Abstract

Purpose

Mortality and suboptimal biological performance are a widespread problem in finfish farming. The associated losses constitute an environmental opportunity cost that needs to be thoroughly assessed to prioritize actions aiming at reducing the environmental impacts of finfish aquaculture. We here propose and demonstrate the use of a new parameterized and consequential LCA model of sea-trout production designed to assess the environmental opportunity costs of suboptimal biological performances, considering distinct mortalities and biological feed conversion ratios (FCRs) along the rearing process.

Methods

Primary data was collected in Danish and Italian farms to reconstitute the whole production process for sea-reared trouts. The level of detail allowed us to divide this production into seven different growth stages for which mortality and biological FCR can be assessed and modified. Excretion and valorization of fish sludge were modeled with a calibrated mass-balance model. Together with fish sludge, dead fish was modeled as valorized by anaerobic digestion. The foreground system was linked to the consequential version of ecoinvent 3.8 for which the embedded uncertainty was considered in Monte Carlo simulations. The model was used to assess the current environmental opportunity costs and evaluate the effect of losses happening at different timings along the rearing process.

Results and discussion

Results showed a low environmental opportunity cost for the current mortality rate of 5% as suppressing this mortality decreased impacts by 3.5 to 5% across impact categories. Decreasing the biological FCR decreased the environmental impacts proportionally. The timing of the losses was shown to greatly influence the environmental opportunity cost, and the same mortality rate happening in the late stages had substantially more impact than in the first stages. The valorization of the dead fish showed a negligible contribution to the reduction of impacts in the current system but showed a substantial contribution in the case of higher mortalities, such as observed for other farms and foreseen in the future.

Conclusion

The model demonstrated that assessing an opportunity cost by multiplying the lost biomass by a unique impact factor constitutes an oversimplification neglecting the losses timing and the fact that fish biomass is not a marketable product. Even though the current environmental opportunity cost for losses appeared neglectable, suboptimal biological FCR should be tackled. The model and approach can be used to project trout farming within future disease regimes and assess the trade-offs regarding fish health issues and new treatments and practices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

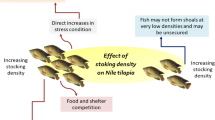

Over the last decade, worldwide fish farming has caught up with fisheries and is now responsible for half of the global fish production and expected to play a predominant role in fulfilling the increasing population nutritional demand (FAO 2020). Farmed fish is indeed a valuable source of proteins and omega-3 that can be incorporated in diets with generally lower environmental impacts compared to other types of animal products (Tilman and Clark 2014; Poore and Nemecek 2018; Philis et al. 2019). Regardless of the species and production technologies, the key asset of fish farming over land animals production is a low feed conversion ratio (FCR, calculated as feed input needed per fish output) as finfish are ectotherm animals that do not require as much energy to regulate their body temperature and do not require energy to fight gravity thanks to water support (Tlusty et al. 2018; Bohnes et al. 2019). Nevertheless, finfish farming is one of the fastest growing food sectors in the world (FAO 2020) and remains associated with environmental impacts. Three recent reviews (Bohnes and Laurent 2019; Bohnes et al. 2019; Philis et al. 2019) of the LCA literature cover more than 65 studies and offer a consistent overview of the efforts made to systematically assess the environmental impacts of the diversity of finfish farming systems. These critical reviews list better waste management, FCR improvement, and new farming practices as directions to decrease the environmental impacts. Overall, there is a consensus about the problematic lack of assessment of the fish health and biological performance-related aspects in LCA such as diseases, medicines, disinfectants, escaped and dead fish, and management of sludge among others. This gap is mainly due to difficulties to get detailed life cycle inventories (LCI) at the fish farm level which imply aggregated inventories for “monolithic” and black-box fish farms models that are hardly parameterizable. The gap also stems from the scarcity of LCI for the productions of interests such as chemicals and drugs, for which knowledge on emission and characterization factors also remain limited (Nyberg et al. 2021). Filling these gaps is even more relevant considering the general call for a “new paradigm to help solve the global aquaculture disease crisis” (Stentiford et al. 2017). Finfish aquaculture diseases are indeed plaguing the sector which is experiencing huge losses each year at a global scale. The estimates for the associated global economic losses amount to at least US$ 10 billion (Shinn et al. 2015; Just Economics 2021) per year, and China is for instance losing 15% of its production each year (Leung and Bates 2013) with similar figures for Norwegian salmon aquaculture (Bang-Jensen et al. 2019) or European finfish aquaculture in general (Shinn et al. 2015). The losses due to fish health issues can be associated either to routine mortality, disease outbreaks that can kill up to 100% of the fish, and FCR increase via stress and affections which weaken the fish without killing it (Murray and Peeler 2005; Monir et al. 2015; European Union 2018). Due to the rise of antimicrobial resistance, climate change, and the intensification of production associated with a growing demand, the health issues are considered as a major threat to the development of the finfish farming sector (Bang-Jensen et al. 2019; Peck et al. 2020).

The environmental impact and societal cost that can be associated with health issues in finfish farming have rarely been looked at. These impacts and costs are due to the losses associated to a waste of resources, the additional treatment of biological waste, the cost of treatments and biosecurity measures, and the contamination of wild stocks (Skilbrei 2012; Monir et al. 2015; Abolofia et al. 2017; Just Economics 2021). Studies and reports have recently started to address the issue using a LCA approach. Philis et al. (2021) study and compare the environmental impacts of different biological delousing treatments for salmon production and show that such treatments constitute an insignificant contribution to the overall production’s environmental impact for the considered categories (< 1%). However, the study cannot assess the treatments' efficiencies and their impacts on salmon mortality, which hinders the comparison’s equity between production with and without treatment. Cristiano et al. (2022) assess different options to valorize sludge and dead fish in a modern Norwegian smolt farm from a life cycle perspective. Besson et al. (2014, 2016) study the life cycle environmental performance gain associated with genetic improvement of the FCR and growth rate in an African catfish farm.

A recent report (Just Economics 2021) assesses the overall environmental, social, and economic cost of salmon farms in the main producing countries. In particular, the cost of lice treatment and the environmental impact of the wild stock depletion due to lice spreading from fish farms are assessed. Furthermore, the economic opportunity cost of mortality is assessed by multiplying the lost biomass by the salmon price. Following this logic, the environmental opportunity cost could be defined and calculated as the lost biomass multiplied by a single emission factor for commercial-size fish. This approach would however be oversimplified because a fish dying at the beginning of its growth period will not be fed anymore while losing the fish just before slaughtering will constitute a complete waste of the investments and the associated impacts. These discrepancies could become particularly influent on the assessment for finfish species grown in systems where the FCR and inputs/outputs vary over the different growth stages, such as for anadromous finfishes (e.g., salmonids). Furthermore, multiplying the total lost biomass by the average impact to produce 1 kg of fish boils down to considering an indistinct “fish biomass” as a marketable product. Instead, a LCA must consider the demand for fish of a commercial size, and not for “fish biomass” in general which does not fulfill the obligatory properties on the market (Weidema 2003). This difference of perspective could considerably change the estimated opportunity cost. Modeling the distinct consequences of events happening at different growth stages and the responses of the production program has already been done for environmental or economic assessment (Bala and Satter 1989; Château and Chang 2010; Abolofia et al. 2017; Ferreira et al. 2021), but never adapted to LCA to our knowledge. Assessing the environmental opportunity cost of losses and being able to predict the environmental impacts of a farming system under different biological performances thus require a new disaggregated and detailed LCA allowing modification of this performance at different stages in the production cycle. In particular, the model should be able to modulate separately the two main components of biological performance, namely the mortality rate and the biological FCR, i.e., the ratio of feed input over the sum of dead and live fish productions, which differs from the economic FCR (feed/live fish).

To move further away from an opportunity cost estimate which does not consider market mechanisms and attribute an impact to losses in the past, consequential LCA constitutes a relevant approach to assess consequences of poor biological performances and take decisions accordingly. Only one consequential LCA of trout production has been published so far (Samuel-Fitwi et al. 2013), and the finfish aquaculture LCAs remain dominated by attributional approaches.

To address these needs, we present a parameterized and consequential LCA model for sea-trout production, with new primary data, which allows modeling of biological FCR and mortality rate changes at six different points along the rearing process. We use the model to assess the environmental opportunity cost of the current biological performance, i.e., of the mortality and of the suboptimal biological FCR. We also test the influence of different mortality timings on the environmental consequences of an increase in demand for Danish sea trout by assessing the sensitivity of the model to these timings. In addition to varying the biological performance in the foreground, we considered the uncertainty in the background and regarding our modeling of the valorization of losses and sludge via anaerobic digestion, which could influence the estimated costs and the sensitivity to the timings of the losses. Our study also presents the impacts and the contribution analysis of the system under its current biological performance.

In challenging times of change for the fish farming sector, this work aims at refining our understanding of the health-related issues in fish farming by increasing the detail and accuracy of LCA modeling and discussing the notion of environmental opportunity cost in LCA.

2 Methods

2.1 Fish farms under study and division of cultivation stages

The functional unit is defined as an increase in demand for 1-kg live weight of sea-reared rainbow trout (Oncorhynchus mykiss) at commercial weight which is 2.4 kg on average (noted as 2.4 lw. trout for simplicity). To get a satisfying level of division between the life stages, we reconstituted the whole production process by combining primary data from Italy from indoor hatchery to 0.08 lw. trout (“hatchery,” “fry/fingerling,” “On-growing 1, 2, 3” in Fig. 1) and from Denmark for life stages from 0.08 lw. trout to the final sea-reared trout (“On-growing DK,” “Seafarm 1,” “Seafarm 2” in Fig. 1). Overall, this means that the very beginning of the fish growth is covered by the Italian data, and the produced young fish is an input to the first Danish stage for the rest of the fish growth. The Italian farm is in the north of Tuscany in the west Apennine drainage and, with the exception of the hatchery, does not use electricity as the water flows and is oxygenated by gravity. The primary data provided for this farm represent average production figures over 2018, 2019, and 2020, for a total production of 100 tons per year.

Foreground product system. A colored number under a growth stage division (upper panel) indicates an input of the associated process in the lower panel. Growth stages with the same name and different numbers (e.g., On-growing 1, 2, 3) constitute virtual divisions of a same physical cultivation stage. lw., live weight; DK, Denmark

The Danish on-growing stage (“On-growing DK” in Fig. 1) from 0.08 to 1 lw. trout is an outdoor semi-recirculating farm for which the business model imposes the overlap and commercialization of three sizes of trout during the same year. It produces 1 lw. trout as the main product that are sent to sea cages where they keep growing to the commercial weight (2.4 lw. trout) that are then sold for consumption, and smaller 0.3 lw. trout that are sold to other fish farms. It also co-produces larger trouts directly sold for consumption which are therefore functionally equivalent to the sea-reared 2.4 lw. trout. The primary data for this cultivation stage cover two years of production (2019, 2020) in a farm which produces 400 tons total live weight per year. Finally, the 1 lw. trout are reared in Danish sea cages for 7–8 months up to reaching their commercialization weight (FU). Roe constitutes 11% of the produced biomass but was included as part of the FU (1 kg of 2.4 lw. trout with 11% of roe mass). Data on sea cages were collected for seven Danish farms over 2019 and 2020 for a total production of 2500 tons per year. According to the production type clusters proposed by Philis et al. (2019), the reconstituted production process can classify as “land-based intensive flow-through” until the weight of 1 kg is reached and as “open sea-based rearing” until the commercialization weight is reached. The overall mortality rate calculated as the ratio of dead biomass over the total biomass bioproduction of sea-reared trout amounted to 5% (cf. Table 2), which is in the same order of magnitude as the average value reported for the whole Danish sector (6.4% for 2021 across all types of trout farming systems according to Danmarks Statistik (2021)). The sludge is filtered out and collected in all land-based stages and the dead fish in all stages.

To improve the granularity of the parametrization and model the current mortality as close as possible to reality, we further subdivided these “physical” cultivation stages in eight “virtual” fish growth stages based on direct information from the producers about mortality rates along the rearing process (cf. Fig. 1). These subdivisions are implemented such as the losses are happening at the very end of each virtual stage. The biological FCR of each physical cultivation stage was used to interpolate the feed inputs of the virtual growth stages. The other inputs and outputs to the virtual growth stages (electricity, oxygen, fuel, chemicals) were calculated proportionally to the feed inputs (cf. OR II.2). This implies that for each growth stage, we assumed that fish deaths occur after consuming all the feed and excreting all the residues. Thus, the mass balances between inputs and outputs are respected. Virtual growth stages are henceforth simply referred to as “growth stages.”

2.2 LCA framework and product system

2.2.1 System boundaries, consequential modeling, and stochastic LCA

We performed a consequential LCA using ecoinvent 3.8 consequential as the background database. We therefore studied the consequences of an increase in demand for 1 kg of 2.4 lw. sea-reared trout and considered marginal mixes and technologies as responding to this increase in demand. The marginal Danish electricity mix was modeled at the fish farm level.

The LCA is stochastic, and we performed Monte Carlo simulations considering the background uncertainty of ecoinvent and the uncertainty of the anaerobic digestion process in the foreground (cf. Sect. 2.5).

The scope of the system excludes slaughtering, considered neglectable in terms of environmental impacts, and starts with the eggs hatching without considering any burden for the egg production. The sludge and losses are valorized via anaerobic digestion, and the substitution of natural gas on the Danish market is modeled.

We modeled the substitutions of corresponding growth stages for the co-produced 0.3 lw. and 2.4 lw. trout in the growth stage “On-growing DK” (cf. Fig. 1). Thus, the model accounts for the business model of this farm, and the mass balances are respected. Conceptually, the substituted 0.3 lw. trout production comes from another farm which shares the same first growth stage division as the main production line, but the division from 80 to 300 g (“On-growing 2”) was modeled with the Italian data only. For further reference, we name this substituted production “parallel production line” (cf. Fig. 1). The 2.4 lw. trouts substitute the functionally equivalent sea-reared trouts.

2.2.2 Life cycle inventory and product system

The complete life cycle inventories of the different growth stages and of the overall production are presented in Online Resource II.1. The collected data for the production’s economic inputs covers feed, oxygen, fuel for boats and on-site trucks and machineries, chemotherapeutants, electricity, and treatments of dead fish sludge. No transport of the fish to consumer was modeled, neither between the land-based stages, because they were assumed close to each other. Table 1 shows the feed and fish inputs and outputs of the different growth stages, and Table 2 displays the associated FCRs and mortality rates. The product system is shown in Fig. 1.

Even though chemical and medicine inputs were provided, no inventories for the medicines exist in ecoinvent 3.8, and the few therapeutic inventories available in the literature (Jiménez-González et al. 2004; De Soete et al. 2017; Emara et al. 2019; Parvatker et al. 2019) do not cover the ones used in the trout production. This literature instead highlights that the use of other medicines as proxies can constitute a major source of error as chemically similar molecules can be associated with very different production routes (Parvatker et al. 2019). On the grounds of this, the inputs are not included in the inventory and impact calculations, but the input amounts are presented in the life cycle inventory table in Online Resource II.1 for completeness.

The peracetic acid production was modeled based on the inventory provided by Echeverria et al. (2021). As no inventory was available for the quaternary ammonium salt (biocide) production, we used benzyl chloride, one of its chemical precursors (Rossberg et al. 2006). Similarly, copper pyrithione was modeled as pyridine production and chloramine inventory was not considered. No direct emissions were modeled for the chemotherapeutants used in the farm due to the absence of the characterization factor for the substance and/or uncertainty regarding the fate of the substance through the farm and its biological processes such as biofilters, solid filters, and lagoons (Emara et al. 2019).

The feed composition was provided by the producers and is given in Table 3. The feed contains 50% of plant-based ingredients, which is similar to the composition recently used by Sanchez-Matos et al. (2022) and significantly more than in the organic composition used by Samuel-Fitwi et al. (2013) (77% fish-based). The same heat and electricity inputs to the feed production as the ones used by Samuel-Fitwi et al. (2013) were considered. To model consequences of an increase in demand, we connected the poultry meal and hemoglobin meals to the marginal markets for feed and energy as modeled by Schmidt and De Rosa (2020) because these inputs are dependent coproducts. Indeed, following the logic of consequential modeling, no increase in hemoglobin meal production will be induced by an increase in production for it, and the eventual consequence will be an additional demand for their equivalent in megajoules from the marginal producer of energy feed (maize and wheat) and in kilograms of protein on the protein feed market (soybean meal). The corresponding amounts of energy and protein are calculated in Table S1 in Online Resource I.6. Note that in the ecoinvent consequential database, fish oil and rapeseed oil which are part of the modeled fish feed are also eventually connected to these marginal feed markets in their product systems. The ecoinvent processes connected to the foreground system are shown in Online Resource II.3. Only direct land use changes are considered in the ecoinvent processes.

2.2.3 Impact assessment

We assessed 10 impact categories with 9 impact assessment methods from ReCiPe (H) (Huijbregts et al. 2017), namely global warming with 100-year time horizon (GW100), terrestrial acidification (TA100), terrestrial, human, freshwater ecotoxicity (TETinf, HTinf, FETinf), particulate matter emissions (PM), ozone depletion (ODinf), and eutrophication, both for freshwater and marine ecosystems (FE, ME). For the latter category, which is particularly relevant for aquaculture systems, ReCiPe proposes a freshwater eutrophication method (FE), which only considers phosphorus emissions, and marine eutrophication (ME) method which only accounts for nitrogen emissions. This distinction is based on the hypothesis that only one element is limiting in each ecosystem type (Elser et al. 2007; Cosme and Hauschild 2016, 2017). As these distinctions are not commonly made in other LCAs of fish farms, we also used the generic eutrophication (Eutro.) potential from CML-IA to allow a comparison to other LCAs’ results.

2.3 Joint modeling of mortality, biological feed conversion ratio, and excretion

Parameterized mortality, biological FCR, and excretion are modeled conjointly to ensure input and output mass balances. It is important to note that mortality and biological FCR can be modified independently as the biological FCR measures the overall conversion of feed into biomass, dead or live. The economic FCR instead, usually reported as “FCR” in other studies, is defined as the ratio of feed/live fish and is affected by different mortality rates. To ensure consistent modeling of the nutrient and mass balance while using the model from Papatryphon et al. (2005), we considered a fixed phosphorus (P) and nitrogen (N) content in the fish of 0.00415 kg P and 0.022 kg N per kg live weight fish (wet), as they represented average reported values in the literature (Shearer 1984; Skonberg et al. 1997; Bureau and Cho 1999; Bücker et al. 2020). Based on the same studies, magnesium (Mg) and potassium (K) fish composition were respectively fixed at 0.38 and 4.6 g kg live weight fish−1 and used to estimate the substitutions associated with the valorization of dead fish (cf. Sect. 2.5). The feed P and N contents were calculated based on the content of each ingredient (cf. Table 3). Details about fish and feed composition are presented in Online Resource I.6.

Modulating the biological FCR necessarily implies a modification of the N and P excretion to close the mass balances because the N and P contents in feed and fish and the feed digestibility are modeled as constant. The theoretical minimum biological FCR for each growth stage can therefore be calculated as the one which sets the liquid P excretion to zero, as we found P to be the limiting nutrient before N in the mass balances. The P excreted in the feces remains the same as its digestibility in the feed remains constant. Thus, for this minimal theoretical biological FCR, all digested P is assumed as perfectly metabolized and incorporated in the fish biomass. Note that this minimal biological FCR constitutes a necessary mathematical limit and theoretical performance optimum for the modeling purposes but is biologically unachievable. Finding this theoretical limit allows using the model within the theoretical boundaries. The analyst can thus modify the FCR by choosing the value of an improvement parameter which fixes the biological FCR to its minimum value when set to 1 and keeps the current FCR when set to 0 (cf. Online Resource I.1). Once the biological FCR is changed for a growth stage, the new fish biomass outputs are calculated accordingly, and the new excretion is calculated by closing mass balances as previously explained.

The production of solid feces is calculated as the non-digestible part of proteins, carbohydrates, and lipids in feed, shown in Online Resource I.6 and based on Aubin et al. (2011). Together with the non-ingested fraction of feed (0–0.05), a constant proportion of the solid feces is captured by solid filters and exported as sludge. In addition, a plant lagoon removes part of the N and P emissions before the water is returned to the river. The constant fraction of feces captured by the filter and the lagoon removal rate were calibrated by comparing the mass-balance model’s output and the monitored outlet concentration in the “On-growing DK” stage (cf. Fig. 1).

Changes in mortality are modeled via two distinct parameters: loss level and loss reduction. Loss level (values from 0 to 1) is the fraction of the live production which dies in addition to the current mortality, while loss reduction is the fraction of losses that is avoided. In the model, any loss level combined with a loss reduction of 1 would lead to zero losses for the growth stage. The loss level parameter allows modeling a mortality due for example to a disease affecting the fish farm, while the loss reduction parameter allows simulating the effect of a new treatment or practice that increases the survival of the fish.

All losses were considered as dead fish that can be collected (cf. Sect. 2.5), and no escapees, cannibalism, or bird predation was considered. For the growth stage division “On-growing DK” which produces three different sizes of trout, the losses and FCR modification are applied proportionally to the mass ratios of the three different flows.

As observed and modeled by Besson et al. (2016), the effect of FCR reduction on the life cycle inventory of a fish farm differs depending on what the current limiting factor is. If the limiting factor is the fish density in the tanks, improving the FCR allows only to reduce the amount of feed needed per kilogram of fish but does not reduce the needed amount of other production inputs. However, if the limiting factor is the nutrient discharge in the environment, a FCR improvement allows to obtain the same production while reducing all other inputs. Based on the Danish regulation limiting nutrient discharge for fish farms (Jokumsen and Svendsen 2010), the model assumes no current limit on the fish density, and all inputs per kilogram of fish proportionally decrease when the FCR is improved.

The equations and parameters used to modify FCR, mortality, and excretion in the different growth stages are presented in detail in Online Resource I.1 and I.2. The whole model and associated code are available on GitHub (Jouannais 2023).

2.4 Valorization of losses and sludge

Modeling the environmental effects of different fish farm biological performances required to consider the “valorization” of losses and sludge. The dead fish in the Danish farms considered in this study are currently collected and used as substrate for anaerobic digestion, and thus generating biogas and recycling nutrients for field fertilization. This method can be expected to keep developing further as it constitutes an efficient valorization of nutrient and energy while neutralizing biohazard due to infected fish (Estevez et al. 2022). We modeled anaerobic digestion of fish sludge and dead fish by considering a fixed input of electricity and heat per kilogram of dry substrate calculated from the techno-economic assessment by Kratky and Zamazal (2020). This inventory covers the pretreatment of the substrate (hygienization and crushing), homogenization, and fermentation at 28 °C. Biotechnological research is still carried on to improve and stabilize the process and yields, and operating conditions of fish waste anaerobic digestion vary substantially across studies (Chen et al. 2010; Ivanovs et al. 2018; Bücker et al. 2020). Based on seven yields reported in these studies and displayed in OR I.3.1, we modeled the uncertainty and variability of the methane yields obtained from this fermentation of dead fish with a triangular distribution ranging from 380 to 920, with a mode of 550 ml CH4 . g dry dead fish−1. While dead fish was modeled as a mono-substrate, the anaerobic digestion of fish sludge usually requires mixing it with another substrate to lower the N and P concentrations, avoiding NH3 accumulation during the process and suiting the microbial communities. A volume ratio sludge/cow manure varying between 0.30 and 0.40 was modeled (Brod et al. 2017), and the associated CH4 yield varying between 300 and 400 ml CH4 . g dry substrate−1 was assumed (Estevez et al. 2022). CO2 is also produced by the fermentation, and we assumed a fixed volume ratio CO2/CH4 of 0.465 (Bücker et al. 2020) for both fish and sludge. This CO2, together with other gases present in minor fractions, is degassed during the upgrade of this biogas to biomethane that we modeled with amino washing. The resulting biomethane substitutes heat based on its lower heating value.

The solid and liquid fractions of the fermentation’s digestate contain the amounts of N, P, K, and Mg calculated with the mass-balance model (cf. Sect. 2.4). Both fractions can be used for fertilization but the liquid; mineralized fraction presents the highest bioavailability for plants. Based on laboratory and field experiments on the mineralization rates and comparing agronomic efficiencies of different digestates, substrates, and industrial fertilizer reported by Brod et al. (2017) and Goddek et al. (2018), we modeled uncertain substitution coefficients with industrial fertilizers with uniform distributions for N ranging 0.8 to 1, and from 0.2 to 0.8 for P, K, and Mg. By definition, an agronomic efficiency of 1 implies a substitution coefficient of 1. As fish sludge digestion requires an input of manure that would have been otherwise spread over fields without digestion, we modeled the overall fertilizer substitution resulting from the combination of manure with the fish sludge according to the differences in agronomic efficiencies between non-digested and digested manure reported by Brod et al. (2017). We refer the reader to Online Resource I.3 for the parameters and equation describing these substitutions.

2.5 Simulations and evaluation of the environmental opportunity costs

To demonstrate the use of the model and study the effects of different biological performances along the production cycle, we first estimated the current environmental opportunity cost of mortality and suboptimal FCR by calculating the impacts for the current system with the reported biological performance and when the system is pushed to its theoretical limits. We first estimate the environmental opportunity cost of mortality alone by simulating no mortality at all and calculating the difference of impact between this configuration and the current system. We then set the biological FCRs in all stages to their theoretical minimum values to estimate the environmental opportunity cost of the biological FCR. Finally, we assume no mortality and minimum theoretical FCRs to estimate the opportunity cost of the overall biological performance. All configurations share the same 1000 Monte Carlo iterations regarding the background and the anaerobic digestion parameters (paired sampling).

To study the distinct effect of losses occurring at different timings along the production cycle, we performed a series of six local sensitivity analysis by increasing the loss level by 15% in each of the growth stages separately. For example, the first sensitivity analysis considers 15% loss level in the hatchery while the rest remains unchanged. We assess the change of the impacts for the functional unit in each of these six configurations.

For all configurations used to estimate the opportunity costs or in the sensitivity analysis, the modifications regard only the main production line while the substituted parallel line remains unchanged (cf. Fig. 1).

3 Results

3.1 Current environmental impacts

The boxplot on the left part of Fig. 2 shows the results of the stochastic LCA for the current system’s biological performance. The global warming impact (GW100) of the current system had a median score of 4 kg CO2-eq. per kg live trout with a first and third quartile at 3.5 and 4.5 kg CO2-eq. The median terrestrial acidification (TA) obtained a median score of 0.014 kg SO2-eq. As expected, the eutrophication impacts vary considerably depending on the choice of the LCIA method because different methods consider fundamentally different impact pathways. The generic eutrophication freshwater and marine water eutrophication impacts had median scores of respectively 0.055 kg PO4-eq., 0.008 kg P-eq., and 0.07 kg N-eq. ODinf and PM respectively showed median scores of 1.5E-7 kg CFC-11-eq. and 0.006 kg PM10-eq. Regarding toxicity, HTinf and TETinf respectively scored at 0.9 and 0.025 kg 1.4-DC-eq. while FETinf showed a median score of 0.8 kg 1.4-DC-eq. with a substantially lower dispersion of the results than for the other toxicity categories. The contribution analysis is available in OR I.4 and shows that the feed production was responsible for most of the impact for GW100 (95%), PMF (85%), TA100 (75%), TETinf (99%), FD (88%), ODinf (80%), and PMF (77%), while the direct emissions of N and P were the main contributors for FETinf and the three eutrophication categories. For HTinf, the electricity consumption was mainly responsible for the impact (120%) while the substitutions occurring in the product system of the feed reduced the impact by 20%.

Boxplots for the environmental impacts associated with an increase in demand for 1 kg of 2.4 lw. trout. The box limits represent the 1st and the 3rd quartile of the scores from the stochastic simulations. The edges of the vertical lines correspond to the minimums and maximums. Current, unmodified primary data

3.2 Current environmental opportunity cost

The suppression of mortality (II in Fig. 2), currently distributed along the different growth stages (cf. Fig. 2), brings the economic FCR from 1.3 to 1.24. For the considered impact categories, the existing 5% mortality rate seems to be associated with a moderate environmental opportunity cost. When assuming no mortality (II in Fig. 2), the median impact scores are reduced for all impact categories, although to a different degree: from a minimum of 3.2% (ME, OD) to a maximum of 5.2% (HTinf) (cf. Fig. 2). This observation on the median scores remains valid for all paired stochastic iterations across scenarios as shown in Fig. S5 of Online Resource I.5. The losses have thus little weight on the environmental impact because they are generally low and because they are distributed along the growth stages and do not all concentrate at the very end of the life cycle (cf. Sect. 3.2). The valorization of the dead fish has a small contribution to the total impact (cf. Online Resource I.4), but additional simulations with higher mortality rates show that it can reduce impacts when assuming very low biological performances. For example, a reduction of 5% in GW impact was calculated when assuming a 95% loss level in fry/fingerling rearing to demonstrate the behavior of the model under extreme assumptions (cf. Online Resource I.4.1).

On the other hand, the opportunity cost of a suboptimal biological FCR in every growth stage is substantial (III, IV in Fig. 2). Simulating the same mortality rate with a theoretical minimum biological FCR for all growth stages (III in Fig. 2) reduced all median impact scores by at least 30% with a maximum 42% reduction for FETinf (cf. Fig. 2 and Online Resource II.4). These reduction percentages show an absolute theoretical limit of what can be expected in terms of impact reduction for any attempt to improve the biological performance. When simulating the theoretical minimum FCR (III, IV in Fig. 2), the economic and biological FCRs decrease by 30% to reach the value of 0.9, which thus constitute the minimum theoretical FCRs for the whole production. Similar FCR values can be measured in very performant closed systems for salmonids (Samuel-Fitwi et al. 2013; Philis et al. 2019). As also reported by Papatryphon et al. (2004) and d’Orbcastel et al. (2009), all environmental impacts decrease in similar proportions together with the economic FCR. This observation holds for simulated changes of the FCR within the same production system and does not hold anymore across systems as Philis et al. (2019) report no correlation between FCR and impacts within the diversity of farming systems.

3.3 Sensitivity of losses in different growth stages

Figure 3 shows for three impact categories that the effects of 15% loss level (in addition to the current mortality rates) are hardly noticeable if losses happen before the trout’s weight reaches 80 g (end of “On-growing 1”). The trends are similar for the other impact categories shown in OR I.5 and II.4. As expected, the later are deaths occurring in the production cycle, the higher is their negative influence on the environmental impact of the farm. Losses occurring in the last growth stage increase the environmental impact by 15–16% for all impact categories except for global warming, ozone depletion, and human toxicity for which the impact increased by less than 13%. It is worth noting that a 15% loss level in the last stage constitutes a 85% production efficiency compared to the baseline for the activity delivering the functional unit. The expected impact increase would therefore theoretically be 17.6% (1/0.85). The fact that the impact increase is lower than this expected value is due to the valorization of losses which compensates for the efficiency loss (cf. Online Resource I.4.1). The magnitude of this compensation varies across impact categories. These results illustrate how the environmental impact due to the mortality rate depends on the growth stage that is affected by losses—and confirm that the model functions as intended.

Boxplots for the environmental impacts associated with an increase in demand for 1 kg of 2.4 lw. trout for different timings of 15% loss level. The left panel shows the impact score expressed in the corresponding impact category unit. The box limits represent the 1st and the 3rd quartiles of the scores from the stochastic simulations. The right panel shows the percentage of median increase by setting the current median score as a baseline (0). The results for the other impact categories are presented in Online Resource I.5 and II.4. Legend of the horizontal axis: Current, unmodified primary data; Mort. Growth stage X, scenario with modified mortality in the growth stage X

4 Discussion

4.1 Comparison of the current system’s impacts to the literature

Overall, the results show impacts similar to those reported in the review of 24 salmonid farm LCAs by Philis et al. (2019), even though a relevant comparison must consider the modeling choices, mainly attributional versus consequential modeling. In particular, the found median impact score of 4 kg CO2-eq. kg trout−1 for global warming (GW) is higher than the average value of 3 kg CO2-eq. kg trout−1 reported for open sea-based system of salmonids in the review. The median terrestrial acidification (TA) score of 0.014 kg SO2-eq. kg trout−1 is also the average value reported by the same authors for similar systems. Similarly, the median generic eutrophication impact (Eutro) of 0.055 kg PO4-eq. kg trout−1 corresponds to the average value across the studies reviewed by Philis et al. (2019) for open sea-based salmonid farms. The recent LCA of land-based rainbow trout production in Spain by Sanchez-Matos et al. (2022) reports a ReCiPe freshwater (FE) impact of 0.007 kg P-eq. kg trout−1, which is very close to the median value of 0.008 kg P-eq. kg trout−1 that we obtained for the same impact assessment method.

4.2 Feed contribution and influence of modeling choices

The feed major contribution to the impact is also documented in LCA studies of trout open sea-based systems, in opposition to fully recirculating aquaculture system RAS where electricity consumption usually dominates the contribution analysis (Samuel-Fitwi et al. 2013; Philis et al. 2019). It is worth noting that the fish feed modeling could benefit from more specific databases for agricultural products such as Agribalyse or Agrifoot-print, as used by Sanchez-Matos et al. (2022) for a similar trout production system, although consequential modeling should be kept consistent. However, our conclusions on the environmental opportunity costs and the importance of the timing of the losses would likely remain the same with these different modeling choices as Sanchez-Matos et al. (2022) also found a very important contribution of the feed to most impact categories (from 50 to 90% of the selected impact categories, besides eutrophication occurring on site).

The high contribution of the feed to the impacts also suggests that the demonstrated model behavior can be generalized to a good extent to a model in which the production limiting factor would be fish density instead of nutrient discharge. As explained in Sect. 2.4, this would mean that an improved FCR would only reduce the feed input per fish output, while the inputs which are not proportional to the feed consumption would remain the same. This would therefore not change the results substantially for the impact categories where feed dominates. However, our assessment did not account for infrastructures that could constitute a non-neglectable (> 5%) contribution to some impact categories, as found in the rare studies which consider capital goods (Bohnes et al. 2019). In this case, and assuming fish density as the limiting factor, the influence of an improved biological FCR would decrease while the influence of mortality, which increases all the necessary amounts of inputs per functional unit, would remain the same.

Overall, estimating direct N and P emissions using a mass balance model is very sensitive to the assumptions made regarding the N and P compositions of the feed and the trout. Values ranging from 0.03 (Asmala and Saikku 2010) to 0.07 (Darzi 2021) kg P per kg fish produced are reported in the literature, for different fish species and conditions. As most LCAs rely on mass-balance models to estimate N and P emissions, a systematic reporting of the fish N and P contents considered the model would facilitate comparisons and potentially reduce the range of eutrophication results observed in the literature (Philis et al. 2019). Additionally, there is uncertainty and variability regarding the response of the filters when the biological FCR is modified. Instead of modeling a constant proportion of the excretion being filtered out, a fixed filtering capacity could be modeled which would possibly change the influence of FCR modification on the eutrophication impacts for the land-based parts.

4.3 Average opportunity cost versus opportunity cost in LCA

The results illustrate that changes in mortality rates are not directly proportional to changes in environmental impact. There are fundamental differences between assessing an environmental opportunity cost by multiplying losses by the impact associated to 1 kg of fish or by using a consequential LCA model. Indeed, when neglecting the FCR variation across the growth stages divisions (cf. Table 2), that is both due to inherent fish metabolic differences (Wurts 2016) and to different rearing systems (Philis et al. 2019), and when assuming that all growth stages need the same inputs, then 1 kg of fish biomass virtually represents the same investment of feed regardless of the size and weight of the dead individuals. However, these assumptions constitute serious oversimplifications and describe fish production as a monolithic process instead of a succession of different stages with unique characteristics (e.g., land-based or sea-based, using or not a specific chemical).

Furthermore, calculating the opportunity cost with such a simplified model would return a virtual cost for the losses that happened, while estimating it with consequential LCA means estimating first the impact of an increase in demand for a farm subjected to a certain biological performance and the impact of the same production from a farm with the better performance. The opportunity cost will then be the difference between the two impacts. The two approaches are fundamentally different in their framing as the simplified one does not aim at embracing consequences considering market mechanisms as it attributes a cost to an undifferentiated biomass, which is not a product in the LCA framework. In the present study, the market demand does not exist for fish biomass but only for 2.4 lw. sea-reared trout. This demand triggers chained demands for the different growth stages functioning as distinct processes with specific products, i.e., trouts of different sizes.

Due to these differences, the model should not be used to estimate the opportunity cost of a catastrophic viral outbreak (e.g., 80% of fish lost in the sea stage) as this would instead estimate the difference of impacts between a baseline and a farm that consistently produces trout with 80% mortality as a response to an increase in demand. The model is thus built to simulate the production under durable disease regimes as the ones associated with climate and ecosystem changes (Leung and Bates 2013; Reverter et al. 2020).

4.4 Towards full appraisal of the impacts of fish health issues

Despite the relatively low existing opportunity cost for the fish farms considered in this study, we believe that addressing mortality should not be considered a secondary effort, and this cost could be higher in other fish production systems. Indeed, the reported value of 5% of losses used in this study is substantially lower than the value of 15% losses reported for Norwegian salmonid production (Bang-Jensen et al. 2019). Differences in the estimate methodology may be involved in the discrepancies, but overall 5% seems to correspond to a lower boundary for current losses in European finfish aquaculture (Just Economics 2021). Fifteen percent of losses are also reported for Brazilian fish farms (Tavares-Dias and Martins 2017). Parasitic diseases and the resulting higher biological FCR were found responsible for 80% of the economic loss associated to health issues in Bangladesh carp farms (Monir et al. 2015). The same modeling approach could be used to estimate the environmental opportunity costs for these other cases.

It could be legitimately argued that fish welfare and suffering of animals under human’s responsibility should be reduced at all costs and regardless of the associated environmental impact (Huntingford et al. 2006), which would make a thorough LCA on this topic pointless. This argument is not compelling, firstly because LCA does not necessarily aim at optimizing a process but can be used instead to help forecasting the environmental impacts of finfish aquaculture in the future and planning accordingly, and secondly, because fish welfare is also part of broader trade-offs. Reducing losses with new practices may lead to new impacts, and the systemic approach of LCA aims at embracing this complexity, which is acknowledged by fish health experts themselves. The “Environmental impact of treatments in fish aquaculture” was ranked first among several topics regarding new treatments in a survey by Katharios et al. (2019) in which 124 fish health experts and stakeholders were asked to rank different potential research directions by order of importance.

The model here presented is designed to capture the opportunity cost of poor biological performances. It must be noted that this cost is only one part of the environmental trade-offs associated with health management in fish farms, and improving biological performance will likely involve the environmental impacts of new treatments and practices. These impacts remain scarcely included in LCA studies, but the recent use of ecotoxicity and antibioresistance characterization factors for different antibiotics (Nyberg et al. 2021) in a trout production LCA by Sanchez-Matos et al. (2022) is promising. They also use proxies for the production life cycle inventories of antibiotics despite the associated risk of error (cf. Sect. 2.3) which hinders a precise assessment of the trade-offs. Overall, the efforts made to better embrace the direct emissions and details of health management at the fish farm level could be overshadowed by the uncertainty in the inventory. We therefore join Bohnes and Laurent (2019) and Philis et al. (2019) in advocating for a systematic assessment of uncertainties in the next LCAs for finfish aquaculture.

5 Conclusion

This study has shown that the current losses and their timing along the studied trout production constitute a minor environmental opportunity cost, while bringing the biological FCR closer to its minimal value would substantially decrease the environmental impact. The model is ready to be combined with inventories regarding the solutions undertaken to improve the biological performance.

Concluding, this work sheds light on one aspect of the trade-offs that exist in health management in fish farming and can be used to estimate the environmental consequences of new treatments and farming practices, or project aquaculture into futures with different disease regimes, i.e., disease frequency and severity. These trade-offs are unavoidable when adopting a “One-Health” perspective (Stentiford et al. 2020), which embraces human, non-human, and ecosystemic health as a whole and therefore requires a systemic environmental assessment for the management of biological performances in finfish aquaculture. Future research efforts to assess these trade-offs should focus on refining inventories and characterization factors for chemotherapeutants.

The availability of detailed primary data allowed us to estimate the environmental impacts associated with distinct timings for biological performance changes, but a complete understanding of the environmental consequences of disease regimes will require the combination of LCA with other modeling approaches such as epidemiology and agent-based modeling. Indeed, disease regimes do not tackle individual farms, and thus reducing the biological performance of single production lines all other things being equal. A poor biological performance due to diseases in a farm is likely to propagate to other farms, eventually multiplying the environmental costs by spreading it to a whole sector (Jonkers et al. 2010; Peeler and Taylor 2011; Oidtmann et al. 2014; Ferreira et al. 2021), or even to humans (Ziarati et al. 2022). Sudden viral outbreaks such as infectious hematopoietic necrosis (IHN) on salmonids require the destruction of all the fish and temporary shutdowns of the farms (Bang-Jensen et al. 2019), which hinder the capacity for a production to answer to increases in demand. This is a problem for the economic performance of finfish farms and their capacity to ensure food supply first of all, and secondarily also for those working with modeling the impact of finfish farming, particularly when this requires the identification of marginal productions (Weidema et al. 1999) able to respond to such increases in demands. To fully appraise the consequences of poor biological performances in finfish farming, the scope of LCA studies should therefore be extended to consider the production of whole sectors, such as in our case, the entire European trout production, considering a network of distinct growth stages connected by epidemiology and market relationships (cf. Fig. 1 and “parallel production line”). While increasing the models’ complexity, this would allow a better systemic understanding of the finfish health issues’ environmental consequences to facilitate the prioritization of efforts to tackle them and secure a sustainable food supply.

Data availability

All data for the reproducibility of the results can be found in the article and in the additional online resources and the GitHub repository. “Online Resource I” (docx): Main equations of the model, additional figures, feed and fish specificities. “Online Resource II” (xlsx): Sheet "OR II.1": Life Cycle Inventories, technosphere matrix. Sheet "OR II.2": Interpolation of the growth stages according to the timing of the losses. Sheet "OR II.3": Correspondence between foreground activities and background activities. Sheet "OR II.4": Numerical results associated with Figs. 3 et 4. Sheet "OR II.5": Table of the model’s parameters. The code of the model allowing reproduction of the results is available at https://github.com/PJGilmw/Fish_performance_LCA (Jouannais 2023).

References

Abolofia J, Wilen JE, Asche F (2017) The cost of lice: quantifying the impacts of parasitic sea lice on farmed salmon. Mar Resour Econ 32:329–349. https://doi.org/10.1086/691981

Asmala E, Saikku L (2010) Closing a loop: substance flow analysis of nitrogen and phosphorus in the rainbow trout production and domestic consumption system in Finland. Ambio 39:126–135. https://doi.org/10.1007/s13280-010-0024-5

Aubin J, Tocqueville A, Kaushik SJ (2011) Characterisation of waste output from flow-through trout farms in France: comparison of nutrient mass-balance modelling and hydrological methods. Aquat Living Resour 24:63–70. https://doi.org/10.1051/alr/2011008

Bala BK, Satter MA (1989) System dynamics simulation and optimization of aquacultural systems. Aquac Eng 8:381–391. https://doi.org/10.1016/0144-8609(89)90032-0

Bang-Jensen B, Gu J, Sindre H (2019) The health situation in norwegian aquaculture. Veterinaerinstituttet 37–41

Besson M, Aubin J, Komen H et al (2016) Environmental impacts of genetic improvement of growth rate and feed conversion ratio in fish farming under rearing density and nitrogen output limitations. J Clean Prod 116:100–109. https://doi.org/10.1016/j.jclepro.2015.12.084

Besson M, Komen H, Aubin J et al (2014) Economic values of growth and feed efficiency for fish farming in recirculating aquaculture system with density and nitrogen output limitations: a case study with African catfish (Clarias gariepinus). J Anim Sci 92:5394–5405. https://doi.org/10.2527/jas.2014-8266

Bohnes FA, Hauschild MZ, Schlundt J, Laurent A (2019) Life cycle assessments of aquaculture systems: a critical review of reported findings with recommendations for policy and system development. Rev Aquac 11:1061–1079. https://doi.org/10.1111/raq.12280

Bohnes FA, Laurent A (2019) LCA of aquaculture systems: methodological issues and potential improvements. Int J Life Cycle Assess 24:324–337. https://doi.org/10.1007/s11367-018-1517-x

Brod E, Oppen J, Kristoffersen AØ et al (2017) Drying or anaerobic digestion of fish sludge: nitrogen fertilisation effects and logistics. Ambio 46:852–864. https://doi.org/10.1007/s13280-017-0927-5

Bücker F, Marder M, Peiter MR et al (2020) Fish waste: an efficient alternative to biogas and methane production in an anaerobic mono-digestion system. Renew Energy 147:798–805. https://doi.org/10.1016/j.renene.2019.08.140

Bureau DP, Cho CY (1999) Phosphorus utilization by rainbow trout (Oncorhynchus mykiss): estimation of dissolved phosphorus waste output. Aquaculture 179:127–140. https://doi.org/10.1016/S0044-8486(99)00157-X

Château PA, Chang YC (2010) A system dynamics model for marine cage aquaculture. In: Proceedings of the 28th International Conference of the System Dynamics Society. pp 1–17

Chen X, Romano RT, Zhang R (2010) Anaerobic digestion of food wastes for biogas production. Int J Agric Biol Eng 3:61–72. https://doi.org/10.3965/j.issn.1934-6344.2010.04.061-072

Cosme N, Hauschild MZ (2016) Effect factors for marine eutrophication in LCIA based on species sensitivity to hypoxia. Ecol Indic 69:453–462. https://doi.org/10.1016/j.ecolind.2016.04.006

Cosme N, Hauschild MZ (2017) Characterization of waterborne nitrogen emissions for marine eutrophication modelling in life cycle impact assessment at the damage level and global scale. Int J Life Cycle Assess 22:1558–1570. https://doi.org/10.1007/s11367-017-1271-5

Cristiano S, Baarset H, Bruckner C et al (2022) Innovative options for the reuse and valorisation of aquaculture sludge and fish mortalities: sustainability evaluation through life-cycle assessment. J Clean Prod 352:131613. https://doi.org/10.1016/j.jclepro.2022.131613

d’Orbcastel ER, Blancheton JP, Aubin J (2009) Towards environmentally sustainable aquaculture: comparison between two trout farming systems using life cycle assessment. Aquac Eng 40:113–119. https://doi.org/10.1016/j.aquaeng.2008.12.002

Danmarks Statistik (2021) Accounts statistics for aquaculture by unit, farm type and items. www.statbank.dk/AKREGN1. Accessed 15 Mar 2023

Darzi G (2021) Nitrogen and phosphorus loading values in rainbow trout (Oncorhynchus mykiss) farming system in marine floating cage in the southern Caspian Sea. J Aquac Mar Biol 10:103–106. https://doi.org/10.15406/jamb.2021.10.00313

De Soete W, Jiménez-González C, Dahlin P, Dewulf J (2017) Challenges and recommendations for environmental sustainability assessments of pharmaceutical products in the healthcare sector. Green Chem 19:3493–3509. https://doi.org/10.1039/c7gc00833c

Echeverria D, Venditti R, Jameel H, Yao Y (2021) A general life cycle assessment framework for sustainable bleaching: a case study of peracetic acid bleaching of wood pulp. J Clean Prod 290:125854. https://doi.org/10.1016/j.jclepro.2021.125854

Elser JJ, Bracken MES, Cleland EE et al (2007) Global analysis of nitrogen and phosphorus limitation of primary producers in freshwater, marine and terrestrial ecosystems. Ecol Lett 10:1135–1142. https://doi.org/10.1111/j.1461-0248.2007.01113.x

Emara Y, Lehmann A, Siegert MW, Finkbeiner M (2019) Modeling pharmaceutical emissions and their toxicity-related effects in life cycle assessment (LCA): a review. Integr Environ Assess Manag 15:6–18. https://doi.org/10.1002/ieam.4100

Estevez MM, Tomczak-Wandzel R, Kvamme K (2022) Fish sludge as a co-substrate in the anaerobic digestion of municipal sewage sludge- maximizing the utilization of available organic resources. EFB Bioeconomy J 2:100027. https://doi.org/10.1016/j.bioeco.2022.100027

European Union (2018) Blue bioeconomy last update: 2018 situation report and perspectives. WWW.EUMOFA.EU

FAO (2020) World fisheries and aquaculture in review. FAO 35:4–13

Ferreira JG, Taylor NGH, Cubillo A et al (2021) An integrated model for aquaculture production, pathogen interaction, and environmental effects. Aquaculture 536. https://doi.org/10.1016/j.aquaculture.2021.736438

Goddek S, Delaide BPL, Joyce A et al (2018) Nutrient mineralization and organic matter reduction performance of RAS-based sludge in sequential UASB-EGSB reactors. Aquac Eng 83:10–19. https://doi.org/10.1016/j.aquaeng.2018.07.003

Huijbregts MAJ, Steinmann ZJN, Elshout PMF et al (2017) ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int J Life Cycle Assess 138–147. https://doi.org/10.1007/s11367-016-1246-y

Huntingford FA, Adams C, Braithwaite VA et al (2006) Current issues in fish welfare. J Fish Biol 68:332–372. https://doi.org/10.1111/j.0022-1112.2006.001046.x

Ivanovs K, Spalvins K, Blumberga D (2018) Approach for modelling anaerobic digestion processes of fish waste. Energy Procedia 147:390–396. https://doi.org/10.1016/j.egypro.2018.07.108

Jiménez-González C, Curzons AD, Constable DJC, Cunningham VL (2004) Cradle-to-gate life cycle inventory and assessment of pharmaceutical compounds. Int J Life Cycle Assess 9:114–121. https://doi.org/10.1007/BF02978570

Jokumsen A, Svendsen LM (2010) Farming of freshwater rainbow trout in Denmark. DTU Aqua Reports 219:1–47

Jonkers ART, Sharkey KJ, Thrush MA et al (2010) Epidemics and control strategies for diseases of farmed salmonids: a parameter study. Epidemics 2:195–206. https://doi.org/10.1016/j.epidem.2010.08.001

Jouannais P (2023) PJGilmw/Fish performance LCA: fish performance LCA v1.0.0. https://doi.org/10.5281/ZENODO.7759944

Just Economics (2021) Dead loss: the high cost of poor farming practices and mortalities on salmon farms

Katharios P (2019) Disease Prevention in Farmed Fish 5:333–334. https://doi.org/10.1016/S0033-3506(05)81658-0

Kratky L, Zamazal P (2020) Economic feasibility and sensitivity analysis of fish waste processing biorefinery. J Clean Prod 243:118677. https://doi.org/10.1016/j.jclepro.2019.118677

Leung TLF, Bates AE (2013) More rapid and severe disease outbreaks for aquaculture at the tropics: implications for food security. J Appl Ecol 50:215–222. https://doi.org/10.1111/1365-2644.12017

Monir S, Bagum N, Rahman S (2015) Parasitic diseases and estimation of loss due to infestation of parasites in Indian major carp culture ponds in Bangladesh. Int J Fish Aquat Stud 2:118–122

Murray AG, Peeler EJ (2005) A framework for understanding the potential for emerging diseases in aquaculture. Prev Vet Med 67:223–235. https://doi.org/10.1016/j.prevetmed.2004.10.012

Nyberg O, Rico A, Guinée JB, Henriksson PJG (2021) Characterizing antibiotics in LCA—a review of current practices and proposed novel approaches for including resistance. Int J Life Cycle Assess 1816–1831. https://doi.org/10.1007/s11367-021-01908-y

Oidtmann BC, Pearce FM, Thrush MA et al (2014) Model for ranking freshwater fish farms according to their risk of infection and illustration for viral haemorrhagic septicaemia. Prev Vet Med 115:263–279. https://doi.org/10.1016/j.prevetmed.2014.04.005

Papatryphon E, Petit J, Kaushik SJ, van der Werf HMG (2004) Environmental impact assessment of salmonid feeds using life cycle assessment (LCA). AMBIO A J Hum Environ 33:316–323. https://doi.org/10.1579/0044-7447-33.6.316

Papatryphon E, Petit J, Van Der Werf HMG et al (2005) Nutrient-balance modeling as a tool for environmental management in aquaculture: the case of trout farming in France. Environ Manage 35:161–174. https://doi.org/10.1007/s00267-004-4020-z

Parvatker AG, Tunceroglu H, Sherman JD et al (2019) Cradle-to-gate greenhouse gas emissions for twenty anesthetic active pharmaceutical ingredients based on process scale-up and process design calculations. ACS Sustain Chem Eng 7:6580–6591. https://doi.org/10.1021/acssuschemeng.8b05473

Peck MA, Catalán IA, Damalas D et al (2020) Climate change and European fisheries and aquaculture: solutions and future directions. Project Synthesis Report. https://doi.org/10.25592/uhhfdm.804

Peeler EJ, Taylor NGH (2011) The application of epidemiology in aquatic animal health-opportunities and challenges. Vet Res 42:1–15

Philis G, Ziegler F, Gansel LC et al (2019) Comparing life cycle assessment (LCA) of salmonid aquaculture production systems: status and perspectives. Sustain 11. https://doi.org/10.3390/su11092517

Philis G, Ziegler F, Jansen MD et al (2021) Quantifying environmental impacts of cleaner fish used as sea lice treatments in salmon aquaculture with life cycle assessment. J Ind Ecol 1–14. https://doi.org/10.1111/jiec.13118

Poore J, Nemecek T (2018) Reducing food’s environmental impacts through producers and consumers. Science 360(80):987–992. https://doi.org/10.1126/science.aaq0216

Reverter M, Sarter S, Caruso D et al (2020) Aquaculture at the crossroads of global warming and antimicrobial resistance. Nat Commun 11:1–8. https://doi.org/10.1038/s41467-020-15735-6

Rossberg M, Lendle W, Pfleiderer G et al (2006) Chlorinated hydrocarbons. In: Ullmann’s encyclopedia of industrial chemistry

Samuel-Fitwi B, Nagel F, Meyer S et al (2013) Comparative life cycle assessment (LCA) of raising rainbow trout (Oncorhynchus mykiss) in different production systems. Aquac Eng 54:85–92. https://doi.org/10.1016/j.aquaeng.2012.12.002

Samuel-Fitwi B, Schroeder JP, Schulz C (2013) System delimitation in life cycle assessment (LCA) of aquaculture: striving for valid and comprehensive environmental assessment using rainbow trout farming as a case study. Int J Life Cycle Assess 18:577–589. https://doi.org/10.1007/s11367-012-0510-z

Sanchez-Matos J, Regueiro L, González-García S, Vázquez-Rowe I (2022) Environmental performance of rainbow trout (Oncorhynchus mykiss) production in Galicia-Spain: a life cycle assessment approach. Sci Total Environ 856:159049. https://doi.org/10.1016/j.scitotenv.2022.159049

Schmidt J, De Rosa M (2020) Certified palm oil reduces greenhouse gas emissions compared to non-certified. J Clean Prod 277. https://doi.org/10.1016/j.jclepro.2020.124045

Shearer K (1984) Changes in elemental composition of hatchery-reared rainbow with growth and reproduction. Can J Fish Aquat Sci 41:1592–1600

Shinn AAP, Pratoomyot J, Bron JE et al (2015) Economic impacts of aquatic parasites on global finfish production. Glob Aquacult Advocate 82–84

Skilbrei OT (2012) The importance of escaped farmed rainbow trout (Oncorhynchus mykiss) as a vector for the salmon louse (Lepeophtheirus salmonis) depends on the hydrological conditions in the fjord. Hydrobiologia 686:287–297. https://doi.org/10.1007/s10750-012-1028-x

Skonberg DI, Yogev L, Hardy RW, Dong FM (1997) Metabolic response to dietary phosphorus intake in rainbow trout (Oncorhynchus mykiss). Aquaculture 157:11–24. https://doi.org/10.1016/S0044-8486(97)00141-5

Stentiford GD, Bateman IJ, Hinchliffe SJ et al (2020) Sustainable aquaculture through the One Health lens. Nat Food 1:468–474. https://doi.org/10.1038/s43016-020-0127-5

Stentiford GD, Sritunyalucksana K, Flegel TW et al (2017) New paradigms to help solve the global aquaculture disease crisis. PLoS Pathog 13:1–6. https://doi.org/10.1371/journal.ppat.1006160

Tavares-Dias M, Martins ML (2017) An overall estimation of losses caused by diseases in the Brazilian fish farms. J Parasit Dis 41:913–918. https://doi.org/10.1007/s12639-017-0938-y

Tilman D, Clark M (2014) Global diets link environmental sustainability and human health. Nature 515:518–522. https://doi.org/10.1038/nature13959

Tlusty M, Tyedmers P, Ziegler F et al (2018) Commentary: Comparing efficiency in aquatic and terrestrial animal production systems. Environ Res Lett 13. https://doi.org/10.1088/1748-9326/aae945

Weidema B (2003) Market information in life cycle assessment. Danish Environ Prot Agency Environ Proj 863:147

Weidema BP, Frees N, Nielsen AM (1999) Marginal production technologies LCA methodology. Int J Life Cycle Assess 4:48–56

Wurts WA (2016) Using equations to improve feeding and growth of channel catfish. World Aquac 46:58–60

Ziarati M, Zorriehzahra MJ, Hassantabar F et al (2022) Zoonotic diseases of fish and their prevention and control. Vet Q 42:95–118. https://doi.org/10.1080/01652176.2022.2080298

Acknowledgements

The authors thank all members of the AquaHealth project for the insightful discussions around this work. We greatly thank the fish farming professionals in Denmark and Italy for their trust, time, and the data and insights that they provided.

Funding

Open access funding provided by Aalborg University Library. This research was carried out within the AquaHealth project, funded by the ERA-NET Cofund BlueBio program, grant no. 9082-00010.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Communicated by Arnaud Hélias.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Jouannais, P., Gibertoni, P.P., Bartoli, M. et al. LCA to evaluate the environmental opportunity cost of biological performances in finfish farming. Int J Life Cycle Assess 28, 1286–1301 (2023). https://doi.org/10.1007/s11367-023-02211-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-023-02211-8