Abstract

Purpose

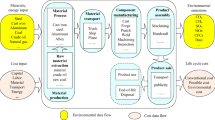

This paper provided an integrated method to evaluate environmental impact and life cycle cost (LCC) of various alternative design schemes in the early design and development stages of complex mechanical product; an optimization method of product design schemes based on life cycle assessment (LCA) and LCC is proposed as a supporting design tool to achieve optimal integration of environmental impact and cost of the design.

Methods

The applied research methods include product level deconstruction model, LCA/LCC integrated analysis model, and the product design scheme optimization method. In the life cycle environmental assessment, GaBi software and CML2001 evaluation method are used to evaluate product environmental impact. In terms of product design configuration scheme optimization, the TOPSIS method is used to optimize the design schemes generated. Taking the internal and external trim of automobile as an example, the specific implementation process of the method is illustrated.

Results and discussion

The case study indicates that, when comprehensively considering the environmental impact and cost, the composite indices of the optimal and worst schemes are 0.8667 and 0.3001, respectively; their costs are ¥164.87 and ¥179.68, respectively; and the eco points of environmental impact are 14.74 and 39.78, respectively. The cost of the two schemes are not much different, but the environmental impact of the optimal scheme is only 37.1% of the worst scheme’s; When cost is the only factor to be considered, the lowest cost design scheme is about 36.7% of the maximum scheme’s cost, and the environmental impact of the lowest cost design scheme is about 1.6 times of the maximum cost scheme’s. When environmental impact is the only factor to be considered, the least environmental impact of design scheme accounts about 31.7% of the largest; the cost of design scheme with the least environmental impact accounts for about 58.1% of the largest one’s. Integrating LCA and LCC, scientific suggestions can be provided from several perspectives.

Conclusions

By considering the environmental impact and LCC, this paper proposes a method of product design scheme optimization as a supporting design tool which could evaluate the design options of the product and identify the preferred option in the early stage of product design. It is helpful to realize the sustainability of the product. In order to improve the applicability of this method, the weighting factors of environmental impact and cost could be adjusted according to the requirements of energy saving and emission reduction of different enterprises.

Similar content being viewed by others

References

Allacker K (2012) Environmental and economic optimisation of the floor on grade in residential buildings. Int J Life Cycle Assess 17(6):813–827

Bare JC, Hofstetter P, Pennington DW et al (2000) Midpoints versus endpoints: the sacrifices and benefits. Int J Life Cycle Assess 5(6):319–326

Bekel K, Pauliuk S (2019) Prospective cost and environmental impact assessment of battery and fuel cell electric vehicles in Germany. Int J Life Cycle Assess. https://doi.org/10.1007/s11367-019-01640-8

Bovea MD, Vidal R (2004) Increasing product value by integrating environmental impact, costs and customer valuation. Resour Conserv Recycl 41(2):133–145

Chiesa M, Monteleone B, Venuta ML et al (2016) Integrated study through LCA, ELCC analysis and air quality modelling related to the adoption of high efficiency small scale pellet boilers. Biomass Bioenerg 90:262–272

Delogu M, Zanchi L, Maltese S et al (2016) Environmental and economic life cycle assessment of a lightweight solution for an automotive component: a comparison between talc-filled and hollow glass microspheres-reinforced polymer composites. J Clean Prod 139:548–560

Deng C, Wang LQ, Wu J (2007) Research on LCA and LCC integration method. China Mech Eng 18(15):1804–1809 (in Chinese)

Guinee JB (2002) Handbook on life cycle assessment operational guide to the ISO standards. Int J Life Cycle Assess 7(5):311–312

Heijungs R, Settanni E (2013) Toward a computational structure for life cycle sustainability analysis: unifying LCA and LCC. Int J Life Cycle Assess 18(9):1722–1733

Jiang Z, Zhang H, Yan W et al (2011) An evaluation model of machining process for green manufacturing. J Comput Theor Nanos 4(4):1724–1728

Kang L, Liu Y, Liang X (2015) Multi-objective optimization of heat exchanger networks based on analysis of minimum temperature difference and accumulated CO2 emissions. Appl Therm Eng 87:736–748

Kjær LL, Pagoropoulos A, Hauschild M et al (2015) From LCC to LCA using a hybrid input output model—a maritime case study. Procedia CIRP 29:474–479

Kuo, Chi T, Chen et al (2014) Applying multi-objective planning in low-carbon product design. Int J Precis Eng Man 15(2):241–249

Lee JY, An S, Cha K et al (2010) Life cycle environmental and economic analyses of a hydrogen station with wind energy. Int J Hydrog Energy 35(6):2213–2225

Lindahl M, Sundin E, Sakao T (2014) Environmental and economic benefits of Integrated Product Service Offerings quantified with real business cases. J Clean Prod 64(2):288–296

Ma J, Kim N (2016) Optimal product design for LCA with the case study of universal motors. Int J Precis Eng Man 17(9):1229–1235

Mayyas AT, Qattawi A, Mayyas AR et al (2012) LCA-based selection for a sustainable lightweight body-in-white design. Energy 39(1):412–425

Mistry M, Koffler C, Wong S (2016) LCA and LCC of the world’s longest pier: a case study on nickel-containing stainless steel rebar. Int J Life Cycle Assess 21(11):1637–1644

Nakano K, Hirao M (2011) Collaborative activity with business partners for improvement of product environmental performance using LCA. J Clean Prod 19(11):1189–1197

Nowack M, Hoppe H, Guenther E (2012) Review and downscaling of life cycle decision support tools for the procurement of low-value products. Int J Life Cycle Assess 17(6):655–665

Roberts KG, Gloy BA, Joseph S et al (2010) LCA of biochar systems: estimating the energetic, economic, and climate change potential. Environ Sci Technol 44(2):827–833

Seo KK, Park JH, Jang DS et al (2002) Approximate estimation of the product LCC using artificial neural networks in conceptual design. Int J Adv Manuf Technol 19(6):461–471

Shi JL, Wang Y, Fan S et al (2019) An integrated environment and cost assessment method based on LCA and LCC for mechanical product manufacturing. Int J Life Cycle Assess 24(1):64–77

Simões CL (2012) Modelling the economic and environmental performance of engineering products: a materials selection case study. Int J Life Cycle Assess 17(6):678–688

Su JCP, Wang YT (2012) A decision support system to estimate the carbon emissions and cost of product designs. Int J Precis Eng Man 13(7):1037–1045

Sun YD, Zhang X, Ning RX et al (2011) Research on development process of complex product based on multi-level design structure matrix. J Mechanical Eng 47(16):166–175 (in Chinese)

Tambouratzis T, Karalekas D, Moustakas N (2015) A methodological study for optimizing material selection in sustainable product design. J Ind Ecol 18(4):508–516

Valkama J, Keskinen M (2008) Comparison of simplified LCA variations for three LCA cases of electronic products from the ecodesign point of view. Paper presented at the IEEE International Symposium on Electronics & the Environment, San Francisco, May 19-22

Wang K, Zheng YJ (2012) A new particle swarm optimization algorithm for fuzzy optimization of armored vehicle scheme design. Appl Intell 37(4):520–526

Xu SD, Geng XL (2017) Method of multi-attribute group decision-making by combining cloud model and TOPSIS. Appl Res Comput 10:90–93 (in Chinese)

Zhang Y, Liang K, Li J et al (2016) LCA as a decision support tool for evaluating cleaner production schemes in iron making industry. Environ Prog Sustain 35(1):195–203

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Wulf-Peter Schmidt

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, L., Dong, W., Jin, Z. et al. An integrated environmental and cost assessment method based on LCA and LCC for automobile interior and exterior trim design scheme optimization. Int J Life Cycle Assess 25, 633–645 (2020). https://doi.org/10.1007/s11367-019-01691-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-019-01691-x