Abstract

Purpose

Propylene oxide (PO) is one of the useful chemicals that is predicted to experience a compound annual growth rate of 3.9% from 2020 through 2027. The environmental burdens of the current PO production process and its corresponding utility system including power generation system need to be determined quantitatively as a response to increasing demands for its environmentally sustainable production process in the energy transition period from fossil fuels towards renewable energy resources.

Methods

A new methodology is proposed to study the PO production process called exergy-aided environmental life cycle assessment (EELCA), using the US National Renewable Energy Laboratory’s database known as life cycle inventory (LCI) database. EELCA is dedicated to LCA studies of processes in the energy transition period and is aided by Monte Carlo simulation (MCS) as a tool for discernibility analysis which brings another dimension to the EELCA because MCS was often used to assess uncertainty in LCA studies. EELCA impact categories are classified into two classes: (i) emission-dependent impact categories addressed by ReCiPe and (ii) resource-dependent impact categories covered by cumulative exergy demand (CExD). The alternative energy like bioenergy is evaluated through the stepwise scenarios assisted by MCS, which are employed in openLCA with 10,000 iterations.

Results and discussion

The cumulative exergy depletion of the base scenario is 6.1898 MJ (CExD). The human health and ecosystem impacts are 3.65E-06 DALY and 1.58E-08 species.yr, respectively. Human health-total (2.7E-4 DALY) is the most important category, where the power generation system by residual fuel oil (33.19%) is on top of the list. By analysing statistically discernible scenarios using EELCA, it has been proven that natural gas is not a proper choice for energy mix in the energy transition period. This is because natural gas-based scenarios present more burden compared to residual fuel oil-based scenarios especially regarding human toxicity, freshwater ecotoxicity, marine ecotoxicity, terrestrial acidification, and particulate matter formation. This study shows that the reduction in environmental impacts without changes in the production process technology is feasible through implementing bioenergy scenarios.

Conclusions

Having applied successfully EELCA, this study shows that PO production in the present configuration is not sustainable at all. The statistically discernible scenarios regarding energy mix selection help to enhance sustainability of the PO production process. Moreover, by examining the application of CExD along with LCA analysis, it is proved that by using the concept of CExD, we were able to represent the environmental impacts of the entire system with one figure, which tremendously facilitates the calculations in MCS.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Propylene oxide is the third primary propylene derivative in addition to polypropylene and acrylonitrile which is a highly reactive chemical intermediate used for producing polyether polyols, polyether glycols, propylene glycols, 1,4-butanediol, isopropanolamine, polyalkylene glycols, and many other useful products (EU 2002). It is also used in agriculture as a fumigant for the post‐harvest fumigation of fruits, nuts, and spice crops (Durrani and Vidrio 2016). Propylene oxide global market is estimated at $14.4 billion in 2020 and is projected to achieve $18.8 billion by 2027 with a compound annual growth rate of 3.9% for the period of 2020–2027 (Research and Markets 2021).

Propylene oxide has a variety of toxic impacts on the environment and humans. Short-term acute exposure of animals and humans to propylene oxide will cause eye and respiratory tract irritation. In humans, dermal contact (even with dilute solutions) can cause skin irritation and necrosis (EU 2002).

To cope with the increasing need for new sustainable production processes of propylene oxide, the environmental burdens of its current processes need to be determined quantitatively. As the life cycle thinking concept became increasingly significant in the past decade, the life cycle assessment (LCA) method (ISO 2006) was developed and is currently recognized as a significant tool for sustainability assessment (Jacquemin et al. 2012).

The early studies on environmental impacts of propylene oxide were not focused on propylene oxide production technology, while it focuses on the chemistry of the propylene oxide, e.g. Kolman et al. (2002) presented a comprehensive review of propylene oxide genotoxic impacts on the environment and human. Later, environmental impacts of propylene oxide industrial production have been studied using conventional environmental impact assessment (EIA) techniques (Dubosc 2006). Guan et al. (2013) studied the environment-friendly propylene oxide production technology (Guan 2013). They analysed the production status and market demand for propylene oxide. However, the core of research on propylene oxide production focuses on the green synthesis of propylene oxide; as an example, Sheldon (2017) reviewed the fundamental concepts and principles of green and sustainable chemistry using various mass-based metrics for measuring greenness of processes producing chemicals including propylene oxide. Minimal studies on exploiting LCA to analyse the environmental impact of propylene oxide and its derivatives are presented in the literature. In one of the few studies, Bauer and Maciel (2004) studied the propylene glycol’s production transient state operation from propylene oxide by using LCA analysis, which can be interpreted as gate-to-gate analysis for propylene oxide. They considered both environmental impacts and traditional economic evaluation during the process design. Obtained results showed that quantifying the major indicators will help the engineer to make decisions during the process design to minimize environmental impacts based on economic concerns.

The evaluation of energy-intensive processes, e.g. propylene oxide production, evidently needs the energy-centred impact categories such as cumulative exergy demand (CExD) (Bösch et al. 2007). This has been proven through a number of case studies, e.g. poly ether process (Ghannadzadeh 2018a), ethylene dichloride–vinyl chloride process (Ghannadzadeh 2018b), chlorine process (Ghannadzadeh and Tarighaleslami 2019), ethylene oxide process (Ghannadzadeh and Meymivand 2019), crude oil refinery (Ghannadzadeh and Raei 2018), dairy processing factory (Tarighaleslami et al. 2020), glycerin production process (Ghannadzadeh and Tarighaleslami 2020), and ammonia process (Ghannadzadeh et al. 2020). However, despite the importance of the propylene oxide production process, no case study in the literature uses exergetic LCA to improve the environmental sustainability of the entire propylene oxide process. Besides, a limited number of studies have taken into account both utilities and process, whereas there is a room for further studies that consider the entire production stages as it is the key point of the life cycle thinking. Examples of such research are the assessments of tertiary butyl hydroperoxide-based and of H2O2-based propylene oxide technologies (Ghanta et al. 2013) and LCA of CO2-based polymers considering alternation of propylene oxide production technologies (von der Assen et al. 2016) where LCA results reveal that polyol production process environmental impacts are mainly originated from propylene oxide production if CO2 is utilized as a feedstock for polyols.

Fossil fuel depletion, CO2 emission, global warming, and the environmental effects of fossil fuels are considered as a major concern internationally which is dedicated to the energy transition. In this process, petro-based scenarios pass via the so-called green petro-based fuels such as natural gas (NG) (Wu et al. 2016). At the end of this path, it has been desired to reach a totally renewable energy source (Droege 2011). However, to minimize energy use, prior to performing fuel switching in the energy transition phase, energy efficiency and demand reduction must be conducted in the plant (Tarighaleslami et al. 2020). Renewable energy sources, including biofuels, have been promoted as a possible solution to address these problems. Propylene oxide production derived from propylene using immobilization of whole cells of Methylosinus sp. CRL 31 in a gas–solid bioreactor was introduced by Hou (1984). Various publications examine LCA of biofuels, while the authors could not find any literature regarding energy transition for industrial production of propylene oxide.

Although there are notable researches on the propylene oxide production available in the literature, we observe a clear gap regarding an inclusive study on propylene oxide production reflecting environmental effects (including carbon and energy footprints) and the energy transition. To the best of the authors’ knowledge, minimal study has been conducted combining the exergy concept with LCA to improve the environmental sustainability of a propylene oxide production process. It must be noted that there is not even a single publication combining LCA and exergetic methods to improve the sustainability of a propylene oxide production process including the energy and utility system. Hence, this paper explores whether there is a possible option towards the environmentally sustainable process as an available mid-term alternative for propylene oxide production without introducing any change of the technology.

The aim of this research is to develop a new exergy-aided methodology dedicated for the LCA studies on the processes in the period of the energy transition. Unlike the previous methods, this method focuses on the power generation (PG) system. This methodology is called exergy-aided environmental life cycle assessment (EELCA) and is presented in details, which enhance the contribution of this paper. In this methodology, it is absolutely necessary to analyse the scenarios to see whether they are sensitive to the occurred changes in PG system. To do so, Monte Carlo simulation (MCS) is implemented to show its usefulness and ability to assess the significance of the changes in comparison to different energy mix scenarios similar to the analysis that was presented as discernibility analysis (Heijungs and Kleijn 2001). In this case, discernible scenarios are defined to lay the foundations for a reasonable comparison (Lanzuela et al. 2015). Therefore, the robustness of the obtained results is enhanced by conducting the preliminary analysis using MCS. Another contribution of this research focused on the particular propylene oxide production process is the application of MCS as a tool for discernibility analysis. This brings another dimension to the EELCA because MCS was often used to assess uncertainty in the LCA studies. Therefore, the paper starts with introducing the EELCA framework, where first the LCA of propylene oxide production is presented followed by the ReCiPe-centred (Goedkoop et al. 2009) and exergetic diagnosis. Then, the PG system effect in the sustainability index of the propylene oxide production is quantitatively assessed. Finally, the energy scenarios supported by MCS are assessed to examine whether they enhance the total sustainability index of the whole propylene oxide production process. The software of openLCA 1.5.0 is used to analyse the case study based on the new concept of EELCA.

2 Materials and methods

2.1 Methodology to define scenarios for EELCA

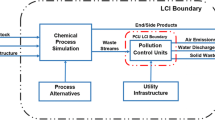

This section presents an exergy-aided methodology dedicated for the LCA studies on the processes in the energy transition period, where the heart of the process technology remains unchanged, whereas only utility systems will be retrofit. This exergy-aided methodology (Fig. 1) has four steps as follows:

2.1.1 Diagnosis on the utilities through ReCiPe (emissions) and CExD (resources)

The first step is to pinpoint the utility units that are the main source of environmental burdens, which means a small improvement in the most damaging unit can make high improvement in the sustainability of the whole system. Because only the energy transition phase is considered in this study, the reaction section, which is known as the heart of the process, is considered as an imaginary black box. In such a case, the utility system is considered to be out of this boundary. This is because of the intrinsic characteristics of the process, where the utility system can be considered for a sustainable transition without any effect on the heart of the process technology.

In this regard, both LCIA methods, the ReCiPe and the CExD, must be implemented in the base-case. In fact, the goal of the current research is not to compare the above-mentioned impact assessment methods; this study aims to present the results from two perspectives, ‘emissions’ through ReCiPe and ‘resources’ through CExD, thus enriching the results of LCA study.

2.1.2 Definition of scenarios for utilities

In the transition stage, once the conventional fuels are phased out, it is important to study the energy mix (EM) consisting of different classes of fuels. Based on the worst-case scenario, EM in the methodology presented here starts with residual fuel oil (RFO). In fact, RFO plays an important role in PG, as its price is typically less than other liquid fuels. In 1973, RFO produced 16.8% of the power in the USA. By 1983, it had fallen to 6.2%, and as of 2005, PG from all forms of petroleum, including diesel and RFO, is only 3% of total production (DOE 2004). This trend seems to be continued as the environmental and human health concerns associated with the high sulphur content of RFO have led to new policies and legislations that have significantly lowered expectations for the global use of RFO in the future. For instance, in the marine transportation sector, the MARPOL regulations will require consistent emission reductions for consuming RFO that contains sulphur levels of no more than 0.5% in the specified areas as early as 2020 or as late as 2025 (EIA 2015). Likewise, in the PG sector, the decline is the result of environmental limitations on emissions besides the price competition with NG. In the power plants, the oil heating, extra pollution control, and the additional maintenance required after the burning costs, it often outweighs the low price of the fuel when compared to NG. The CO2 emission associated with RFO burning is higher than NG combustion (EIA 2015). A number of revamping projects all over the world indicate that the worst image between the various fuels in PG plants belongs to RFO. Therefore, applying the concept of the worst-case scenario, RFO can be selected as the single source of PG for the base scenario. After having chosen RFO as the starting point, NG as a transitional fuel and biomass as a representative of renewables, will be chosen.

As already shown in the recent case studies, e.g. glycerin production process (Ghannadzadeh and Tarighaleslami 2020), the definition of energy transition scenarios is a delicate task. It is essential to define proper energy transition scenarios out of RFO, NG, and biomass as the improperly defined scenarios might lead to unreasonable burdens. Hence, a smooth transition must be driven with a stepwise and flexible operation, meaning that renewable energy type must be introduced with relatively small steps into the system to minimize the probability of operational failure. Such a strategy gives the flexibility to easily come back to the initial conditions at any stage if required. Therefore, seven different symmetrical energy mix scenarios are defined in this research; in each step, one-third change in PG system can guarantee the flexible energy transition. It means the defined scenarios begin with 100% RFO followed by the addition of one-third (or equal to 33%) of alternative fuels (NG and biomass) in each step as shown in Table 1, which is based on the literature (Ghannadzadeh 2018a). For this case study, 33% introduction of alternative energy source in each step is the unique value that provides the opportunity to define a set of seven asymmetric energy transition scenarios while minimizing the possible number of fuel switching options.

2.1.3 Discernibility analysis using Monte Carlo simulations

The defined scenarios in the previous section need to be analysed to examine if the one-third change in the fuel supply of the PG system moving from low-grade fuels towards high-grade fuels can be considered as a discernible scenario. Therefore, the discernibility analysis of the defined scenarios needs to be conducted employing MCS as demonstrated in the literature (Ghannadzadeh and Tarighaleslami 2020). MCS input parameters are given in Table 2 based on the literature (Ghannadzadeh 2018a).

Clearly, both alternative fuels detailed in the previous step (NG and biomass) are ‘resources’. As we change the ‘resources’, we need to check whether the whole system is sensitive to the ‘resources’ or not. In other words, the scenarios need to be discernible in terms of ‘resources’ at this stage, so discernibility analysis is limited to CExD because it aggregates all the resources.

2.1.4 Quantify improvements of utilities regarding emissions (ReCiPe) and resources (CExD)

The last but not definitely the least step is to find out how much the sustainability of the process under consideration can be improved without requiring revamping of the technology of the heart of the production process, to be regarded as a realistic solution that can be achieved in mid-term. Therefore, this step plays an important role to quantify precisely the impacts by translating different impacts with different units to the quantities that can be compared together.

2.2 LCA framework

2.2.1 Goal and scope definitions

The current work is targeted to estimate the environmental burdens of a propylene oxide production for different energy transition scenarios (RFO, NG, and biomass) in the USA. To achieve this goal, an attributional LCA study based on the EELCA methodology presented in Sect. 2.1 focusing on the environmental impacts linked with resources depletion and emissions will be performed.

2.2.1.1 System boundaries

The scope of this research is limited to the cradle-to-gate for all studied scenarios, which is meaningful as we aim at measuring the sustainability index of the propylene oxide ‘production’ process. Figure 2 shows precisely the system boundaries of the propylene oxide production certainly including the PG system.

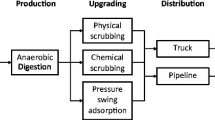

Figure 3 presents the block flow diagram (BFD) for the propylene oxide production process. In this process, the propylene oxide production occurs through catalyst-based direct oxidation with minimal side products where the silver-based catalyst is used (Schultz et al. 2016). The process begins with propylene and oxygen as the raw materials. Pure oxygen with a purity of 99.6% is fed to the reactor. Propylene and oxygen feeds are sent to the reactors with separate flows. Before entering the feeds to the reactor cycle, feeds are preheated. Before entering propylene into the reactor, it is mixed with the recycled propylene, and then the mixture is pumped to high pressure and preheated. The reaction commences at high temperature and pressure, 350 °C and 30 bar, respectively. In the reaction section, two reactors are designed in parallel. It provides the opportunity to operate continuously with one reactor at a time, while the other reactor is regenerating the catalyst. A small amount of side products is produced in this reaction. In addition, steam is generated; as in general, the propylene oxide reaction is exothermic. The generated steam is used as the utility within the production plant. The reactor product enters the separation system where through the distillation unit, in the first step, the bulk of produced propylene oxide is separated from unreacted propylene and other by-products. The separated unreacted propylene is recycled back to be mixed with propylene and be fed to the reactor, while the propylene oxide mixture as a residue of the first stage distillation moves to the second stage distillation for further purification into the desired product specification.

2.2.1.2 Functional unit

In this LCA study, the functional unit is the electricity required for the production of 1 kg petro-based propylene oxide. In the process under consideration, to produce 1 kg propylene oxide from 0.77258 kg propylene and 0.09861 kg liquid oxygen, the amount of required electricity is 0.28314 kWh, which can be produced by different sources. It should be noted that in addition to electricity, 0.13102 L of RFO and 0.14531 m3 NG combusted in industrial boilers, as well as 0.928 kg sodium chloride and 0.689 sodium hydroxide, are required as detailed in Sect. 2.2.2.

2.2.2 Life cycle inventory data

The data used in this LCA study for foreground and background processes is based on the US LCI database presented by the National Renewable Energy Laboratory (NREL 2014) where this work aims to estimate the environmental burdens of a propylene oxide production process for different energy transition scenarios (RFO, NG, and biomass) in the USA.

The US LCI database for the case of propylene oxide production process as well as PG systems is well-implemented in a study (openLCA 2014a) performed in openLCA 1.5.0 (openLCA 2016), leading to a database (2014b) that consider the interaction between several processes. It should be noted that for all of the defined scenarios, the same database explained in this section is used.

Table 3 presents the LCI data regarding the propylene oxide plant, where propylene oxide is a single product in the foreground system. Likewise, in the background system, electricity is a single product. This means that the case study under consideration does not need for any allocation method.

2.2.3 Life cycle impact assessment

In this work, the impact categories have been classified into two classes: (i) emission-dependent impact categories, which will be addressed by ReCiPe, and (ii) resource-dependent impact categories, which will be covered by CExD.

2.2.3.1 ReCiPe

The environmental burdens in this LCA study are calculated using the ReCiPe endpoint method in openLCA software. Ten environmental impacts under consideration are as follows: climate change (human health and ecosystem), ozone depletion, terrestrial acidification, ecotoxicity (freshwater, marine, and terrestrial), freshwater eutrophication, and particulate matter and photochemical oxidant formation.

2.2.3.2 CExD

The CExD, coined by Bösch et al. (2007), represents the sum of exergy of all resources required to provide a process:

where CExD is calculated in MJ-Eq, mi represents mass of material resource i in kg, nj represents the amount of energy from energy carrier j in MJ, Ex(ch)i represents exergy per kg of substance i (MJ-Eq/kg), and rex-e,j represents exergy to energy ratio of energy carrier j (MJ-Eq/MJ).

Clearly, all the exergy components should be obtained separately. For instance, the standard molar chemical exergy of substances can be calculated using Eq. 2:

where ex̊ch,j represents the standard molar chemical exergy in kJ/mol and \(\Delta_f G_i^{^\circ}\) represents the standard Gibb's free energy of formation of substance in kJ/mol. In addition, nel represents number of elements in compound.

Furthermore, Eq. 3 presents the exergy associated with the heat flow that is represented by the Carnot cycle in order to calculate the possible obtainable shaft-work from a heat source:

where Exth represents thermal exergy in MJ, Q represents energy in MJ, and T represents temperature in K. In addition, c represents the environment, and h represents the heat source.

2.2.4 Normalization

Normalization is needed to simplify the LCA results. Different units of the environmental impact categories can be transformed into a unique dimensionless number, which facilitates the comparison of results.

The approach of hierarchist world ReCiPe H/H [person/year] is used in this LCA study because perspective H is based on the most common policy principles with regard to time frame and other issues. Moreover, ReCiPe website presents the normalization factors (ReCiPe Normalization 2000), which are used in openLCA 1.5.0 (openLCA 2016).

3 Results and discussion

3.1 Diagnosis on the utilities through ReCiPe (emissions) and CExD (resources)

The first step is to explore the PG system rank among the units that cause environmental impacts. Therefore, LCA was used to assess the base-case of the propylene oxide production process.

3.1.1 ReCiPe

The corresponding value of each environmental impact is presented in Table 4. The environmental burdens of the base-case are presented based on two main categories according to ReCiPe, which are human health (HH) and ecosystem (ES). The human health value in total is 3.65E-06 DALY, which contains five subcategories with a different order of magnitude from climate change potential at 2.77E-06 DALY to photochemical oxidant formation potential impact at 4.07E-10 DALY. The ecosystems-total impact is evaluated at 1.58E-08 species.yr, containing 5 different subcategories varying from 1.57E-08 species.yr for climate change potential to marine ecotoxicity potential evaluated at 3.79E-13 species.yr.

The normalized anthropogenic environmental impacts in accordance with the ‘World ReCiPe H/H [person/year]’ weighting set and normalization are presented in Table 5.

Table 5 presents the most important environmental impacts categories for the propylene oxide production process. The most important category with a normalized value of is HH-total (0.00027), while HH-CC ranked the second most important category with 2.00E-04. HH-PMF and ES-total stand on the next ranks with corresponding normalized quantities of 4.58E-05 and 1.72E-05, respectively. The following subsections present the contributions of impact categories in terms of chemical and process components.

3.1.1.1 Human health-total

Table 5 reports that the HH-total is on the first place with the quantity of 0.00027. Table 6 presents the sources of the HH-total based on the process and chemical flows from the process point of view. The PG system supplied by RFO (33.19%) is on the top of the list ahead of NG supplied steam generation system (23.36%) and RFO (19.55%), which underlines the contribution of utilities to the HH-total. Table 6 also reports the environmental impacts caused by chemical components. The HH-total is primarily due to the emissions of CO2-fossil fuel (72.04%), SO2 (8.53%), NOx (4.25%), Hg (3.78%), CH4 (2.78%), and SOx (2.71%). It should be noted that the emissions of CO2 and CH4, known as the top 5 chemical substance emissions, are not a result of the intrinsic nature of the propylene oxide production process that can be mitigated by PG system improvement.

3.1.1.2 Human health-climate change

The HH-CC potential impact for the base-case scenario is presented in Table 7. The RFO supplied PG system ranks at the top of the list (38.73%) ahead of NG steam generation system (29.38%), RFO (22.10%), and bituminous coal (4.28%), which highlights the impact of different utilities on human health based on climate change. According to Table 7, the HH-CC potential impact is mainly due to CO2 emissions from fossil fuels (94.83%) and CH4 (3.66%). Chemical components such as CO2 and CH4 can be avoided since due to the nature of the technology, they are not related to the heart of the production process.

3.1.1.3 Human health-particulate matter formation

Table 8 presents the HH-PMF potential impact. At the top of the list, NG processing plant (45.56%) can be seen followed by RFO supplied PG system (21.16%) and RFO supplied steam generation system (15.67%), bituminous coal (8.45%), and NG (5.97%), highlighting the utility contribution in human health-associated burdens due to the formation of particulate matter. Referring to Table 8, the HH-PMF potential impact is mainly due to the emissions of SO2 (49.82%), NOx (24.81%), SOx (15.84%), and the particulates with a size of between 2.5 and 10 µm (8.87%).

3.1.1.4 Ecosystems-total

As one of the most important impacts, ES-total needs to be detailed, while it cannot be seen in the top of the list in Table 5. The components that contribute to the ES-total are presented in Table 9. The RFO supplied PG system (38.64%) is ranked top in the list followed by NG supplied steam generation system (29.26%), RFO (22.06%), and bituminous coal (4.28%), emphasizing the burdens on ecosystem as a result of utility production. Table 9 reports the ES-total burdens are caused by CO2 — fossil fuels (94.44%), and CH4 (3.64%) emissions.

3.1.2 CExD

The exergy of resources taken from the environment that is unavailable in the future applications is presented by CExD. According to the CExD findings in this research, the cumulative exergy depletion related to the base scenario is equivalent to 6.1898 MJ non-renewable energy sources. The exergy content of the resources in the ecoinvent database is considered in the CExD including all types of exergy such as chemical exergy. The CExD describes the summation of the removed exergy from the environment for a product. This can be done by considering the total exergy of the whole considered resources. Furthermore, CExD evaluates the required energy quality and includes energy carriers’ exergy and also the materials with no heating values.

Table 10 presents the units that are the environmental burdens according to CExD where the NG supplied steam generation system (91.51%) ranks at the top of the list ahead of RFO supplied steam generation system (1.00%) and the PG system supplied by RFO (0.57%), emphasizing the contribution of utilities in the total exergy demand extracted from the environment.

3.2 Discernibility analysis using Monte Carlo simulations

Having defined the scenarios based on what is described in Sect. 2.1.2, we are in the position to move to the next step of the methodology. In fact, after applying the rectangle distribution, all of the results do not have the same quantity, which basically makes it possible to define statistically discernible scenarios based on the base-case one, paving the way for a fair comparison. It should be noted that although the rectangle distribution is selected, wide-ranging histogram (Fig. 4) presents a similar form to previously published case studies (e.g. Ghannadzadeh and Tarighaleslami 2020). It shows that all of the trials do not possess identical value, revealing their relative independence (Hong et al. 2010), which lay the foundations for the definition of the statistically discernible scenarios. This depicts that the carried out MCS, which proposes the defined scenarios according to the presented model, is highly sensitive to the 33% variation in the PG source. Therefore, MCS application is meaningful to prevent misleading conclusions given over- or underestimations.

The MCS procedure must be repeated to ensure acquiring values that represent the selected distribution sufficiently. In this paper, MCS is repeated 10,000 times in each run based on openLCA 1.5.0. Therefore, MCS provides confidence intervals that estimate the CExD values for scenarios 1–7, which are approximated and formed with the rectangle distribution. The acquired confidence intervals (95%) have the value of 8.521, 9.731, 10.984, 9.729, 8.495, and 6.151 (Fig. 5). The total predicted mean values of CExD for scenarios 2–7 are 7.414, 8.598, 9.868, 8.609, 7.380, and 6.151, respectively.

Overall, the MCS results for CExD demonstrate the environmental profiles of the propylene oxide production technology are adequately sensitive to the change in input electricity, providing a better basis to compare the LCA results between the different scenarios associated with PG systems. It is deduced that 33% volatility is sufficiently considerable to define a different scenario from the base scenario. Consequently, the following subsections are devoted to the PG system to assess the available alternatives in the short-term to medium-term besides the long-term alternatives to diminish the environmental burdens by the entire propylene oxide production process.

3.3 Quantify improvements on emissions (ReCiPe) and resources (CExD)

3.3.1 ReCiPe

Figure 6 depicts the results associated with the seven scenarios based on ReCiPe regarding the ecosystem and human health impact categories. Scenario 7 is the best scenario while scenario 4 is the worst one.

From Fig. 7, the least environmental burdens for 9 out of 10 potential impacts, which are CC, OD, PMF, TA, and the entire ecotoxicity impact categories are linked to scenario 7.

It should be noted that despite the fact that in terms of POF potential impact, the full biomass-based scenario is the least environmentally sustainable scenario, it becomes the most sustainable scenario compared to the NG-based scenarios and certainly the RFO-based scenarios considering results for all other potential impact categories that are discussed in detail below.

3.3.1.1 Ecosystems-climate change

The CC potential impact is presented in Fig. 7a, which represents global warming potential. Figure 7a depicts the highest CC potential impact which belongs to scenario 1 (8.35E-09 species.yr) followed by scenario 2 (8.28E-09 species.yr). The CC potential impact for the base scenario is mainly due to CO2 and CH4 emissions. It can be seen that scenario 7 has the best condition for CC with the value of 6.45E-09 species.yr.

3.3.1.2 Ecosystems-freshwater ecotoxicity

The FE potential impact is presented in Fig. 7b, where the FE shows the different trend than the CC potential impact. It shows that the electricity generated using NG is the worst choice with 1.25E-12 species.yr where it has identical order of magnitude with a renewable energy source and even the RFO power. For instance, the FE potential impact associated with the RFO power for scenario 1 is 7.98E-13 species.yr mainly due to the releases of Ag, Ba, Ni, and Cu.

3.3.1.3 Ecosystems-marine ecotoxicity

The ME potential impacts associated with all scenarios are presented in Fig. 7c. The rank of the scenarios for this impact category is the same as that of FE. In fact, scenarios 4 and 3 are more critical compared to the other scenario with the impact of 2.56E-13 species.yr and 2.33E-13 species.yr, respectively. The ME potential impact associated with the renewable resource is the best scenario with 1.69E-13 species.yr, and it has the identical order of magnitude with other scenarios. The primary reason that the scenarios based on fossil fuel-based technologies, like base-case scenario, show the high impact is the discharge of Ag, Hg, Ba, and Ni.

3.3.1.4 Ecosystems-terrestrial acidification

Acidification is known as an index to measure the amount of a specific type of component in the soil, and a deviation from this amount could be harmful. ES-TA is a result of atmospheric deposition of inorganic components that may change the acidity of the soil such as phosphates, sulphates, and nitrates. As demonstrated in Fig. 7d, the worst scenario for this impact category is scenario 4, with 3.69E-11 species.yr. TA potential impact associated with the base-case scenario is mainly as a result of the release of SO2, NOx, and SOX.

3.3.1.5 Ecosystems-terrestrial ecotoxicity

The TE potential impact is presented in Fig. 7e where the base scenario is significantly worse than all the other scenarios, with TE potential impact of 2.34E-12 species.yr predominantly due to the discharges of Ni, Co, Hg, Se, Cd, C3H6, and Be. The second worst scenario is scenario 2 with 2.08E-12 species.yr. The best choice is bio-based scenario with 1.54E-12 species.yr and with similar order of magnitude with the NG-based scenario (1.55E-12 species.yr).

3.3.1.6 Human health-climate change

Figure 7f shows that the lowest CC potential impact is assessed for the bio-based scenario at 1.14E-06 DALY, while the impacts associated with the scenario that contains 100% NG are still high (1.44E-06 DALY). Nonetheless, the scenario with 100% RFO is more critical than any other scenarios, with 1.47E-06 DALY, followed by scenarios 2 and 3 with the potential impact of 1.46E-06 DALY and 1.45E-06 DALY, respectively. For the base-case scenario, the majority of CC is due to CH4 and CO2 emissions.

3.3.1.7 Human health-human toxicity

The HT potential impact is presented in Fig. 7g, which represents the toxicity of a chemical constituent as well as accumulation in the human food chain and environmental persistence. As demonstrated in Fig. 7g, the trend of HT potential impact is very different than the CC potential impact. In this impact category, scenario 4 has the worst results (9.46E-08 DALY). For the base-case scenario, it is substantially as a result of discharges of Ba and As. Scenario 7 with 100% renewable resource has the least burden with HT potential impact of 6.76E-08 DALY.

3.3.1.8 Human health-ozone depletion

The OD potential impact is presented in Fig. 7h with stratospheric ozone layer destruction as a consequence of anthropogenic emissions of OD substances. As demonstrated in Fig. 7h, all RFO-free scenarios result in roughly identical environmental burdens concerning the OD potential impact estimated at 4.91E-12 DALY. For the base-case scenario, the OD potential impact originally occurs as a result of methane, tetrachloro-, R-10 emissions.

3.3.1.9 Human health-particulate matter formation

The PMF potential impact, which indicates the intake fraction of fine particulate matter with diameter ranges less than 10 μm (PM10), is demonstrated in Fig. 7i. The results of PMF potential impact show the same trend as the results of the HT potential impact; the worst scenario is NG-based scenario with 3.86E-07 DALY. For the base-case scenario, PMF potential impact is predominantly due to NOx, SO2, and SOx emissions and particulates with the size of between 2.5 and 10 µm.

3.3.1.10 Human health-photochemical oxidant formation

The POF potential impact is presented in Fig. 7j. As discussed previously, although common sense takes into account that scenario 5 is being more environmentally friendly compared to scenario 4, our findings regarding the POF potential impact confirm the opposite. Considering the entire impact categories, scenario 4 is less environmentally sustainable than scenario 5. Nonetheless, regarding POF potential impact, scenario 4 causes less environmental burdens, contrasted to scenario 5 as reported in Fig. 7j. The substantial bulk of POF on the base-case scenario is due to the discharge of SO2, NOx, CH4, and NMVOCs.

3.3.2 CExD

Figure 8 summarizes the findings of CExD for the entire propylene oxide production that presents the environmental sustainability of each scenario. The exergy depletion has been taken into account for the entire propylene production.

Figure 8 shows possible ranges of CExD, from 6.15 to 9.86 MJ-Eq for non-renewables depending on the composition of EM. Depending on the PG system, the rank of the scenarios changes. Figure 8 shows that the biomass-based scenarios are preferred in contrast to the NG-based scenarios. Moreover, the biomass-based scenarios are a little bit more environmentally sustainable than the RFO-based scenarios. In addition, the NG electricity source has an impact on CExD, which seems to be the worst choice compared with the biomass electricity and even the RFO electricity. This means the RFO electricity is much more environmentally sustainable compared to the NG electricity.

The results of CExD show that a high percentage of renewable energy reduces the common concerns regarding the conservation of non-renewable resources and GHG emissions, which are consistent with the results of ReCiPe. Scenario 5 based on the fossil sources (67% NG), as well as the renewables (33% biomass), has higher CExD than scenario 6, which is defined based on the fossil sources (33% NG) and on renewable energy (67% biomass).

3.4 Discussion

The significant benefits of applying EELCA to a propylene oxide production process have been demonstrated in this research. It has been shown that these benefits are not likely to be achieved without EELCA where, as an example, the unpleasant public image of the propylene oxide production process originated from the point that its production can cause discharges of tremendously hazardous components to the environment. As opposite, according to EELCA, which considers the whole production process of propylene oxide, the effects of the common hazardous components from this process on ecosystem and human health are not as significant as CO2 emissions from the combustion of RFO at the PG system. Therefore, it is recommended that special attention be taken to the PG of propylene oxide production process technology to prevent environmental burdens correlated with fuel combustion such as RFO and assess the effects of the utility system that is not at the core of the production process technology and can be revamped.

This paper evaluates the possibility of environmentally sustainable propylene oxide production without significant changes in process technology, which is considered as an achievable mid-term alternative. Therefore, to reduce the environmental burdens of existing propylene oxide production processes as much as possible, several energy transition-based alternatives are evaluated. These alternatives comprise the utility modifications, as process technology revamping is practically impossible due to strict process constraints.

Furthermore, the sensitivity of the propylene oxide process technology to the NG and biomass (as the alternatives of RFO) is examined considering the entire production process including the PG system, utilities, and transportations. Although it is possible to assess the PG system on a stand-alone basis without considering the propylene oxide production process, it is helpful for engineers to evaluate both systems in a single study. It allows determining the minimum level of introducing new technologies into the entire production process in order to fulfil the required specifications specified in the current environmental legislation as should be considered in the research studies that focus investment in the alternative energy supplies (D’Alessandro et al. 2010). For example, in a case where X% enhancement of the environmental sustainability of the entire propylene oxide production process is required, a possibility can be Y% increase in the share of the more sustainable fuel at the power and heat generation system, instead of changing the synthesis reactor, which is the heart of the process technology. Any modification at the reactor level dictates a series of modifications on the rest of the process due to its domino effect. However, it must be noted that currently, many countries have strict environmental emission regulations in place, while these standards do not cover greenhouse gas (GHG) emissions. In addition, current rare standards on GHG emissions do not include the so-called indirect emissions, particularly emissions that result from the generation of fuels. For the case of propylene oxide process, it has been proved that by increasing the portion of alternative energy resources such as biomass even by 33%, the environmental impacts of the propylene oxide production can be significantly decreased, as it can be seen in scenarios 5, 6, and 7. It should be noted that introducing only 33% of the biomass in scenario 5, the EM leads to environmental burden reduction as opposed to scenario 4. This highlights the significance of the EM appropriate selection among the feasible energy resources in order to enhance sustainability in a phase that aggregation of renewable energy represents a growing trend in recent years (Zhou et al. 2017). The goal is to move from fossil fuels, with high carbon content, in EM to use more renewable energy sources and fossil energy with lower carbon content (Zou et al. 2016), which is known as the green energy transition. However, it must be noted that in real cases through the energy transition period, the economy of the energy mix must be considered before planning for scenario definitions. This means the availability, accessibility, and utilization cost of each renewable option individually and in a mix must be considered to achieve the most flexible energy mix option with lower supply cost.

To quantify the environmental effects of each scenario, EELCA is used as a strong tool for the engineer to evaluate each single modification on the sustainability of the whole propylene oxide production process. In fact, replacing RFO with NG, which has been promoted as green energy, is examined as the first transition step into sustainability by considering the growing trend of NG power by the year of 2022 in the short-term (Vahl and Filho 2015) and mid-term by the year of 2030 (Xiao et al. 2016). These changes lead to sustainable augmentation related to only the CC (ES and HH), TE, and OD. Therefore, the significance of EELCA in measuring each effect is emphasized in comparison to the biased assessment. The predictions suppose that NG has less environmental burdens in contrast with the RFO. Nevertheless, according to EELCA, the environmental sustainability of NG is even less than RFO considering FE, HT, ME, PMF, and TA impacts, which fundamentally reflects the sustainability of the NG electricity debatable for this specific example, which highlights the importance of choice of fuels as demonstrated in the previous research works (Brynolf et al. 2014; Chang et al. 2017; de Almeida et al. 2017). Therefore, EELCA provides a general picture for selecting appropriate fuel. In the moving from NG towards renewable energy resources, immediate alternatives like energy saving based on RFO will be applied as the future works.

Besides, EELCA results show scenario 4 has the worst environmental sustainability, while the best option is scenario 7. In addition, scenario 7 is the most sustainable scenario for 9 out of 10 impact categories, CC, OD, PMF, TA, and all ecotoxicity categories.

The total cumulative exergy depletion of the propylene oxide process can be reduced from 4.828E-01 to 4.825E-01 MJ-Eq in accordance with CExD. In this study, CExD, one of the exergetic LCIA methods, has been successfully examined as the results are consistent with ReCiPe. It should be noted that there are other exergy-based LCIA such as cumulative exergy extraction from the natural environment (CEENE) (Dewulf et al. 2007; Nhu et al. 2016), where the resource category of the land use is taken into account. The application of CEENE or consideration of land use through the recent exergy-based approaches (Alvarenga et al. 2013; Taelman et al. 2016) can have a significant impact on the environmental burdens associated with the biomass-based scenarios. Nevertheless, the application of both CExD and ReCiPe in this study provides us with a relatively comprehensive insight into the environmental impacts of all the scenarios made of different types of fuels.

Indeed, the summation of environmental burdens caused by the process can be reduced from dimensionless normalized findings of 9.63E-06 to 9.43E-06 according to ReCiPe by conducting fuel switching from RFO to the bio-based feedstock. Nevertheless, scenario 4 seems to have the lowest POF potential impact compared to scenario 7. In addition, scenario 4 shows the lowest POF potential impact, highlighting the importance of EELCA in quantifying each effect. Finally, EELCA reports the environmental sustainability of each bio-based scenario, which has less environmental sustainability considering POF effect, interpreting its effect to a magnitude analogous with other effects. Reminding that since both PG and steam generation systems have been considered as the major reason of environmental burden due to fossil fuel combustion, the proposed principle can also be implemented to the steam generation unit in the future studies. Implementing process integration optimization techniques in utility systems such as steam cogeneration (Ghannadzadeh et al. 2012) and centralized utility systems (Tarighaleslami et al. 2017) along with the proposed LCA study can even cause a further reduction in environmental burdens of chemical processes such as propylene oxide production process. Therefore, more environmentally sustainable propylene oxide production process can be achieved in the future process revamping.

4 Conclusion

Propylene oxide production technology can result in considerable hazardous chemical components; besides, it is an energy-intensive process that can lead to environmental burdens. To assess the role of NG-based and bio-based PG in sustainability augmentation of the whole propylene oxide production process, an exergy-aided environmental life cycle assessment (EELCA) assisted by Monte Carlo simulations focusing on the environmental impacts linked with resources depletion and emissions has been studied in this paper.

The significance of the appropriate selection of EM via conducting sensitivity analysis on the entire production process is presented by EELCA. The application of a wide range of energy resources by EELCA confirms that under strict process constraints, the sustainability enhancement analysis is still possible, which can be used to assess the minimum required renewable energy to achieve sustainability under the worst conditions. In this case, EELCA is a powerful tool to quantify the accurate effect of each chemical component on the environment. For example, regarding human health, it has been demonstrated that CO2 has much more unfavourable effects than the common hazardous components. Surprisingly, EELCA reveals NG-based scenarios could be less environmentally sustainable compared to RFO-based scenarios considering FD, FE, HT ME, PMF, and TA impacts.

The current project focuses on the propylene oxide production; it is recommended that EELCA be conducted to other chemical processes to find the most sensitive process to the energy transition of PG from NG towards renewable energy resources. As a result, this helps the decision-makers to identify a process, which has the most significant benefit from the alternative PG systems. Furthermore, it is recommended to utilize other exergy-based LCIA such as CEENE to take the resource category of the land use into account in the future works.

Data availability

The authors declare that the data supporting the findings of this study are available within the article and the cited references.

References

Alvarenga RAF, Dewulf J, Van Langenhove H, Huijbregts MAJ (2013) Exergy-based accounting for land as a natural resource in life cycle assessment. Int J Life Cycle Assess 18:939–947

Bauer, Maciel F (2004) Incorporation of environmental impact criteria in the design and operation of chemical processes. Braz J Chem Eng

Bösch ME, Hellweg S, Huijbregts MA, Frischknecht R (2007) Applying cumulative exergy demand (CExD) indicators to the ecoinvent database. Int J Life Cycle Assess 12:181–190

Brynolf S, Fridell E, Andersson K (2014) Environmental assessment of marine fuels: liquefied natural gas, liquefied biogas, methanol and bio-methanol. J Clean Prod 74:86–95. https://doi.org/10.1016/j.jclepro.2014.03.052

Chang Z, Wu H, Pan K et al (2017) Clean production pathways for regional power-generation system under emission constraints: a case study of Shanghai. China J Clean Prod 143:989–1000. https://doi.org/10.1016/j.jclepro.2016.12.021

D’Alessandro S, Luzzati T, Morroni M (2010) Energy transition towards economic and environmental sustainability: feasible paths and policy implications. J Clean Prod 18:291–298. https://doi.org/10.1016/j.jclepro.2009.10.015

de Almeida CF, Maciel VG, Tsambe M, de Abreu Cybis LF (2017) Environmental assessment of a bi-fuel thermal power plant in an isolated power system in the Brazilian Amazon region. J Clean Prod 154:41–50. https://doi.org/10.1016/j.jclepro.2017.03.209

Dewulf J, Bösch ME, Meester BD et al (2007) Cumulative exergy extraction from the natural environment (CEENE): a comprehensive life cycle impact assessment method for resource accounting. Environ Sci Technol 41:8477–8483. https://doi.org/10.1021/es0711415

DOE (2004) In: Fuel and energy source codes and emission coefficients. https://web.archive.org/web/20041101051713/. http://eia.doe.gov/oiaf/1605/coefficients.html

Droege P (2011) Urban energy transition: from fossil fuels to renewable power. Elsevier

Dubosc Y (2006) BASF, Dow and Solvay unite for the production of propylene oxide in an environment-friendly factory. Ludwigshafen, Germany

Durrani L, Vidrio E (2016) Environmental fate of propylene oxide. California Environmental Protection Agency, California, USA

EIA (2015) With increased regulation, continued decline in residual fuel oil demand is expected. https://www.eia.gov/todayinenergy/detail.php?id=23292#. Accessed 3 Dec 2017

EU (2002) Methyloxirane (propylene oxide) summary risk assessment report, European Commission, Institute for Health and Consumer Protection European Chemicals Bureau, https://echa.europa.eu/documents/10162/c9918161-1be3-4b76-9088-72eaee9cfaca

Ghannadzadeh A (2018a) Assessment of power generation from natural gas and biomass to enhance environmental sustainability of a polyol ether production process for rigid foam polyurethane synthesis. Renew Energ 115:846–858. https://doi.org/10.1016/j.renene.2017.07.059

Ghannadzadeh A (2018b) Exergy-aided environmental sustainability assessment of ethylene dichloride-vinyl chloride production process. Chem Eng Res Des. https://doi.org/10.1016/j.cherd.2017.08.016

Ghannadzadeh A, Meymivand A (2019) Environmental sustainability assessment of an ethylene oxide production process through cumulative exergy demand and ReCiPe. Clean Techn Environ Policy 21:1765–1777. https://doi.org/10.1007/s10098-019-01748-3

Ghannadzadeh A, Perry S, Smith R (2012) Cogeneration targeting for site utility systems. Appl Therm Eng 43:60–66. https://doi.org/10.1016/j.applthermaleng.2011.10.006

Ghannadzadeh A, Tarighaleslami AH (2019) Exergetic environmental sustainability assessment supported by Monte Carlo simulations: a case study of a chlorine production process. Env Prog & Sust Energ. https://doi.org/10.1002/ep.13179

Ghannadzadeh A, Tarighaleslami AH (2020) Environmental life cycle assessment of glycerine production: energy transition from natural gas to biomass. Sustain Energy Technol Assess 42:100775

Ghannadzadeh A, Shabani R, Ale Ebrahim H (2020) Environmental life cycle assessment of an ammonia production process through cumulative exergy demand and ReCiPe: a focus on power generation from natural gas and biomass. Int J Exergy 33(4):411–426

Ghanta M, Fahey DR, Busch DH, Subramaniam B (2013) Comparative economic and environmental assessments of H2O2-based and tertiary butyl hydroperoxide-based propylene oxide technologies. ACS Sustain Chem Eng 1:268–277

Goedkoop M, Heijungs R, Huijbregts M et al (2009) ReCiPe 2008+. A life cycle impact assessment method which comprises harmonised category indicators at the midpoint and the endpoint level

Guan (2013) Research on environment friendly propylene oxide production technology. http://en.cnki.com.cn/Article_en/CJFDTotal-LNHG201307012.htm. Accessed 14 Jun 2018

Heijungs R, Kleijn R (2001) Numerical approaches towards life cycle interpretation five examples. Int J Life Cycle Assess 6:141–148

Hong J, Shaked S, Rosenbaum RK, Jolliet O (2010) Analytical uncertainty propagation in life cycle inventory and impact assessment: application to an automobile front panel. Int J Life Cycle Assess 15:499–510. https://doi.org/10.1007/s11367-010-0175-4

Hou CT (1984) Propylene oxide production from propylene by immobilized whole cells of Methylosinus sp. CRL 31 in a gas-solid bioreactor. Appl Microbiol Biotechnol 19(1):1–4

ISO (2006) 14040 International standard. Environmental management–life cycle assessment–principles and framework, International Organisation for Standardization, Geneva, Switzerland

Jacquemin L, Pontalier P-Y, Sablayrolles C (2012) Life cycle assessment (LCA) applied to the process industry: a review. Int J Life Cycle Assess 17:1028–1041

Kolman A, Chovanec M, Osterman-Golkar S (2002) Genotoxic effects of ethylene oxide, propylene oxide and epichlorohydrin in humans: update review (1990–2001). Mut. Res./Rev. Mut Res 512:173–194. https://doi.org/10.1016/S1383-5742(02)00067-4

Lanzuela NE, Sanchís FJR, Señer AR et al (2015) Uncertainty analysis in the environmental assessment of an integrated management system for restaurant and catering waste in Spain. Int J Life Cycle Assess 20:244–262. https://doi.org/10.1007/s11367-014-0825-z

Nhu TT, Schaubroeck T, Henriksson PJG et al (2016) Environmental impact of non-certified versus certified (ASC) intensive Pangasius aquaculture in Vietnam, a comparison based on a statistically supported LCA. Env Pol 219:156–165. https://doi.org/10.1016/j.envpol.2016.10.006

NREL (2014) US life-cycle inventory database. In: National Renewable Energy Laboratory. http://www.nrel.gov/lci/. (June 2014)

openLCA (2014a) openLCA 1.4 case study of a beer bottle: aluminium can vs PET bottle. openLCA. http://www.openlca.org/wp-content/uploads/2015/11/141031_LSA-Case-study_Beer-containers_PET-vs-ALU.pdf

openLCA (2014b) http://www.openlca.org/wp-content/uploads/2015/11/CaseStudyPETvsALUempty.zolca

openLCA (2016) http://www.openlca.org/

ReCiPe Normalization 2000 Factors (2010) https://sites.google.com/site/lciarecipe/file-cabinet

Raei B, Ghannadzadeh A (2018) Environmental sustainability enhancement of a petroleum refinery through heat exchanger network retrofitting and renewable energy, Adv Environ Technol. https://doi.org/10.22104/aet.2018.2340.1118

Research and Markets (2021) https://www.globenewswire.com/en/news-release/2021/03/09/2189395/28124/en/Global-Propylene-Oxide-Industry-2020-to-2027-Market-Trajectory-Analytics.html

Schultz E, Schwartz M, Yu K (2016) Production of propylene oxide from propylene using patented silver based catalyst. Senior Design Reports (CBE)

Sheldon R (2017) The E factor 25 years on: the rise of green chemistry and sustainability. Green Chem

Taelman SE, Schaubroeck T, De Meester S et al (2016) Accounting for land use in life cycle assessment: the value of NPP as a proxy indicator to assess land use impacts on ecosystems. Sci Tot Env 550:143–156. https://doi.org/10.1016/j.scitotenv.2016.01.055

Tarighaleslami AH, Walmsley TG, Atkins MJ et al (2017) Total site heat integration: utility selection and optimisation using cost and exergy derivative analysis. Energ 141:949–963

Tarighaleslami AH, Ghannadzadeh A, Atkins MJ, Walmsley MR (2020) Environmental life cycle assessment for a cheese production plant towards sustainable energy transition: natural gas to biomass vs. natural gas to geothermal. J Clean Prod 275:122999

Vahl FP, Filho NC (2015) Energy transition and path creation for natural gas in the Brazilian electricity mix. J Clean Prod 86:221–229. https://doi.org/10.1016/j.jclepro.2014.08.033

von der Assen N, Bardow A, Patel M (2016) From life-cycle assessment towards life-cycle design of carbon dioxide capture and utilization, 1st edn. Wissenschaftsverlag Mainz GmbH, Aachen

Wu K, Paranjothi G, Milford JB, Kreith F (2016) Transition to sustainability with natural gas from fracking. Sust En Tech Assess 14:26–34

Xiao B, Niu D, Guo X (2016) Can natural gas-fired power generation break through the dilemma in China? A system dynamics analysis. J Clean Prod 137:1191–1204. https://doi.org/10.1016/j.jclepro.2016.07.198

Zhou DQ, Meng FY, Bai Y, Cai SQ (2017) Energy efficiency and congestion assessment with energy mix effect: the case of APEC countries. J. Clean. Prod. 142. Part 2:819–828. https://doi.org/10.1016/j.jclepro.2016.08.166

Zou H, Du H, Broadstock DC et al (2016) China’s future energy mix and emissions reduction potential: a scenario analysis incorporating technological learning curves. J. Clean. Prod. 112. Part 2:1475–1485. https://doi.org/10.1016/j.jclepro.2015.08.012

Author information

Authors and Affiliations

Corresponding author

Additional information

Communicated by Guido W. Sonnemann.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ghannadzadeh, A., Tarighaleslami, A.H. Exergy-aided environmental life cycle assessment of propylene oxide production. Int J Life Cycle Assess 27, 20–37 (2022). https://doi.org/10.1007/s11367-021-01969-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-021-01969-z