Abstract

Purpose

In prospective life cycle assessment (pLCA), inventory models represent a future state of a production system and therefore contain assumptions about future developments. Scientific quality should be ensured by using foresight methods for handling these future assumptions during inventory modelling. We present a stepwise approach for integrating future scenario development into inventory modelling for pLCA studies.

Methods

A transdisciplinary research method was used to develop the SIMPL approach for scenario-based inventory modelling for pLCA. Our interdisciplinary team of LCA and future scenario experts developed a first draft of the approach. Afterwards, 112 LCA practitioners tested the approach on prospective case studies in group work projects in three courses on pLCA. Lessons learned from application difficulties, misunderstandings and feedback were used to adapt the approach after each course. After the third course, reflection, discussion and in-depth application to case studies were used to solve the remaining problems of the approach. Ongoing courses and this article are intended to bring the approach into a broader application.

Results and discussion

The SIMPL approach comprises adaptations and additions to the LCA goal and scope phase necessary for prospective inventory modelling, particularly the prospective definition of scope items in reference to a time horizon. Moreover, three iterative steps for combined inventory modelling and scenario development are incorporated into the inventory phase. Step A covers the identification of relevant inventory parameters and key factors, as well as their interrelations. In step B, future assumptions are made, by either adopting them from existing scenarios or deriving them from the available information, in particular by integrating expert and stakeholder knowledge. Step C addresses the combination of assumptions into consistent scenarios using cross-consistency assessment and distinctness-based selection. Several iterations of steps A–C deliver the final inventory models.

Conclusion

The presented approach enables pLCA practitioners to systematically integrate future scenario development into inventory modelling. It helps organize possible future developments of a technology, product or service system, also with regard to future developments in the social, economic and technical environment of the technology. Its application helps to overcome implicit bias and ensures that the resulting assessments are consistent, transparently documented and useful for drawing practically relevant conclusions. The approach is also readily applicable by LCA practitioners and covers all steps of prospective inventory modelling.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

While LCA has a long tradition of systematically handling a variety of uncertainties, dealing with the uncertainty about future developments is a comparatively new challenge of prospective LCA (pLCA) (Pesonen et al. 2000; Arvidsson et al. 2018; van der Giesen et al. 2020). pLCA inventory models represent a future state of a production system and inevitably include assumptions about future developments. When integrating these future assumptions into the process of inventory modelling, LCA practitioners may build on scientific methods provided by the research field of foresight (European Commission; OECD). In particular, the future scenario approach (Kosow und Gaßner 2008) is a suitable method to systematically account for future uncertainties. It has been readily applied by the pLCA community, as a recent review (Bisinella et al. 2021) analysed 514 articles on the combination of LCA and future scenarios. However, only a quarter of these studies are based on consistent knowledge of the scientific background of the future scenario methodology (Bisinella et al. 2021). Most studies use foresight keywords and employ future scenarios as a general concept, but do not follow the scientific principles and systematic procedure of the scenario methodology. A large share of studies do not define a time horizon and lack transparency regarding the choices made for the future scenarios. In addition, 97% of the studies address foreground parameters, but only 41% address background parameters, hinting that the latter are prone to be neglected (Bisinella et al. 2021). This phenomenon has also been discussed in (Mendoza Beltran et al. 2020) and (Arvidsson et al. 2018). Recommendations from the systematic review (Bisinella et al. 2021) emphasize the necessity to ensure transparency and communicability of studies combining LCA and future scenarios. Furthermore, it is recommended that the goal and scope definition of the LCA and the future scenario approach be aligned with each other. Moreover, scenarios should be contextual, i.e. identify key factors and their potential development, while also taking into account the potential impacts of background developments. To fulfil these criteria, it is recommended to include stakeholders and specialists into the process (Bisinella et al. 2021). These recommendations enable a more balanced development of the combined use of LCA and future scenarios. The study presented in this article aims to contribute to this progress with a particular focus on prospective small-scale LCAs, which are addressing technology development. Although general recommendations are available for prospective small-scale LCAs (Arvidsson et al. 2018; Villares et al. 2017; van der Giesen et al. 2020; Thonemann et al. 2020; Cucurachi et al. 2018; Thomassen et al. 2019; Buyle et al. 2019; Moni et al. 2020), practitioners still face the challenge to convert these into a practically applicable procedure. Practical guidance is only published for specific elements of prospective inventory modelling, such as technological upscaling (reviewed in (Tsoy et al. 2020)), but does not systematically cover the entire process of prospective inventory modelling. Given the limited time resources in many pLCA studies, a readily applicable step-by-step manual covering all the necessary steps reduces the barriers to fulfilling quality requirements when integrating the future scenario approach into LCAs. Therefore, the presented study seeks to develop a step-by-step manual for prospective inventory modelling in small-scale LCAs covering all the necessary steps. Comparable guidance was published in (Spielmann et al. 2005) for medium-scale LCAs (in particular applied to transport systems). We decided to develop an approach independently of this guidance for medium-scale LCAs, since our intention was to provide an approach that is particularly suitable for the requirements of small-scale LCA practitioners. In summary, our research goal was to develop and bring into application a step-by-step approach for prospective inventory modelling fulfilling the following criteria:

-

1.

The approach should be easily applicable by small-scale LCA practitioners.

-

2.

The approach should ensure that scientific standards of the future scenario approach are met.

-

3.

The approach should cover all the necessary steps for prospective inventory modelling.

This article presents the derived approach, which is called Scenario-based Inventory Modelling for Prospective LCA (SIMPL) approach. Section 2.1 describes the transdisciplinary development of this approach, followed by a summary of the scientific foundations in Sect. 2.2. Section 3 presents the results, i.e. a step-by-step approach for prospective inventory modelling for small-scale LCAs, while Sect. 4 illustrates its application with an example. In the discussion (Sect. 5), we compare the presented SIMPL approach against the requirements set for its development and discuss methodological choices and their alternatives. Finally, conclusions and recommendations are given in Sect. 6.

2 Methods

Section 2.1 describes the methods that were used to develop the SIMPL approach, while Sect. 2.2 provides information on the principles and definitions that build the methodological foundation of the SIMPL approach.

2.1 Development of the SIMPL approach

The methodological shortcomings of many pLCA studies (as detected in (Bisinella et al. 2021) and summarized in the introduction) can be attributed to a lack of integration between the scientific communities of foresight and LCA: While the future scenario approach is used in many pLCA studies, scientific standards of the foresight community are often not met. To better integrate the scientific knowledge and principles of the foresight community into pLCA practitioning, the mutual understanding of principles, standards and requirements between both scientific communities needs to be improved. This mutual understanding is a prerequisite to develop a readily applicable step-by-step manual that meets the requirements and standards of both communities. To ensure the necessary exchange and integration, a transdisciplinary research approach was applied for developing the SIMPL approach, according to the principles summarized in (Lang et al. 2012). Consequently, the research process can be divided into 3 phases:

-

(a)

Collaborative problem framing and building a collaborative research team

-

(b)

Co-creation of solution-oriented and transferable knowledge through collaborative research

-

(c)

(Re-)integrating and applying the co-created knowledge

In the following, we will describe the steps taken in each of these phases. In general, the phases were not passed linearly, but in iterative and recursive ways, which is typical for transdisciplinary research in sustainability science (Lang et al. 2012).

2.1.1 Phase (a): collaborative problem framing and building a collaborative research team

As part of phase (a), the research goal was defined as developing and bringing into application a step-by-step approach for prospective inventory modelling, fulfilling three main criteria:

-

1.

The approach should be easily applicable by small-scale LCA practitioners.

-

2.

The approach should ensure that scientific standards of the future scenario approach are met.

-

3.

The approach should cover all necessary steps for prospective inventory modelling.

Specific requirements for the criteria were likewise defined as part of phase (a), although owing to the iterative character of the transdisciplinary development method (Lang et al. 2012), these requirements were adapted through insights gathered during the process rather than set up in one step at the outset. Most importantly, the specifics of criterion (1) were formulated with insights gained from the courses given in phase (b) (cf. Sect. 2.1.2 and suppl. mat. 1, Sect. 1.3). The specifics of criterion (1) are:

-

1.1

The approach is easily understandable.

-

1.2

The approach involves a manageable/scalable effort.

-

1.3

It can be readily integrated into the existing LCA framework as determined by the ISO standard.

-

1.4

The approach offers choices so it can be adapted to the requirements of different research problems.

-

1.5

The approach delivers practical benefits.

More detailed aspects of criterion (2) can be formulated in line with (Bisinella et al. 2021): The approach ensures.

-

2.1

Terminology is in alignment with foresight terminology.

-

2.2

Transparency and communicability of pLCA studies is enhanced.

-

2.3

Scenarios are developed contextually, i.e. by identifying key factors and their potential development.

-

2.4

Goal and scope definition of the LCA and the future scenario approach are in alignment.

-

2.5

Stakeholders and specialists are included in the process.

-

2.6

The impact of background developments is taken into account.

-

2.7

Uncertainties and sensitivities are addressed.

Criterion (3) requires the inclusion of:

-

3.1

The goal and scope definition that is relevant for inventory modelling

-

3.2

All the steps of prospective inventory modelling

As another task of phase (a), we set up a collaborative research team including scientists with expertise in pLCA, foresight and sustainability science (for details, cf. suppl. mat. 1, Sect. 1.1) and planned the research processes of phases b and c.

2.1.2 Phase (b): co-creation of solution-oriented and transferable knowledge through collaborative research

Phase (b) can be further broken down into the following steps:

-

(b1)

Literature research provided the scientific background from the available scientific evidence.

-

(b2)

Through an initial phase of discussions within the research team, followed by personal reflection and conceptualization, we created a first draft of an approach for prospective inventory modelling for small-scale LCAs, bringing together knowledge and perspectives from the different scientific fields.

-

(b3)

In three courses with LCA practitioners, we gained knowledge about the practical requirements and the potential for improvement. In each course, the SIMPL approach was introduced by the research team and afterwards applied by the participants to their own case studies in group work. The application was supervised by the members of the research team and presented by the participants at the end of the course. Each course was followed by a process of reflection on the lessons learned, discussions within the project team and an adaptation of the approach.

-

(b4)

After the third course, a longer phase of reflection, discussion and in-depth application to case studies was used to solve the remaining problems of the approach.

More details on each step are documented in suppl. mat. 1, Sect. 1.3. Additionally, table A0 in suppl. mat. 1 gives an overview on the technical data of the courses.

2.1.3 Phase (c): (re-)integrating and applying the co-created knowledge

The key goal of this phase is to integrate the derived approach into LCA practice. This can be achieved by continuing the courses (c.1). A pLCA course will be given by the research team once a year. Furthermore, it was pointed out by participants of the courses that citable documentation of the SIMPL approach itself would be desirable as a way to support the practical application in their research. Therefore, the documentation provided in this article is seen as step (c.2) in order to support the practical application of the SIMPL approach. We hope that a further in-depth application of the SIMPL approach will be made possible through this article, leading to an improvement of pLCA practice as well as further development of the approach itself.

2.2 Methodological foundations and terminology of the SIMPL approach

The SIMPL approach is built upon the methodological principles of LCA and the future scenario approach. This section explains the methodological background of the SIMPL approach and defines all terms used in the results section. Since the principles of LCA are familiar to the readers of this journal, this section focuses on the scientific principles and terminology of the foresight community and the future scenario approach in particular. It includes only few definitions on LCA terminology that are important for understanding the results section.

The scientific principles of the future scenario approach provide the foundation of the SIMPL approach and are explained in Sect. 2.2.1. Since a scenario type needs to be chosen for the SIMPL approach, a description of the different types is given in Sect. 2.2.2. In order to actually integrate future scenario development into inventory modelling for prospective LCA, the SIMPL approach suggests to incorporate the general steps of future scenario development into the first two phases of LCA. Therefore, these general steps of future scenario development are presented in Sect. 2.2.3. This introduces the term ‘key factor’, so it is defined what key factors are and how they relate to inventory parameters within the SIMPL approach in Sect. 2.2.4, which also leads to the definition of inventory parameters themselves. Afterwards, specific requirements for the collection of information for future scenario development are described in Sect. 2.2.5. Finally, specific tools can be applied for some of the general steps of the future scenario development, so Sect. 2.2.6 briefly explains the tools that are recommended for use in the SIMPL approach. Furthermore, Sect. 2.2.6 can be used to look up details on tools and methodological alternatives when applying the SIMPL approach.

2.2.1 Scientific principles of the future scenario approach

The research field of foresight builds on the understanding that different future developments are possible. Consequently, foresight can be defined as ‘the disciplined analysis of alternative futures’ (European Commission; OECD). The future scenario technique is a particular foresight method to account for future uncertainties in a transparent and systematic way. The scenarios themselves describe plausible and relevant pictures of the future, often encompassing the paths that lead to these distinct future situations (European Commission; OECD)(Kosow und Gaßner 2008). Therefore, the aim of scenario development is not to predict what will actually happen, but to explore the different possibilities of future developments, i.e. what could happen. Thus, important criteria for the scientific quality of future scenario development (Kosow and Gaßner 2008; Gerhold et al. 2017) are plausibility and consistency, i.e. the scenarios have to be conceptually feasible and devoid of contradictions. Moreover, scenarios have to be documented in a transparent and traceable way and have to make use of all available and relevant knowledge (details are given in Sect. 2.2.5).

2.2.2 Scenario types

There are a variety of scenario types and typologies, e.g. (van Notten et al. 2003; Börjeson et al. 2006), and new types are under development, e.g. (Erdmann and Schirrmeister 2016). We refer to the typology given by Börjeson et al. (2006), since it was shown by (Bisinella et al. 2021) that previous works on the combination of LCA and future scenarios can be classified by this typology, so it is assumed to cover the variety of scenario types applied. This typology differentiates explorative, predictive and normative scenarios. Depending on the research question, a combination of these three basic types is possible.

Explorative scenarios

Explorative scenarios follow the basic assumption that several alternative future developments are possible (cf. Sect. 2.2.1) and allow for the exploration of the possible developments. Since future uncertainties increase with the time anticipated, the range of possible future developments can be depicted as a funnel (cf. Fig. 1a). Choosing specific assumptions and investigating their specific implications is referred to as developing what-if-scenarios (Börjeson et al. 2006). The attempt to explore a broad or even full range of future uncertainties is known as developing cornerstone scenarios. Frequently, a ‘best case’ and a ‘worst case’ serve as cornerstone scenarios. However, the scope of the possible developments will not always follow this ‘good-or-bad’ logic, neither is it necessarily one-dimensional. The Shared Socioeconomic Pathways (SSPs) are an example of a well-established set of explorative scenarios including four cornerstone scenarios (O’Neill et al. 2017) (Fig. 1b). Additionally, this set of scenarios includes a ‘middle of the road’ scenario, which is often used to illustrate an intermediate development alongside the possible extreme developments.

Illustration of explorative scenarios: a scenario funnel with cornerstone scenarios and b the Shared Socio-Economic Pathways as an example for a set of explorative scenarios with four cornerstone scenarios and one intermediate scenario (based on (O’Neill et al. 2017))

Predictive scenarios

With the predictive scenario type, a single ‘likely’ scenario is developed. Since a fundamental aspect of the future scenario approach is that scenarios are not predictions (cf. Sect. 2.2.1), it should be critically scrutinized as to whether it is justified to call a future development ‘certain’ or ‘likely’. Often, by intuition, an average case or business-as-usual scenario is chosen as the most likely scenario, however, a rationale for this is often lacking. Predictive scenarios may be most suitable when uncertainties are assumed to be negligible, e.g. when a study is looking into the very near future and/or a future assumption is hardly disputed (e.g. the magnetic field of the Earth will not change its direction over the next 30 years).

Normative scenarios

Normative scenarios explicitly incorporate values and desired future developments. Often, at first, a vision of the future is generated and then pathways to reach this vision are identified and analysed.

2.2.3 General steps of future scenario development

From various approaches, an archetype scenario development process can be abstracted (European Commission; Kosow and Gaßner 2008; Erdmann and Schirrmeister 2016; Dönitz and Schirrmeister 2013; Tiberius et al. 2020). Kosow and Gaßner (2008) will serve as a reference in this article, as they condense the most important principles into easily understandable steps. Accordingly, the process of scenario development comprises five stages, the last one being optional:

-

1.

Scenario field definition: The goal of the scenario development is specified. Furthermore, system boundaries (including temporal and geographical boundaries), data sources and stakeholder participation, the scenario type (see Sect. 2.2.2) and other relevant aspects of the scope are defined.

-

2.

Key factor identification: It is systematically analysed which factors have a high impact on the uncertain future development. Factors with a high impact are called ‘key factors’.

-

3.

Key factor analysis: Alternative assumptions are made on the possible future developments of each key factor.

-

4.

Scenario generation: Consistent combinations of key factor assumptions are combined and integrated into scenarios. If there are many consistent combinations, making a selection becomes necessary.

-

5.

Optional: Scenario transfer: The generated scenarios can be further applied or processed. Options include the evaluation of desirability, development of strategies and use for communication.

2.2.4 Definition of key factors vs. inventory parameters

Section 2.2.3 introduces the term ‘key factor’ as a factor with high impact on the uncertainties of the developed future scenarios. In order to explain what role ‘key factors’ play within the SIMPL approach and how they relate to ‘inventory parameters’ of the inventory model, which are familiar to the LCA community, we will define and explain the terms ‘key factor’ and ‘inventory parameter’ in the following.

Key factors

‘Key factors’ significantly influence the inventory parameters (and consequently, the pLCA results), but are not part of the inventory model. One key factor may influence several inventory parameters simultaneously. In order to avoid inconsistencies between the assumptions made about the influenced inventory parameters, it is important to identify the influencing key factors. For instance, political decisions may influence the future development of several processes in an inventory model, so the same suppositions about these political decisions should underlie the assumptions about all processes. Additionally, consideration of key factors helps provide an understanding of the broader conditions under which the pLCA results are valid, and thereby supports the development of practical recommendations. Potential key factors will be referred to as ‘factors’ before their influence on the inventory model has been testified.

Inventory parameters

The essential parameters of the inventory model are the quantified elementary and intermediate flows, e.g. material and energy inputs, emissions and products. Furthermore, parameters influencing these flows can be defined quantitatively when modelling the inventory. This is usually done for a better overview and efficient modelling of several alternatives. A parameter influencing the inventory model flows can be implemented for a specific process (e.g. a process efficiency giving the ratio of outputs to inputs) or the entire inventory model (e.g. an energy efficiency parameter relevant for several processes). Alternative choices, for example between different input materials or different production systems, often need to be implemented as well. They can be modelled through alternative production routes within an inventory model and quantification of each route’s share in the total production. In some cases, modelling each alternative route in a separate model can improve the overview. All elements described in this paragraph are called ‘inventory parameters’ throughout this article.

In addition, inventory parameters are often categorized into foreground and background parameters by the LCA community. Foreground parameters are based on primary data obtained by the LCA practitioners themselves. Background parameters relate to generic data taken from databases (Klöpffer and Grahl 2014). Throughout this article, ‘inventory parameters’ refers to foreground and background parameters.

2.2.5 Collection of information

Epistemic uncertainties about future developments cannot be eliminated or reduced by collecting precise data, in contrast to stochastic uncertainties, e.g. about technical parameters in retrospective inventory modelling. Consequently, methodological requirements for the collection of information are more complex. The utilization of all the available and relevant knowledge is important for the quality of the scenarios (Gerhold et al. 2017). According to (van Notten et al. 2003), there are two principle approaches for the information collection: desk research at the one end, and participatory methods at the other. Participatory methods include experts and stakeholders in knowledge collection, e.g. through interviews, surveys (such as Delphi surveys) or workshops. Kosow and Gaßner (2008) differentiate between systematic-formalized scenario approaches, having a strong focus on desk research, and creative-narrative scenario approaches, focusing on participatory methods. The former offer an in-depth analysis including empirical insights and theoretical foundations. The latter utilize the intuitive and implicit knowledge of the involved stakeholders and experts, synthesize their insights into a general overview and reach a common understanding through exchange, while also providing legitimacy through participation. Most future scenarios are developed using a combination of systematic-formalized desk research and creative-narrative participation (Kosow and Gaßner 2008), ideally utilizing the advantages of both approaches. The development of future assumptions on key factors in particular (step 3 in Sect. 2.2.3) inherently includes intuitive and creative aspects, so stakeholder participation is essential for this step (Kosow and Gaßner 2008). The other steps can theoretically be covered in a purely analytical fashion, but still benefit from participatory methods. Stakeholder and expert participation is a key element according to the recommendations for combining future scenarios and LCA outlined in (Bisinella et al. 2021). Table 1 gives an overview on recommended methods for the collection of information at each step of the SIMPL approach.

2.2.6 Specific tools for the general steps of the future scenario approach

Specific tools for key factor identification

In order to obtain a good overview of potential key factors, it is necessary to consider factors from different areas that could affect the future development of the analysed technology. We recommend PEST approaches since they ensure that a variety of potentially relevant areas are considered in a systematic, structured way, thereby reducing the risk of blind spots. PEST approaches were initially used in strategic management for the identification of key factors in the macro-environment of institutions (Fahey and Narayanan 1986). They serve as checklists for scanning different potentially influential areas and are frequently used in future scenario development. PEST stands for political, economic, socio-cultural and technological factors. A wide range of variants exists. PESTEL (Issa et al. 2010) was chosen for the SIMPL approach as the best fit for pLCA, as it adds both environmental and legal factors, which are often relevant for the technologies being assessed. A thorough explanation of the principle and an example for practical application can be found in (Ulubeyli and Kazanci 2018). A table for practical application is provided in supplementary material 2. Other approaches also include cultural, ethical or demographic factors (Fahey and Narayanan 1986). Stakeholder integration can further reduce the risk of blind spots. It might take place via survey sheets providing the PESTEL checklist and the research question, or through brainstorming workshops. Ideally, stakeholders from all PESTEL areas are involved, but inclusion of sector experts, experts from competing technologies or potential customers already enhances the overview.

In order to analyse the interrelationships between several factors and identify the most influential factors among them, typical methods include influence analysis of factors and cross-impact-balance analysis of factor projections (Kosow and Gaßner 2008; Schweizer and Lazurko 2020). Both are table-based solutions. Causal loop diagrams (CLD) are a less common but graphical alternative (de Vries 2012). Since inventory modelling is usually based on a flow chart of the production system, CLDs as a likewise graphical solution allow for a graphical linkage and were easily adopted by LCA practitioners in our courses (cf. Sect. 2.1). Additionally, CLDs can be used as a starting point for quantitative modelling of key factors when this option seems appropriate in terms of the research question and the available resources. For these reasons, CLDs were chosen for the SIMPL approach. A thorough explanation of CLD principles and their application in sustainability science can be found in (de Vries 2012) pages 24–25 and 36–44. Examples given in suppl. mat. 1, Sect. 2 illustrate the principle. In short, when creating a CLD, the general task is to draw an outline of the relevant variables with their connections to each other using arrows. If one parameter (A) is connected to another (B) with an arrow and a plus, it means that an increase in A will lead to an increase in B, and likewise, a decrease in A will lead to a decrease in B. If A points to B with a minus, it means that an increase in A will lead to a decrease in B, while a decrease in A will lead to an increase in B. The last aspect leads to most misunderstandings and should therefore be kept in mind. Literature research and stakeholder integration are important for an in-depth understanding of the connections and interrelationships. Workshops with phases of collective discussion and individual reflection are a suitable tool to develop the CLD in collaboration with stakeholders.

Specific tools for scenario generation

Cross-consistency assessment (CCA) (Ritchey 2002; Zwicky and Wilson 1967) also known as cross-impact analysis (CIA) (Bishop et al. 2007; Culka 2018; Bradfield et al. 2005), is a widely used standard for checking consistency when developing scenarios and has no commonly used alternatives. For CCA, assumptions about factors are checked pairwise. If two assumptions are inconsistent with each other (for logical or empirical reasons), all combinations of assumptions including the inconsistent pair of assumptions can be excluded from further analysis. A straightforward inconsistency might be found for some pairs of assumptions, but some pairs of assumptions might also be more or less consistent. Therefore, pseudo-quantitative scales or colour scales are usually applied to differentiate the more consistent pairs from the less consistent pairs. Depending on the purpose and available resources, it can be decided whether only the most consistent or all the more or less consistent pairs should be considered for further analysis. If the number of factors is small, a cross-consistency check can be performed by hand. A table is provided in supplementary material 3 for the consistency check of up to five factors. For a higher number of factors, software tools (Bañuls and Turoff 2011) will be needed. A more detailed description of CCA can be found in (Ritchey 2002), particularly on pages 5–7. An example given in suppl. mat. 1, Sect. 2 illustrates the principles. Stakeholder involvement can help to overcome biased perspectives on correlations. Stakeholder perspectives can be collected through surveys. In case many opposing perspectives are found, workshops or Delphi surveys can help to reach a consensus.

3 Results: the SIMPL approach for Scenario-based Inventory Modelling for Prospective LCA

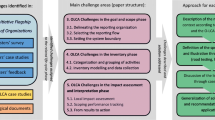

For integrating the future scenario approach into LCA inventory modelling, the four mandatory steps of future scenario development (Kosow and Gaßner 2008) (cf. Sect. 2.2.3) were incorporated into the first two phases of LCA as displayed in Fig. 2, leading to

The four mandatory steps of future scenario development (Kosow and Gaßner 2008) (yellow) were adapted and integrated into the first two LCA phases (blue), allowing for scenario-based inventory modelling for pLCA (green). Adaptations of the last two LCA phases (grey) are beyond the scope of this article. Also, the adaptation of the goal and scope phase would have to be extended when addressing the last two phases

-

1.

Adaptations and additions required for prospective inventory modelling within the goal and scope definition and

-

2.

Three iterative steps (A–C) for combined inventory modelling and scenario development within the inventory analysis.

The integration of the four mandatory steps of future scenario development is essential elements of the SIMPL approach to ensure that quality standards of the scientific foresight community are met. Within the steps, different tools and options are offered to keep the approach adaptable for specific research problems and scalable according to available capacities.

3.1 Integrating scenario field identification into the LCA goal and scope definition

The precise definition of the research goal and scope is the first step of both LCA and future scenario approach, being called ‘goal and scope definition’ in LCA and ‘scenario field identification’ in scenario development. Hence, when integrating scenario development into inventory modelling for pLCA, the scenario field identification should be integrated into the LCA goal and scope definition (cf. Fig. 2). This integration leads to adaptations and additions which are explained in the following subsections.

3.1.1 Definition of the prospective LCA research question

Stakeholder participation and iterative adaptations are key elements of a precise goal definition in both disciplines (Klöpffer and Grahl 2014; Kosow and Gaßner 2008). However, participatory methods for goal definition are more commonly used by the foresight community and frequently neglected in LCA studies. Therefore, special attention should be paid to stakeholder involvement when integrating scenario field identification into the goal definition (cf. Table 1).

3.1.2 Choice of temporal boundaries/time horizon

Temporal boundaries need to be specified in LCA and are supposed to be valid for all parameters included in the assessment to ensure consistency (Klöpffer and Grahl 2014). For pLCA, the temporal boundaries lie in the future and should be defined according to the standards of scenario field identification, i.e. a specific year (or period) in the future is chosen as the ‘time horizon’.

An appropriate time horizon allows for the emerging technology under investigation to have reached maturity (i.e. sufficient diffusion into the market), as that is when its environmental impacts are most significant. Additionally, a comparison with an already established technology provides meaningful results only if both technologies have the same degree of maturity at the time of comparison (Thonemann et al. 2020). Furthermore, when choosing the temporal boundaries, it is usually necessary to ensure that sufficient data on all relevant foreground and background processes are available for the year chosen in retrospective LCA. Similarly, when choosing the time horizon for prospective LCA, consideration should be given to the future years for which assumptions about background processes are available from already existing future scenarios. Stakeholder integration can be helpful in finding a suitable time horizon (cf. Table 1).

3.1.3 Choice of scenario type

Depending on the research question and the time horizon, the most suitable scenario type should be chosen, which can be explorative (cornerstone or what-if), predictive or normative (cf. Sect. 2.2.2). In the following, the approach will be given for the case of explorative scenarios. Deviations for the other scenario types can be found in supplementary material 1. As the most important difference, in explorative cornerstone scenarios, several assumptions for each key factor and inventory parameter need to be managed, while for predictive and what-if scenarios, single assumptions might be chosen. Furthermore, normative scenarios take a backcasting perspective that requires finding (one or several) assumptions for each key factor and inventory parameter to reach a certain goal. ‘Key factor’ and ‘inventory parameter’ are defined in Sect. 2.2.4.

3.1.4 Prospective definition of the production system and related scope items

The first outline of the production system (to be drawn within the goal and scope phase according to LCA standards, e.g. (Klöpffer and Grahl 2014)) should already depict the potential future state of the technology corresponding to the time horizon. If several alternative scenarios are to be developed, which is typically the case for explorative scenarios, several alternative outlines might be necessary. Likewise, related elements of the LCA scope definition (e.g. the functional unit and the geographical boundaries) have to be defined in accordance with the chosen time horizon and future scenario type and potential future changes have to be considered (Thonemann et al. 2020; Bisinella et al. 2021). For instance, the functional unit of a cleaning technology for industrial waste water might be ‘1 m3 of clean water’ today, but could become ‘xx g of rare metal’ in the future, as the metal recovery becomes more efficient and metal scarcity more relevant. Similarly, equipment for an emerging technology might currently only be produced within narrow geographical boundaries, but in the future could be manufactured globally, so that geographical boundaries need to be adapted.

3.2 Integrating scenario development into inventory modelling

For a systematic prospective inventory modelling, the three steps A–C illustrated in Fig. 2 need to be done iteratively. Several iterations of steps A–C lead to the final inventory model(s) as the result of the pLCI.

3.2.1 Step A: Identify relevant inventory parameters and key factors

Inventory parameters and other factors are relevant if they significantly influence the results of the pLCA. Relevant factors are called key factors. The terms ‘inventory parameters’ and ‘key factors’ are defined and explained in Sect. 2.2.4.

Steps A1–A3 are summarized in Table 2 and explained in the following. For details on the applied tools, cf. Sect. 2.2.6.

Step A1: Preliminary inventory model and sensitivity analysis

The inventory model identifies the inventory parameters, while a sensitivity analysis helps to assess their impact on the LCA results, i.e. their relevance. Therefore, at the beginning of the iterative steps A–C for pLCI, both preliminary inventory modelling and a preliminary sensitivity analysis need to be conducted based on rough estimates. Through several iterations of steps A–C, the preliminary inventory model will become more and more detailed and finely tuned until a final inventory model is created. The preliminary sensitivity analysis helps to select the most relevant inventory parameters for a closer analysis in step B (Fig. 2). On the other hand, it helps to determine which inventory parameters have only negligible influence on the LCA results and thus, can be neglected during step B.

The preliminary inventory model is developed from the flow chart drafted during the goal and scope phase (cf. Sect. 3.1.4). It depicts the anticipated future state of the technologies as defined in the goal and scope (the status of all processes at the time horizon, e.g. fully industrialized, market-diffused processes instead of lab-scale processes). Consequently, it includes future assumptions about all inventory parameters. Several alternative assumptions about the inventory parameters may be plausible and this needs to be reflected in the inventory model. It is possible to include several alternative assumptions in one inventory model, e.g. by alternative processes optionally connected to the main process chain or by defining alternative values for inventory parameters on process efficiencies. Likewise, it is possible to create several alternative inventory models, e.g. for modelling two different production systems leading to the same product. Whether the best choice is (i) one inventory model including all alternative future assumption or (ii) several alternative inventory models each representing a consistent combination of future assumptions, depends on the number and complexity of alternative assumptions, as well as on the practitioner’s preferences. Insights from experts, particularly technology developers and experts with experience in technological upscaling of similar technologies, are helpful in creating these preliminary prospective inventory models. They can be obtained through interviews and surveys (cf. Table 1).

For a better overview, it can be helpful to organize hierarchically the inventory parameters which have been identified as relevant, e.g. define a few main inventory parameters each including a couple of subordinated inventory parameters. For instance, the electricity mix can be defined as a main inventory parameter, with the respective shares of different technologies for electricity generation being the subordinated inventory parameters. Likewise, the choice of one specific production pathway can be defined as a main inventory parameter, with all the inventory parameters which belong to this specific production pathway being the subordinated inventory parameters. What constitutes a suitable hierarchy depends on the research question, and also on the practitioner’s preferences, so no general recommendations can be given here.

Step A2: PESTEL

When looking for key factors, a systematic search ensures clarity and thoroughness. The PESTEL checklist helps to consider political, economic, sociological, technical, environmental and legal factors (Fahey and Narayanan 1986), as explained in Sect. 2.2.6. In this instance, technical is not related to the specifics of the technology in focus (which is already covered by the inventory model(s) in A1). Instead, technical key factors may be technical preconditions or threads to this technology’s progress, e.g. the development of necessary infrastructural prerequisites or a competing technology. Stakeholders and experts, ideally from each PESTEL domain, should be integrated via survey sheets or brainstorming workshops to avoid blind spots (cf. Table 1).

Step A3: Causal loop diagrams connected to the inventory model(s)

After listing potential key factors, we need to know how exactly these factors affect the pLCA results, i.e. which inventory parameters they influence and in what way. Furthermore, it is necessary to know which connections between key factors may cause interdependencies between inventory parameters and thus, have to be considered to ensure that assumptions about inventory parameters are consistent.

These issues will be solved by drawing a CLD and linking it to the inventory model(s). The working principle of CLDs is explained in Sect. 2.2.6. The methodological novelty of linking CLDs and LCIs is illustrated in Fig. 3. In order to gain additional insights and perspectives into connections and overcome biased perspectives on interdependencies, stakeholders and experts should be integrated into drawing the CLD, e.g. through workshops with phases of collective discussion and individual reflection (cf. Table 1).

Illustration of step A3 with a simplified example: factors identified through PESTEL and their interrelations are displayed in a CLD and connected to the inventory model. It shows that an inventory foreground parameter (additional filter in process 3) and an inventory background parameter (market for acid 1) depend on the same key factor (legislation on toxic emissions), which needs to be regarded for consistent future scenarios. Key factors (having relevant connections to the inventory model and/or to other factors) are marked with a frame

The CLD includes the factors identified using PESTEL. Factors identified using PESTEL but showing no direct connection to the inventory parameters and no significant connections to other factors can be neglected. In contrast, factors having a direct connection to the inventory model and/or many connections to other factors eventually leading to the inventory are most relevant, i.e. actual key factors.

Step A3 can be based on rough estimates at the beginning and will become more finely tuned after several iterations of steps A–C.

Step A delivers an overview (e.g. a list or a table) of inventory parameters, key factors and their connections, which are relevant for the pLCA results. These inventory parameters, key factors and connections between them need to be addressed when making future assumptions in step B.

3.2.2 Step B: Find future assumptions for each key factor and each relevant inventory parameter

Future assumptions for each key factor and each relevant parameter can either be taken from already existing scenarios (step B1) or obtained through considerations by the practitioners, utilizing the available literature and expert knowledge (step B2). Assumptions about inventory parameters need to be quantified, while assumptions about key factors only need to be qualitatively described to assess their influence on the inventory parameters. In both cases, it is necessary to choose some assumptions based on distinctness to keep the number of assumptions manageable (Step B3). Table 3 summarizes the necessary steps for finding future assumptions.

Step B1: Adopt assumptions

The inventory background parameters (e.g. electricity mix) and key factors (e.g. climate policy) are often relevant for a variety of research questions. Hence, future assumptions about these parameters can sometimes be found in scenarios which have already been published. In some cases (e.g. a broadly analysed technology), this might even be the case for inventory foreground parameters.

Adopting assumptions saves time and potentially allows to benefit from resources invested in future scenario processes specifically dedicated to the respective key factors/inventory parameters. Conversely, integration of the pLCA results into broader scientific studies or discussions will be more feasible if they are based on generally accepted future assumptions or embedded into well-known future scenarios. The quality of the adopted assumptions can be ensured by choosing future scenarios from acknowledged sources and/or checking the scenarios using quality criteria (cf. Sect. 2.2.1).

Ideally, a future scenario can be found that covers all the relevant background parameters and key factors, automatically ensuring the consistency of the adopted future assumptions. Since this will not always be possible, it is feasible to adopt assumptions about one parameter from one scenario and assumptions about another parameter from another scenario. However, assumptions from different scenarios need to be checked for consistency (step C). Likewise, it might be possible to choose a future scenario covering several relevant key factors/inventory parameters as a ‘framework scenario’ and add assumptions about the remaining factors/parameters from other sources or the practitioner’s own considerations. In which case, the consistency check only has to be done for the added key factors.

Analyzing the literature on scenarios for the identified key factors and relevant inventory parameters, including peer-reviewed articles as well as reports from governmental institutions, companies, NGOs or other organizations, is very important for this step. Interviews with experts on the identified key factors and relevant inventory parameters can help in finding and assessing the relevant literature (cf. Table 1).

If no future assumptions can be found for a factor/parameter, they have to be derived as explained in step B2. If only qualitative assumptions are found in already published scenarios, these can be used as a basis for quantification. On the other hand, when complex quantitative information is available from external scenarios or models, algorithms may be necessary to automatically transfer them into an inventory model. For instance, future assumptions from integrated assessment models (IAMs) have been combined with the ecoinvent database to create LCI datasets on future electricity production by (Cox et al. 2020; Sacchi et al. 2022). Bisinella et al. (2021) give an overview on how external models can in principle be combined with pLCA.

Step B2: Derive assumptions

Deriving future assumptions about a key factor or inventory parameter usually starts with a qualitative description, followed by a quantification in the case of an inventory parameter. For instance, we can assume that the electricity demand for producing a product might decrease significantly or only slightly in the future, depending on the technological progress of the production technology. This is a set of two explorative cornerstone assumptions given as qualitative descriptions. Next, they can be quantified: a significant improvement might represent a 40% reduction of electricity demand, whereas a slight improvement might mean a 5% reduction.

Deriving assumptions is typically necessary for inventory foreground parameters, since these parameters are specific for a particular technology and hence, less likely to be the subject of readily available future scenarios. The inclusion of expert knowledge is crucial when deriving the future assumptions, as it by nature includes intuitive and creative aspects (cf. Sect. 2.2.5). Process engineers or plant development experts from the technology’s industry sector can provide important insights based on experience with similar technologies. Their knowledge can be collected through interviews and survey sheets. Delphi surveys and interactive workshops can help to create a common understanding out of different expert opinions.

Furthermore, many approaches have been suggested for making assumptions about the development of technology, especially during the upscaling of emerging technology to mature technology. However, these approaches are highly technology-specific, so no general recommendations can be given. Different upscaling protocols may be required for different types of technologies, such as those proposed by (Piccinno et al. 2016) for chemical technologies. Scaling relationships are utilized in (Caduff et al. 2011, 2012, 2014). Furthermore, van der Hulst et al. (2020) provide additional guidance for upscaling. Technological learning is addressed in (Louwen et al. 2016). A more comprehensive review of applied upscaling approaches in different technological contexts has been published by Tsoy et al.( 2020). Additionally, the hierarchy of data collection and estimation methods for LCA given by Parvatker and Eckelman (2019) can be helpful for deriving future assumptions about foreground parameters.

Step B3: Distinctness-based selection of assumptions

When many different assumptions about a parameter are possible, it is reasonable to choose the ones which differ most but which still seem plausible or at least a few markedly distinct ones. Choosing only the most different assumptions as cornerstones allows a range of coverage since all other assumptions lie somewhere between the most distinctly different ones. On the other hand, choosing a few distinctly different assumptions allows ‘what-if’-implications of special interest to be highlighted (e.g. reaching specific policy targets that are under present discussion).

Sometimes the distinctness-based selection is straightforward. For instance, instead of considering the assumptions that the efficiency of a process increases by 20%, 21%, 22%, …, we will assume that it could increase by 20% in the worst case and by 40% in the best case. An average case of 30% may be considered as well. With more complex parameters, the distinctness-based selection becomes more multifaceted as well, e.g. when choosing between different process set-ups. Hence, more dimensions may become relevant so that there can be more than two cornerstone assumptions and other logics than the best-case-worst-case constellation.

Interviews and workshops with experts and stakeholders can help to choose assumptions or verify the choices made. Ideally, they can be combined with the stakeholder and expert interaction in step B2.

All the future assumptions about inventory parameters found in step B need to be integrated into the preliminary inventory model(s), leading to refined versions of the models made in step A. This means that assumptions about different parameters need to be combined, which is the task in step C.

3.2.3 Step C: combine assumptions into future scenarios

From the various plausible future assumptions identified in step B for each of the key factors/inventory parameters identified in step A, numerous formally possible combinations can be formed. However, only internally consistent combinations represent reasonable scenarios with practical relevance. Therefore, CCA (step C1) can be used to exclude all inconsistent combinations. Nevertheless, a high number of consistent combinations may remain, making a distinctness-based selection of scenarios (step C2) necessary. Table 4 summarizes the necessary steps for combining future assumptions into future scenarios.

Step C1: Cross-consistency assessment

The procedure of CCA is explained in Sect. 2.2.6. Once a pair of two parameter assumptions can be excluded as inconsistent, combinations including this pair of assumptions do not need to be analysed any further. Hence, it can be helpful to check for consistency of a few assumptions separately at different points of the iterative process. If parameters are organized hierarchically as main parameters and subordinated parameters, a consistency check can be done within and between the main parameters. For instance, it may help to check consistency of inventory foreground parameters separately. Thereafter, the consistency of sets of consistent foreground parameters with background parameters can be checked.

To avoid biased conclusions on correlations, stakeholders and experts should be asked to provide perspectives from their field of expertise (cf. Table 1). The cross-consistency check can be handed out to them as a survey sheet and interviews can increase understanding with regard to the choices made. Based on that, interactive workshops and Delphi surveys can help to reconcile different perspectives into a common, legitimized conclusion.

Step C2: Distinctness-based selection of scenarios

When assumptions are found for each parameter, a distinctness-based selection of assumptions needs to be made (step B3). Combining the remaining assumptions can still lead to a high number of scenarios, and this number may remain high after the consistency check. Consequently, the overview and clarity can be improved and effort reduced by choosing only sufficiently different scenarios, showing the implications of these differences, and possibly covering a range of more similar scenarios in between. The choices should be made in accordance with stakeholder perspectives, which can be gained through interviews and workshops, ideally in combination with step C1.

4 Illustrating the results with an example

The purpose of this section is to demonstrate the working principles of the SIMPL approach with an example. Consequently, many details of the example provided on alternative jet fuels were neglected or simplified. Also, steps A–C have to be passed several times iteratively, but it would be laborious to show each iteration and its incremental progress. Instead, the main procedure will be explained for each step separately, hinting to the connections between steps where necessary.

4.1 Integrating scenario field identification into the LCA goal and scope definition

4.1.1 Definition of the pLCA research question

Two different production pathways for alternative jet-fuel will be compared. The first possibility is the production from non-food biomass (second-generation bio-fuels), referred to hereafter as ‘biomass-to-jet-fuel’ or ‘BTJ’. For simplicity, only straw was regarded as BTJ raw material in this illustrative example. The second production route generates jet-fuel from CO2 and H2, the latter being produced through water electrolysis, therefore called ‘power-to-jet-fuel’ or ‘PTJ’ throughout this article.

Thus, the starting point for the research question was ‘Jet-fuel from power or bio-waste: Which production route will be more environmentally favorable in the future?’. The necessary further refinement of the research question took place through the definition of scope items as explained in the following.

Literature, especially LCAs on both technologies, were reviewed, showing a high variation in results impeding the comparison. Three experts from related fields were consulted when formulating the research targets, which led to the exclusion of the application of alternative fuel in ships and a focus on bio-waste as the only raw material for BTJ.

4.1.2 Choice of temporal boundaries/time horizon

2050 was chosen as the time horizon, since we assumed (in agreement with technology experts interviewed) that both emerging technologies might have matured to serve mass markets by 2050 and appropriate future scenarios on energy production (as crucial background processes) are available for 2050 as well.

4.1.3 Choice of scenario type

The long-term perspective (the time horizon 2050 lies almost 30 years in the future) and the early development stage of the technologies are connected with a high degree of uncertainty. Therefore, an explorative scenario approach is more appropriate than a predictive one (cf. Sect. 2.2.2). The research interest is not directed to any specific implications but rather general, so cornerstone scenarios covering a range of possible developments are more suitable than what-if scenarios showing specific implications. Similar research questions leading to other scenario types can be found in supplementary material 1.

4.1.4 Prospective definition of the production system and related scope items

According to the explorative scenario approach, several potential future states of the two technologies were summarized in preliminary flow charts of the production systems. To avoid repetition, details on the production systems are only described in Sect. 4.2.1.

One kilogram of jet-fuel was chosen as the functional unit, based on the assumption that jet-fuel is the main product, while other products of both production pathways (e.g. diesel and gasoline) are considered by-products. Additionally, it was assumed that there is no difference between the fuels in the use phase, leading to a cradle-to-gate approach. Regarding geographical boundaries, it was assumed that production will take place in Germany. In this example, the functional unit and geographical boundaries were assumed to be constant over time and different scenarios. Examples for potential future changes can be found in supplementary material 1.

With these definitions, the refined research question was ‘Jet-fuel from power or bio-waste: Which production route will be more environmentally favorable in Germany in 2050?’.

4.2 Integrating scenario development into inventory modelling

In the following, details on BTJ will be presented directly in the article for illustration, while the respective details on PTJ can be found in supplementary material 1.

4.2.1 Step A: Identify key factors and relevant parameters

Step A1: Relevant inventory parameters

For each of the two technologies (BTJ and PTJ), inventory models describing the potential production state in 2050 were created for the identification of relevant inventory parameters. A first brief iteration through steps B and C revealed first future assumptions about production systems and led to selection criteria for these assumptions. Namely, we decided to select cornerstone assumptions of high and low technological progress, which cover a range of possible success levels of technological progress in-between them. Inventory models suitable as starting points were taken from literature (Humbird et al. 2011; Balch et al. 2020; Wittmann and Liao 2016; Hank et al. 2020), for details cf. supplementary material 1. Interviews with experts for each technology supported the literature research and the choice of preliminary inventory models. The decision was made to create two separate inventory models for high and low technological progress of BTJ (depicted in Fig. 4b, already containing connections to the CLD). For PTJ, all assumptions were incorporated into one inventory model by branching between process options (cf. supplementary material 1). Table 5 summarizes the relevant inventory parameters identified. For a better overview, they were structured into main and subordinated inventory parameters. Through preliminary sensitivity analysis, the cereal type of straw production was found to have only a negligible impact on the results and could be excluded as a relevant inventory parameter.

a CLD and its connections (numbers [1]–[4]) to the inventory models for BTJ. This CLD is a simplified version to ensure a good overview for explaining the general principle. A more elaborate version can be found in suppl. mat. 1, Sect. 2.2.3. b Inventory models for BTJ. Numbers [1] to [4] mark the connections from the CLD. Greek letters numerate the two assumptions (α low, β high) for the parameter I (technological progress of BTJ)

Steps A2 and A3: Key factors and their connections to the inventory model

Next, potential key factors were identified through PESTEL (filled-in checklist in supplementary material 1) in step A2 and connected to each other and the inventory parameters in step A3. The PESTEL was filled in by several team members separately and then discussed, leading to a common list. This list was discussed with two experts (one from the field of sustainable transport scenarios and one from the field of alternative fuels), which led to the addition of subsidies and climate change impact of conventional air traffic as potential key factors. The CLD was created by several members of the research team through phases of discussion, personal reflection and literature research. Afterwards, it was discussed with three experts (the above-mentioned plus an expert for bio-economy). The inclusion of more experts and stakeholders, ideally from each PESTEL domain, would be desirable for an actual case study, but resources were limited for this illustrative example.

Figure 4 shows a simplified version of the CLD and its links to the inventory models for BTJ. For a more elaborate CLD, connections to the PTJ inventory model and a detailed explanation of the connections, cf. supplementary material 1. Climate policy affects the foreground processes through its various connections to the technological progress of BTJ and PTJ. The technological progress affects the choice of technology options/production systems, which can be represented by different inventory models (connection [1a] in Fig. 4a, b). Similarly, it determines the efficiency of the foreground processes, i.e. the ratio of outputs to inputs or the demand for inputs ([1b] in Fig. 4a, b, [2b] in supplementary material 1). At the same time, climate policy reinforces the share of renewable technologies in inventory background processes for the production of electricity (connection [3]). Therefore, climate policy can be identified as a key factor influencing several inventory parameters ([1]–[3]). Moreover, consistency between the respective assumptions about foreground and background parameters I–III requires special attention in steps B and C. Furthermore, for BTJ, the necessary soil sustainment is a key factor. If the supply of surplus straw falls short of demand, additional measures may become necessary, e.g. soil fertilization for soil sustainment leading to changes within the LCA background processes of straw production (connection [4]). Consequently, climate policy (v) and straw surplus (vi) are included as key factors in Table 5 and marked with a frame in Fig. 4.

4.2.2 Step B: find future assumptions for each key factor and each relevant inventory parameter

As discovered in step A (cf. Table 5), the development of background processes for the production of electricity is connected to the development of foreground processes for BTJ and PTJ, since they all depend on climate policy (v). Ideally, we would have found an already existing set of explorative scenarios that covers the key factor climate policy and the inventory parameters of the electricity supply and technological progress that depend on it. Since such an ideal scenario could not be found, we only adopted assumptions about climate policy (v) and energy supply (III) directly from suitable scenarios (step B1). Next, we derived assumptions about the foreground processes for BTJ and PTJ (I, II) based on literature analysis and interviews with two technology experts for each technology (step B2). Likewise, assumptions about background data regarding future straw supply were derived for the background processes on straw production (IV) based on considerations on soil sustainment (vi). For all the parameters, cornerstone assumptions were chosen based on interviews with the four technology experts (distinctness-based selection step B3). Integrating more experts and utilizing more advanced methods (e.g. workshops or Delphi surveys) would be desirable for an actual case study, but resources were limited for this illustrative example. Assumptions about inventory parameters (I-IV) were quantified and incorporated into the inventory models. Assumptions about key factors (v, vi) were kept qualitative.

Step B1: adopting assumptions

Looking for future assumptions about climate policy (v) and the resulting supply with energy (III) in Germany in 2050, we did not find a set of explorative cornerstone scenarios, so we chose two separate scenarios, which could serve as cornerstones for possible developments (distinctness-based selection/step B3). Hence, we chose a future scenario describing an entirely renewable energy supply for Germany in 2050 developed by the German environmental agency (UBA 2014) for adopting a set of assumptions, which we named ‘green energy future’ for our purposes. In addition, we chose a scenario describing a future energy supply resulting from low ambitions for a green energy transition (Prognos and Ewi 2014), to adopt a set of assumptions called ‘business-as-usual energy future’. (Limitations to the suitability of both external scenarios for this pLCA study will not be discussed since it is only an illustrative example.) The future assumptions adopted are summarized in Table 6.

Step B2: deriving assumptions

In order to derive future assumptions about inventory parameters of the foreground processes (I & II), we screened the available literature, interviewed two experts on each technology and kept in mind the external influences discovered with the CLD in step A. Instead of dealing with all possible developments in each inventory model, we made low progress assumptions for each relevant inventory parameter in the low progress inventory, as well as high progress assumptions for each relevant inventory parameter in the high progress inventory (distinctness-based selection/step B3). The choices were made based on the expert interviews. An overview on the final, quantitative assumptions is given in Table 7 for BTJ and in supplementary material 1 for PTJ.

Regarding soil sustainment (vi), it is a generally accepted rule of thumb that 70–80% of the straw resulting as a by-product from cereal cultivation should be plowed back into the ground to sustain soil quality, while the remaining 20–30% can be used for other applications (Münch 2008; Kaltschmitt 1995). The straw that can be produced in accordance with this in Germany will probably not be sufficient to fulfil the German demand for jet-fuel (UBA 2014). Thus, a plausible assumption is that only surplus straw is used for BTJ, which implicitly limits the total amount that can be produced. Another possibility is to model the soil fertilization that becomes necessary for soil sustainment due to straw removal within the inventory model. Hence, we derived two cornerstone assumptions for future straw supply (IV), namely ‘No additional soil fertilization’ and ‘Additional soil fertilization’ within step B2.

4.2.3 Step C: combine assumptions into future scenarios

Step C1: consistency check

Consistency within assumptions on each key factor and within assumptions on each main inventory parameter: The directly adopted assumptions about climate policy and energy production summarized in ‘green energy future’ (III.ε + v.ε) and ‘business-as-usual energy future’ (III.ζ + v.ζ) are assumed to be internally consistent as they were adopted from the same external scenarios in both cases, and these external scenarios are assumed to be internally consistent (cf. Table 6).

Further, the assumptions derived for subordinate inventory parameters regarding technological progress for both BTJ and PTJ are assumed to be consistent within each main assumption I.α, I.β, II.γ, II.δ (cf. Table 7 and supplementary material 1). They were already chosen under the paradigm of high or low technological progress according to step B3, and potential inconsistencies were discussed within the project team and with the interviewed experts.

Consistency of assumptions between key factors and main inventory parameters: Fig. 5 shows the CCA for combining the assumptions on the main inventory parameters and underlying key factors. In a first step (Fig. 5a), we noted down the different assumptions for each main inventory parameter in columns and rows to get a matrix of all formally possible combinations. Duplicates were greyed out. There are 24 pairwise combinations of assumptions, and 16 formally possible combinations of assumptions on all the main inventory parameters. Next, we applied a pseudo-quantitative scale (and colour scale):

CCA for the illustrative case study: a Matrix for pairwise consistency check through a pseudo-quantitative scale and colour scale, Greek letters numerate the different assumptions made for inventory parameters I–IV and key factory v and vi. b Overview on the resulting consistent scenarios. It is possible to select all consistent scenarios (x, o, #, *), only the most consistent ones (x, o), or the most distinctive ones (#, *). Quantitative values for the assumptions for each scenario can be taken from Tables 6 and 7 and A2 in suppl. mat. 1 through the codes given in the last row

-

−3 (dark red) for strong negative correlation/inconsistency to − 1 (light red) for slight negative correlation/inconsistency

-

0 (white) for no correlation,

-

1 (light green) for slight positive correlation/consistency to 3 (dark green) for strong positive correlation/consistency

The CCA was done separately by several members of the research team and discussed within the research team. Afterwards, it was discussed with an external expert. Finally, the following considerations led to the assessment given in Fig. 5:

-

In the business-as-usual energy future, ambitions for decarbonization are generally low, so it is very unlikely that straw would be used for jet fuel to an extent that makes additional soil fertilization necessary (− 3 in Fig. 5a). The scenario behind the green energy future (UBA 2014) emphasizes that only surplus biomass should be used for energy production, thus, an extensive straw use making additional soil fertilization necessary can be seen as highly implausible in the green energy future, too (− 3). In turn, ‘no additional soil fertilization’ appears highly probable in both energy futures (+ 3). Since ‘additional soil fertilization’ is inconsistent with both energy futures, it can be excluded from further considerations.

-

There is a correlation between energy mix and technological progress since all parameters depend on climate policy (Fig. 4). The correlation is stronger for electricity-based fuel technologies (− 3 or + 3), as they only provide environmental advantages in combination with renewable electricity, while bio-based fuel is more independent of the energy mix, but still more plausibly successful due to R&D funding when climate policy is successful in general (− 2 or + 2). Since both technologies depend on climate policy, it is more plausible that one's technological improvement is successful if the other one’s is, too. Additionally, a combination of both technologies could result in the highest environmental advantage (cf. suppl. mat. 1, Sect. 2.2.3). On the other hand, BTJ and PTJ are competing technologies, so one's success might mean the other one’s decline. Due to these opposing interrelations, their correlation is overall rated neutral (0), which means that all combinations of assumptions need to be considered. (In contrast, a strong correlation (+ 3 or − 3) would lead to the exclusion of certain combinations of assumptions).

Thus, 12 combinations including a − 3 (dark red) pair of assumptions were excluded as inconsistent (Fig. 5a). The remaining four combinations (two very consistent and two sufficiently consistent scenarios) are summarized in Fig. 5b. All quantitative assumptions about inventory parameters can be traced back from the final row of Fig. 5b (assumptions for inventory models) to Tables 6 and 7 and Table A2 in supplementary material 1.

Step C2: distinctness-based selection of scenarios

To reduce the number of scenarios from four to two, it would be possible to select ‘x’ and ‘o’ as the general best and worst case (cf. Fig. 5b). Alternatively, one could select ‘#’ and ‘*’, delivering a sufficiently consistent framework to show each technology’s greatest possible advantages over the other (cf. Fig. 5b).

The presentation of the final LCA results of the illustrative example is not necessary for the understanding of the demonstrated procedure. It would also not be appropriate since too many simplifications (cf. supplementary material 1) had to be made for this very broad (yet illustrative) comparison.

5 Discussion

5.1 Evaluating the SIMPL approach with the requirements defined in development phase (a)

In the following, we will discuss to what extent the SIMPL approach in its current state fulfils the criteria set for its development (cf. Sect. 2.1.1) and what limitations it has.

5.1.1 Criterion (1): The approach should be applicable by small-scale LCA practitioners

-

1.1

The approach is understandable for LCA practitioners.

During the fourth course (the last course up to now) there were little to no confusion and application mistakes, which were very prevalent at the beginning of the courses. Thus, an acceptable status has been reached. However, the general concept and structure as well as the application of tools still demand unaccustomed thinking from the LCA practitioners, which can be seen as an application barrier.

-

1.2

The approach comes with manageable/scalable effort.

The SIMPL approach requires significant resources. The general set-up of integrating the four mandatory steps of future scenario development into the goal and scope and inventory phase is seen as essential and demands time and effort from the LCA practitioners. This time and effort is scalable, since specific choices are left to the practitioners, particularly the intensity of stakeholder interaction (with the exception that stakeholder interaction is mandatory in step B2). Thereby, the approach enables a thorough future scenario development process when the necessary resources are available, but it can still be used to avoid fundamental biases when applied in a rudimentary way due to limited time resources.

-

1.3

The approach can be readily integrated into the existing LCA framework as given by the ISO standard.

As displayed in Fig. 2, this is the case.

-

1.4

The approach offers choices so it can be adapted to the requirements of different research problems.

While the general set-up of integration of the four mandatory steps of future scenario development is not to be changed, the approach offers choices between different tools for each step. Practical tools are recommended in Sect. 3 for straightforward application, but alternatives are described in Sect. 2.2.6 for adaptability. A particular requirement discovered in the courses was the necessity to implement alternative developments of the entire product system instead of merely adapting quantitative parameters within the processes of the process chain. This option was integrated through the possibility of creating several inventory models for several scenarios and organizing the respective inventory parameters hierarchically.

-

1.5

The approach delivers practical benefits.

The following list of practical benefits, observed from case studies at the courses for LCA practitioners (cf. Sect. 2.1.2), provides evidence that this requirement is fulfilled:

-