Abstract

Purpose

Despite the industrial and scientific acceptance of life cycle assessment (LCA) to determine the environmental performance of products, none of the existing information on LCA provides explicit and clear recommendations on how to apply it when evaluating bio-based fertilizer (BBF) production systems. This situation affects the reliability of the results and causes confusion among practitioners, technology developers, and other stakeholders. Here, we first present the practitioners’ current LCA methodological choices and then discuss the extent to which LCA standards and guidelines are correctly applied. This review intends to identify LCA methodological application hotspots towards the definition of consensual LCA methodological choices for BBFs.

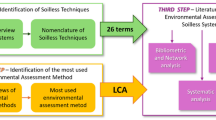

Method

LCA studies for BBF production systems were reviewed together with currently available LCA standards and guidelines to define which LCA methodological options are adopted by LCA practitioners in the first place, and then to determine whether these options are within the framework of existing LCA standards and guidelines. The results obtained are presented and discussed to finally debate and evidence the need for consensual LCA methodological choices for BBFs.

Results and discussion

A total of 48 documents were reviewed between LCA standards and guidelines (8) and studies (40). Most of the reviewed studies state that BBFs are the main product of the system (30), while the remaining ones state them as secondary products. Although the standards and guidelines statements are interrelated, it is challenging to follow their recommendations when applied in studies evaluating BBF production. For instance, LCA studies do not clearly define the studies’ promotor, motivation, and specific research question which leads to a lack of justification regarding the taken choice between attributional or consequential LCA. Therefore, the next LCA methodological choices such as functional unit, allocation criteria, biogenic carbon management, and end-of-life status of feedstock, are not justified.

Conclusion

It has been evidenced that the lack of consensual LCA methodological choices is affecting the proper use of the LCA by practitioners that aim to assess BBFs production systems. Thus, it shall be imperative for researchers and technology developers to work on the definition of common LCA methodological choices. This study has concluded that more guidance on the process of defining the study’s promotor, motivation, and specific research question is highly needed by practitioners since this would lead to the definition of common goals and scopes, first, and then, set the path to define standard LCA methodological choices.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Because of the constantly growing population, the demand for products and services has increased over the years. Because of this, several industries are pursuing the implementation of new sustainable production practices so they can cover this growing demand without harming the environment and with minimum consumption of supplies and non-renewable resources. The fertilizer industry pursues this goal too since it is well known for its high energy demand, reliance on scarce natural resources, and its high environmental impacts. Higher demand for agri-food products increases the consumption of fertilizers and thus, increases the depletion of non-renewable resources and the release of emissions to the ecosystem. Because of this, the fertilizer industry has been encouraged to implement more sustainable and circular economy production practices.

The importance of reaching more circular and sustainable fertilizer production systems was specifically underlined by the 2015 Circular Economy Action Plan (EC 2015) which set the basis for the development of the 2019 EU fertilizing products regulation (2019/1009) (EC 2019); whose application is mandatory for all EU member states from May 2022 onward. These new rules aim to facilitate the access of organic and waste-based fertilizers to the EU single market. The EU regulation divides fertilizing products into categories based on their Product Function Categories (PFC) that are subject to specific formulation, safety, and quality requirements such as limits for contaminants. Furthermore, the regulation defines that these PFC shall only consist of the component materials listed in the regulation lists of component materials categories (CMC) and thus comply with its requirements. The CMC requirements for compost are detailly presented in the supplementary material. These CMCs include, but are not limited to, virgin material substances and mixtures, fresh crop digestate, polymers (nutrient and other), and by-products which is a secondary product derived from a production process and it can be useful and converted to a usable product or it can be waste such as animal by-products including waste of animal origin that can be converted to a biofertilizer. Within the meaning of Directive 2008/98/EC lays down measures to protect the environment and human health by minimizing the generation of waste by reducing the overall impacts of resource use and improving the efficiency of such use, which are crucial for the transition to a circular economy (EC 2008). Thus, the regulation would open the door for the fertilizer industry to use bio-wastes which are capable of being decomposed by the action of biological processes (EPA 2019), as renewable nutrient sources.

In addition to the new EU fertilizer rules, the new circular economy action plan for a cleaner and more competitive Europe (EC 2020) also boosts the production of organic and waste-based fertilizers since it aims to ensure the sustainability of renewable bio-based materials. This new plan states the Commission’s desire to develop an Integrated Nutrient Management Plan to ensure a more sustainable application of nutrients and to stimulate the markets to recover nutrients. Furthermore, this document states that the commission will consider reviewing the current wastewater and sewage sludge directives with the end of evaluating natural nutrient removal techniques.

In this context, promoting the implementation and evaluation of technologies for recovering nutrients from biomass to produce fertilizers is a priority on the commission's agenda. In 2017, it was estimated that the EU-28 states generated 86 million tonnes of bio-waste, mainly food and garden waste (EEA 2020). Therefore, fertilizers wholly or partially derived from it have the potential to reduce Europe’s dependence on mineral total N since it is estimated that 46% of the total N applied to agricultural soil in Europe comes from mineral fertilizer (Duan et al. 2020).

The production of bio-based fertilizers (BBFs) could help the EU fertilizer industry to close the loop of the agro-food production systems and introduce to the EU single market more resource-efficient and more environmentally sustainable fertilizer products. Agricultural wastes (from crop production, livestock production, and slaughtering systems), food wastes (from food production and consumption systems), animal by-products (manure), and sewage sludge (from wastewater treatment systems) are biomass sources and CMCs from which nutrients (e.g., phosphorus and nitrogen) could be recovered and used to produce BBFs that fit the PFCs of the EU fertilizer regulation.

From an environmental perspective, the presence of BBFs in the EU market could decrease the depletion of the phosphate rock and diminish the use of the high-energy consuming processes, such as the Haber–Bosch process, to obtain ammonia. From an economic perspective, the creation of this new market where residual biomass will be seen as a raw material for agricultural purposes and not as a waste could bring further economic benefits and create qualified job opportunities in rural areas.

Although using biomass to produce bio-based products (fertilizers, chemicals, materials, etc.) and bioenergy (biofuels, power, and/or heat) towards a more circular and bio-based economy promises to enhance the sustainability of many production systems (Rogers et al. 2017), analytical tools and methods can help to verify if that is indeed the case. Life cycle assessment (LCA) provides a method to assess the production of bio-based products such as BBFs from an environmentally sustainable perspective, and it can be also used with other specific assessment techniques such as life cycle costing and risk assessments to evaluate different production alternatives.

LCA provides a clear framework to quantify the potential environmental impacts (benefits or burdens) related to processes, services, or products through their life cycle (Skowroñska and Filipek 2014). Thus, in the field of biorefining which is the synergetic processing of biomass into several marketable biobased products (food and feed ingredients, chemicals, materials, minerals, CO2) and bioenergy (fuels, power, heat) (ETIP 2009), LCA has become a popular approach to determine the environmental performance of this process into a large spectrum of bio-based products and energies through the sustainable operation of existing or new technologies referred as biorefineries (Axelsson et al. 2012).

As a reaction to the existing worldwide policies (e.g., the US Renewable Fuel Standard (EPA 2020) and the EU Renewable Energy Directive (EC 2018a), LCA studies have focused on assessing the biorefinery functionality of producing bioenergy and biofuels. In fact, most of the literature alludes to the environmental impacts of producing biofuels such as bioethanol, bio-oil, biogas, and methanol as primary/determinant products of the assessed biorefining process (Wiloso et al. 2012; Menten et al. 2013; Hjuler and Hansen 2018). However, despite the growing interest of markets and policymakers in other biorefinery product outputs such as BBF, there is still limited LCA information about the environmental impacts of its production. The latter since most of the studies consider the production of BBF as a secondary function of the biorefining process. Therefore, BBFs are mostly considered dependent products from biorefineries whose primary function is either (i) the production of fuels or energy, or (ii) the management of wastes. This has been evidenced by Lam et al. (2020) where only 7 out of 65 reviewed LCA studies considered nutrient recovery from sewage sludge as the primary function of the biorefining system; whereas the remaining 58 studies consider waste treatment as the main function of the assessed system. Therefore, BBF as another function of the biorefining process in addition to bioenergy and bioproducts manages wastes in a sustainable way and helps to achieve the circular economy goals.

The few existing LCA studies that consider the production of bio-based products as the primary function of the biorefinery focus on the production of bio-based chemicals such as the production of photodegradable 2,5-furan dicarboxylic acid (Novais et al. 2017), polyhydroxylalkonoates (Fernandez-Lopez et al. 2015), polybutylene succinate (Mohammadi et al. 2016), 2,3-butanediol (Ganrot et al. 2007), l-lactic acid and ethyl lactate (Martínez-Blanco et al. 2013a), and a polyol and bioresin (Martínez-Blanco et al. 2013b), which are not key raw materials for the fertilizer industry and do not promote the production and use of BBFs. Additionally, these studies mostly use oil crops, sugar-based and cellulosic feedstocks as main biomass sources overlooking the abundant availability of renewable biomass-related resources such as animal by-products like manure (Montazeri et al. 2016; Dunn 2019).

With the political priority of promoting the implementation and evaluation of technologies for recovering nutrients from biomass to produce BBFs, LCA studies focus on the biorefineries’ functionality of nutrient recovery to obtain BBFs as primary/determinant products. The objective of this work is therefore to discuss the application of LCA methodology when the production of BBF as a main product and co-product (Cradle-to-Gate).

Therefore, this work reviews, presents, and discusses information from existing LCA standards, guidelines, and studies regarding biomass biorefining to obtain BBFs. This review aims to contribute to the discussion regarding how to improve the consistency and comparability of BBFs’ LCA results towards the development of a common LCA guideline for BBFs. This is by revealing the existing methodological complexities and by providing useful insights for LCA practitioners involved in research, industry, and policymaking.

The different LCA methodological options to assess the environmental impacts due to the application of BBF to soil (gate-to-grave) have not been reviewed in this work since the literature (e.g., research studies, guidelines, standards, and emission models) is extensive and deserves a specific review work. In fact, future work should present and discuss the different LCA methodological decisions in the BBF application life cycle stage (e.g., nutrient release and GHG mission models) since the models used for the calculation of these application emissions affect the whole life cycle (cradle-to-grave) results of BBF (Harrison and Webb 2001; Egas et al. 2019; Walling and Vaneeckhaute 2020).

2 Definitions, methodologies, and standards

The framework under which the reviewed BBF LCA studies were carried out is presented next, along with key fertilizers and LCA definitions. A clear understanding of what the guidelines and standards mean will enable this paper to discuss and provide insightful recommendations towards an agreed LCA approach for BBFs.

2.1 Definitions

This study follows the EN 16760 standard (CEN 2015) definition of biomass: a “material of biological origin i.e., material produced by the growth of microorganisms, plants or animals.” Therefore, also in coherence with it and the EU fertilizers regulation (EC 2019), this study defines a BBF as a “fertilizer product derived from renewable biomass-related resources which purpose is to provide plants or mushrooms with nutrients or improve their nutrition efficiency.” BBFs are obtained from physical, chemical, and/or biological biorefining processes. This biorefining process treats the renewable biomass-related resource inputs, such as manure, into final easy-to-transport marketable fertilizing products that have a better nutrient composition than the raw input material.

According to its PFC, the EU fertilizer regulation refers to organic, inorganic (mineral), and organo-mineral fertilizing products that shall only be made of materials that comply with the requirements of the 11 listed CMCs. Thus, since there is not an explicit reference to bio-based fertilizing products in the PFC defined by the EU fertilizer regulation, the natural question is: To which PFC do BBFs belong? The regulation defines (i) organic fertilizer as one containing organic carbon and nutrients of solely biological origin (biomass); (ii) a mineral fertilizer as one releasing nutrients from the mineral origin; and (iii) organo-mineral fertilizers as a co-formulation of both (organic and mineral) since they might contain one or more materials from mineral and biological origin.

For instance, compost is a BBF that could be labelled and marketable as an organic (fully derived from biomass) fertilizing product according to the EU fertilizing regulation. The latter if it complies with the PFC requirements for solid organic fertilizers (Table 1) and the CMC requirements for compost (CMC 3 in Annex II, part I of the EU fertilizer regulation).

However, if any organic BBF is mixed with a non-organic CMC (virgin mineral nutrients, microorganism, polymers, etc.) to produce customized fertilizer formulations adapted to specific crop/soil they will become “Tailor-made fertilizers” (TMFs). Thus, under the EU regulation, a TMF could be labelled as organo-mineral (partially derived from biomass) fertilizer. The latter if it complies with the organo-mineral fertilizers PFC requirements (Table 1) and the CMC requirements for its organic and non-organic materials. The CMC and the other input materials for BBF related to any EU-regulated PFC shall not exceed the maximum limit values summarized in Table 1 for organic and organo-mineral fertilizers. The review of TMF LCA studies is out of the scope of this work.

2.2 LCA method

Life cycle assessment (LCA) is a scientifically accepted methodology standardized by the ISO 14040 and 14044 standards used to assess the environmental impacts (benefits or burdens) of a product or service life cycle (ISO 2006a). A complete LCA has a “cradle-to-grave” approach which includes each stage of the product’s life cycle, from the exploitation of raw materials, through the stages of production and use, until the waste management stage. LCA follows four well-defined steps (i) goal and scope definition, where the functional unit (FU) and the system boundaries are chosen; (ii) life cycle inventory analysis, where the quantifiable inputs and outputs are analysed and their sources are identified; (iii) life cycle impact assessment; where the life cycle inventory data is transformed into potential environmental impacts; and finally (iv) interpretation, where the results are verified, and conclusions are driven.

2.3 Existing standards and guidelines

Table 2 presents the reviewed standards and guidelines. The ISO 14040 and 14044 standards are the main LCA methodological references for studies and lifecycle thinking and from them, many specific application guidelines for specific product categories have been derived and validated such as the European EN 16760 standard (Bio-based products—life cycle assessment). The ILCD handbook and the official EU Product Environmental Footprint (PEF) guide. From them only the, EN 16760 standard provides more specific LCA guidance to assess bio-based products for industrial applications, excluding food, feed, and energy; and it focuses on how to handle methodological specificities of the bio-based part of the product while the ILCD handbook and the PEF guideline offer general and practical guidance when dealing with LCA methodological issues and choices. However, through specific PEF guidelines, known as Product Environmental Footprint Category Rules (PEFCR), the PEF aims to generate and communicate comparable environmental footprint results among common product categories which are categorized products and services in 21 groups such as products of agriculture, forestry and fishing, water supply services, and education services (CAP 2008). Currently, a PEFCR for bio-based products such as BBFs does not exist.

Due to the need for specialized and official guidance to environmentally assess bio-based products in the PEF Framework, the JRC has published different specialized reports. These reports do not constitute a formal PEFCR, but they do provide important insights about how to implement the PEF in the biorefining process to obtain bio-based products. One of these reports is the JRCPlastics Report which considers biomass as an alternative feedstock to produce bio-based plastics. This report can be used by LCA practitioners to overcome some methodological issues when assessing the production of BBFs since it gives LCA advice when using alternative feedstock for plastics production.

The International Environmental Public Declaration (EPD) System which is based on the full life-cycle approach based on ISO standards 14040, 14041, 14042, and 14043 is another international initiative based on the LCA ISO standards that aims to guide industries regarding how to determine and communicate the environmental impacts of their goods or services. These standards are labelled to ISO 14025 that disclose the life cycle environmental performance of products using pre-determined parameters (European Commission 2001). These are not PCRs for BBFs in the EPD system but, PCRs for basic organic chemicals (PCRBOch) and for mineral and chemical fertilizers (PCRMChF) are available. Both the PCRBOch and the PCRMChF could also be used to guide LCA studies of BBFs since the biorefining process could generate BBFs that, after the addition of supplements, could become tailored-made fertilizers.

None of the presented LCA standards and guidelines provide specific information for BBFs. Nonetheless, their information is the methodological foundation of many research papers and industrial reports that aim to determine the environmental performance of the biorefining process whose main function is to produce BBF.

3 Life cycle assessment studies of bio-based fertilizers

3.1 Selection and overview of the reviewed studies

Literature published until March 2022 has been searched via google scholar. To identify the most relevant literature a parallel 2-step search strategy was carried out. In one direction, the search focussed on identifying “life cycle analysis of nutrient recovery” and in a second direction on identifying “life cycle analysis of fertilizers.” From the search results, only studies that have used biomass as feedstock have been reviewed and used in this document. As result, 40 studies were selected for this review since they present LCA outcomes of biorefining processes that use biomass to generate BBF as a primary or secondary output.

3.1.1 LCA methodological practices for BBF as primary products

Thirty out of the 40 reviewed studies focus on the biorefinery functionality on the recovery of nutrients and clearly state that a BBF is the primary product of its biorefining process. Relevant information about these 30 reviewed studies is summarised in Table 3. As shown, 11 out of 30 studies have assessed biorefineries with a configuration of multiple technologies to produce BBFs; however, the remaining studies have assessed single gasification and composting technologies (5 studies each) and pyrolysis (3 studies) (Fig. 1A) to obtain BBFs such as struvite (10 studies), biochar (6 studies), compost (5 studies) and N compounds (3 studies) and Digestate (1 study) (Fig. 1C) from feedstocks like wastewater (9 studies), manure (6 studies), and agricultural residues (5 studies) (Fig. 1B).

The methodological recommendations stated in the LCA standards and guidelines presented in Sect. 2 are discussed and contrasted together with the LCA methodological practices followed by the 30 LCA studies that have a BBF as the primary product (Table 3).

Goal and scope definition step

The goal definition of an LCA describes the study’s context and its purpose in detail, A well-defined goal is crucial to determine the study’s scope, boundaries, and FU. Properly defining the goal of the study has a clear repercussion on what is, probably, the most important LCA methodological choice: Shall the study follow an attributional or consequential LCA approach? Selecting either approach, attributional or consequential, will have a deep repercussion on how the practitioner shall develop the life cycle inventory, determine the impact assessment, and interpret the results.

The attributional LCA (ALCA) approach, also referred to as a retrospective or descriptive approach, describes the potential environmental impacts that can be attributed to the studied system over its life cycle. It analyses an average operation (e.g., on an annual basis) and allows allocation when dealing with multifunctional systems. On the other hand, the consequential LCA (CLCA) approach, referred to as a prospective or market-oriented approach, identifies the potential environmental impacts that a decision made in the studied system has over itself and over other processes and systems outside of the defined boundaries (in the market). It analyses changes or constraints in operation (e.g., changes in demand) and it avoids allocation when dealing with multifunctional systems.

The ISO standards do not make an explicit reference to either Attributional (ALCA) or consequential (CLCA) LCA approaches. The ILCD handbook provides guidance regarding the use of either ALCA or CLCA methodological approaches. This handbook links possible “goal situations” depending on the study’s goal and applications to either ALCA or CLCA.

One of the goal situations when the ILCD suggests the use of ALCA is when the goal of the study is related to a micro-level decision such as the development of PCR, benchmarking, and eco-design of products. Thus, under strict ILCD compliance, the PEF guide and PCRs shall clearly state their compliance with the ALCA approach. The latter since their goal is to guide practitioners to obtain reliable LCA results that can be later used for benchmarking and communication purposes. The PEF guidelines and the developed PEFCRs are largely based on the ILCD handbook recommendations; however, they lack a clear statement communicating that they follow an ALCA approach. On the other hand, the PCRs developed under the international EPD system explicitly state that they follow an ALCA approach.

Currently, the debate regarding which LCA approach (attributional or consequential) shall be followed is still going and each position is being argued by several authors (Weidema et al. 2018, 2019; Brander et al. 2019). Nonetheless, it was found that the goal of 26 out of the 30 reviewed studies was to define the environmental performance of biorefining technologies to the generation of BBF. However, only 5 of these 26 studies clearly state that they follow an ALCA approach as required by the ISO standards. The goal of the remaining 3 studies was to define how the decision of using the assessed biorefinery to produce BBFs will environmentally affect its production system and the fertilizers market. Thus, these three studies clearly state that they follow a CLCA approach.

Regarding the definition of the system boundary, the reviewed studies showed that the preferred system boundary is Cradle-to-Gate (20 out of 30 studies) and it is regardless of the used feedstock, FU, and produced BBF (Fig. 2). The different system boundaries and the wide variety of goals defined in the reviewed studies complicate the direct comparison of the environmental performance of finished and intermediate BBFs products and thus, of their production chain. Despite the legitimacy of setting a different objective and scope between studies, it is necessary to be transparent and communicate as best as possible what these are and the arguments leading to their definition. Clear communication of what is and is not included within the boundaries of the system would reduce misinterpretation and improve discussion and comparison of results across studies.

Functional unit

The FU should describe the main function of the assessed system and it should facilitate the comparability and interpretation of the results among systems with the same functionality (Ahlgren et al. 2013). Neither the ISO 14040 nor ISO 14044 standard, state-specific requirements for the definition of the FU as longest it is consistent with the study`s goal. However, the ILCD handbook, PEF guide, and the JRCPlastic require the FU to comply with four common features (“What,” “How much,” “How well,” and “How long”).

The EN 16760 standard acknowledges that bio-based products, such as BBF, could be intermediate and have many functions, such as the formulation of TMF. Therefore, it recommends the use of a weight or volume-based FU to which all other input and output flows, needed to fulfil the assessed system function, quantitatively relate. On contrary, the PCRs for basic organic chemicals and mineral or chemical fertilizers explicitly state that the FU of the LCA study shall be “1000 kg of packed product ready for delivery.”

Most of the reviewed studies have used a mass-based FU to report the LCA outcomes despite the BBF produced (Fig. 3). Additionally, all the 18 studies that have set a Cradle-to-Gate system boundary have used a mass-based FU to report the LCA outcomes. This mass-based FU refers to outputs of the system such as the mass of nutrients (N or P) in the obtained BBF (10 studies) or to the total mass (wet or dry) of the final product obtained (5 studies). This mass-based FU also refers to inputs of the system such as the mass (wet or dry) of consumed feedstock (9 studies). None of the reviewed studies are fully compliant with the FU requirements stated in the ILCD handbook, the PEF guides the JRCPlastic report since the defined FU only covers two (“What” and “How much”) of the four required FU features.

The clearest example of inconsistencies among FU defined in the reviewed LCA studies of common BBF is during the definition of “How much.” Struhs et al. (2020) and Hamedani et al. (2019) reported the environmental impacts of biochar production from forest residue and manure via the pyrolysis process. These authors have chosen two different functional units (per mass of product and per mass of feedstock) and this makes difficult the comparison of the results. Hamedani et al. report GWP outcomes of − 2.9 and − 0.49 kg of CO2 eq per 1 kg of biochar from willow and pig manure respectively. While Struhs et al. report GWP outcomes of 172 kg CO2 eq to produce biochar from 1 kg manure as feedstock.

Another example of incoherent FU among LCA studies of common products is for struvite and biostimulant production. Nemethy (2016) uses a FU based on the mass of nutrients (P) in the struvite and reports − 20.1 kg CO2 eq of GWP per 1 kg of P content in struvite while Temizel-Sekeryan et al. (2021) use a FU based on the final product mass and report 7.08 kg CO2 eq of GWP per 1 kg of produced struvite. Regarding the biostimulant products, the impacts reported by Vijay Anand et al. (2018) and Colantoni et al. (2017) are incomparable due to the usage of different functional units (per volume and mass of product respectively), technologies (expulsion and hydrolysis respectively), and feedstocks (algae and agricultural residues respectively) their results are incomparable. The examples above have evidenced that reaching common criteria for the definition of FU should be a priority among the LCA community. The latter since the use of different FU among LCA studies for similar BBF affects their direct comparison, limits the discussion of these studies, and affects a proper business-to-business (B2B) and business-to-consumer (B2C) communication of the LCA results, which ultimately affects the reliability of them among stakeholders.

Life cycle inventory

The life cycle inventory (LCI) step involves the identification, collection, calculation, and quantification of the physical inputs (raw materials, energy, and auxiliary materials) and output (co-products and wastes) flows related to the FU produced by the assessed foreground system. Due to its relevance to LCA, several studies have underlined critical issues when developing the LCI for bio-based products and these concerns are applicable to BBFs. The studies have focussed their discussion on (i) the accounting of biogenic carbon and (ii) the environmental burdens allocation procedures in the biorefinery outputs and in the production of biomass feedstock.

Biogenic carbon accounting

When accounting for the BBFs’ biogenic carbon content, two approaches can be followed (Shen et al. 2010; Helin et al. 2013; Wiloso et al. 2016). The first approach excludes biogenic carbon emissions and uptakes from the LCI to assume biogenic carbon neutrality (Johnson 2009; Liska et al. 2014). It does not account for biogenic carbon equivalent uptakes embedded in the biomass feedstock (Ceq-0), biogenic carbon equivalent emissions from the BBF production (Ceq-2) stage, and biogenic carbon equivalent emissions due to the BBF application/End-of-Life (Ceq-4).

The second approach accounts for biogenic carbon equivalent emissions (Ceq-2 and Ceq-4) and uptakes (Ceq-0) in the LCI and therefore specific characterization factors for biogenic emissions in the LCIA step shall be used to ensure biogenic carbon neutrality (Rabl et al. 2007; Kendall et al. 2009; Bishop et al. 2021). However, this approach relies on the data availability and accuracy for biogenic carbon emissions and uptakes at all life cycle stages. Since it is often difficult to close the biogenic carbon balance, this approach is likely to lead to an inaccurate calculation of the biogenic carbon emissions that would inevitably affect the total carbon equivalent balance calculations in a Cradle-to-Gate (Ceq-2 + Ceq-3-Ceq-0) and Cradle-to-Grave (Ceq-2 + Ceq-4 + Ceq-3-Ceq-0) system assessment as shown in Fig. 4. An inaccurate total carbon balance will affect the reported GWP for the BBFs.

The ISO 14040 and 14044 do not provide clear methodological recommendations about biogenic carbon accounting but ensuring a carbon balanced system shall be a priority of the LCA practitioners. None of the 30 reviewed studies clearly indicate how they have treated biogenic carbon emissions and uptakes in their studies.

Allocation within the biorefinery outputs

Allocation defines how the LCI input and output flows are partitioned in multifunctional systems between the primary product and the co-products when following the ALCA approach. All the reviewed standards suggest avoiding allocation (based on biophysical or other relationships) between the systems’ primary products and coproducts whenever it is possible. Instead, they recommend subdividing the system or to expand its boundaries. The system expansion approach is also known as substitution (Guinée 2002). The PCR for chemicals fertilizers only allow biophysical allocation if dividing the system is not possible.

A total of 10 studies assessed monofunctional systems that did not require the use of allocation. These studies report LCA results for BBF such as compost, biochar, and struvite. The remaining 20 studies assessed multifunctional systems, 3 of these studies followed a CLCA approach and avoided allocation by expanding their system boundaries until reaching a greater economic system. For instance, Ahlgren et al. (2012) expanded the system to determine the impacts of producing N compounds as the primary product from a system that also generated heat, electricity, hydrogen, oxygen, energy-rich gas as coproducts. Sharara et al. (2019) biorefinery’s primary product was biochar and obtained syngas as a coproduct. Finally, Igos et al. (2017) reported LCA results for struvite while also producing ammonium sulphate and treated wastewater as products.

Among 20 multifunctional studies, the remaining studies follow an ALCA approach but only 10 of them clearly state and provide details about the method used to avoid or implement allocation; 4 studies applied economic allocation, 5 expanded their system and 1 study subdivided it. None of these 4 studies provide data to derive the applied economic allocation factors and it is not clear which specific systems were used to replace the coproducts (energy or biofuels) when the studies expanded the system to avoid allocation.

Allocation in the production of feedstock

The biomass feedstock used in BBFs’ production systems originates in an upstream multifunctional system and it could be a product, co-product, or waste flow. If it is a product or coproduct, the biomass feedstock will enter the foreground system (biorefinery) with environmental burdens assigned by its system of origin thus, the user of these flows will account for a share of the feedstock production environmental burdens. In this case, according to EPD, physical or economical allocation will be required if material or energy data cannot be measured separately for the product.

However, when biomass feedstock is considered waste that could be recycled/reused, the EPD and the PEF follow two approaches.

On one hand, the EPD (2021) considers that a reusable waste flow has fully reached its end-of-waste state before the biorefinery and considers it as a secondary material/fuel free of environmental burdens (Fig. 5A). Therefore, the environmental burdens of producing it are carried by the waste producer system while the burdens of further processing this secondary material/fuel are attributed to the product system using it. Neither the producer nor user of the waste as secondary material/fuel is allowed to account for credits from system expansion in the international EPD system. This modelling approach is to “make information traceable, documented, and possible to verify, and to support the concept of modularity” as stated in the General Program Instructions for the International EPD system (EPD 2021). In contrast to the EPD, the PEF end-of-life modelling approach implies that the waste stream has not fully reached its end-of-waste state before the biorefinery. Therefore, through the application of the PEF Circular Footprint Formula the biorefinery environmental burdens and possible credits are shared between the producer and the user of the reusable/recyclable waste flow (secondary material/fuel) through its “A” factor (Fig. 5B). Furthermore, the producer and user of the waste as secondary material/fuel are allowed to account for credits when using the PEF Circular Footprint Formula. The two opposite approaches followed by the EPD and the PEF shows the need of a clear consensual approach regarding how to calculate and include the environmental loads of using reusable/recyclable waste flows as biomass feedstocks in BBF production system.

None of the reviewed studies clearly state its compliance with either the EPD or the PEF but out of 30 reviewed studies in which BBFs are the primary product, 20 studies do not report environmental burdens due to feedstock production. This shows that most of the studies have assumed that the feedstock is a waste that has reached its end-of-waste state before the biorefinery; therefore, the BBF LCA results only account for the feedstock processing burdens in the biorefinery. The remaining 10 review studies did not consider biomass feedstock as waste and did report environmental burdens due to its production. However, only 3 of these 10 studies clearly stated the allocation criterion used in the upstream feedstock production system. Through economic allocation, Ahlgren et al. (2008, 2012) assign environmental burdens to the agricultural and forest residues used to produce N compounds through gasification. Pradel and Aissani (2019) use sewage sludge to produce P compounds in a biological acidification system and it assigns environmental burdens to the feedstock inputs through an allocation factor based on product- and process-related parameters (Pradel et al. 2018).

Life cycle impact assessment

The life cycle impact assessment (LCIA) step is where the LCI is translated into environmental impact indicators per produced FU. The LCIA methods provide a more complete environmental product profile since they group and report different environmental impacts. Some of these LCIA methods are CML (Guinée 2002), PEF (EC 2018b), ILCD (EC 2012), or ReCiPe (Huijbregts et al. 2017). Table 4 presents the LCIA methods used on the reviewed bio-based fertilizer LCA studies the detail of this data is presented in the supplementary material.

The CML LCIA method in its different versions (i.e., CML-IA baseline and no baseline, CML 2000, and CML 2001) is used the most (9 studies). Other LCIA methods that are used are the ReCiPe (v2008 and v2016) endpoint and midpoint and the TRACI method (v2 and v2.1). The IPCC guideline is not an LCIA method, and it exclusively reports GWP; however, some studies use it as a reference without specifying any other method (5 studies). Only one study (Avadí 2020) used the LCIA method proposed by the International Life Cycle Data System (ILCD) whose goal is to provide greater consistency and quality assurance when applying LCA.

All the studies followed the midpoint approach; however, in 2 of the cases, one for producing biochar from manure and one for obtaining struvite from wastewater both midpoint and endpoint approaches are used.

Figure 6 presents the impact categories and Table 5 shows the total environmental impacts that are reported by the reviewed LCA studies. All the reviewed studies report GWP however, none of them differentiate among GWP due to fossil, biogenic, land use, or land use change. Other impact categories that are commonly reported by the studies are eutrophication (EP), acidification (AP), and human ecotoxicity (HTP). Some environmental impact categories that are not widely addressed are water use (Wuse) and water resource depletion (W-RD). In fact, Wuse is reported by Temizel-Sekeryan et al. (2021) who study producing Struvite from manure via precipitation, and Sharara et al. (2019) who used the TRACI and IMPACT World + methods for producing biochar from manure via gasification. Colantoni et al. (2017) also reported Wuse outcomes for producing biostimulants from agricultural residues via the hydrolysis process but it did not state the use of any specific LCIA method. The study by Vijay Anand et al. (2018) for producing biostimulants from algae by expulsion is the only study reporting W-RD since it is also the only study using the ILCD method. Land use, photochemical ozone formation, and smog are reported in only one case.

The environmental impacts of the different case studies are presented in detail in the supplementary material. Some of the studies are not included in this supplementary table due to the lack of reporting the impacts or reporting them in percentage. Among different impacts which are reported, the Environmental Footprint (EF) V.3 method impacts are chosen to present in this supplementary table. It should be mentioned most of the cases are not comparable due to the usage of different technologies, different functional units, or different feedstocks.

Comparable LCIA results from the reviewed BBF studies to produce 1 kg of N compounds from forest residues by gasification technology and from different organic residues are available for 3 reviewed studies. The highest GWP outcome is reported by Gilbert et al. (2014) which is 0.67 kg of CO2 eq and the lowest is 0.004 kg of CO2 eq is reported by Ahlgren et al. (2008). Eutrophication is only studied by Ahlgren et al.

Other comparable LCIA results are the ones given by Wu et al. (2013) and Sharara et al. (2019) that assessed the production of biochar through gasification technology and reported the impacts per 1 tone of feedstock (manure). They report 23.4 kg of CO2 eq and − 5.87 kg of CO2 eq of GWP respectively. The net negative value reported by Sharara et al. is due to avoid GHG emissions by syngas combustion, instead of natural gas.

Finally, Styles et al. (2018) report LCIA results per 1 m3 of liquid digestate. Styles et al. comparer the impacts of conventionally managing liquid digestate from food waste against the production and use of digestate biofertilizer (DBF) extracted from liquid digestate. According to the results of this study, DBF generates less environmental impact. However, under the worst-case assumptions, DBF extraction could increase global warming and cumulative energy demand.

3.1.2 LCA studies where BBF are secondary products

A total of 10 reviewed studies focusses the biorefinery functionality as a waste management process (2 studies) or as bioenergy and biochemicals production process (7 studies), and thus, their primary product is not a BBF (Table 6). Because of the latter, these studies do not provide further information, such as results and LCA methodological choices, regarding the co-produced BBF. Despite assessing multifunctional systems, only 3 studies clearly state the allocation criterion used in the assessment and thus, only from them, it could be possible to derive the emission burdens related to the BBF (secondary products). Only one of these studies explicitly states that it follows an attributional LCA (ALCA) as the main assessment approach.

These 10 reviewed studies evidence the lack of consensus regarding the definition of the system boundaries and functional units when assessing multifunctional biorefineries. As shown in Table 6 and Fig. 7A, even when assessing the production of common primary products such as bioenergy through the bio refinement of common feedstocks such as lignocellulosic and microalgal biomass, there is not a clear trend regarding the use of a cradle-to-gate or a cradle-to-grave approach.

Regarding the FU definition, most of the LCA studies assessing bioenergy production prefer to use a FU associated with the mass of feedstock entering the biorefinery and not a FU related to the energy production (Fig. 8). In fact, only one of the assessed studies that produce bioenergy uses an energy-related FU. The studies that assess the treatment of wastes prefer to use a Cradle-to-Grave approach and a FU associated with the mass of feedstock entering the waste management system.

Regarding the reported environmental impacts (Fig. 6), Global Warming Potential (GWP) is reported by all 10 studies followed by eutrophication and acidification which are reported by 7 studies and human ecotoxicity which is reported by 5 studies.

The results of the environmental impacts of the mentioned case studies which reported their environmental impacts are presented in detail in the supplementary material. As they use different technologies, different feedstock, and different functional units, the results are not comparable.

Among the cases whose main product is bioenergy (6 studies), only 3 cases indicated their LCIA method. Fiorentino et al. (2014) used CML 2001 to assess the impacts of producing biodiesel as a primary product through the Biofine process from Brassica carinata biomass per ha per year. The GWP is reported 499.2 kg CO2 eq, AP kg SO2 eq, AD 4.9 kg Sb eq, POP 0.1 kg C2H4 eq, and FEU 1.82 kg P eq.

Ubando et al. (2020) reported the GWP of producing torrefied microalgal biomass (TMB) as biofuel through the torrefaction process from microalgae. In this study, the ReCiPe 2016 LCIA method is used. GWP of the Open Pool cultivation system and closed-type photobioreactor are the same (0.13 kg CO2 eq/ kg of TMB).

Heller et al. (2003) present the impacts of the application of sewage sludge biosolids fertilizer which are produced from willow biomass crops per hectare in two different locations (Syracuse and Little Valley). Tools for Environmental Analysis and Management have been used as the LCIA method. The results show GPW is between 8.5 and 9 Mg CO2 eq/ ha, Air acidification is between 115.2 and 306.1 kg SO2 eq/ ha and FEU reported 198.5 kg P eq/ ha in 1 case and 71.8 kg P eq/ ha for another case.

Those studies that focus on biorefinery functionality as waste management have used different technologies, different FU, and different LCIA methodologies. Kim et al. (2017) studied the environmental and economic impacts of the fertilizer drawn forward osmosis (FDFO) and nanofiltration (NF) hybrid system using microfiltration or ultrafiltration (UF) as a pre-treatment process. The results showed that the FDFO-N hybrid system using thin film composite forward osmosis (TFC) FO membrane has less environmental impact than conventional reverse osmosis hybrid systems due to lower consumption of energy and cleaning chemicals. However, they only present the results of impacts as a relative contribution percentage.

Żygadło and Dębicka (2016) reported presents the percentage of water and air emissions of treating mix residues in 6 impact assessment categories through Mechanical–biological treatment technology. The result of this study shows that analyzed mechanical–biological treatment plant does not have a negative impact on the environment.

Bernstad and La Cour (2012) summarize the GWP results of 25 case studies treating food wastes. The results show both absolute values and relative ranking of compared treatment alternatives differ largely in relation to their impact on global warming potential.

4 Towards consensual LCA methodology for bio-based fertilizers

Without any doubt LCA is a well-established method to track the environmental impacts of a product’s life cycle; however, there is a need of establishing standard procedures and common LCA methodological choices for BBFs to answer common research questions with reliable and comparable results. The formulation of common research questions among LCA studies for BBFs is imperative since it would lead to the definition of common goals and scopes and thus, set the path to define standard LCA methodological choices to define common FU, system boundaries, allocation procedures, development of LCI and LCIA methods. Thus, a consensual LCA methodology shall first focus on the definition of a common research question that allows different actors to move towards the production of sustainable fertilizing products that use biomass as raw materials to develop a greener economy. As shown in Table 7, depending on the promotor and its motivation to conduct a BBFs LCA study, many different research questions could arise however, as evidenced by this study only two LCA approaches, ALCA or CLCA, are capable to answer the possible questions.

As shown by the reviewed studies, LCA practitioners are more likely to use ALCA to answer the questions such as “What is the environmental performance of producing BBFs in a specific system?” while CLCA is used to answer questions like “How is the environmental performance of the agricultural sector will be affected due to an increment on the use of BBFs and a reduction on the use of mineral fertilizers?” Both questions refer to the same BBF but, the answers obtained will be different and yet complement each other as they will give important environmental information regarding the production and consumption of BBFs to reach a greener economy. Because of the importance of using ALCA and CLCA appropriately, administrations should clearly state which, how, and when each of these two approaches will be used to assess BBF, and once they do so, LCA practitioners should assume their responsibility to clearly indicate in their reports and research studies which LCA approach they have followed and why.

In a European context, a coordinated and coherent application of LCA by clear ALCA and CLCA guidelines would allow the EU to reach the goals of the Circular Economy Action plan since robust, reliable, and comparable LCA results will allow the production of climate-neutral, resource-efficient, and competitive BBFs with a highly competitive environmental footprint. In fact, in line with the Sustainable Development Goals and as part of the review of Directive 2008/98/EC, a consensual LCA framework for BBFs, that specifies when and how to apply ALCA or CLCA, would help to demonstrate economic actors, producers, and consumers that technologies to refine biomass into BBFs are efficient tools to reduce food and agricultural wastes and produce sustainable fertilizing products. Furthermore, a clear guide to quantifying and demonstrating the environmental performance of nutrient recovery from wastes to produce BBFs would encourage the market to implement these sustainable nutrient recovery technologies and a more responsible and sustainable application of nutrients to the soil; goals that are aligned with the ambitions of the future EC Integrated Nutrient Management Plan.

5 Conclusions

A total of 8 LCA standards that could be used to assess BBFs were reviewed together with 40 LCA studies that assess the production of BBFs as primary (30 studies) or secondary (10 studies) products. The 40 LCA studies that assess the production of BBFs as primary products mostly used wastewater, manure, and agricultural residues as a biomass source. Common general recommendations and LCA practices were founded among these standards; however, despite claiming to be related to each other, it is challenging to follow their recommendations when aiming to assess BBFs. This disabled a coherent and harmonic implementation of LCA among practitioners and discourage the use of LCA among stakeholders to determine and communicate the environmental performance of BBFs.

The lack of a standardized LCA guide to assessing BBFs and obtaining robust, reliable, and comparable results was evidenced when reviewing the LCA studies. For instance, a total of seven different functional units were used to report the results of studies that have implemented either cradle-to-gate, cradle-to-grave, or gate-to-gate system boundaries. It was also identified a preference towards ALCA when assessing BBFs among practitioners since 26 out of 30 studies preferred this approach. However, only 4 studies clearly stated the application of the ALCA approach. When dealing with multifunctional systems economic allocation and system expansion to avoid allocation were the most used choices by practitioners.

Most of the studies (19 out of 30) considered the biomass feedstock as a waste flow that has fully reached its end-of-waste state before the biorefinery and thus the environmental burdens of producing it are carried by the waste producer system and no burdens are assigned to the BBF production system. The remaining 10 studies do assign environmental burdens to feedstock production since feedstock is either considered as a co-product flow or as a waste that was not yet reached its end-of-waste state when arriving at the biorefinery. Nonetheless, only 3 out of these 10 studies properly indicate the applied allocation criterion for the upstream feedstock production system.

The lack of guidance has led practitioners to report results for 16 different environmental impact categories which are presented in the studies in various combinations. GWP is the only impact category that is reported by all the studies however, the results cannot be compared since the studies follow 9 different LCIA methods which for instance implement different versions of IPCC characterization factors to calculate GWP. This is in addition to the uncommon LCA methodological choices among studies when either applying the ALCA or CLCA approaches. The environmental impacts are also incomparable due to the differences in used technologies, FU, and LCIA methodologies.

Abbreviations

- AD:

-

Abiotic depletion

- AP:

-

Acidification

- ALCA:

-

Attributional LCA

- ALO:

-

Agricultural land occupation

- BBF:

-

Bio-based fertilizers

- CED:

-

Cumulative energy demand

- CFU:

-

Colony-forming unit

- CLCA:

-

Consequential LCA

- CMC:

-

Component materials categories

- CP:

-

Carcinogenic

- DBF:

-

Digestate biofertilizer

- EC:

-

European Commission

- EP:

-

Eutrophication

- EPA:

-

United States Environmental Protection Agency

- EPD:

-

Environmental Product Declaration

- ETP:

-

Eco-toxicity

- FAETP:

-

Fresh water ecotoxicity potential

- FDFO:

-

Fertilizer drawn forward osmosis

- FEU:

-

Freshwater eutrophication

- F-RD:

-

Fossil resource depletion

- FU:

-

Functional unit

- GWP:

-

Global warming potential

- HTP:

-

Human ecotoxicity

- ILCD:

-

International Life Cycle Data system

- IR:

-

Ionising radiation

- ISO:

-

International Organisation for Standardisation

- JRC:

-

Joint Research Centre

- LU:

-

Land use/change

- LCA:

-

Life cycle assessment

- LCI:

-

Life cycle inventory

- LCIA:

-

Life cycle impact assessment

- MECO:

-

Marine ecotoxicity

- MEU:

-

Marine eutrophication

- MBT:

-

Mechanical-biological treatment

- M-RD:

-

Metal resource depletion

- NF:

-

Nanofiltration

- NCP:

-

Non-carcinogenic

- NLT:

-

Natural land transformation

- ODP:

-

Ozone depletion

- PFC:

-

Product function categories

- PEF:

-

Product environmental footprint

- PEFCR:

-

Product environmental footprint category rules

- PFeU:

-

Fossil energy use

- PCR:

-

Product category rules

- PMF:

-

Particular matter formation

- POCP:

-

Photochemical ozone formation

- POP:

-

Photochemical oxidation potential

- PPP:

-

Polluter pays principle

- RP:

-

Respiratory effects

- SM:

-

Smog

- TECO:

-

Terrestrial ecotoxicity

- TETP:

-

Terrestrial ecotoxicity potential

- TMB:

-

Torrefied microalgal biomass

- TMF:

-

Tailor-made fertilizers

- ULO:

-

Urban land occupation

- W-RD:

-

Water resource depletion

- Wuse :

-

Water use

References

Ahlgren S, Baky A, Bernesson S et al (2008) Ammonium nitrate fertiliser production based on biomass – Environmental effects from a life cycle perspective. Bioresour Technol 99:8034–8041. https://doi.org/10.1016/J.BIORTECH.2008.03.041

Ahlgren S, Baky A, Bernesson S et al (2012) Consequential life cycle assessment of nitrogen fertilisers based on biomass – a Swedish perspective. Insciences J 80–101. https://doi.org/10.5640/INSC.020480

Ahlgren S, Björklund A, Ekman A et al (2013) LCA of biorefinieries-identification of key issues and methodological recommendations. Report No 2013:25, f3 The Swedish Knowledge Centre for Renewable Transportation Fuels, Sweden. Available at www.f3centre.se

Amann A, Zoboli O, Krampe J et al (2018) Environmental impacts of phosphorus recovery from municipal wastewater. Resour Conserv Recycl 130:127–139. https://doi.org/10.1016/j.resconrec.2017.11.002

Avadí A (2020) Screening LCA of French organic amendments and fertilisers. Int J Life Cycle Assess 25:698–718. https://doi.org/10.1007/S11367-020-01732-W

Axelsson L, Franzén M, Ostwald M et al (2012) Review of methodological choices in LCA of biorefi nery systems - key issues and recommendations. Biofuels Bioprod Biorefining 6:246–256. https://doi.org/10.1002/bbb

Bernstad A, La Cour JJ (2012) Review of comparative LCAs of food waste management systems - Current status and potential improvements. Waste Manag 32:2439–2455. https://doi.org/10.1016/j.wasman.2012.07.023

Bishop G, Styles D, Lens PNL (2021) Environmental performance comparison of bioplastics and petrochemical plastics: a review of life cycle assessment (LCA) methodological decisions. Resour Conserv Recycl 168. https://doi.org/10.1016/J.RESCONREC.2021.105451

Bisinella de Faria AB, Spérandio M, Ahmadi A, Tiruta-Barna L (2015) Evaluation of new alternatives in wastewater treatment plants based on dynamic modelling and life cycle assessment (DM-LCA). Water Res 84:99–111. https://doi.org/10.1016/J.WATRES.2015.06.048

Bradford-Hartke Z, Lane J, Lant P, Leslie G (2015) Environmental benefits and burdens of phosphorus recovery from municipal wastewater. Environ Sci Technol 49:8611–8622. https://doi.org/10.1021/es505102v

Brander M, Burritt RL, Christ KL (2019) Coupling attributional and consequential life cycle assessment: a matter of social responsibility. J Clean Prod 215:514–521. https://doi.org/10.1016/J.JCLEPRO.2019.01.066

CAP (2008) CPA 2008 structure. 1–133

Colantoni A, Recchia L, Bernabei G (2017) Analyzing the environmental impact of chemically-produced protein hydrolysate from leather waste vs. enzymatically-produced protein hydrolysate from legume grains. Agric7:62 https://doi.org/10.3390/AGRICULTURE7080062

Duan Y-F, Bruun S, Stoumann Jensen L, et al (2020) D1.5 Mapping and Characterization of CNP Flows and Their Stoichiometry in Main Farming Systems in Europe. In: Nutr. – Nurtur. Circ. Econ. https://www.nutri2cycle.eu/wp-content/uploads/2022/06/D.1.5-Report-on-the-mapping-and-characterization-of-CNP-flows-and-their-stoichiometry-in-main-farming-systems-in-Europe-.pdf. Accessed 2 Dec 2022

Dunn JB (2019) Biofuel and bioproduct environmental sustainability analysis. Curr Opin Biotechnol 57:88–93. https://doi.org/10.1016/j.copbio.2019.02.008

EC (2008) Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives (Text with EEA relevance)

EC (2012) Characterisation factors of the ILCD Recommended Life Cycle Impact Assessment methods Database and supporting information, First edit. Publications Office of the European Union, Luxembourg

EC (2013) Commission Recommendation of 9 April 2013 on the use of common methods to measure and communicate the life cycle environmental performance of products and organisations (2013/179/ EU). Off J Eur Union 56

EC (2015) COMMUNICATION FROM THE COMMISSION TO THE EUROPEAN PARLIAMENT, THE COUNCIL, THE EUROPEAN ECONOMIC AND SOCIAL COMMITTEE AND THE COMMITTEE OF THE REGIONS Closing the loop - An EU action plan for the Circular Economy COM/2015/0614 final. Brussels

EC (2018a) DIRECTIVE (EU) 2018a/2001. Promotion of the use of energy from renewable sources. Off J Eur Union

EC (2018b) Supporting information to the characterisation factors of recommended EF Life Cycle Impact Assessment methods: New methods and differences with ILCD. Publications Office of the European Union, Luxembourg (Luxembourg)

EC (2019) REGULATION (EU) 2019/1009 of the European Parliament and of the Council of 5 June 2019 laying down rules on the making available on the market of EU fertilising products and amending Regulations (EC) No 1069/2009 and (EC) No 1107/2009 and repealing Regula. Off J Eur Union 2019:1–114

EC (2020) COMMUNICATION FROM THE COMMISSION TO THE EUROPEAN PARLIAMENT, THE COUNCIL, THE EUROPEAN ECONOMIC AND SOCIAL COMMITTEE AND THE COMMITTEE OF THE REGIONS A new Circular Economy Action Plan For a cleaner and more competitive Europe COM/2020/98 final. Brussels

EEA (2020) Bio-waste in Europe — turning challenges into opportunities. Report No 4/2020. Publications Office of the European Union, Luxembourg

Egas D, Vasilaki V, Katsou E et al (2019) Implementation of the Product Environmental Footprint Category Rules for dairy products: an approach to assess nitrogen emissions in a mass balanced dairy farm system. J Clean Prod 215:1149–1159. https://doi.org/10.1016/j.jclepro.2019.01.110

CEN (2015) Bio-based products—life cycle assessment, EN 16760 standard. European Committee for Standardization

EPA (2019) Waste Definitions. Waste Guidelines. Environment Protection Authority, South Australia. https://www.epa.sa.gov.au/files/4771336_guide_waste_definitions.pdf. Accessed 6 Apr 2022

EPA (2020) Renewable Fuel Standard Program: Standards for 2020 and Biomass-Based Diesel Volume for 2021 and Other Changes (85 FR 7016). Environmental Protection Agency

EPD (2019) PCR Basic Organic Chemicals 2011:17, version 2.11. International Environmental Product Declaration system

EPD (2020) PCR Mineral or chemical ferilizers 2010:20- Version 3.0. International Environmental Product Declaration system

EPD (2021) General Programme Instructions for the International EPD System. Version 4.0. International Environmental Product Declaration system

ETIP (2009) Biorefinery concepts. European Technology and Innovation Platform

European Commission (2001) Environmental Product Declarations (ISO 14025). eUR 1–25

Fernandez-Lopez M, Puig-Gamero M, Lopez-Gonzalez D et al (2015) Life cycle assessment of swine and dairy manure: pyrolysis and combustion processes. Bioresour Technol 182:184–192. https://doi.org/10.1016/J.BIORTECH.2015.01.140

Fiorentino G, Ripa M, Mellino S et al (2014) Life cycle assessment of Brassica carinata biomass conversion to bioenergy and platform chemicals. J Clean Prod 66:174–187. https://doi.org/10.1016/j.jclepro.2013.11.043

Ganrot Z, Dave G, Nilsson E (2007) Recovery of N and P from human urine by freezing, struvite precipitation and adsorption to zeolite and active carbon. Bioresour Technol 98:3112–3121. https://doi.org/10.1016/J.BIORTECH.2006.10.038

Gilbert P, Alexander S, Thornley P, Brammer J (2014) Assessing economically viable carbon reductions for the production of ammonia from biomass gasification. J Clean Prod 64:581–589. https://doi.org/10.1016/J.JCLEPRO.2013.09.011

Guinée JB (2002) Handbook on life cycle assessment : operational guide to the ISO standards. Kluwer Academic Publishers

Hamedani SR, Kuppens T, Malina R (2019) Life cycle assessment and environmental valuation of biochar production: two case studies in Belgium. Energies 12:2166. https://doi.org/10.3390/EN12112166

Harrison R, Webb J (2001) A review of the effect of N fertilizer type on gaseous emissions. Adv Agron 73:65–108. https://doi.org/10.1016/S0065-2113(01)73005-2

Helin T, Sokka L, Soimakallio S et al (2013) Approaches for inclusion of forest carbon cycle in life cycle assessment - a review. GCB Bioenergy 5:475–486 https://doi.org/10.1111/GCBB.12016

Heller MC, Keoleian GA, Volk TA (2003) Life cycle assessment of a willow bioenergy cropping system. Biomass Bioenerg 25:147–165. https://doi.org/10.1016/S0961-9534(02)00190-3

Hishinuma T, Kurishima H, Yang C, Genchi Y (2008) Using a life cycle assessment method to determine the environmental impacts of manure utilisation: biogas plant and composting systems. Aust J Exp Agric 48:89–92. https://doi.org/10.1071/EA07246

Hjuler SV, Hansen SB (2018) LCA of biofuels and biomaterials. Life Cycle Assess Theory Pract 755–782. https://doi.org/10.1007/978-3-319-56475-3_30

Huijbregts MAJ, Steinmann ZJN, Elshout PMF et al (2017) ReCiPe2016: a harmonised life cycle impact assessment method at midpoint and endpoint level. Int J Life Cycle Assess 22:138–147. https://doi.org/10.1007/S11367-016-1246-Y

Igos E, Besson M, Navarrete Gutiérrez T et al (2017) Assessment of environmental impacts and operational costs of the implementation of an innovative source-separated urine treatment. Water Res 126:50–59. https://doi.org/10.1016/J.WATRES.2017.09.016

Ishii SKL, Boyer TH (2015) Life cycle comparison of centralized wastewater treatment and urine source separation with struvite precipitation: focus on urine nutrient management. Water Res 79:88–103. https://doi.org/10.1016/J.WATRES.2015.04.010

ISO (2006a) Environmental management - life cycle assessment - principles and framework, ISO 14040 standard. International organization for standardization

ISO (2006b) Environmental management - life cycle assessment - requirements and guidelines, ISO 14044 standard. International organization for standardization

Jeong ST, Cho SR, Lee JG et al (2019) Composting and compost application: trade-off between greenhouse gas emission and soil carbon sequestration in whole rice cropping system. J Clean Prod 212:1132–1142. https://doi.org/10.1016/J.JCLEPRO.2018.12.011

Johnson E (2009) Goodbye to carbon neutral: getting biomass footprints right. Environ Impact Assess Rev 29:165–168. https://doi.org/10.1016/J.EIAR.2008.11.002

JRC (2010) International Reference Life Cycle Data System (ILCD) Handbook - General guide for Life Cycle Assessment - Detailed guidance. Publications Office of the European Union, Luxembourg, First edit

Kendall A, Chang B, Sharpe B (2009) Accounting for time-dependent effects in biofuel life cycle greenhouse gas emissions calculations. Environ Sci Technol 43:7142–7147. https://doi.org/10.1021/ES900529U

Khoo HH, Ee WL, Isoni V (2016) Bio-chemicals from lignocellulose feedstock: sustainability, LCA and the green conundrum. Green Chem 18:1912–1922. https://doi.org/10.1039/c5gc02065d

Kim JE, Phuntsho S, Chekli L et al (2017) Environmental and economic impacts of fertilizer drawn forward osmosis and nanofiltration hybrid system. Desalination 416:76–85. https://doi.org/10.1016/j.desal.2017.05.001

Kjerstadius H, Saraiva AB, Spångberg J, Davidsson Å (2017) Carbon Footprint of Urban Source Separation for Nutrient Recovery. https://doi.org/10.1016/j.jenvman.2017.03.094

Lam KL, Zlatanovi L, Van Der Hoek JP (2020) Life Cycle Assessment of Nutrient Recycling from Wastewater: a Critical Review. https://doi.org/10.1016/j.watres.2020.115519

Linderholm K, Tillman AM, Mattsson JE (2012) Life cycle assessment of phosphorus alternatives for Swedish agriculture. Resour Conserv Recycl 66:27–39. https://doi.org/10.1016/J.RESCONREC.2012.04.006

Lindfors L-G, Christiansen K, Hoffman L et al (1995) Nordic guidelines on life-cycle assessment. Denmark, Copenhagen

Liska AJ, Yang H, Milner M et al (2014) (2014) Biofuels from crop residue can reduce soil carbon and increase CO2 emissions. Nat Clim Chang 45(4):398–401. https://doi.org/10.1038/nclimate2187

Martínez-Blanco J, Lazcano C, Boldrin A et al (2013a) Assessing the environmental benefits of compost use-on-land through an LCA perspective. 255–318. https://doi.org/10.1007/978-94-007-5961-9_9

Martínez-Blanco J, Lazcano C, Christensen TH et al (2013b) Compost benefits for agriculture evaluated by life cycle assessment. A Review Agron Sustain Dev 334(33):721–732. https://doi.org/10.1007/S13593-013-0148-7

Mbaya AMK, Dai J, Chen GH (2017) Potential benefits and environmental life cycle assessment of equipping buildings in dense cities for struvite production from source-separated human urine. J Clean Prod 143:288–302. https://doi.org/10.1016/J.JCLEPRO.2016.12.111

Menten F, Chèze B, Patouillard L, Bouvart F (2013) A review of LCA greenhouse gas emissions results for advanced biofuels: the use of meta-regression analysis. Renew Sustain Energy Rev 26:108–134. https://doi.org/10.1016/J.RSER.2013.04.021

Mohammadi A, Cowie A, Mai TLA et al (2016) Quantifying the greenhouse gas reduction benefits of utilising straw biochar and enriched biochar. Energy Procedia 97:254–261. https://doi.org/10.1016/J.EGYPRO.2016.10.069

Montazeri M, Zaimes GG, Khanna V, Eckelman MJ (2016). Meta-Analysis of Life Cycle Energy and Greenhouse Gas Emissions for Priority Bio-Based Chemicals Meta-Analysis of Life Cycle Energy and Greenhouse Gas Emissions for Priority Bio-Based Chemicals. https://doi.org/10.1021/acssuschemeng.6b01217

Nemethy A (2016) Analyzing the process of struvite recovery with life cycle assessment: a case study. 34

Nessi S, Bulgheroni C, Konti A et al (2020) Comparative Life Cycle Assessment (LCA) of Alternative Feedstock for Plastics Production Draft report for stakeholder consultation - Part 1: The plastics LCA method. Publications Office of the European Union, Luxembourg

Novais SV, Zenero MDO, Junior EFF et al (2017) Mitigation of greenhouse gas emissions from tropical soils amended with poultry manure and sugar cane straw biochars. Agric Sci 8:887–903. https://doi.org/10.4236/AS.2017.89065

Pergola M, Piccolo A, Palese AM et al (2018) A combined assessment of the energy, economic and environmental issues associated with on-farm manure composting processes: two case studies in South of Italy. J Clean Prod 172:3969–3981. https://doi.org/10.1016/J.JCLEPRO.2017.04.111

Pradel M, Aissani L (2019) Environmental impacts of phosphorus recovery from a “product” Life Cycle Assessment perspective: allocating burdens of wastewater treatment in the production of sludge-based phosphate fertilizers. Sci Total Environ 656:55–69. https://doi.org/10.1016/J.SCITOTENV.2018.11.356

Pradel M, Aissani L, Canler JP et al (2018) Constructing an allocation factor based on product- and process-related parameters to assess environmental burdens of producing value-added sludge-based products. J Clean Prod 171:1546–1557. https://doi.org/10.1016/J.JCLEPRO.2017.10.112

Rabl A, Benoist A, Dron D et al (2007) How to account for CO2 emissions from biomass in an LCA. Int J Life Cycle Assess 12:281. https://doi.org/10.1065/LCA2007.06.347/METRICS

Rebello S, Anoopkumar AN, Aneesh EM et al (2020) Sustainability and life cycle assessments of lignocellulosic and algal pretreatments. Bioresour Technol 301

Rogers JN, Stokes B, Dunn J et al (2017) An assessment of the potential products and economic and environmental impacts resulting from a billion ton bioeconomy. Biofuels, Bioprod Biorefining 11:110–128. https://doi.org/10.1002/bbb.1728

Rufí-Salís M, Calvo MJ, Petit-Boix A et al (2020) Exploring nutrient recovery from hydroponics in urban agriculture: an environmental assessment. Resour Conserv Recycl 155:104683. https://doi.org/10.1016/J.RESCONREC.2020.104683

Saer A, Lansing S, Davitt NH, Graves RE (2013) Life cycle assessment of a food waste composting system: environmental impact hotspots. J Clean Prod 52:234–244. https://doi.org/10.1016/J.JCLEPRO.2013.03.022

Sena M, Seib M, Noguera DR, Hicks A (2021) Environmental impacts of phosphorus recovery through struvite precipitation in wastewater treatment. J Clean Prod 280:124222. https://doi.org/10.1016/J.JCLEPRO.2020.124222

Sharara M, Kim D, Sadaka S, Thoma G (2019) Consequential life cycle assessment of swine manure management within a thermal gasification scenario. Energies 12:4081. https://doi.org/10.3390/EN12214081

Shen L, Worrell E, Patel MK (2010) Environmental impact assessment of man-made cellulose fibres. Resour Conserv Recycl 55:260–274. https://doi.org/10.1016/J.RESCONREC.2010.10.001

Skowroñska M, Filipek T (2014) Life cycle assessment of fertilizers: a review. Int Agrophysics 28:101–110. https://doi.org/10.2478/intag-2013-0032

Spångberg J, Jönsson H, Tidåker P (2013) Bringing nutrients from sea to land – mussels as fertiliser from a life cycle perspective. J Clean Prod 51:234–244. https://doi.org/10.1016/J.JCLEPRO.2013.01.011

Struhs E, Mirkouei A, You Y, Mohajeri A (2020) Techno-economic and environmental assessments for nutrient-rich biochar production from cattle manure: a case study in Idaho, USA. Appl Energy 279:115782. https://doi.org/10.1016/j.apenergy.2020.115782

Styles D, Adams P, Thelin G et al (2018) Life cycle assessment of biofertilizer production and use compared with conventional liquid digestate management. Environ Sci Technol 52:7468–7476. https://doi.org/10.1021/acs.est.8b01619

Temizel-Sekeryan S, Wu F, Hicks AL (2021) Life cycle assessment of struvite precipitation from anaerobically digested dairy manure: a Wisconsin perspective. Integr Environ Assess Manag 17:292–304. https://doi.org/10.1002/IEAM.4318

Ubando AT, Rivera DRT, Chen WH, Culaba AB (2020) Life cycle assessment of torrefied microalgal biomass using torrefaction severity index with the consideration of up-scaling production. Renew Energy 162:1113–1124. https://doi.org/10.1016/j.renene.2020.08.068

Ubando AT, Rivera DRT, Chen WH, Culaba AB (2019) A comprehensive review of life cycle assessment (LCA) of microalgal and lignocellulosic bioenergy products from thermochemical processes. Bioresour Technol 291

Vijay Anand KG, Eswaran K, Ghosh A (2018) Life cycle impact assessment of a seaweed product obtained from Gracilaria edulis – a potent plant biostimulant. J Clean Prod 170:1621–1627. https://doi.org/10.1016/J.JCLEPRO.2017.09.241

Walling E, Vaneeckhaute C (2020) Greenhouse gas emissions from inorganic and organic fertilizer production and use: a review of emission factors and their variability. J Environ Manage 276:111211. https://doi.org/10.1016/J.JENVMAN.2020.111211

Weidema BP, Pizzol M, Schmidt J, Thoma G (2018) Attributional or consequential life cycle assessment: a matter of social responsibility. J Clean Prod 174:305–314. https://doi.org/10.1016/j.jclepro.2017.10.340

Weidema BP, Pizzol M, Schmidt J, Thoma G (2019) Social responsibility is always consequential — Rebuttal to Brander, Burritt and Christ (2019): Coupling attributional and consequential life cycle assessment: a matter of social responsibility. J Clean Prod 223:12–13. https://doi.org/10.1016/J.JCLEPRO.2019.03.136

Wiloso EI, Heijungs R, De Snoo GR (2012) LCA of second generation bioethanol: a review and some issues to be resolved for good LCA practice. Renew Sustain Energy Rev 16:5295–5308. https://doi.org/10.1016/J.RSER.2012.04.035

Wiloso EI, Heijungs R, Huppes G, Fang K (2016) Effect of biogenic carbon inventory on the life cycle assessment of bioenergy: challenges to the neutrality assumption. J Clean Prod 125:78–85. https://doi.org/10.1016/J.JCLEPRO.2016.03.096

Wu H, Hanna MA, Jones DD (2013) Life cycle assessment of greenhouse gas emissions of feedlot manure management practices: land application versus gasification. Biomass Bioenerg 54:260–266. https://doi.org/10.1016/J.BIOMBIOE.2013.04.011

Żygadło M, Dębicka M (2016) The environmental assessment of mechanical-biological waste treatment by LCA method. Struct Environ 8:260–265

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This study has been carried out in the framework of the FERTIMANURE project which received funding from the European Union's Horizon2020 research and innovation programme under grant agreement No 862849. Joan Colón has received funding from the 2018 call for Ramón y Cajal Grants from the Ministry of Science, Innovation and Universities (reference RYC2018-026231-I) co-financed by the State Research Agency and the European Social Fund.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Communicated by Brad G. Ridoutt.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Egas, D., Azarkamand, S., Casals, C. et al. Life cycle assessment of bio-based fertilizers production systems: where are we and where should we be heading?. Int J Life Cycle Assess 28, 626–650 (2023). https://doi.org/10.1007/s11367-023-02168-8

Received:

Accepted:

Published: