Abstract

Purpose

The depletion of natural resources and the downgrading of the environment, driven by globalization and consumerism phenomena, are worldwide pushing the interest in sustainable manufacturing paradigm and environment preservation. It is moreover clear to academia and practitioners that the cosmetics industry needs to update its current operations to face new sustainable requirements and norms due to its ever-growing size and massive consumption of natural resources. Different methodologies, metrics, and indicators have been and are being proposed for solving the complex issues of environmental sustainability evaluation of cosmetics processes and products.

Methods

Among these approaches and methods, product-related assessment tools (e.g., life cycle assessment) are usually more focused on the environmental dimension of sustainability, and they are always based on the life cycle of the product. The core of this paper is on the development of a novel tool to classify cosmetics products based on the results of LCA: the eco-friendliness assessment tool (EFAT). The methodology of the work is structured into 5 main phases: definition of the scientific background of the work, definition of the tool requirements, tool development, testing of the tool, analysis of the results. The eco-friendliness assessment tool proposed is structured into two main parts: (i) process flow 1: environmental impact score and (ii) process flow 2: supplier environmental sustainability assessment.

Results

The tool has been tested on a cosmetics product manufactured in a cosmetics company located in Italy. The acquisition of raw material process and primary packaging process are the two most critical processes resulting from the impact analysis of LCA methodology. The application of the EFAT tool shows the two possible most sustainable improved scenarios are as follows: (i) exploiting transportation of the primary packaging by sea and (ii) adopting the European location of the primary packaging supplier. The results coming from the tool application allowed the definition of the company product eco-friendliness. The eco-friendliness is symbolized by an alphabetical letter and a color.

Conclusions

The paper proposes a practical tool to assess the environmental sustainability level of cosmetics products, with the intention to overcome two of the main literature gaps found in the state of the art: (i) absence of LCA methodology implementation in the cosmetics industry on makeup products, (ii) absence of tools that rely on the results of the LCA analysis of a cosmetic product for understanding its sustainability level of sustainability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

The organizations’ interest in the implementation of sustainable practices is nowadays evident (Abubakr et al. 2020). Besides the necessity to overcome the problems related to the depletion of natural resources and their price increase, other drivers have been identified in the literature review carried out by Neri et al. (2021) that are leading the companies to embrace the path toward sustainability. According to Neri et al. (2021), those drivers can be divided into external (i.e., regulatory, support, external pressures, and market) and internal ones (i.e., organization, staff, information, innovation, and economic). Since brand image and firm reputation are the world’s new opinion makers (Suresh et al. 2011), the agenda for most organizations include building and maintaining strong corporate reputations and brands by integrating environmental, social, and economic responsibility issues into daily business operations (Suresh et al. 2011). Also, the management support and commitment to enhance sustainability are recognized as relevant, along with personal management satisfaction (Neri et al. 2021). Among many sectors of modern societies, manufacturing contests negatively affect the environment and communities (Saad et al. 2019). Regarding the environmental dimension, the massive extraction of virgin raw materials to create new products and components and the energy consumption required for the production processes are some of the main issues hurting our planet (Garetti and Taisch 2012). Thus, the current global focus is on supporting and coercing manufacturing industries to implement cleaner and more efficient production practices that enable the development of products and services with reduced negative environmental and societal impacts (Gbededo et al. 2018). Considering the previous reflection, sustainable manufacturing approaches become key to pursuing the goals of sustainable development. From the 1970s until the late 1990s, tools, initiatives, and approaches evolved from purely “end-of-pipe” solutions (which are usually costly and inefficient) toward whole system approaches, by changing products, processes, services, and systems, so that waste is minimized, and resources are used more efficiently and effectively, in almost closed loops (Acerbi et al. 2021; Lozano 2020; Sassanelli et al. 2019).

Different methodologies have been and are being proposed for solving these complex issues, from the well-known Design for X (Sassanelli et al. 2020) to new concept like product assessment throughout its entire life cycle. Other methodologies, metrics, and indicators are related to the circular economy paradigm (Rocca et al. 2021), specifically to the adoption of the 6R methodology which offers a closed-loop, multiple-product life cycle system as the basis for sustainable manufacturing (Abubakr et al. 2020; Acerbi et al. 2021; Sassanelli et al. 2020). Also, eco-efficiency initiatives (methods such as energy modelling, eco-design, lean-green, and energy management systems) can allow the firm to reduce the amount of resources used to produce goods, which in turn decreases the organization’s operating cost while decreasing its environmental impact (Suresh et al. 2011). All these approaches and methods have been designed with specific objectives and have different scopes and data requirements. Also, product-related assessment tools (Ness et al. 2007) are usually more focused on the environmental dimension of sustainability, and they are always based on the life cycle of the product. The most established and well-developed tool in this category is life cycle assessment (LCA) (Curran 2013). Because of its continuous growth worldwide and due to its high consumption of natural resources, the cosmetics industry represents one of the main sectors requiring a long-term vision to manage sustainability (Rocca et al. 2022a). The need to guide the sector toward a green transition is pushed by a strong emphasis on improving the environmental and social sustainability of its activities and products (Acerbi et al. 2023; Rocca et al. 2022a). Rocca et al. (2022a, b, c) present a systematic literature review aimed to identify the assessment tools that can be applied to evaluate environmental sustainability performances in the cosmetics industry and to understand the state of the art of LCA methodology application in the cosmetics industry (Rocca et al. 2022c). Among the most often cited methods in the literature for assessing the environmental sustainability of cosmetics, the LCA methodology is the most used. Beyond the objective results on environmental loads, a LCA study can provide very few tools and methodologies available to assess the level of sustainability of a product, and none of them is based on LCA (Rocca et al., 2022c). The core of this paper is therefore on the development of a novel tool to classify cosmetics products based on the results of LCA. The rest of the paper is structured as follows: Sect. 2 shows the methodology underlines the work; Sect. 3 describes the development of the tool, while Sect. 4 proposes an application of the tool to a real industrial case. Finally, the paper ends with Sect. 5 highlighting some conclusions and possible future developments of the work.

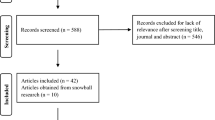

2 Research methodology

In this section, the research methodology of the work is presented. The methodology is structured into 5 main phases: (1) definition of the scientific background of the work, (2) definition of the tool requirements, (3) tool development, (4) testing of the tool, (5) analysis of the results. A schematization of the research methodology process is also reported in Fig. 1, while each single phase of the methodology is better explained in the sub-sections below.

2.1 Scientific background and state of the art

As it emerged from the literature analysis proposed by Rocca et al. (2022a), there is enough evidence of a trend of green purchasing in the cosmetics market. The authors point out that the aspects related to cosmetic product sustainability should always encompass the entire product life cycle. According to the analysis conducted, it is indeed widely accepted that adopting a triple bottom line (TBL) (Okorie et al. 2021) and a LCT approach is the direction to take when dealing with sustainable issues. Moreover, there is clear evidence that LCA is widely used to quantitatively measure cosmetic products’ environmental impact, which brings as a major advantage the fact of providing decision-makers with objective results. The confusion which characterizes this sector for what regards laws and regulations can lead cosmetics companies to feel lost in their soon-to-become inevitable transition to a sustainable business. According instead to the literature review conducted by Rocca et al. (2022c), the environmental impact assessment methods most found in the literature are four: (i) LCA, (ii) carbon footprint, (iii) water footprint, and (iv) environmental risk assessment.

The LCA is applied to quantify the environmental impacts of cosmetics ingredients and their extraction process, cosmetics packaging, and skincare products. Usually, the critical phase of the life cycle that negatively affects the most the environment is the raw materials extraction process. In the case of rinse-off products or products that can be carried around by consumers, the use phase can be critical in terms of sustainability. Considering the above considerations, the main research gaps outlined in the previous works of the authors are reported below (Rocca et al. 2022a, c):

-

(1)

The implementation of the LCA methodology in the cosmetics industry does not cover makeup products. In fact, although case studies have been found in the literature applied to makeup packaging, LCA analyses covering the life cycle of a makeup product are not present.

-

(2)

No tool that relies on the results of the LCA analysis of a cosmetic product exists in the literature for understanding their level of sustainability.

-

(3)

Currently adopted methodologies are focused on measuring the environmental impacts of products (e.g., LCA), neglecting social and economic considerations, especially from social and economic perspectives.

-

(4)

The cosmetics industry is characterized by a lack of standards and precise regulations, for what regards the transition to sustainability.

-

(5)

It is not yet developed a comprehensive framework that enables and guides the shift to a sustainable business in the cosmetics sector (considering the triple perspective of consumers, cosmetic product lifecycle, and managerial practices), especially regarding small medium enterprises (SMEs), which usually have not the resources to develop their own frameworks and sustainable business models.

Among these gaps, the present contribution tries to develop an innovative sustainability tool able to overcome the shortage of instruments for the sustainability level evaluation of a cosmetics product starting from LCA results (Gap 2) testing it on a makeup product (Gap 1). The proposed tool has been named the eco-friendliness assessment tool (EFAT). Starting from these considerations, a literature search has been conducted aiming to identify models or tools (not strictly developed for or applied in the cosmetics industry) allowing the interpretation, in environmental sustainability terms, of the results obtained from the LCA and to have a complete view of the state of the art to spot possible gaps to be addressed. Google Scholar was chosen as the scientific database to be consulted. The keywords entered in the search bar were as follows: “Sustainability tool based on LCA” and the papers resulting from the first 30 pages of research, ordered by relevance, were analyzed. Tools meeting the goal of this literature search were not found. However, the authors found relevant highlights, recounted in the following bulleted list.

-

(a)

Streamlined LCA tools instead of complex LCAs: A full LCA conducted in accordance with the ISO standards is usually too time-consuming and expensive for industrial companies (Heidari et al. 2019). Therefore, there is an increasing demand for simpler methods to demonstrate a company’s resource efficiency potential without the exploitation of more complex software for LCA.

-

(b)

Eco-efficiency tools to compare economic and environmental sustainability: Eco-efficiency assessments can support companies in developing and successfully implementing a business strategy toward sustainability since their objective is to obtain more service, function, and hence value with less environmental impact (Grosse-Sommer et al. 2020). Usually, the final output of the eco-efficiency tools consists of a matrix allowing the comparison of environmental impacts in relation to a product’s cost-effectiveness (Grosse-Sommer et al. 2020).

-

(c)

Normalization and weighting to compare environmental indicators of different products: This is the most interesting aspect of the development of the tool to assess products’ eco-friendliness. For a holistic comparison of product or process alternatives, a single environmental score is needed (Grosse-Sommer et al. 2020), and many papers suggest a two-step approach constituted by normalization and weighting. Normalization is a procedure needed to compare across impact categories to prioritize or to resolve trade-offs between product alternatives by eliminating the units of measure of the environmental impact indicators (Pieragostini et al. 2012). The impacts can be further aggregated into a single environmental impact function by attaching weights to the impacts to indicate their relative importance (Pieragostini et al. 2012).

-

(d)

Colour scale to represent the level of sustainability. Some scoring systems found on the scientific database end by assigning each material, product, and process a color representing the level of sustainability (Curzons et al. 2007; Ladu and Morone 2021). The simple color coding system is used to flag differences in environmental scores. Usually, green, yellow, and red are the most used colors to express something acceptable (good), intermediate, or not acceptable (bad) respectively.

2.2 Tool requirements

According to the main gaps and elements analyzed from the literature and explained in the previous sections, the scope of the paper is to propose a practical tool to assess the environmental sustainability level of cosmetics products, based on the following elements and requirements:

-

LCA results-based: the tool has to be developed starting from the results of the LCA analysis conducted on cosmetics products. Therefore, it must be preceded by a detailed implementation of the LCA.

-

Simplicity and ease of use: in a short period, the features of the tool and how to use it must be explained to the practitioners. Hours of training should not be necessary since the tool has to be simple. In this way, it is possible to immediately comprehend how it should be applied. Moreover, the output of the tool should be clear and instantly understandable.

-

Suitable for a cosmetics manufacturer: the eco-friendliness assessment tool (EFAT) is not intended for final consumers. The tool is thought to be used by a cosmetics manufacturer to show customers (i.e., other cosmetics brands) the sustainability of their products. Therefore, when the marketing department presents different products to the clients, with the same function but having different formulas and packaging, the customer can have a clear idea about the level of sustainability of the different alternatives.

3 Tool development

A detailed explanation of the development of the tool is displayed in this section. The tool aims at classifying cosmetics products based on their environmental sustainability level. To depict the sustainability level, a previous LCA of the product must be conducted. The same scoring system integrated within the environmental sustainability assessment tool allows to compare cosmetics products belonging only to the same category. Specifically, as Cosmetics Europe declares, there are seven categories of cosmetics and personal care items: (i) oral care, (ii) skincare, (iii) sun care, (iv) hair care, (v) decorative cosmetics, (vi) body care, and (vii) perfumes (Cosmetics Europe website 2022). The tool not only allows comprehending the sustainability level of different products but can also be exploited to compare a product with its improved or worsened versions resulting from the what-if analyses conducted in the interpretation phase of the LCA. Under a life cycle perspective, in order to propose a comprehensive tool able to consider also the relationship with the stakeholders of the cosmetics supply chain, the supplier’s sustainability assessment model presented in Acerbi et al. (2023) has been integrated into the tool. This model is based on a questionnaire to be filled out by the suppliers of a cosmetics manufacturer to understand their interest in sustainability and the actions they are carrying out to achieve economic, social, and environmental sustainability goals. The integration of the supplier’s sustainability assessment model ensures better visibility of the sustainability of the upstream supply chain actors.

3.1 Structure of the tool

The eco-friendliness assessment tool proposed in this paper is structured into two main parts, as reported in Fig. 2: (i) process flow 1: environmental impact score and (ii) process flow 2: supplier environmental sustainability assessment. The following diagram points out all the relevant steps required to design the eco-friendliness assessment tool.

The output of Process 1 is the environmental impacts score (EIS), a number between 1 and 4 expressing the degree of environmental sustainability of a cosmetic product considering the impacts it generates in its life cycle. Process 1 is composed of three steps:

-

Step 1: quantification of environmental impacts through LCA

-

Step 2: assignment of numerical scores to environmental impacts

-

Step 3: computation of the environmental impacts score

Process 2 aims at computing the suppliers environmental sustainability assessment score (SESAS) by interpreting the results of a questionnaire filled by the raw materials suppliers of the cosmetic product under study presented in Acerbi et al. (2023). Also, process 2 is made up of three steps:

-

Step 4: creation of the suppliers’ environmental sustainability assessment questionnaire

-

Step 5: calculation of the grade of the suppliers’ environmental sustainability questionnaire

-

Step 6: computation of the Suppliers Environmental Sustainability Assessment Score

By integrating the outputs of the two processes in a matrix (step 7), it is possible to find out four levels of eco-friendliness for a cosmetic product. A detailed description of all the steps is provided in the following paragraphs.

3.1.1 Step 1: quantification of environmental impacts through LCA

The starting point for the implementation of the eco-friendliness assessment tool is the LCA of a cosmetic product since it allows the estimation of the environmental impact indicators. For the definition of the activities to be included within the system boundaries, the product category rules (PCR) for the assessment of the environmental performance of cosmetics developed in the framework of the International EPD® System is taken as reference (Cosmetics (Soap, Perfume and Toilet Preparations) - Product Category Classification: UN CPC 35321 and 35323, 2020). The activities to be included in the LCA analysis can be grouped into upstream processes, core processes, and downstream processes, as highlighted in Table 1.

Some of the activities depicted in Table 1 may be overlooked by the LCA practitioner because of the following: (i) they are not relevant in terms of the environmental impacts they generate, (ii) or the cosmetics manufacturer does not have enough visibility over certain upstream or downstream stages of the supply chain. Regarding the quantification of the environmental impacts, many assessment methods are available. Taking the CML-IA impact assessment method as a reference (Simapro Database Manual 2020), the most relevant impact categories possible to consider are as follows: global warming (climate change), abiotic depletion (elements), abiotic depletion (fossil fuels), acidification, eutrophication, photochemical oxidation.

3.1.2 Step 2: assignment of numerical scores to environmental impacts

After obtaining the LCA results, the goal is to simplify the comparison of environmental impacts, eliminating the units of measure. Two alternative solutions are available in the literature for this scope: (a) normalization, the division of all indicators by a reference value; (b) assignment of a score to each environmental indicator according to its value. The second option is chosen for the eco-friendliness assessment tool since it is not dependent on the choice of the reference value. In fact, different reference values can lead to different quotients. Referring to the second option, each environmental indicator is assigned a score between 1 and 4 depending on its value. The choice linked to the adoption of this scoring scale system can be traced back to the use of a top-down thinking approach for designing the eco-friendliness assessment tool. In fact, the starting point was to depict what the final output of the tool should be: placing a cosmetic product within a matrix consisting of four quadrants corresponding to four levels of eco-friendliness. Consequently, to ensure linearity, it was decided to maintain four levels also for the definition of the scoring scale system regarding the environmental impacts. From a score equal to 1, which corresponds to the lowest degree of environmental sustainability, each impact category can grow up to a score equal to 4, indicative of the highest degree of environmental sustainability. Therefore, each impact category has a specific scale that defines the ranges in which the indicator value is assigned a score equal to 1, a score equal to 2, 3, or 4 (Figs. 3, 4, and 5). The steps needed to define the ranges are described below.

-

Calculation of the average value for each impact category. The average value is the boundary between score 2 and score 3. The maximum value and the minimum one for each impact category are the outer extremes of the scoring scale.

-

The boundary between score 1 and score 2 is the average of the indicator values that are higher than or equal to the average itself.

If all the values (it can be one value or more than one) that are higher than the average value are equal to the upper extreme value, the upper average is the mean between those values and the average value.

-

The boundary between score 3 and score 4 is the average of the indicator values that are lower than or equal to the average itself.

If all the values (it can be one value or more than one) that are lower than the average value are equal to the lower extreme value, the lower average is the mean between those values and the average value. Steps 1, 2, and 3, needed to define the ranges, have to be carried out for each impact category to create a different scale for each indicator. The scoring scales must be updated each time a new LCA is introduced in the system. What remains invariant is the presence of the four scores (1, 2, 3, and 4). This approach can push cosmetics manufacturers to become more sustainable.

3.1.3 Step 3: computation of the environmental impacts score

Different modalities are available to attribute weights to the indicators. It was decided to exploit a “distance to target” weighting approach linked to the concept of “planet boundaries” and “carrying capacity” to prioritize the environmental impact categories that need to be urgently addressed. In the literature review considered, it was pointed out the approach introduced by Bjørn et al. (2015) and revised by Vargas-Gonzalez et al. (2019), according to which a set of planetary boundaries–based weighting factors is proposed. These weighting factors result from a comparison between the carrying capacity of planet Earth and current emissions or consumption levels. Therefore, they can be used also to pinpoint the issues where current emissions or consumptions are higher than the defined carrying capacity (Vargas-Gonzalez et al. 2019). The ratio used as a weighting factor is referred to (Vargas-Gonzalez et al. 2019) as a “reduction factor” and is defined for each impact category by the following formula:

The list of the suggested weighting factors developed by Bjørn et al. (2015) and Vargas-Gonzalez et al. (2019) is shown in Table 2.

Observing Table 2, climate change is considered the most urgent environmental challenge. Additionally, resource overuse has become a political priority with international governing bodies encouraging the implementation of circular economy approaches (Vargas-Gonzalez et al. 2019). The final weights allocated to the environmental impact indicators are normalized with the mathematical formula reported in Fig. 6.

The same impact categories quantified in the previously conducted LCA analysis should be considered for the weight setting. At this point, a weighted sum is required to obtain a single score from all the values of the environmental impact indicators. The score of each indicator is multiplied by the indicator weight, and then all these products are summed together. The result of these calculations is called the “Environmental Impacts Score” (Fig. 7).

3.1.4 Step 4: creation of the suppliers’ environmental sustainability assessment questionnaire

The goal of creating a survey to be sent to the suppliers of the cosmetics manufacturer is to investigate if and how the suppliers are embracing a sustainability path. Questions should be formulated to cover all the facets of the environmental dimension since the EFAT aims to figure out the level of environmental sustainability of a cosmetic product. According to Acerbi et al. (2023), eleven criteria can be considered for the environmental evaluation of suppliers and, therefore, for the creation of the questionnaire: cruelty-free programs and certifications, water pollution, toxicity level of production activities (e.g., freshwater ecotoxicity, acidification), local territory safeguard and correct harvest practices, circular practices, recycling initiatives, plastic reduction policies, supply chain traceability, energy consumption, production practices and operations impacts’ traceability, ISO 14001 (environmental management system), time needed to be compliant with environmental requirements, willingness to be audited and share information about environmental performance improvement.

The sustainability survey must be sent to all the suppliers of the cosmetics manufacturer producing the raw materials included in the formula of the cosmetic product under evaluation. The extraction and manufacturing of raw materials are often the most critical phases of the LCA analyses in the cosmetics sector. The cosmetics manufacturer can decide the number of questions of the survey and their weights; therefore, the maximum score achievable by filling the survey depends on these two factors. If the form consists of n questions with equivalent weight and equal to 1 and the supplier can assign a score from 0 to 5 to each question, the maximum score that can be obtained is 5.

3.1.5 Step 5: calculation of the grade of the suppliers’ environmental sustainability questionnaire

Cosmetics companies can purchase the inputs for their production processes from different types of actors having different roles in the supply chain. Instead, a producer owns factories to manufacture the ingredients that will be included in the cosmetics formulas. Therefore, two alternatives are available for the design of the questionnaire: (i) a personalized questionnaire is built for each supplier considering its role in the supply chain, (ii) a single questionnaire is created and sent to all suppliers regardless of their type. In this case, maybe not all questions can be answered by all suppliers, so the “not applicable” option is accepted. Always looking at the requirements the tool must satisfy, option number two is less time-consuming and easier to implement, also to interpret results and calculate scores for each supplier. Therefore, accepting the possibility of receiving “not applicable” as answers to the questionnaire, for each supplier is computed a grade following the process illustrated in Fig. 8.

3.1.6 Step 6: computation of the supplier’s environmental sustainability assessment score

The suppliers environmental sustainability assessment score is the mathematical average of all suppliers’ grades obtained from the questionnaire submitted to the raw materials providers of the cosmetic product under study (Fig. 9).

3.1.7 Step 7: assessment of the eco-friendliness

One of the requirements of the tool is the immediate comprehension of the final output. Therefore, for a clear understanding of the level of eco-friendliness, the creation of a matrix is employed. A 2 × 2 matrix is a useful instrument for representing results and comparing them based on two factors. As previously stated, even some articles found in the literature dealing with the concept of eco-efficiency place different alternatives in a matrix depending on their economic and environmental sustainability. In this case, the two dimensions of the matrix are as follows: (i) X-axis, environmental impacts score; (ii) Y-axis, supplier’s environmental sustainability assessment score.

The final eco-friendliness matrix allowing the definition of the product eco-friendliness is shown in Table 3. The eco-friendliness is symbolized with an alphabetical letter and a color (Fig. 10). There are four possible scenarios and, therefore, four possible levels of eco-friendliness.

It was decided to confer more relevance to the EIS with respect to the SESAS for the eco-friendliness levels definition. In fact, the EIS is based on the results of the LCA analysis and is a better indicator of the eco-friendliness level than the questionnaire, which relies on the subjectivity of the person filling it out.

4 Application of the tool: the mascara case study

The eco-friendliness assessment tool (EFAT) has been tested and validated on a cosmetic product manufactured by a company located in northern Italy. Since the object of the study is a mascara, it was decided to use the tool to understand the level of eco-friendliness of products belonging to the macro-category “eye makeup products” and sub-category “mascaras,” according to cosmetics product categorization (Cosmetics Europe website 2022). The seven steps for the tool development applied to the case study are described in the next sections. The company involved is specialized in the development and manufacturing of makeup products, and, among its creations, mascaras are the flagship line.

4.1 Step 1: quantification of environmental impacts through LCA

As described above, the first step for the development of the tool consists in the application of the LCA methodology. The four LCA phases for the evaluation of the environmental impacts of the product analyzed are described below.

4.1.1 Goal and scope definition

This LCA analysis was performed with the primary goal of measuring the environmental impacts generated by a mascara along its life cycle. By highlighting the life cycle phases, processes, and materials impacting the most, the company is intended to evaluate alternative sourcing, manufacturing, and packaging solutions to reduce harmful environmental damages. To carry out the LCA, all inputs and outputs of processes were referred to one mascara: the functional unit. The activities within the system boundaries, and thus included in the LCA analysis, are reported in Table 4.

The activities outside the system boundaries and not considered in the study were:

-

Raw material transportation from producers to distributors: More than twenty raw materials are included in the product formula. The company mainly buys raw materials from distributors, while, in some cases, it also purchases the raw materials directly from manufacturers. Not all manufacturers and distributors specify where the raw materials come from in their packing list or other documentation. In addition, these data are difficult to collect because the same supplier may be sourcing from different manufacturers. In turn, the manufacturer may be purchasing its inputs from suppliers around the world.

-

Finish product transportation from the company client’s warehouses to final customers: The company does not have any information regarding where the final consumers are located.

-

Use phase: The use phase is related to the cosmetics utilization by the final consumer. Normally, in the case of a cosmetic product, the consumption of resources does not happen when the consumer applies the product but during its removal phase. Nowadays, many solutions are available to remove cosmetics: oily detergents, micellar water, makeup remover wipes, soap, and simply water. The consumer habits and choices significantly affect the environmental impact generated during product use, but strong assumptions should be made to consider the use phase in the LCA. This is the reason why this life cycle stage was not considered for the determination of the environmental impacts that will then be used as inputs for the creation of the tool. However, in the end, a test scenario has been implemented where the use phase is included in the LCA.

It was decided also to exclude from the analysis the components of mascara that are considered negligible, meaning the ones under a cutoff value of 0.05% (Table 5). Regarding instead the allocation procedure, the physical allocation method was used to weigh a multi-output process. The data collected to carry out the investigation were related to 2020. Most of the data on the consumption of resources (materials and energy) were taken directly from the production site through interviews organized with the departments’ managers of the company (i.e., quality department, purchasing department, bulk production department, warehouse, general services). Moreover, data were collected from the manufacturing execution system adopted by the company, from business documents, and directly from the field through weighting operations, material inspection activities, and label reading. To obtain data related to the impacts due to the production of raw materials and auxiliary materials, transport emissions, and waste treatment, it was necessary to rely on international databases (mainly ELCD database and Ecoinvent). Moreover, Google Maps was used to determine the distances between suppliers and customers and the company.

4.1.2 Inventory analysis

Many interlinked steps characterize the mascara fabrication process. A process flow diagram was developed to have a clear idea of all the activities within the plant. Then, all the unit processes were grouped into ten macro-processes that are illustrated in Fig. 11.

For these processes, data related to inputs and outputs were collected and entered into an Excel file. The creation of the Excel file was beneficial in facilitating future data entry into the SimaPro software, used for environmental impacts calculation. All the data related to the quantification of inputs and outputs were referred to the functional unit of one mascara. As previously declared, to be coherent with the concept of life cycle assessment, a scenario where the use phase is considered was built. To conduct the study of the environmental impacts generated during the use phase (i.e., makeup removal phase), the following assumptions were made:

-

Mascara can be applied 50 times (about 0.25 g of product are used per application)

-

The consumer uses 2 g of facial soap and one disposable cotton to remove mascara

-

Soap is rinsed-off using 0.5 l of lukewarm water (40 °C)

-

One cotton pad weighs 0.5 g, and in a plastic package (weight of the plastic package: 10 g) there are 80 cotton pads

The end-of-life waste scenario is, together with the use phase, a downstream process meaning that is carried out outside the company production site. When the product finishes, it was assumed that the final consumer discards it in the undifferentiated waste that will end up in landfills as inert waste. Regarding the samples (i.e., bulk sample and mascara in primary packaging sample), they are discarded by the external laboratory. It was assumed they are hazardous waste and are incinerated. All the data collected during the inventory analysis were entered into the SimaPro software, while the databases considered for the study were Ecoinvent v3, Agri-footprint, and ELCD.

The analysis in SimaPro was conceived as follows:

(a) Processes creation and, for each process, inputs and outputs were highlighted. Under the SimPro “materials” category, the outputs of these processes were as follows: (i) raw materials, (ii) bulk, (iii) bulk sample, (iv) primary packaging, (v) mascara in P1, (vi) mascara in P1 sample, (vii) secondary packaging, (viii) mascara in P2, (ix) tertiary packaging, (x) mascara packed and ready for shipping (mascara in P3).

Among these outputs, the three final ones of the mascara production process were as follows: (i) “Mascara packed and ready for shipping,” (ii) “Bulk sample,” and (iii) “Mascara in P1 sample” (see Fig. 10). At this point, three assemblies have been created in the SimaPro “assembly” section, and then three waste disposal scenarios, and, finally, three life cycles.

(b) To each assembly, one for each of the three main processes outputs, the transportation activity, either to go from the company to the external laboratory or to move the finished products to the client’s warehouses, was added.

(c) To represent the end-of-life of outputs, it was first created, among the processes, the waste disposal scenario, and then, among the “life-cycle phases,” the end-of-life scenario.

(d) Three life cycles, related to the three main outputs, were realized by adding the assembly (therefore considering all the impacts generated by the production of the assembly), the end-of-life scenario, and, potentially, the use phase previously created.

The following diagram summarizes how the analysis was built in SimaPro (Fig. 12).

4.1.3 Impact assessment

The impact assessment method selected and used to calculate impact assessment results was CML baseline. This method was created by Leiden University in 2001 (Muthu 2020) and can be distinguished into a baseline version and a non-baseline one. The baseline version is suggested since it considers the most common impact categories used in LCA and is recommended by the environmental product declaration (EPD). Six impact categories were considered in the LCA analysis because they are the most relevant ones (EPD and Unifarco S.p.a., 2016, 2017, 2018): (i) abiotic depletion (kg Sb eq.), (ii) abiotic depletion (fossil fuels) (MJ), (iii) global warming (GWP100a) (kg CO2 eq.), (iv) photochemical oxidation (kg C2H4 eq.), (v) acidification (kg SO2 eq.), (vi) eutrophication (kg PO43−eq.). The impacts of the second and the third life cycles had been created (i.e., bulk sample life cycle, and mascara in P1 sample life cycle) were negligible with respect to the mascara life cycle. In fact, the quantity transported in both cases was minimal if allocated to the single mascara. Consequently, the environmental impacts due to the samples were negligible compared to those from the production of mascara. For this reason, they have been disregarded in subsequent analyses. The environmental impacts obtained for the product were evaluated without considering the use phase. These results are shown in Table 6 and in Fig. 13.

On the other hand, in Table 7 and Fig. 14, the use phase is also considered. These results are compared with those in which the use phase is not considered.

4.1.4 Interpretation of the results

The acquisition of raw material process and primary packaging process are the two most critical processes resulting from the impact analysis. A detailed study of these processes is proposed, considering possible environmental impact improvements. A more in-depth analysis of the impacts of the mascara production carried out within the company production site is also proposed. Finally, considerations regarding the use phase are reported.

Acquisition of raw materials

Raw materials are difficult to optimize from a sustainability standpoint as the mascara formula can hardly change. The company could try to understand what potential replacement raw materials for those with more impact could be. However, this analysis would take months to be carried out because, even if replacement raw materials were found, tests would have to be implemented to understand whether they alter the formula and, therefore, whether the mascara’s performance would remain the same.

Packaging

The high environmental impacts attributed to the acquisition of the primary packaging are due to the Chinese location of the supplier, implying intercontinental transportation from China to Italy. Around 60% of global warming impacts related to all the activities necessary to fill the mascara are due to the transportation activity of the primary packaging. As an example, assuming that the primary packaging supplier is in Europe (for example, in Berlin) instead of Shanghai, it can be seen in Table 8 that the value of all impact indicators decreases dramatically.

Aircraft is a highly polluting means of transport. It has been noted that even by simply changing the means of transportation necessary for the acquisition of the primary packaging from air to ship, impacts are considerably reduced (Table 9). In this scenario, Shanghai (China) and Trieste (Italy) were assumed as the port of origin and destination, respectively. An on-carriage transportation phase by truck from the port of Trieste to the company production plant was also considered. The airplane has advantages in terms of delivery speed. A ship coming from China takes from 30 to 40 days to reach the Italian coasts; consequently, it is necessary to plan the shipping and be punctual in finishing the production process of the primary packaging.

Another potential improvement action the company could implement is to select suppliers that offer primary packaging of materials other than plastic. A significant negative impact (26.9%) on global warming is caused by the manufacturing of plastic bottles. Therefore, another what-if analysis was conducted to evaluate the benefits of choosing primary packaging components in recycled aluminum and recycled plastics. It was decided to include the wiper in the assessment since the supplier is the same as the bottle, and both components are made of plastic material. The following assumptions were considered to carry out the what-if analysis:

-

The weight of the bottle and wiper remains unchanged

-

To produce 1 ton of primary aluminum, 14,000 KWh of energy is needed (Educazione Digitale 2018a).

-

The production of recycled aluminum requires 95% less energy than the production of primary aluminum (Educazione Digitale 2018b).

-

One thousand liters of water and 950 kWh of energy are needed to produce 1 ton of recycled plastic (Romei RePlastics website 2022).

In Table 10, the results of this analysis are shown.

Finally, the last what-if analysis performed is related to the unit carton material (Table 11). It is quantified how the environmental impacts change if mascara’s secondary packaging is made of recycled cartons.

The histograms of Fig. 15 summarize the results of the what-if analyses with respect to the AS-IS situation.

Narrowing the focus on the impacts generated by the company production plant, the resources consumed for which the company is directly responsible are as follows: (i) micro-filtered water, used as raw material and to clean machinery equipment and bins; (ii) electric energy, necessary to power the production machinery; (iii) natural gas, exploited for warming physical spaces and water. Moreover, the impacts of the treatment processes linked to the waste produced during the mascara fabrication cannot be neglected by the cosmetics manufacturer (Table 12). The waste is related to the containers (of raw materials and packaging components) and the wastewater.

Taking into consideration the entire product life cycle, the impacts generated by the production processes within the production plant are not so relevant. Also considering the use phase, soap and water consumption determines an environmental impact of this phase significantly higher than the one related to the production of mascara. Therefore, consumer habits and choices significantly affect the environmental impact generated during product use.

4.2 Step 2: assignment of numerical scores to environmental impacts

The EFAT offers the possibility to compare both different products belonging to the same sub-category and to observe how potential improvement actions, highlighted in the interpretation phase of the LCA methodology, can improve the level of environmental sustainability of a product. In this case, the impacts values of the mascara AS-IS situation (without considering the use phase) and of the what-if analyses scenarios were the starting point for the definition of the scoring scale of the environmental impacts (Table 13).

Following the directions of Figs. 3, 4, and 5, the scoring scale for each environmental impact was determined (Table 14). As an example, it is provided the complete calculation procedure only for the global warming impact category since for the other categories, the calculations are the same (Fig. 16, Table 15).

Table 16 exhibits the scores assigned to each environmental impact indicator.

4.3 Step 3: computation of the environmental impacts score

The weight of each environmental category and the calculation of the EIS are proposed in Table 17. It is provided the complete calculation procedure only for the AS-IS scenario since the same procedure is valid also for the other scenarios.

Looking at the summary reported in Table 18, the scenario related to the change in the geographical positioning of the primary packaging supplier corresponds to the best value, in terms of sustainability, of the EIS. This is consistent with the quantitative estimate of the environmental impacts, illustrated in Fig. 14. The worst value relates to the AS-IS situation; in fact, all the what-if analyses coincide with improvement actions.

The results of the EIS depend on how the scoring scale is built. In turn, the scoring scale depends on how many and which LCA analyses are considered.

4.4 Step 4: development of the suppliers’ environmental sustainability assessment questionnaire

The questionnaire (Acerbi et al. 2023), was sent to the seventeen suppliers of the raw materials included in mascara formula. A rate from 0 to 5 has been assigned to each of the thirty-three questions covering many environmental topics as follows: animal testing, water consumption and treatment, toxicity emissions, harvesting procedures, circular economy practices, supplier’s selection choices, energy consumption, environmental certifications, environmental management systems. Each question had a weight equal to 1. Some suppliers are distributors who buy and resell raw materials without making any modifications. These suppliers do not own any production sites. Therefore, for some questions related to possible eco-friendly solutions implemented in the plants, the answer “not applicable” was also accepted.

4.5 Step 5: calculation of the grade of the suppliers’ environmental sustainability questionnaire

Upstream stakeholders in the cosmetics supply chain are increasingly involved in projects concerning environmental sustainability. Some of the seventeen surveyed suppliers have a robust environmental management system in place and they report their sustainability results in an annual report. The supplier’s grade was calculated for fourteen suppliers that sell the 68% product raw materials. Table 19 highlights the computation of the grade for each player.

4.6 Step 6: computation of the supplier’s environmental sustainability assessment score

Just one value of the SESAS can be computed since, in this case, the raw materials suppliers of the mascara are always the same regardless of the considered scenario. The SESAS resulted to be 79, a signal value of the concrete interest in becoming more sustainable from an environmental point of view.

4.7 Step 7: assessment of the eco-friendliness

The final position of mascara within the eco-friendliness matrix, considering the six scenarios, is shown in Fig. 17.

The high value of the SESAS resulted in the positioning of the six scenarios at the top quadrants of the eco-friendliness matrix. Consequently, the green area (eco-friendliness level A) and the orange area (eco-friendliness level C) were the only ones affected by this case study. As was already predictable by looking at the values of the environmental impacts, the two most sustainable scenarios were as follows: (i) transportation of the primary packaging by sea, (ii) European location of the primary packaging supplier. Changing the primary and secondary packaging material caused an increase in the EIS compared to the base case even though, in the end, the levels of eco-friendliness were C, like the AS-IS situation.

5 Discussions, conclusions, and future development

The cosmetics industry is living a worldwide expansion and the growth of the sector implies increasing in natural resources consumption, emissions, and waste production. Moreover, society is nowadays concerned about environmental issues, and many businesses are aware of the importance to monitor the environmental performance of products and processes. LCA is the most implemented methodology in the cosmetics sector. More in detail, the LCA is mainly used for assessing the environmental impacts generated by raw materials, production processes, packaging components, and skincare products. The output of the LCA are absolute numbers associated with the environmental impact category indicators, and this analysis does not display a level of sustainability of products and processes analyzed. To fill the gaps found in the literature, the goal of this paper was to conceptualize and develop an LCA-based tool to assess the level of eco-friendliness of cosmetics products to classify them from an environmental sustainability point of view. The tool, characterized by easiness of use and simplicity, is suitable for a cosmetics manufacturer. Two parallel process flows are required to implement the tool. The first one is finalized with the computation of the environmental impacts score (EIS) which is based on the LCA analysis (steps 1, 2, and 3). The second process is intended to calculate the supplier’s environmental sustainability assessment score (SESAS) starting from a questionnaire sent to the raw material suppliers of the cosmetics manufacturer to investigate their interest in environmental sustainability (steps 4, 5, and 6). By integrating the outputs of the two processes in a matrix (step 7), it is possible to find out four levels of eco-friendliness for a cosmetic product: A (green), B (yellow), C (orange), and D (red). The tool was implemented and tested on a mascara manufactured by an Italian SME. The authors proposed a practical tool to assess the environmental sustainability level of cosmetics products, based on the elements and requirements described in Sect. 2.2, with the intention to overcome two of the main literature gaps found in literature in this field: (i) absence of LCA methodology implementation in the cosmetics industry on makeup products, (ii) absence of tools that relies on the results of the LCA analysis of a cosmetic product for understanding its sustainability level of sustainability. The eco-friendliness assessment tool was designed for a cosmetics manufacturer, but one of its strengths is its potential exploitation also in other sectors. In fact, all the steps required to implement the tool, from the LCA analysis to the EIS and SESAS calculation, are independent of the industry being considered. And since the analysis of the literature revealed that these kinds of tools are not so widespread, the eco-friendliness assessment tool can be extended in the future to other sectors.

5.1 Discussion on the mascara case study

The environmental impacts generated by a mascara produced by the company selected for the validation of the tool have been calculated with respect to six impact categories. This activity constituted the first step for the implementation of the EFAT. Excluding the use phase, the most harmful processes of the product life cycle were the acquisition of raw materials and the acquisition of primary packaging. The latter is due to the emissions related to the transport activity. By conducting a simple what-if analysis, it was possible to see that the impacts decreased dramatically if local suppliers were selected, or transportation by sea was preferred. Considering that LCA is based on several assumptions made by practitioners, the environmental impacts are also different depending on the hypotheses the study is conducted. A scoring scale definition is necessary for assigning a score between 1 and 4 to each environmental indicator depending on its value. Every time a new LCA of a cosmetic product enters the set of conducted LCAs, the scoring scale is updated. The weighted sum of the scores and the weight of each indicator allows the estimation of the EIS, a first signal of the level of eco-friendliness. The scenario related to the change in the geographical positioning of the primary packaging supplier corresponded to the best value, in terms of sustainability, of the EIS. This is consistent with the quantitative estimate of the environmental impacts. The worst value is related to the AS-IS situation; in fact, all the what-if analyses coincided with improvement actions.

Then, the integration of the suppliers environmental sustainability assessment score ensured the positioning of the cosmetic product under study within an eco-friendliness matrix. The most eco-friendly scenarios corresponded to the ones with the highest value of EIS (i.e., P1 transport by sea and P1 supplier located in Berlin) since the SESAS was always 79, regardless of the considered scenario. In the future, the company may extend the tool implementation to other makeup and skincare categories to understand which ones are currently the most sustainable and to identify, through LCA, the production activities that negatively affect the environment. The company could think also about spotting alternative solutions that could be introduced to enhance the eco-friendliness of its products. A cost–benefit analysis must be undertaken to understand the feasibility of the improvement actions.

5.2 Limitations and future development

One of the limitations of the tool refers to its environmental focus. In fact, the EFAT considers only environmental sustainability. Therefore, the tool could be updated by adding the economic and social sustainability dimensions. Social life cycle assessment (SLCA) and life cycle costing (LCC) could be included in the LCA to guarantee a more comprehensive sustainability analysis. A second limitation is represented by the fundamental importance of basing the implementation of the tool on assumptions that must remain unchanged throughout the entire application of the tool and for all the products belonging to the same sub-category that are compared in terms of eco-friendliness. The most complex and time-consuming activity when applying the tool is the detailed implementation of the LCA. The greater the level of detail according to which this analysis is carried out, the more truthful will be the level of eco-friendliness obtained for a certain product. The third limitation regards the questionnaire necessary to compute the SESAS. The survey, in fact, should be sent also to the packaging suppliers of the cosmetics manufacturer and not only to the raw materials ones to get a more complete view of upstream supply chain sustainability.

Trying to boost the cosmetics product sustainability under a LCT perspective, the authors suggest integrating EFAT with specific circular economy (CE) metrics, able to quantify the circularity degree of a cosmetic product. Both cosmetic products and packaging indeed are looking for more sustainable solutions, addressing the research and development especially toward bio-based and biodegradable materials. The cosmetic industry depends on biodiversity as it provides a source of innovation and raw materials. Nature is established as a source of fundamental inputs and ingredients. As confirmed by the scientific literature, it is important for cosmetic companies to keep up with the expectations of consumers (Chin et al. 2018), as a crescent number of people are slowly shifting their mindset, seeking sustainability through their purchases. Consequently, national and international policies are continuously increasing, and sustainability standards and certifications are on the rise (Rocca et al. 2022a). One solution is to use innovative natural ingredients and circular resources to meet sustainability and performance demands in categories such as skin care, hair care, bath and shower products, and color cosmetics.

A second possible further development is the integration of EFAT in flexible industrial architecture enabled by digital technologies. Digital transformation is globally recognized as the transition enabled by Industry 4.0 (I4.0) technologies (Quadrini et al. 2021). It allows new automation architectures for production processes: (i) enhancing flexibility and scalability (Yoh 2001), (ii) enabling the integration of modern information and communication technologies (ICTs), and (iii) increasing efficiency and production performances (Tao et al. 2019). Together, technologies like machine-to-machine (M2M) communications (Cimino et al. 2019), cyber-physical systems (CPSs) (Negri et al. 2017), internet of things (IoT), and cloud computing (CC), allow companies to manage manufacturing processes in a more intelligent and agile way (Rocca et al. 2022b). Many works in literature have already assessed the interaction between I4.0 sustainability. Trying to put together the sustainability-oriented and technology-oriented views under the same umbrella, the concept of smart sustainability has been proposed by experts as a new way of making circular economies and sustainable practices (Rocca et al. 2020; Rosa et al. 2019). The integration of novel tools and metrics for environmental evaluation of cosmetics products within data-driven and interoperability-oriented industrial architectures can provide a state-of-the-art advancement in the field of information and communication technology (ICT) design for resource consumption assessment and traceability for manufacturing systems in the cosmetics industry.

Data availability

The data that support the findings of this study are available from the company involved in the study, but restrictions apply to the availability of these data, which were used under license for the current study, and so are not publicly available. Data are however available from the authors upon reasonable request and with permission of the company.

References

Abubakr M, Abbas AT, Tomaz I, Soliman MS, Luqman M, Hegab H (2020) Sustainable and smart manufacturing: an integrated approach. Sustain (switzerland) 12(6):1–19. https://doi.org/10.3390/su12062280

Acerbi F, Sassanelli C, Terzi S, Taisch M (2021) A systematic literature review on data and information required for circular manufacturing strategies adoption. Sustain (switzerland) 13(4):1–27. https://doi.org/10.3390/su13042047

Acerbi F, Rocca R, Fumagalli L, Taisch M (2023) Enhancing the cosmetics industry sustainability through a renewed sustainable supplier selection model a renewed sustainable supplier selection model. Prod Manuf Res 11(1). https://doi.org/10.1080/21693277.2022.2161021

Bjørn A, Hauschild MZ (2015) Introducing carrying capacity-based normalisation in LCA: framework and development of references at midpoint level. Int JLCA 20(7):1005–1018. https://doi.org/10.1007/s11367-015-0899-2

Chin J, Jiang BC, Mufidah I, Persada SF, Noer BA (2018) The investigation of consumers’ behavior intention in using green skincare products: a pro-environmental behavior model approach. Sustain (Switzerland) 10(11). https://doi.org/10.3390/su10113922

Cimino C, Negri E, Fumagalli L (2019) Review of digital twin applications in manufacturing. Comput Ind 113(103130):1–15. https://doi.org/10.1016/j.compind.2019.103130

Cosmetics Europe website (2022) Cosmetic products.

Cosmetics (2020) (soap, perfume and toilet preparations) - product category classification: UN CPC 35321 and 35323.

Curran MA (2013) Life Cycle Assessment: a review of the methodology and its application to sustainability. Curr Opin Chem Eng 2(3):273–277. https://doi.org/10.1016/j.coche.2013.02.002

Curzons AD, Jiménez-González C, Duncan AL, Constable DJC, Cunningham VL (2007) Fast life cycle assessment of synthetic chemistry (FLASC™) tool. Intern JLCA 12(4):272–280. https://doi.org/10.1065/lca2007.03.315

Educazione Digitale (2018a) Alluminio: produzione e caratteristiche

Educazione Digitale (2018b) Il ciclo virtuoso dell’alluminio

EPD and Unifarco S.p.a. (2016) Dichiarazione Ambientale di Prodotto (EPD – Environmental Product Declaration) dei prodotti cosmetici rinse-off in conformità alla ISO 14025. 0–16

EPD and Unifarco S.p.a. (2017) DICHIARAZIONE AMBIENTALE DI PRODOTTO (S-P-01257) PRODOTTI LEAVE ON Dolomia Skincare e Fragranze. 0–26

EPD and Unifarco S.p.a. (2018) DICHIARAZIONE AMBIENTALE DI PRODOTTO PRODOTTI RINSE OFF Dolomia Skincare. 0–23

Garetti M, Taisch M (2012) Sustainable manufacturing: trends and research challenges. Prod Plan Control 23(2–3):83–104. https://doi.org/10.1080/09537287.2011.591619

Gbededo MA, Liyanage K, Garza-Reyes JA (2018) Towards a life cycle sustainability analysis: a systematic review of approaches to sustainable manufacturing. J Clean Prod 184:1002–1015. https://doi.org/10.1016/j.jclepro.2018.02.310

Grosse-Sommer AP, Grünenwald TH, Paczkowski NS, van Gelder RNMR, Saling PR (2020) Applied sustainability in industry: the BASF eco-efficiency toolbox. J Clean Prod 258:120792. https://doi.org/10.1016/j.jclepro.2020.120792

Heidari MD, Mathis D, Blanchet P, Amor B (2019) Streamlined life cycle assessment of an innovative bio-based material in construction: a case study of a phase change material panel. Forests 10(2):1–16. https://doi.org/10.3390/f10020160

Ladu L, Morone PP (2021) Holistic approach in the evaluation of the sustainability of bio-based products: an integrated assessment tool. Sustain Prod Consum 28:911–924. https://doi.org/10.1016/j.spc.2021.07.006

Lozano R (2020) Analysing the use of tools, initiatives, and approaches to promote sustainability in corporations. Corp Soc Responsib Environ Manag 27(2):982–998. https://doi.org/10.1002/csr.1860

Muthu SS (2020) Estimating the overall environmental impact of textile processing: life cycle assessment of textile products. In Assessing the Environmental Impact of Textiles and the Clothing Supply Chain (Second Edition). 105–129

Negri E, Fumagalli L, Macchi M (2017) A review of the roles of digital twin in CPS-based production systems. Procedia Manuf

Neri A, Cagno E, Trianni A (2021) A triple bottom line balanced set of key performance indicators to measure the sustainability performance of industrial supply chains. Sustain Prod Consum 26:648–691

Ness B, Urbel-Piirsalu E, Anderberg S, Olsson L (2007) Categorising tools for sustainability assessment. Ecol Econ 60(3):498–508. https://doi.org/10.1016/j.ecolecon.2006.07.023

Okorie O, Obi M, Russell J, Charnley F, Salonitis K (2021) A triple bottom line examination of product cannibalisation and remanufacturing: a review and research agenda. Sustain Prod Consum 27:958–974

Pieragostini C, Mussati MC, Aguirre P (2012) On process optimization considering LCA methodology. J Environ Manage 96(1):43–54. https://doi.org/10.1016/j.jenvman.2011.10.014

Quadrini W, Galparoli S, Nucera DD, Fumagalli L, Negri E (2021) Architecture for data acquisition in research and teaching laboratories. Procedia Comput Sci 180:833–842. https://doi.org/10.1016/j.procs.2021.01.333

Renukappa S, Egbu C, Akintoye A, Suresh S (2011) Drivers for embedding sustainability initiatives within selected UK industrial sectors. INTREST 3(22)

Rocca R, Rosa P, Sassanelli C, Fumagalli L, Terzi S (2020) Integrating virtual reality and digital twin in circular economy practices: a laboratory application case. Sustain (Switzerland) 12(2286)

Rocca R, Sassanelli C, Rosa P, Sergio T (2021) Circular economy performance assessment. In New Business Models for the Reuse of Secondary Resources from WEEEs 17–33

Rocca R, Acerbi F, Fumagalli L, Taisch M (2022a) Sustainability paradigm in the cosmetics industry: State of the art. Clean W Syst 3 https://doi.org/10.1016/j.clwas.2022.100057

Rocca R, Santacruz RFB, Sassanelli C, Rosa P, Fumagalli L, Negri E (2022b) Digital twin and extended reality: strategic approach and practical implementation. In Springer Handbook of Augmented Reality 853–880. https://doi.org/10.1007/978-3-030-67822-7_341

Rocca R, Perossa D, Fumagalli L (2022c) Environmental sustainability performance assessment tools in cosmetics industry: state of the art. XXVII Summer School “Francesco Turco” – Unconventional Plants.

Romei RePlastics website (2022) Reshaping by nature

Rosa P, Sassanelli C, Urbinati A, Chiaroni D, Terzi S (2019) Assessing relations between circular economy and industry 4.0: a systematic literature review. Int J Prod Res 0(0):1–26. https://doi.org/10.1080/00207543.2019.1680896

Saad MH, Nazzal MA, Darras BM (2019) A general framework for sustainability assessment of manufacturing processes. Ecol Indic 97:211–224. https://doi.org/10.1016/j.ecolind.2018.09.062

Sassanelli C, Rosa P, Rocca R, Terzi S (2019) Circular economy performance assessment methods: a systematic literature review. J Clean Prod 229:440–453. https://doi.org/10.1016/j.jclepro.2019.05.019

Sassanelli C, Urbinati A, Rosa P, Chiaroni D, Terzi S (2020) Addressing circular economy through design for X approaches: a systematic literature review. Comput Ind 120:103245. https://doi.org/10.1016/j.compind.2020.103245

Simapro Database Manual (2020) 3–48

Tao F, Zhang H, Liu A, Nee AYC (2019) Digital twin in industry: state-of-the-art. IEEE Trans Ind Infor 15(4):2405–2415. https://doi.org/10.1109/TII.2018.2873186

Vargas-Gonzalez M, Witte F, Martz P, Gilbert L, Humbert S, Jolliet O, van Zelm R, L’Haridon J (2019) Operational life cycle impact assessment weighting factors based on planetary boundaries: applied to cosmetic products. Ecol Indic 107. https://doi.org/10.1016/j.ecolind.2019.105498

Yoh MS (2001) The reality of virtual reality. Proceedings - 7th International Conference on Virtual Systems and Multimedia, VSMM 666–674. https://doi.org/10.1109/VSMM.2001.969726

Funding

Open access funding provided by Politecnico di Milano within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Contributions

Roberto Rocca: conceptualization; methodology; formal analysis; writing—original draft; resources. Federica Acerbi: data curation; methodology; writing—original draft; investigation. Luca Fumagalli: project administration; supervision; validation; writing—review & editing. Marco Taisch: supervision; validation; writing—review & editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Communicated by Peter Rudolf Saling.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rocca, R., Acerbi, F., Fumagalli, L. et al. Development of an LCA-based tool to assess the environmental sustainability level of cosmetics products. Int J Life Cycle Assess 28, 1261–1285 (2023). https://doi.org/10.1007/s11367-023-02219-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-023-02219-0