-kg piglet. Deviating from the PEFCR guidance, the system boundary was set from cradle to slaughterhouse gate, to the point immediately after slaughter when the full carcass is available.

Allocation to co-products within the animal production system was relevant on the farm (disposed carcasses and manure) and before and after slaughter. All manure was handled as it was stored on the farm, and no burden was allocated for the manure as a co-product. Disposed carcasses from farms and the slaughterhouse were managed according to their quality and by-product level, either as co-products for animal feeds or by-products ending in a lower waste hierarchy level handling (e.g. energy and fertiliser use), according to European Commission’s legislation on animal by-products (Regulation (EC) No 1069/2009). Allocation was conducted according to PEFCR guidance, and the burden was allocated using an economic allocation to animal feed co-products (European Commission 2018a). The most typical processing system for by-products in Finland is at the Honkajoki facility. It provides processing of category 2 and 3 animal by-products to various products, and their processing burden has been allocated in full to these end products at the factory gate (Kari Valkosalo, CEO, Honkajoki Ltd, personal communication, 9.12.2020). Here, animal by-products which were not used as animal feeds were therefore managed as waste until the Honkajoki factory gate, and the burden from transport was allocated to main products, i.e. pork, while the processing emissions were allocated fully to by-products.

Feed ingredient allocation (e.g. whey, rapeseed meal, soybean meal) was conducted with the economic approach except for barley sidestreams from ethanol processing from Altia Oyj, for which mass allocation was used because of the lack of data on economic values. A mass allocation factor of 32–37% was received from production, of which an average value of 34% was utilised (Miika Jokinen, Altia Plc, personal communication 2021). In addition, the burden allocated to feed fraction was allocated based on dry matter content to barley protein feed (BPF, 69%) and barley feed (31%).

2.4.1 Compound feed composition and feed production assessment

The European Commission’s Product Environmental Footprint Category Rules (PEFCR) for feed for food-producing animals were followed in conducting an assessment of compound feeds (European Commission 2018c). According to the PEFCR for feed products, it is mandatory to collect primary data on feed ingredients, a nutritional analysis of the feed ingredients, the energy use of the mill operations and outbound transport to livestock farms. These were collected directly from Finnish feed-producing companies, according to data on feed compound use collected from farms.

Feed products utilised as pig feed were divided into three categories: farm-grown feed; purchased regional feed crops; and purchased feed compounds. The feed crop production assessment was conducted for each of the categories separately and utilising corresponding inventory data. The assessment of feed crop production was conducted following PEFCR guidance and is described in detail in Hietala et al. (2022). For the farm-grown feed, the crop cultivation data were collected directly from pig farms which supplied the studied slaughterhouses. ProAgria parcel registry data were utilised to model the regional feed crops and average Finnish feed crops. It was assumed that the single-feed ingredients purchased from another farm were cultivated in the same province where the pig farm was located. Regional crop cultivation data averages were therefore utilised to model the regionally produced feed crops (Hietala et al. 2022). Average Finnish feed crop LCA results according to Hietala et al. (2022) were utilised in the assessment of feed compounds for Finnish feed crop ingredients. Direct land-use change (LUC) from primary production was included according to the PAS2050 protocol (BSI 2011) and using a direct land-use tool developed by Blonk Consultants (2018). According to Blonk Consultants (2018), wheat and pea production in Finnish crop cultivation was allocated with LUC emissions (Hietala et al. 2022).

The relevant feed compounds were defined according to data collected from farms and supplemented with data from Finnish feed producers on relevant pig feed products. The raw material data for feed compounds were collected from Finnish feed manufacturers. For pig feed, the data included the type and amount of feed materials, the type and amount of feed additives and the type and amount of premixtures in the feed product. The relevant feed products were modelled separately by product, and in some parts, feed mill–specific combinations were made to average a number of products that were similar to each other. For the reference period, the typical short shelf-life of feed products was taken into account, assuming that all feed consumed in 2018 meat production had been produced in the previous growing season. The compositions of feed products were therefore also determined to correspond to 2018 production. The origin of the feed ingredients plays an important role especially for water scarcity, but also for LUC and climate change impact; thus, information on origin was also collected directly from feed compound producers whenever it was available. The incomplete data were supplemented with database data according to PEFCR guidance. The average feed mill operation information was collected from each of the feed-manufacturing companies for the recommended 1 year of normal operation. The energy consumption of the processing of feed products was collected as primary data from feed manufacturers. The data collected included the annual use of electricity, heating energy, gas, and possible other forms of energy. In addition, annual water consumption volumes were collected. Average crop-specific consumption volumes were divided into crop production tonnes. Similarly, data on outbound transports from feed manufacturer to farm were obtained from manufacturers as the average of distance transported with means of transport. When the nutritional information about the feed or ingredient was unavailable from the data, nutritional information was collected from feed tables by Natural Resources Institute Finland (2021).

The system boundary for the compound feed products was set from cradle to animal farmgate. In the assessment of feed crops, the system boundary was set as the farmgate, so transport from the farm to feed-producing facility and further on to the animal farm was added and modelled according to transport data collected from Finnish feed-producing companies (A-Rehu, Agrox, Hankkija, Feedex, Rehux). Similarly, the data on processing energy and material use were collected directly from feed-producing companies. The functional unit for feed was 1-kg feed as feed delivered to an animal farm.

For some feed products, in addition to the list of raw materials and the nutritional content, the required information about the composition of the feed product (% for raw materials) was incomplete. To evaluate the composition of such feed products, various feeds corresponding to a known list of raw materials were created with SAS software, and feed compositions corresponding to the given chemical composition were selected from them.

Similarly, for foreign feed products, the composition of the products used, in particular as feed for small piglets, was estimated by optimising the list of raw materials in the product description of imported feeds and the total nutrient content using an Excel Solver.

The nutrient-dry matter and energy contents of the various raw materials were determined using the literature and databases, mainly Feedipedia (Heuzé, et al., 2013). Based on the expert opinions, the total energy content of the feed and the minimum and maximum content of the various raw materials were determined. These data were used as a constraint in the optimisations.

The composition of the feed products was optimised so that the total nutrient content corresponded to the product description. The results were reviewed and adjusted with feed experts.

2.4.2 Diet composition data

As the pork production systems and dietary strategies were known to vary, the main protein source in the diet was used as the determining factor for the classification of the pork-producing farms, and the average diet compositions for each of the identified classes were determined.

Data collected from farms included a description of the feed compounds, types and quantities of feed crops and feed materials, additives and premixes. In determining the nutritional analysis data, national feed analysis data were utilised, which was in accordance with the PEF. The sample sizes are presented in Table 2.

2.5 Definition of average Finnish pork production

To assess average Finnish pork production, the farm characteristics were determined based on surveyed farm data, slaughter animal data and slaughterhouse data. Feed crop production was determined as Finnish average feed crops in the case of purchased feeds and as the regional feed production, weighted according to regional production volumes, in the case of farms’ own feed crop production, as in Hietala et al. (2022). Diet composition was determined by weighting the farm data on diets with the shares of primary protein sources.

3 Results

3.1 Farm data collection

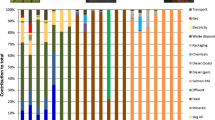

In data collection from pork-producing farms, information about piglet production, nursery production, combined production and fattening pig production farms was analysed for the life cycle assessment. One hundred and ninety-three responses to the first farm survey were received, most of which concerned fattening pig production (n = 147, 58%) and piglet production (n = 63, 25%). The remaining responses concerned nursery production (n = 29, 12%), and the rest, 5%, was mainly combined production (n = 6) and breeding stock production (n = 3). Based on the survey, the main protein sources of different production types were determined, including fattening farms (Fig. 2).

In addition, farms’ own energy production and bedding materials were investigated. Sixty-nine per cent of the surveyed farms reported that they produced their own heating energy (stoker, woodchips, heat pump, biothermal plant, geothermal heat, gas), and 16% of farms had their own electricity production. The most common form of heating was woodchip heating (49%, Supplementary Information, Table1), and fuel oil (16.5%) and pellet heating (9.4%) were also typical. On 47% of the farms, only one bedding material was used, of which 44% was using wood chips or sawdust, while another 44% of the farms used straw, and the remaining 11% had peat as bedding material.

The remaining farms had two or more types of bedding materials. Among these farms, wood chips or sawdust was used on 38% of the farms, 25% had straw and 19% of the farms used peat or hay, which both were used on the same number of farms. Sixteen per cent of the farms did not use any bedding material. Thus, as weighted average, the most typical type of bedding material was woodchips or sawdust (53% of farms) and straw (42% of farms). Other bedding material types were peat (21%) and hay (16%). The most typical manure system was liquid slurry (99%). Four per cent of farms had their own biogas production. Thirty farms produced their own electricity (15.5%), which was mainly solar energy (97%).

Data regarding slaughter weights and the number of slaughter animals were also collected from slaughterhouses. A dressing percentage of 74.5% was used in conversions between live weight and carcass weight when data were lacking. The slaughterhouse data accounted for 139.4 million kg pork in carcass weight, which corresponds to 77% of total Finnish pork production in 2016–2018.

Finnish pig farms were further surveyed with a more detailed questionnaire to which five specialised piglet production farms, three combined production farms, and 17 fattening farms responded. The annual pork production of the surveyed farms was 6.6 million kg. The questionnaire collected especially feed utilisation and specific farm data. The average fattening farm characteristics based on the collected data are presented in Table 3. Diet composition data were used to categorise the fattening farms according to the main protein source in diets, as in Fig. 2. The characteristics of average fattening pig farms categorised according to the main protein source (barley protein feed, legume crops, compound feed) are presented in Supplementary Information, Table 2.

The main protein source of fattening farms average feed portion was determined based on protein amount gained from wet barley protein feed, legume crops (including faba bean, pea and soybean as single feed ingredients) or compound feed. All compound feeds were combined independent of their composition or protein ingredients. The average feed use, based on the entire farm data, as shares of the total dry matter of the feed portion and the average feed use compositions for the farms categorised according to their main protein source, are presented in Table 4. These average feed compositions were weighted according to the ratios of the main protein sources used in Finnish farms, as in Fig. 2, to determine average Finnish feed use on fattening farms.

The average feed use composition of sows and weaned piglets is shown in Supplementary Information, Table 3.

The feed raw materials of domestic Finnish origin included barley, wheat, oats, peas and broad beans, as well as by-products. The countries of origin of soybean-based raw materials were mostly Brazil and the USA (50:50); rapeseed was either domestic or from the Baltic countries.

Electricity, heating energy and water consumption were included in the assessment according to the collected farm data. The consumption volumes of electricity, heating energy and water per adult animal on the farm were an average of 32 kWh for electricity (standard deviation, SD 26 kWh), 31 kWh for thermal energy (SD 34 kWh) and 0.95 m3 for water (SD 0.51 m3). Similarly, the consumption per adult pigs was determined for fattening farms as 398 kWh for electricity (SD 65 kWh), 574 kWh for thermal energy (SD 428 kWh) and 10.02 m3 for water (SD 8.32 m3). In some farms, the electricity (or system which uses electricity) was used for heating, in which case the amount of electricity used also included heating partly or completely. This also increases the ranges and standard deviations.

3.2 Average farm characteristics based on data collection

The average Finnish farm characteristics were determined based on collected farm data as weighted averages, based on production volumes. The average feed use composition of fattening farms was determined as the weighted average of the diets according to the main protein source and the shares of different main protein sources according to the surveys (Table 5).

Similarly, nitrogen excretion was determined as an average weighted by production kilograms, based on excretions calculated from farm-specific feed rations. Bedding material and use were determined as an average based on farm data collection and quality and use of heating energy similarly. Electricity consumption was also based on farm data collection, and 15.5% of it was defined as produced on the farm (solar and wind energy). The default manure system for all farms was liquid slurry, which was the most typical in farm data collection. The piglet production stage was determined based on farm data collection, as the average of specialised piglet production farms. The emissions during the slaughtering stage were determined as an average based on data collected from Finnish pig slaughterhouses.

Regarding feed crop production, the data obtained in farm data collections were not used, as its distribution of soil types differed considerably from the average distribution of pork production areas. The average share of peatlands in the cultivation of the farms that responded to the farm survey was 28%, while the share of peatlands weighted by the production volumes of the largest pork production areas was 8% for barley, for example. In terms of feed crop production, the regional feed crop production of the largest production areas (Southwest Finland, Southern Ostrobothnia) was therefore used to describe the farms’ own cultivation, and average domestic feed crop production was used for the purchased feed. To grasp the average use of regional crops in Finnish production, the weighting of the regional emission factors of the crops was done based on the number of pork production farms in each region. Emission factors for feed crop production were determined as described in Hietala et al. (2022).

3.3 Global warming potential of pork on Finnish fattening farms

The GWP of Finnish pork production was assessed for 20 farms producing pork, and for the preceding piglet production. Of these, 17 were fattening farms, and the remaining three were combined production farms.

In the farm-specific investigation, the GWP ranged between 2.9 and 5.5 kg CO2 eq. kgCW−1, including LUC, and without LUC, between 2.8 and 5.4 kg CO2 eq. kgCW−1. The results of the farm-specific assessments are shown in Fig. 3.

Regarding farm-specific results, GWP was observed to vary considerably between farms. Fattening farms and combined production farms were both included in the investigation; however, they were examined separately due to the differences in the piglet production stage and the difficulty of separating similar life cycle stages from both production types.

When life cycle stages were analysed, the biggest variation could be seen in the burden caused by the production of feed crops used on the farm, which was between 0.4 and 2.9 kg CO2 eq. per kg carcass weight (CW). This included all cereals used on the farm as feed, turnip rape and domestic legumes, all crops which were not included in compound feeds. The largest contribution of emissions from feed crops used on the farm was observed on fattening farms FF4, FF8 and FF9, ranging between 2.3 and 2.9 kg CO2 eq. kgCW−1. The largest impact of the fattening farms in this regard came mainly from the cultivation of their own barley, but also from purchased grain and legumes. Farms differed from their primary protein sources and diet compositions. Most important feed ingredients in FF4 were barley protein feed and own barley; thus, its share in diets was also large. Farm also had large share of organic soils in cultivation (93%), elevating impact of own feed crop production. Farms FF8 and FF9 had compound feeds as their primary protein source, which were fed with feed crops from own cultivation. Besides compound feed, FF8 included good share of own barley, wheat and rapeseed to diets. All crops from own production had rather high climate change impact due to low yields. Similarly, FF9 included own barley and some own wheat and faba bean to fattening pigs’ diets. Especially faba bean had high climate change impact due to low yield, but majority of the burden came from own barley as its share was large and climate change impact was above Finnish average (Hietala et al. 2022). Correspondingly, in combined production, the contribution of feed crops on farm CP3 was largest, at 1.9 kg CO2 eq. kgCW−1.

Another factor that varied significantly between farms was the load caused by compound feed products. The highest contribution caused by compound feed was observed on farms FF3, FF15 and FF13, as well as CP2 and CP1, ranging in total between 0.1 and 1.7 kg CO2 eq. CW−1. Range in compound feed contribution varied due to differences in ingredients, which included soybean, rapeseed and amino acids in different compositions, but also due to share they were used in diets. FF3 had barley protein feed-based diets, which were supplemented with compound feeds. These supplements had larger share of cereals, but also amino acids. Both FF13 and FF15 had compound feed-based diets whose main ingredient was soybean. CP1 had besides barley protein feed 13.7% of the protein in diets from compound feeds, which were mainly based on rapeseed. CP2 had soybean meal as their primary protein source, which was supplemented with soybean-based compound feeds; thus, soybean in total accounted 45% of the protein in diets.

The contribution of piglet production and housing, transport and manure management varied significantly less between farms when combined production farms and fattening farms were examined separately. The contribution of piglet production to fattening farms’ GWP was between 1.15 and 1.24 kg CO2 eq. kgCW−1. However, the slight variation is explained by the average piglet production, which was used in the modelling of all farms. Fattening pig production was also examined separately, without the impacts of upstream piglet production. The results of the fattening stage ranged between 1.6 and 4.2 kg CO2 eq. kgCW−1, including LUC. As the contribution of LUC in the fattening phase was rather small (0.03–0.18 kg CO2 eq. kgCW−1), results without LUC had the same range (Fig. 4). Feed crop production on farm was the most determining contributor; 48% was the median share of the stage, and on the farms with largest GWP, the share was over 70%. On the third of the farms with largest GWP, this stage was the most contributing, except for one farm which had compound feed as the main contributor, with BPF-based diets. Animal processes had also significant impact, 25% being the median share of the stage. Yet, the stage was the largest contributor on those farms which had the lowest GWP, below 2.5 kg CO2 eq. kgCW−1. Largest LUC impacts were on farms FF13 and FF15, which had soybean-based compound feeds as primary source for protein.

3.4 Global warming potential of average Finnish pork

The climate impact of average Finnish pork was 3.6 kg CO2 eq. kgCW−1, including LUC, and without LUC, 3.5 kg CO2 eq. kgCW−1 (Fig. 5).

The largest contribution to the GWP of average Finnish pork was related to the production of feed crops, utilised as feed as such on the farms (1.2 kg CO2 eq. kgCW−1). Feed compounds contributed 0.3 kg CO2 eq. kgCW−1, so feeds accounted for a total of 1.5 kg CO2 eq. kgCW−1. The second most significant contribution came from piglet production, 1.2 kg CO2 eq. kgCW−1, whose emissions were correspondingly mainly made up of feed production.

In average pork production, the third most significant contribution came from manure management and feed digestion, at 0.6 kg CO2 eq. kgCW−1. On pork-producing farms, the most typical manure system was slurry, but there were also solid or deep litter systems. Manure treated in biogas plants produces lower emissions than other systems. There were biogas plants on one piglet production farm, which were part of the average piglet production. Based on the survey, 4% of respondents had biogas production.

The contributions of other emission sources, LUC (mainly from Brazilian soybean) and housing (energy use on farms), transport and slaughterhouse processes to the climate impact of typical Finnish pork remained smaller.

3.5 Global warming potential of pork production depending on different primary protein source

In addition to the average pork production and farm-specific examination, the environmental impacts were examined for pork production categorised according to the main protein source in pig diets. The division was made by separating barley protein feed (BPF), domestic legumes, soybean and compound feed products as the main protein source.

The average GWP was formed by categorising the farms according to the main protein source of feed use and weighting the farm-specific results by the production volumes. The GWP ranged between 3.4 and 4.2 kg CO2 eq. kgCW−1 (SD 0.06–0.8 kg CO2 eq. kgCW−1) for the entire chain and without piglet production between 2.2 and 3.2 kg CO2 eq. kgCW−1 (SD 0.1–0.8 kg CO2 eq. kgCW−1).

The smallest GWP was observed on farms using domestic legumes as the main source of protein (3.4 kg CO2 eq. kgCW−1, without piglet production 2.2 kg CO2 eq. kgCW−1), while the remaining farms were of the same order of magnitude (4.0–4.2 kg CO2 eq. kgCW−1 of slaughter and without piglet production 2.9–3.2 kg CO2 eq. kgCW−1). However, the very low sample sizes are noteworthy, which brings uncertainty to the comparison. Two farms used mainly domestic legumes, two farms also used mainly soybean, compound feeds were the main protein source on six farms, and BPF was most common on eight farms.

3.6 Water scarcity impact of pork produced on Finnish fattening farms

The water scarcity impact of Finnish pork production was evaluated for 20 pork-producing farms, and the preceding piglet production.

In the farm-specific investigation, the water scarcity impact ranged between 0.41 and 1.04 m3 eq. (Fig. 6). The biggest variation was found in the water scarcity impact caused by compound feeds, the variation being between 0.01 and 0.55 m3. The largest burden caused by compound feeds was observed on fattening farms FF6, FF3 and FF2. In combined production, the highest impact from compound feeds was observed on farm CP2. The main protein sources used by these farms were wet BPF, compound feeds and soybean. The second largest variation in the life cycle stage was observed in the use of feed crops on the farm. For the water scarcity caused by the production of feed crops, the variation was between 0.002 and 0.41 m3. The largest burden caused by feed crop production was seen on farms CP2 and CP1 and on fattening farms FF13 and FF14. The main protein sources used by these farms were soybean, wet BPF, domestic legumes and compound feeds. The most significant factors affecting the water scarcity impact on these farms were the purchased domestic barley, wheat, faba beans and inputs from their production. The total combined water scarcity impact of feeds ranged between 0.1 and 0.7 m3; the highest load observed in combined production was on farm CP2 and in fattening farms on farm FF6. The smallest impacts regarding feed were observed on farms FF11 and FF17. Wet BPF was the main protein for both based on the feed ration.

3.7 Water scarcity impact of average Finnish pork

The results of the water scarcity impact of average Finnish pork are shown in Fig. 7.

The most significant contribution to WS came from feed production. It accounted for 41% of the entire water scarcity impact. The water scarcity impact of piglet production is discussed separately in Sect. 3.8, its share was 38%, and the clearest single factor in that stage was the impact of compound feed raw materials. Compound feed products included all ready-made feed mixtures and processed feed products such as rapeseed oil or soybean meal. Among the factors affecting the WS of compound feeds, the most significant were inputs of foreign feed ingredients and irrigation, especially for North American and Baltic ingredients. Significantly smaller shares of the WS came from the farms’ own water use, which included tap water and well water consumed in livestock housing and their own feed crop cultivation. These corresponded to 4% of the water scarcity effect. The remaining 18% consisted of other activities in the chain. This included transport (excl. feed transport), livestock housing and the slaughterhouse processes.

The WS was also investigated by dividing the farms into categories according to the main protein source used. The results showed that the water scarcity effect of farms using wet BPF as the main protein source was lower than other groups, at 0.55 m3 eq. kgCW−1 and SD 0.15 m3 eq. kgCW−1. Farms using compound feeds as the main protein source had the second lowest WS, at 0.66 m3 eq. kgCW−1 and SD 0.17 m3 eq. kgCW−1. The results of farms using soybean or domestic legumes were of the same order of magnitude: 0.73 m3 eq. kgCW−1for those using soybean; SD 0.21 m3 eq. kgCW−1 and 0.74 m3 eq. kgCW−1, SD 0.00 m3 eq. kgCW−1for those using domestic legumes. Regarding WS, the small sample sizes must also be taken into account, which creates considerable uncertainty in the comparisons.

3.8 Environmental impacts of piglet production

The GWP and WS of piglet production were also examined separately, as their contribution to the life cycle impacts of pork was significant. The investigation was carried out only for specialised piglet production farms, as uncertainty is associated with the boundaries of piglet production on combined production farms. Piglet production was limited to a piglet weighing around 30 kg. The investigation included five specialised piglet production farms, one of which was a nursery farm (about 8–30 kg) and one producing piglets up to weaning (about 8 kg). In the investigation, the nursery farm and the production of weaned piglets were combined into one farm (F1). The data collected from specialised piglet production farms corresponded well to the production without data gaps. However, the low sample size and related uncertainties are noteworthy.

For specialised piglet production, the common average and farm-specific impacts of a weaned 30 kg piglet were determined. Farm-specific GWP and WS of piglets (Supplementary Information, Figs. 1 and 2) were used to form an average impact. In farm-specific analysis, a considerable difference was observed between the farm formed as a combination of two farms and the other farms. The most significant difference was caused by the production of feed crops on the farm, which was only done on the nursery farm, but its impact was notable.

In the farm-specific investigation, the greatest variation was observed for the contribution of feed crops (0–49% of emissions), and the second largest for the load related to sows (29–61% of emissions). On specialised piglet production farms, the share of manure emissions ranged between 10 and 31%. The contribution of compound feeds ranged between 12 and 21%.

The GWP of an average approximately 30-kg weaned piglet was 111 kg CO2 eq. piglet−1, including LUC 2.0 kg CO2 eq. piglet−1, and the water scarcity effect was 23.9 m3 eq. piglet−1 (Figs. 8 and 9). The most significant factor in the GWP of average specialised piglet production was the burden caused by sow (41%), which consisted mainly of the production of feed crops and manure management emissions. The second most significant contribution came from feed crops (25%) and the next largest from manure management emissions and feed digestion (20%). Compound feeds accounted for 13% of the emissions.

Regarding the WS, the impact related to sows became most significant for specialised production (on average 61% of the impact, ranging between 56 and 67%). Compound feeds made the second largest contribution, at 35% of the total impact, ranging between 33 and 36%. In compound feeds, the foreign ingredients of products, the irrigation used in their production and production inputs were particularly influential. Among foreign ingredients, Baltic, North American and European raw materials, whose production involved irrigation water and other production inputs, had an impact. Among domestic raw materials, barley, oats and rapeseed were emphasised in the formation of the WS of compound feed products. The use of feed crops as such on the farm constituted a very small proportion of the WS of specialised piglet production farms, on average 3%, ranging between 0 and 7%.

4 Discussion

This study assessed the GWP and WS of Finnish pork. Besides the average Finnish production, a separate assessment was conducted for 20 pork production farms and five piglet production farms.

The GWP of Finnish pork was 3.6 kg CO2 eq. kgCW−1, with a system boundary from cradle to slaughterhouse gate. Similar results have been achieved in European studies of pork production’s environmental impacts. Similarly to this study’s findings, previous studies have found feed crop production to contribute largely to the GWP of pork. Reckmann et al. (2012) reviewed LCA studies of European pork production and reported an average GWP of pork of 3.6 kg CO2 eq. kg pork. Their review combined several different functional units with various system boundaries, so even if a similar magnitude of impact is evident, the level of comparability remains unclear. Dorca-Preda et al. (2021) reported that Danish pork production reached 3.86 kg CO2 eq. kgCW−1 with a comparable system boundary and including direct land-use change according to PAS2050 (BSI 2011). The average slaughter weight was slightly lower in the Danish system (111 kg LW), and the main differences were found in diet composition. Danish production used wheat as the main cereal crop (43%), while barley is most important in Finland (72%), and the fattening pig diet consisted of only 9% wheat. Moreover, the share of soybean in fattening pigs’ diet in Finnish production was 2.3% less (3.8%). Although rapeseed and sunflower seed meal were also less used in Finnish pork production (− 3.7% and − 4.7% respectively), domestic legumes and oat-fractions were used more (+ 5% and + 1.3% respectively). The amount of premix was at the same level, and in Finnish production, by-products or sidestreams were used more, and their composition was different.

Yet, some differences remain in the characterisation of the emissions, leaving some uncertainty in the comparisons. Another recent study assessed the environmental impacts of Portuguese pork production with LCA, resulting in 3.34 kg CO2 eq. kgCW−1 for pork in carcass weight with a system boundary to the farmgate (González-García et al. 2015). In this system, the slaughter weight was also slightly smaller (105 kg), and diet composition differed more significantly, including maize as the most important crop (50% for fattening pigs) and soybean as the second most important (19.4%). In contrast with our study, they did not include LUC emissions, making a full comparison difficult. Finnish pork resulted in 3.5 kg CO2 eq. kgCW−1 without LUC, which is larger than the reported Portuguese pork GWP. Yet potentially large LUC emissions are associated with soybean’s use as the main ingredient in Portuguese pork production, which were not taken into account. Another study by Reckmann et al. (2013) investigated the environmental impact of German pork production. The production characteristics were close to the Finnish one assessed here, with a final weight of 120 kg and a pork yield of 94.7 kg. Reckmann et al. (2013) reported 3.22 kg CO2 eq. kg pork as the GWP of pork without LUC. Diet composition differed from Finnish, as wheat was also the main ingredient in fattening pigs’ diet in this case. Cereals accounted for a total of 63 to 72% of German fattening pigs’ diet, and soybean 2 to 12%, depending on the phase. Also in this case, more soybean was used than in Finland, on average 7%, and it was noted to be of Brazilian origin. In Finnish production, the origin of soybean was half South American and half North American, and even though all the soybean was from sources certified without land-use change, modelling was conducted for average Brazilian soybean with LUC. This was because the certificates extended only about 10 years back, while the PAS2050 method requirement is 20 years. Nevertheless, Finnish pork production GWP is well in line with the results of previous studies. Yet LUC emissions were neglected in the majority of the studies for a full comparison.

In the farm-specific investigation, differences between the farms could be observed. The highest emissions due to compound feeds were observed on fattening farms FF3, FF13 and FF15 and on combined production farms CP2 and CP1.

The main protein source in the feeding of these farms was wet BPF or compound feeds. Of these farms, the share of feeding on those farms whose main protein source was compound feed, and its share in feeding was also significant, also contributing to the emission in question. The emission was mainly caused by domestic feed crops and rapeseed oil, which were used as ingredients for compound feeds. Meanwhile, concentrates given as a supplement to wet BPF feeding had a burdening effect. The most significant factor regarding the contribution of concentrates was the field cultivation of domestic feed crops such as barley. Correspondingly, the most significant emission sources of compound feed were soybean meal and concentrate products, in which the soybean was partly of South American origin, involving emissions from land-use changes such as forest clearing. On the combined production farm CP2, soybean was also the main protein source.

The highest emissions from the production of feed crops used on the farm were observed on farms FF4, FF8 and FF9. A large part of the emissions consisted of the farms’ own cultivation of barley and the cereals and turnip rape purchased for the farm. In addition to the resource efficiency and lower-than-average yield levels of grain production on the farm, the high emission of feed crop cultivation was influenced by the large proportion of peatlands in cultivation (FF4). Feed consumption amounts could be examined with the aid of dry matter intake amounts. The average amount of the dry matter intake was 2.9 kg kgCW−1, which was exceeded on farm FF4 and was lower on farms FF8 and FF9. The most significant explanatory factor therefore remained the high farm-specific emissions from farms’ own grain cultivation.

Dorca-Preda et al. (2021) reported feed use for Danish fattening pigs at 220 kg per animal, corresponding to approximately 2.0 kg kgLW−1. Feed use had declined by about 6% in their observations, yielding lower emissions from nitrogen excretion and manure storage, and reflecting the reduced impact of pork. In farm-specific assessments, feed use in Finnish production ranged between 161 and 392 kg per fattening pig, with an average of 242 kg (SD 61 kg), and from 1.4 kg kgCW−1 to 3.3 kg kgCW−1, with an average of 2.0 kg kgCW−1 (SD 0.51 kg kgCW−1). As previous studies have shown, diet composition affects the emissions generated in feed crop production, but it also affects the animal’s performance, which may be reflected in the environmental load of produced meat (Huuskonen et al. 2023). No correlation between DMI and the environmental impact of 1 kg of pork could be observed here, although all farms exceeding feed consumption of 2.5 kg kgCW−1 had a climate impact above 3.5 kg CO2 eq. kgCW−1. This could not be observed in water scarcity, as both low DMI and high DMI reached high and low impacts. The quality and composition of the feed portion were therefore more important in this case, and the utilised diets seemed to perform equally efficiently in fattening.

Some differences were observed between farms categorised according to the main protein source used. However, it was impossible to detect statistically significant differences, and as the standard deviations extended beyond each other, no significant differences could be detected between farms using different protein sources. Nevertheless, farms using domestic legumes as the main source of protein resulted in the lowest climate impact, while other groups had slightly higher impacts of the same order of magnitude.

The WS of Finnish pork was 0.69 m3 eq. kgCW−1. In the farm-specific investigation, also regarding WS, variation was observed between farms. The largest contribution caused by compound feeds was seen on farms FF6, FF3 and FF2. The main protein sources used by these farms were wet BPF, compound feed and domestic legumes. The most significant factors influencing the WS on these farms were irrigation and inputs of foreign feed ingredients, especially of USA, Asia and EU origin, but also the production of domestic barley and turnip rape. In the production of domestic feed crops, the water scarcity impact is caused mainly through the use of inputs (Hietala et al. 2022).

As water scarcity impact has been much less studied, no peer-reviewed studies were found reporting the water scarcity impact of pork as such. Studies either used different methods, or the scope of the study was at the diet level. Nevertheless, Finogenova et al. (2019) have studied water scarcity impact with the AWARE method for German food imports. They note that pork production is associated with a large amount of water use, but when pork is produced in countries with abundant sources of water (like Finland), with inputs also originating in such countries, the water scarcity impact can remain relatively small. Diet composition and the origin of feed ingredients therefore play an important role, and it was seen that imported ingredients were associated with irrigation or other water-consuming production inputs. For Finnish production and other production systems depending on feed imports from water-scarce countries, environmental efficiency could be improved by increasing the utilisation of rainfed feed ingredients, and in Finland’s case, domestic ingredients.

In the farm-specific assessments, the largest loads caused by the production of feed crops used on farms were seen on farms CP2 and CP1, as well as FF13 and FF14. The main protein sources used by these farms were soybean, wet BPF, domestic legumes and compound feed. The most significant factors affecting the WS on these farms were the contributions from domestic barley, either purchased or self-produced, wheat, faba beans and especially the inputs used for their production.

The WS caused by the feeds was also examined as an aggregate of the total impact of the feeds (feed crops and compound feeds). Among the combined production farms, farm CP2 had the highest load, which was mainly caused by domestic barley and soybean meal. Of the fattening farms, FF6 had the highest load, with compound feeds making the most significant contribution.

Regarding the WS of the farms categorised according to the main protein sources used, the smallest WS was obtained with a feed composition based on wet BPF or compound feeds, while those based on domestic legumes and soybean caused the greatest WS. In terms of GWP, legume-based feeding seemed less burdensome. However, it is also noteworthy here that due to the small sample size, it was impossible to detect significant differences, and the small sample may be anomalous by chance. In future studies, it would be important to gather more farm data on different production systems. Also, different feeding phases should be included in more detail, as here, the fattening phase was included as an average of the total.

One of the strengths of pork production in Finland is the utilisation of sidestreams and co-products in pigs’ diets (about 4% of the diet). Pork production uses barley protein feed, whey and mash as sources of protein. Sidestreams typically have lower environmental impacts than virgin materials, which can also decrease the environmental load of pork. Mackenzie et al. (2016) have studied the utilisation of sidestreams and co-products in the pork production chain and its effects on the environmental impacts of pork. They note that increasing co-product use in pork production chain has the potential to decrease environmental impacts. While a larger share of co-products is used in Finnish production, they are sometimes supplemented with burdening compounds, and a positive impact could be seen in the WS impact. Although a positive effect could not be seen in GWP, this was partly due to the lack of information from the industry for the economic allocation factor. Because of the mass allocation, the sidestream fraction was potentially allocated a larger share of emissions than economic allocation would have yielded.

The results showed that wet BPF as the main or an important protein source seems to be linked to a comparatively smaller WS impact. In addition, in Finnish pork production, feed raw materials that are considered to cause land-use change, e.g. soybean, are used to a lesser extent. Moreover, some pig farms already use biogas plants to reduce manure emissions and utilise biogas as energy.

In terms of energy use, Finnish pig farms heat their premises largely with renewable fuels, the most important of which is woodchips. Light fuel oil for heating has almost been abandoned. A considerable share of the farms also has their own electricity production such as solar power.

To reduce the GWP of pork production, special attention should be paid to the further development of the production of domestic feed crops. This would also support and benefit the mitigation efforts of water scarcity impacts if feed ingredient procurement were directed more to domestic production. In farm-specific analysis, high proportions of peatlands in feed crop production were observed (Hietala et al. 2022). There should be a further focus on how to cut emissions from peatland cultivation, e.g. with regenerative cultivation and farming techniques, but also by directing feed crop production to mineral soils and reducing the use of peatlands in feed cultivation. While regenerative farming techniques can reduce greenhouse gas emissions from peat soils, these are currently neglected in LCA, as there is a lack of robust quantification methods. A development of such assessment methods will therefore be required to demonstrate impacts in product-level LCAs.

Emissions from manure management could be further reduced with various technical solutions, for example, by increasing biogas production. Regarding piglet production, the small sample size also causes uncertainty in the results. In further studies, specialised piglet production should be investigated in more detail. In addition, the LCA of wet BPF should be refined with economic allocation coefficients. This would be of great importance for a more accurate evaluation of the wet BPF and the barley feed fractions resulting from the process, as mass allocation potentially overestimates the impacts of sidestreams.

Regarding WS, the main attention should be paid to the origin and quality of feed ingredients, as the effect of water scarcity can be further reduced by careful ingredient selection.

Water scarcity footprint applications for food products utilizing AWARE method are still rare. As a regional impact assessment method, AWARE challenges the life cycle inventory, and in general, a lot of effort should be invested in collecting regional data. In addition to the water consumption along the production chain, the origin of inputs is an important parameter effecting on the overall WS result. This was seen in the variety between farms (Fig. 6) utilizing different feed crops and compound feeds. However, in this study, the origins of all feed ingredients were known, and only upstream process inputs were unknown by their origin. In general, AWARE is a solid method providing several sets of characterization factors and aggregated characterization factors to be applied all over the globe. In the future, the LCA software should support the full utilization of these CF sets. On the other hand, the biggest bottleneck hindering the even more detailed impact assessment is life cycle inventory, especially in products with wide and complicated life cycles like pork.

The current research investigated the climate change impact and water use of pork production in Finland by following PEF method. These impact categories are understood to be important for the livestock production and are among the sixteen impact categories of PEF. In future research, the remaining PEF impact categories should be investigated in order to conduct a complete PEF study. As the focus in this study has been to investigate Finnish average production instead of a single company-specific product, not all PEF method requirements were found applicable. Large difficulties were encountered in primary data collection, for which PEF requirement is rather high. Also, investigation did not include the whole life cycle, with the retail and use stages, as especially the use stage might differ greatly. One of the main characteristics of PEF method is normalisation and weighting to one environmental footprint value. In future studies, it should be investigated how pork product performance is actually brought out when complete PEF study is conducted, including weighting to environmental footprint.

5 Conclusions

In this study, the GWP of Finnish pork production was 3.6 kg CO2 eq. kgCW−1. The result includes the climate impact caused by land-use change, but the share was very small, at only 3%. The share of feed production was slightly less than half the impacts (43%). Manure processing and digestion accounted for 17%, and piglet production accounted for a good third (33%). The other emissions were generated in transport and in slaughterhouse processes. The WS impact of typical Finnish pork production was 0.69 m3 eq. kgCW−1. The most significant part of the water scarcity effect, 41%, occurred in feed production for fattening pigs. Thirty-eight per cent was constituted by piglet production, and especially in the primary production of feed.

To reduce the GWP of pork production, special attention should be paid to the further development of the production of domestic feed crops. High proportions of peatlands in feed crop production were observed, and how to curb emissions from peatland cultivation should be investigated, e.g. with regenerative cultivation and farming techniques, but also by directing feed crop production to mineral soils and reducing the use of peatlands. Regarding WS, the main attention should be paid to the feed ingredients, as the effect of water scarcity can be further reduced by careful ingredient selection. Directing the use of feed crops produced in water-abundant countries and where irrigation or extensive input use are not associated with feed crop production can help in reducing the WS impact.

Data availability

The data that support this study’s findings are not openly available for reasons of sensitivity and applied restrictions. Information regarding them is available from the corresponding author upon request.

References

Blonk Consultants (2018) Direct Land Use Change Tool. Version 2018

Boulay AM, Bare J, Benini L, Berger M, Lathuillière MJ, Manzardo A, Magni M, Motoshita M, Núñez M, Pastor AV, Ridoutt B, Oki T, Worbe S, Pfister S (2018) The WULCA consensus characterization model for water scarcity footprints: assessing impacts of water consumption based on available water remaining (AWARE). Int J Life Cycle Assess 23(2):368–378

BSI (2011) PAS 2050 - Specification for the assessment of the life cycle greenhouse gas emissions of goods and services. British Standards Institution, London 2011

Clark M, Tilman D (2017) Comparative analysis of environmental impacts of agricultural production systems, agricultural input efficiency, and food choice. Environ Res Lett 12(6):064016

Dorca-Preda T, Mogensen L, Kristensen T, Knudsen MT (2021) Environmental impact of Danish pork at slaughterhouse gate–a life cycle assessment following biological and technological changes over a 10-year period. Livest Sci 251:104622

European Commission (2013) European Commission (2013/179/EU). Commission rec-ommendation of 9 april 2013 on the use of common models to measure and com-municate the life cycle environmental performance of products and organisations

European Commission (2018a) Product Environmental Footprint Category Rules Guidance. PEFCR Guidance document, - Guidance for the development of Product Environmental Footprint Category Rules (PEFCRs), version 6.3, December 2017. Retrieved from: https://eplca.jrc.ec.europa.eu/permalink/PEFCR_guidance_v6.3-2.pdf

European commission (2018b) Product Environmental Footprint Category Rules (PEFCRs) PEFCR red meat version 0.6. Draft

European Commission (2018c) PEFCR Feed for food producing animals. Brussels, Belgium. Retrieved from: https://wayback.archive-it.org/org-1495/20221006221936mp_/https://ec.europa.eu/environment/eussd/smgp/pdf/PEFCR_Feed_Feb%202020.pdf

European Commission (2021) 9332 final: COMMISSION RECOMMENDATION on the use of the Environmental Footprint methods to measure and communicate the life cycle environmental performance of products and organisations.Retrieved from: https://environment.ec.europa.eu/publications/recommendation-use-environmental-footprint-methods_en

FAO (2017) Water for sustainable food and agriculture. Food and Agriculture Organization, Rome

FAO (2011) The state of the world’s land and water resources for food and agriculture (SOLAW) – Managing systems at risk. Food and Agriculture Organization of the United Nations, Rome and Earthscan, London

FAO (2021) AQUASTAT - FAO's Global Information System on Water and Agriculture. http://www.fao.org/aquastat/en/. accessed 26 Jan 2022

Finogenova N, Dolganova I, Berger M, Núñez M, Blizniukova D, Müller-Frank A, Finkbeiner M (2019) Water footprint of German agricultural imports: Local impacts due to global trade flows in a fifteen-year perspective. Sci Total Environ 662:521–529

Gerber, PJ, Steinfeld, H, Henderson, B, Mottet, A, Opio, C, Dijkman, J, Falcucci, A & Tempio, G (2013) Tackling climate change through livestock – a global assessment of emissions and mitigation opportunities. Food and Agriculture Organization of the United Nations (FAO), Rome

González-García S, Belo S, Dias AC, Rodrigues JV, da Costa RR, Ferreira A, Andrade LPD, Arroja L (2015) Life cycle assessment of pigmeat production: Portuguese case study and proposal of improvement options. J Clean Prod 100:126–139

Heuzé, V, Tran, G, Bastianelli, D, Archimede, H & Sauvant, D (2013) Feedipedia: an open access international encyclopedia on feed resources for farm animals

Hietala S, Heusala H, Katajajuuri JM, Järvenranta K, Virkajärvi P, Huuskonen A, Nousiainen J (2021) Environmental life cycle assessment of Finnish beef–cradle-to-farm gate analysis of dairy and beef breed beef production. Agric Syst 194:103250

Hietala, S, Usva, K, Nousiainen, J, Vieraankivi, ML, Vorne, V, & Leinonen, I (2022). Environmental impact assessment of Finnish feed crop production with methodological comparison of PEF and IPCC methods for climate change impact. J Clean Prod, 134664.

Huuskonen A, Hietala S, Hyvönen J, Leinonen I, Manni K (2023) Environmental impacts and animal performance of finishing bulls fed different silage-based total mixed rations. Livest Sci 268:105166

IPCC (2006). IPCC Guidelines for National Greenhouse Gas Inventories: Volume 4 Agriculture, Forestry and Other Land Use, IGES, Japan

IPCC (2013) Myhre, G, Shindell, D, Bréon, FM, Collins, W, Fuglestvedt, J, Huang, J, Koch, D, Lamarque, JF, Lee, D, Mendoza, B, Nakajima, T, Robock, A., Stephens, G, Takemura, T & Zhang, H 2013. “Anthropogenic and natural radiative forcing,” in Climate Change 2013: The Physical Science Basis. Contribution of Working Group 1 to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change, eds T. F. Stocker, D. Qin, G.-K. Plattner, M. Tignor, S. K. Allen, and J. Boschung, et al. (Cambridge; New York, NY: Cambridge University Press), 659–740

IPCC (2019). Refinement to the 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Volume 4: Agriculture, Forestry and Other Land Use. Intergovernmental Panel on Climate Change (IPCC). https://www.ipcc-nggip.iges.or.jp/public/2019rf/vol4.html. —. Chapter 11: N2O Emissions from Managed Soils, and CO2 Emissions from Lime and Urea Application . Intergovernmental Panel on Climate Change (IPCC). 2006. https://www.ipcc-nggip.iges.or.jp/public/2006gl/pdf/4_Volume4/V4_11_Ch11_N2O&CO2.pdf

Joos F, Roth R, Fuglestvedt JS, Peters GP, Enting IG, Bloh WV, Brovkin V, Burke EJ, Eby M, Edwards NR, Friedrich T, Frölicher TL, Halloran PR, Holden PB, Jones C, Kleinen T, Mackenzie FT, Matsumoto K, Meinhausen M, Plattner G-K, Reisinger A, Segschneider J, Shaffer G, Steinacher M, Strassmann K, Tanaka K, Timmermann A, Weaver AJ (2013) Carbon dioxide and climate impulse response functions for the computation of greenhouse gas metrics: a multi-model analysis. Atmos Chem Phys 13(5):2793–2825

Lamnatou C, Ezcurra-Ciaurriz X, Chemisana D, Plà-Aragonés LM (2016) Environmental assessment of a pork-production system in North-East of Spain focusing on life-cycle swine nutrition. J Clean Prod 137:105–115

Mackenzie SG, Leinonen I, Ferguson N, Kyriazakis I (2016) Can the environmental impact of pig systems be reduced by utilising co-products as feed? J Clean Prod 115:172–181

Natural Resources Institute Finland (2021) Feed tables and nutrient requirements of farm animals used in Finland. Available online: https://portal.mtt.fi/portal/page/portal/Rehutaulukot/feed_tables_english. Accessed 28 Dec 21

Natural Resources Institute Finland (2022a) Meat production statistics. Official Finnish Statistics. https://www.luke.fi/en/statistics/meat-production

Natural Resources Institute Finland (2022b). Balance sheet for food commodities. https://www.luke.fi/en/statistics/balance-sheet-for-food-commodities

Noya I, Aldea X, Gasol CM, González-García S, Amores MJ, Colón J, Ponsá S, Roman I, Rubio MA, Casas E, Moreira MT, Boschmonart-Rives J (2016) Carbon and water footprint of pork supply chain in Catalonia: from feed to final products. J Environ Manage 171:133–143

Pré sustainability (2022) SimaPro software. https://simapro.com/. Accessed 13 Jan 2022

Reckmann K, Traulsen I, Krieter J (2012) Environmental impact assessment–methodology with special emphasis on European pork production. J Environ Manage 107:102–109

Reckmann K, Traulsen I, Krieter J (2013) Life cycle assessment of pork production: a data inventory for the case of Germany. Livest Sci 157(2–3):586–596

Regulation (EC) No 1069/2009 of the European Parliament and of the Council of 21 October 2009 laying down health rules as regards animal by-products and derived products not intended for human consumption and repealing Regulation (EC) No 1774/2002 (Animal by-products Regulation)

Saarinen M, Kurppa S, Nissinen A, Mäkelä J (eds) (2011) Aterioiden ja asumisen valinnat kulutuksen ympäristövaikutusten ytimessä. ConsEnv-hankkeen loppuraportti. (in Finnish) (Meal choices and alternatives in housing as the key issues of environmental impacts of consumption. Final report of ConsEnv-project) Suomen ympäristö 14/ 2011

Sevón-Aimonen ML (2002) Suomalaisen sika-aineksen kasvukäyrä ja kasvun koostumus. Maataloustieteen Päivät, Kotieläintiede, 9.-10.1.2002 Viikki, Helsinki. Teoksessa Rinne, M. (Toim.) 2002. Maaseutukeskusten Liiton Julkaisuja 977:63–65

Springmann M, Clark M, Mason-D’Croz D, Wiebe K, Bodirsky BL, Lassaletta L, Willett W (2018) Options for keeping the food system within environmental limits. Nature 562(7728):519–525

Statistics Finland (2021) Greenhouse gas emissions in Finland 1990 to 2019. National Inventory Report under the UNFCCC and the Kyoto Protocol, Submission to the European Union

Usva K, Hietala S, Nousiainen J, Vorne V, Vieraankivi ML, Jallinoja M, Leinonen I (2023) Environmental life cycle assessment of Finnish broiler chicken production–Focus on climate change and water scarcity impacts. J Clean Prod 410:137097

Vermeulen SJ, Campbell BM, Ingram JS (2012) Climate change and food systems. Annu Rev Environ Resour 37:195–222

Virtanen Y, Kurppa S, Saarinen M, Katajajuuri JM, Usva K, Mäenpää I, Mäkelä J, Grönroos J, Nissinen A (2011) Carbon footprint of food–approaches from national input–output statistics and a LCA of a food portion. J Clean Prod 19(16):1849–1856

Funding

Open access funding provided by Natural Resources Institute Finland. This study was supported by funding from the Development Fund for Agriculture and Forestry (Makera), A-Rehu Oy, HKScan Finland Ltd., and the Central Union of Agricultural Producers and Forest Owners (MTK) and Leg4Life project (2019–2025) funded by the Strategic Research Council at the Academy of Finland (grant numbers 327700 and 327698).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Communicated by Niels Jungbluth.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hietala, S., Usva, K., Vieraankivi, ML. et al. Environmental sustainability of Finnish pork production: life cycle assessment of climate change and water scarcity impacts. Int J Life Cycle Assess 29, 483–500 (2024). https://doi.org/10.1007/s11367-023-02258-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-023-02258-7