Abstract

Purpose

As the scale of the organic cultivation sector keeps increasing, there is growing demand for reliable data on organic agriculture and its effect on the environment. Conventional agriculture uses chemical fertilizers and pesticides, whilst organic cultivation mainly relies on crop rotation and organic fertilizers. The aim of this work is to quantify and compare the environmental sustainability of typical conventional and organic pepper cultivation systems.

Methods

Two open field pepper cultivations, both located in the Anthemountas basin, Northern Greece, are selected as case studies. Life cycle assessment (LCA) is used to quantify the overall environmental footprint and identify particular environmental weaknesses (i.e. unsustainable practices) of each cultivation system. Results are analysed at both midpoint and endpoint levels in order to obtain a comprehensive overview of the environmental sustainability of each system. Attributional LCA (ALCA) is employed to identify emissions associated with the life cycles of the two systems. Results are presented for problem-oriented (midpoint) and damage-oriented (endpoint) approaches, using ReCiPe impact assessment.

Results and discussion

At midpoint level, conventional cultivation exhibits about threefold higher environmental impact on freshwater eutrophication, than organic cultivation. This arises from the extensive use of nitrogen and phosphorus-based fertilizers, with consequent direct emissions to the environment. The remaining impact categories are mainly affected by irrigation, with associated indirect emissions linked to electricity production. At endpoint level, the main hotspots identified for conventional cultivation are irrigation and fertilizing, due to intensive use of chemical fertilizers and (to a lesser degree) pesticides. For organic pepper cultivation, the main environmental hotspots are irrigation, machinery use, and manure loading and spreading processes. Of these, the highest score for irrigation derives from the heavy electricity consumption required for groundwater pumping associated with the fossil-fuel-dependent Greek electricity mix.

Conclusions

Organic and conventional cultivation systems have similar total environmental impacts per unit of product, with organic cultivation achieving lower environmental impacts in ‘freshwater eutrophication’, ‘climate change’, ‘terrestrial acidification’ and ‘marine eutrophication’ categories. Conventional cultivation has a significantly greater effect on the freshwater eutrophication impact category, due to phosphate emissions arising from application of chemical fertilizers.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Over the recent decades, organic farming has increased sharply in many parts of the world (EC 2013, 2014; Foteinis and Chatzisymeon 2016). In Europe, a major milestone was the implementation of EC Reg. 2078/92, which promoted organic farming in the belief that it yields more positive ecological effects than conventional farming (EC 1998). Although organic farming is of relatively higher cost than conventional farming, Europe’s organic land expanded by 0.5 M ha/year since 2005, resulting in more than 5 % of European agricultural area being taken up by organic farmland (EC 2013). The steadily increasing demand for organic products derives from consumers’ perceived needs for a healthier way of life, because organic food is considered safer than conventionally grown products (López et al. 2014). Moreover, organic farming plays an important role in the EU agricultural policy framework, which assumes that organic farming has minimal adverse impact on the environment (EC 2007, 2013). As the scale of the organic sector keeps increasing, there is growing demand for reliable data on organic agriculture (EC 2013) and its effect on the environment.

Conventional agriculture uses chemical inputs, such as fertilizers, herbicides and pesticides, whilst organic cultivation mainly relies on crop rotation and residues, the use of organic fertilizers and biological pest control (Stolze et al. 2000; EC 2007, 2013). As a result, it is claimed that organic farming is less harmful to the environment than conventional farming (Stolze et al. 2000; EC 2013, 2014; FAO, 2016). However, this is a matter of debate since the higher crop yield of conventional systems could in certain cases outweigh the environmental benefits per product unit of organic farming (Tuomisto et al. 2012; Meier et al. 2015; Foteinis and Chatzisymeon 2016). On the one hand, organic agriculture claims long-term sustainability by considering medium- and long-term effects of agricultural interventions on the agro-ecosystem (FAO 2016). Moreover, herbicide leachate can reduce the diversity of flora and fauna in freshwater ecosystems and alter their chemical and biological quality (Laini et al. 2012), whilst pesticide residues in food result in high toxic exposure, about 103 to 105 times higher than that from drinking water or inhalation (Margni et al. 2002). Therefore, better evaluation practices for assessing pesticide residues in food need to be established as a matter of priority. Organic agriculture also appears more beneficial to biodiversity, but many knowledge gaps exist (Hole et al. 2005). On the other hand, the main drawbacks of organic farming are its higher cost (EC 2013) and lower crop yield. Crop yield differences between organic and conventional systems range from 5 to 34 %, while, on average, organic cultivation can reach about 80 % of the yield of conventional cultivation but with substantial variations depending on system and site characteristics (De Ponti et al. 2012; Meier et al. 2015). Consequently, it has been reported that environmental impacts per area of farmed land are usually lower for organic systems, but, when related to the quantity produced, the impacts could often be higher depending on the crop and local conditions (Tuomisto et al. 2012; Meier et al. 2015; Foteinis and Chatzisymeon 2016). Nonetheless, a recent review article on LCA studies comparing agricultural products from conventional and organic farming systems (Meier et al. 2015) reported that it is not yet possible to draw a conclusive picture on the general environmental performance of the two farming systems. In this context, comparative LCAs often do not adequately differentiate the specific characteristics of the two systems while basing assumed values for organic systems on those for conventional agriculture (Meier et al. 2015). Crop-specific investigations are therefore necessary into the relative environmental impacts of organic and conventional agriculture systems. A compendium of environmental impacts would enable decision-makers to implement more harmonized and sustainable agricultural policies.

LCA is a powerful tool that quantifies environmental impacts of constituent processes and estimates the overall environmental sustainability of a system, providing informed options to stakeholders including decision-makers, researchers and communities. Therefore, LCA provides a reliable, complete, macroscopic quantification of net environmental impacts, and so its use is steadily increasing (Foteinis et al. 2011; Chatzisymeon et al. 2013). Meier et al. (2015) used LCA to compare several farm products, including milk, beef, pig, poultry, arable crops, fruits and vegetables, produced by different farming systems and concluded that more comprehensive LCAs were needed to compare the environmental sustainability of organic and conventional products (Meier et al. 2015). To date, LCA has been used to investigate the environmental impacts of various farms producing vegetables and fruits (Noponen et al. 2012; Tuomisto et al. 2012; O’Brien et al. 2014; Meier et al. 2015; Foteinis and Chatzisymeon 2016; Fusi et al. 2016), but, to the authors’ knowledge, LCA has not been applied to assess the sustainability of organic and conventional pepper cultivation. Instead, emphasis has been placed on differences between organic and conventional pepper fruit yield or pepper nutritive value, e.g. antioxidant and bioactive composition (Del Amor 2007; Szafirowska and Elkner 2009; López et al. 2014).

The aim of this paper is to compare typical conventional and organic cultivation systems used for open field pepper cultivation in Mediterranean countries, in terms of environmental sustainability. The case studies comprise two open field pepper cultivations, both located in the Anthemountas basin, Northern Greece. LCA is used to quantify the overall environmental footprint and identify particular environmental weaknesses (i.e. unsustainable practices) of each cultivation system. Results are analysed at both midpoint and endpoint levels in order to obtain a comprehensive overview of the sustainability of each system.

2 Materials and methods

2.1 LCA software and libraries

LCA analysis was undertaken using SimaPro, version 8.0.1.4 which incorporates all common life cycle inventory (LCI) datasets, including ecoinvent v3.1, the European Life Cycle Database (ELCD) and the industry-specific Agri-footprint database (PRé 2014).

2.2 Case study and data collection

Capsicum annuum plants (Solanaceae family) include chilli peppers and bell peppers (or paprika). Such plants are cultivated worldwide, with the Mediterranean countries specialising in bell peppers, an example being red peppers grown in Crete, Dodekanisa and Northern Greece, the latter notable for its extended areas of organic pepper cultivation (Delioglou 2010). The case study focuses on organic and conventional Florina pepper (Φλωρίνης in Greek) cultivation in the eastern part of the Anthemountas basin, Northern Greece. This is an area of traditional agriculture where a variety of vegetable crops are cultivated (Andreadakis et al. 2007), and soil conditions are particularly favourable for pepper cultivation, with good drainage properties and pH values between 5.5 and 7.0 (Delioglou 2010). Data were obtained from a certified organic vegetable farm and a conventional pepper farm, which have been operating for at least two decades, by carrying out direct interviews with farmers (Foteinis and Chatzisymeon 2016). These farms were identified by the local agriculturist as representative (i.e. inputs, outputs, agricultural practices and irrigation techniques) of local conditions and therefore were selected for further assessment. All farmers within the greater area work closely with the local agriculturist who has an overview of the agricultural activities, crop management techniques and yield, and application of pesticides and fertilizers by the farmers. Data collected at all stages of open field cultivation were then processed using life cycle assessment (LCA) software.

2.3 System boundaries

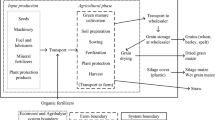

Figure 1 shows the boundaries of conventional and organic pepper cultivation systems. Both systems have similar post-harvesting activities, such as packaging, transportation, sale and consumption, and so these are treated as being outside the boundaries. In each system, seedling growth occurs in a plant nursery where steady temperature and humidity conditions are maintained. By assuming similarity between the plant nurseries, seedling growth is also treated as outside the system boundaries. Therefore, LCA, starting at seedling planting and ending at pepper fruit manual harvesting, is performed for each cultivation system. A mean transportation distance of 30 km from retail to farmer is ascribed, in both systems, to all main environmentally-relevant physical flows, i.e. of manure and chemical fertilizers. Pesticides have negligible weight compared to organic and chemical fertilizers, and so the transport of pesticides from manufacturer to retailer is not included within the boundaries of this LCA.

Plant nurseries are assumed to be located close to the field, and so seedling transportation is external to the boundaries. CO2 sequestration is also considered to be external to the boundaries because, after consumption, the biogenic CO2 fixation of pepper fruit is quickly released back to the atmosphere.

2.4 Functional unit

A yield of 1000 kg (1 t) of marketable pepper fruits is set as the functional unit, and all results are expressed per unit product. This functional unit allows for the fact that organic pepper cultivation achieves 37.5 % lower production yield than conventional cultivation. In both systems, a fraction of the pepper yield is non-marketable, depending on weather conditions and pest control. This fraction is usually small and the waste product, which is of organic nature, is either disposed of or used for other purposes, such as animal feedstock. In our case studies, the farmers dispose the non-marketable yield and so this process and relevant emissions are not included within the system boundaries.

2.5 Assumptions and limitations

The present analysis is based on the following assumptions: (i) data obtained from a certified organic farm and conventional vegetable cultivation are representative of pepper cultivation in the greater area, (ii) no weather extremes occur during cultivation, (iii) average values hold for the technology considered, (iv) energy used for irrigation purposes comes solely from the Greek energy mix, and (v) a mean distance of 30 km for transporting fertilizers and pesticides to the field. The study is limited to data gathered in Northern Greece during the summer of 2015.

2.6 Life cycle inventory (LCI)

Table 1 lists the life cycle inventories (LCIs) for both cultivation systems as mean values calculated over the reference period of summer 2015, obtained from the interview data collected from farmers. It should be noted that in Northern Greece, pepper seedlings are planted in the field during spring, from early to mid-May, and plant cultivation ends in November, when the climate gets colder and light frosts occur.

Mean marketable yields of organic and conventional pepper fruits per 1000 m2 of cultivable area are respectively 2500 ± 500 and 4000 ± 1000 kg. Sales of organic pepper fruits are less sensitive than conventional pepper fruits to shape irregularity and surface imperfections, helping boost the organic cultivation marketable yield. In both cultivation systems, the field undergoes two mechanical agitations (by tractor-driven ploughing and harrowing) before manual planting of seedlings in rows of spacing between 50 and 70 cm. The final seedling spacing ranges from 35 to 45 cm.

Table 1 follows Nemecek and Kagi (2007) and recreates ecoinvent’s LCI dataset for Spanish irrigation water using the same production volume while fitting the ratio of groundwater to surface water and the electricity mix to the regional conditions. In both case studies, water is pumped from drilled wells of 60 m depth, using electric submersible pumps. When creating the Greek irrigation dataset, it is assumed that water is sourced solely from wells, and all energy supplied as electricity from the Greek energy grid, i.e. 54 % lignite, 11 % crude oil, 17 % natural gas and 18 % renewable energy (Chatzisymeon et al. 2013). Drip irrigation is used in both systems.

After the seedlings have been planted, frequent light irrigation is employed, which becomes more intense as the plant mass increases. In general, organic cultivation achieves better water management and requires lower water inputs per farmed area, because soils rich in organic matter retain water more efficiently (Bot and Benites 2005; Kassam et al. 2013). Estimation of irrigation water use is approximate, because such water use depends on soil type, rain frequency, climate, irrigation method and efficiency—the latter partly depending on individual farmers’ environmental awareness. Our interviews indicate that organic farmers are conscious of water saving and irrigation practices. Noting the local climate, where showers occur in May and early June, we estimate that ~400 m3/1000 m2 and ~360 m3/1000 m2 of water are used for conventional and organic open field pepper cultivation, respectively.

Organic cultivation partially covers its fertilizer requirements through crop rotation and residues and (primarily) through application of manure to the field before pepper seedlings are planted. The organic farm under study uses potassium and calcium of organic nature and effective microorganisms (EM) as fertilizers. Conventional pepper cultivation mainly utilizes chemical fertilizers derived from nitrogen, phosphorus and potassium (NPK). Table 1 lists the various system inputs, including chemical fertilizers, herbicides, fungicides and insecticides employed in the conventional and organic farms.

Similar types of machinery are used in both systems. In organic pepper cultivation, the field is firstly ploughed, then harrowed, and afterwards manure is applied by mechanical means. During a single cultivation period, the field is tilled five times, essentially to remove unwanted vegetation. In conventional pepper cultivation, the field is in turn ploughed, harrowed and has herbicides added to the soil. Fertilizing is achieved after planting, by diluting fertilizers in water and feeding them to the plants by drip irrigation. Spray applications of fungicides and insecticides to the field occur three to five times each, depending on hydrometeorological factors, such as rain frequency and temperature variation. A mean application rate of four times each is therefore assumed. Tillage is applied once, purely to improve soil aeration. The final stage of cultivation involves harvesting of pepper fruits, which is performed manually and so does not affect the relative environmental performance of conventional and organic systems. Harvesting is therefore left outside the LCA boundaries.

2.7 Impact assessment methodology

Environmental performances of the two cultivation systems are compared at both midpoint and endpoint levels using the ReCiPe impact assessment method, version 1.10 and SimaPro 8.0.1.4. Midpoint and endpoint methods look at different stages in the cause-effect chain to calculate impact. The first examines the impact earlier in the cause-effect chain, before the endpoint is reached, whereas the latter considers environmental impact at the end of the cause-effect chain. The midpoint or problem-oriented approach translates impacts into environmental themes, such as climate change and human toxicity, whereas the endpoint or damage-oriented approach translates environmental impacts into issues of concern, such as human health, natural environment and natural resources. Endpoint results are associated with higher levels of statistical uncertainty, compared to midpoint results, due to data gaps and assumptions stacking up along the cause-effect chain, but are easier to understand by decision-makers (PRé, 2014, 2016).

At midpoint level, ReCiPe uses the following 18 impact categories, which are given along with their units: ‘climate change’ (CC), kg CO2 to air; ‘ozone depletion’ (OD), kg chlorofluorocarbon (CFC-11) to air; ‘terrestrial acidification’ (TA), kg SO2 to air; ‘freshwater eutrophication’ (FE), kg P to freshwater; ‘marine eutrophication’ (ME), kg N to freshwater; ‘human toxicity’ (HT), kg 1,4 dichlorobenzene (14DCB) to urban air; ‘photochemical oxidant formation’ (POF), kg non-methane volatile organic carbon compounds (MVOCs) to air; ‘particulate matter formation’ (PMF), kg PM10 to air; ‘terrestrial ecotoxicity’ (TE), kg 14DCB to industrial soil; ‘freshwater ecotoxicity’ (FEC), kg 14-DCB to freshwater; ‘marine ecotoxicity’ (MEC), kg 14DCB to marine water; ‘ionising radiation’ (IR), kg U235 to air; ‘agricultural land occupation’ (ALO), m2 year of agricultural land; ‘urban land occupation’ (ULO), m2 year of urban land; ‘natural land transformation’ (NLT), m2 of natural land; ‘water depletion’ (WD), m3 of water; ‘metal depletion’ (MD), Kg Fe; and ‘fossil depletion’ (FD), kg oil. At endpoint level, these categories are translated into 17 endpoint impact categories, which are then multiplied by damage factors and aggregated into 3 endpoint damage categories. These are ‘ecosystems’, ‘resources’ and ‘human health’, the latter of which is partly expressed in terms of reduction in years of life expectancy and the number of years living with a disability (called the Disability Adjusted Life Years (DALYs), an index that is also used by the World Bank and World Health Organization (WHO)). The unit of ‘human health’ is years. The ‘ecosystems’ damage category is expressed as loss of species over a specified area in a given time span, and its unit is years. The ‘resources’ damage category is expressed as the surplus cost of future resource production over a finite time frame (assuming constant annual production), considering a 3 % discount rate, and is given in units of 2000US$ (PRé 2014, 2016). These three endpoint damage categories are normalized, weighted and aggregated into a single score. Even though damage-oriented (endpoint) methods are associated with high levels of uncertainty compared to problem-oriented (midpoint) methods, the aggregation of results into a single score facilitates easier interpretation and better communication to the public. A hierarchical (H) perspective is adopted, providing a consensus model based on common policy principles regarding time frame, etc. (PRé 2014).

Two separate types of LCA are utilized in practice, namely consequential (CLCA) and attributional (ALCA). CLCA assesses the environmental consequences of a change in demand, such as how pollution and resource flows within a system respond to a change in output of the functional unit. ALCA estimates the environmental burden of a product (e.g. pollution and resource flows within a given system) attributed to the delivery of a specified amount of the functional unit, assuming a status quo situation (Thomassen et al. 2008). Given that the goal of the present work is to assess the environmental impacts of conventional and organic pepper cultivation, which are largely unknown, we employ ALCA to identify emissions associated with the life cycles of both systems.

Another important step in implementation of LCA is the sensitivity analysis, which is undertaken as a systematic procedure to estimate the influence of the most significant parameters on the final outcome of the study (Björklund 2002). Here, energy use is an important parameter, and so the diversification of technologies used to compile the energy mix can have a decisive effect on the LCA results (Mathiesen et al. 2009). For this reason, a sensitivity analysis has been performed using different technologies for energy production. The worst scenario comprises the use of lignite. Improvements include supplementing the existing energy mix with other types of technologies based on renewable wind and solar energy sources, which are abundant in Greece. Another important parameter is the yield of marketable pepper fruits, because the different yields from the two systems can vary significantly. Thus, a further sensitivity analysis was also performed to investigate the effect of changed assumptions regarding yields.

3 Results and discussion

3.1 Problem-oriented approach

Results are expressed at midpoint level by means of a problem-oriented approach, which translates impacts into the 18 environmental themes in order to identify key issues related to conventional and organic pepper cultivation systems. Figure 2 shows the life cycle impact assessment (LCIA) results which are expressed in units per tonne of marketable pepper fruit yield normalized using ReCiPe’s European reference inventories. For conventional pepper cultivation, the impact category with by far the highest normalized score is ‘freshwater eutrophication’. This especially high score, about five times higher than the second highest category, ‘marine ecotoxicity’, is primarily attributed (78 %) to the fertilizer stage, when nitrogen and phosphorus from excess chemical fertilizer leach into groundwater or become transported with sediment by runoff, polluting freshwater aquatic ecosystems, and promoting eutrophication (Tuomisto et al. 2012). Other impact categories that contribute to the environmental footprint of conventional pepper cultivation, ordered from the highest to lowest scores, are ‘marine ecotoxicity’, ‘freshwater ecotoxicity’, ‘human toxicity’, ‘marine eutrophication’, ‘natural land transformation’ and ‘terrestrial acidification’. Except for ‘marine eutrophication’, these impact categories are most affected by the irrigation stage, in particular the associated electricity consumption. ‘Marine eutrophication’ (nitrogen enrichment of seawater) receives a lower score than ‘freshwater eutrophication’, reflecting the greater resilience of oceanic ecosystems to direct nutrient emissions when fertilizers are applied in conventional pepper cultivation. The use of pesticides mainly affects ‘marine ecotoxicity’, and to a lesser degree ‘freshwater ecotoxicity’ and ‘human toxicity’. Although drip irrigation pipes have a minor impact on ‘fossil depletion’ due to their fabrication from PVC, their overall impact is very small owing to their longevity.

For organic pepper cultivation (Fig. 2), the midpoint impact category that has the highest score is again ‘freshwater eutrophication’; in this case however, it has a normalized score of 0.253, which is about three times lower than that for conventional cultivation (with a score of 0.780). This confirms the direct environmental impact of chemical fertilizers used in conventional agriculture, especially with regard to freshwater eutrophication. Figure 2 also highlights that irrigation is overwhelmingly the main contributor (~95 %) to ‘freshwater eutrophication’, where organic cultivation is concerned. This is due to the electricity consumed in pumping groundwater for irrigation. In Greece the energy mix is heavily dependent on fossil fuels comprising 54 % lignite, 11 % crude oil, 17 % natural gas and 18 % renewable energy (Chatzisymeon et al. 2013), and so emissions caused by fossil fuel extraction indirectly impact the ecosystem. More specifically, the impact on freshwater is due to phosphate emissions from lignite mining and nitrogen oxide emissions from combustion (Atilgan and Azapagic, 2015). Irrigation is also the main contributor to ‘marine ecotoxicity’, ‘freshwater ecotoxicity’, ‘human toxicity’ and ‘natural land transformation’ impacts. Again, the primary cause is the fossil-dependent energy mix and its associated direct and indirect emissions to the environment. Both lignite mining and combustion processes release toxic materials including metals, sulphurs and polycyclic aromatic hydrocarbons (PAHs) to the environment, thus further contributing to the aforementioned adverse impacts (Stalikas et al. 1997; Atilgan and Azapagic 2015). Machinery use also exhibits higher scores in all impact categories for organic rather than conventional cultivation, owing to the more intense utilization of machinery in organic agriculture. Moreover, manure transportation and spreading processes, absent in conventional cultivation, lead to higher scores being attained for machinery processes because of the considerable quantity of manure used in organic cultivation.

3.2 Damage-oriented approach

The ReCiPe endpoint (damage-oriented) method is next applied. This method can translate environmental impacts into issues of concern or damage categories, namely human health, natural environment and natural resources and thus is a very useful tool for researchers and policymakers. Figures 3 and 4 illustrate the main contributors to the total aggregated environmental impacts of conventional and organic pepper agriculture systems. For conventional cultivation, the main environmental impacts are attributed to irrigation (49.6 %) and fertilizers (40.2 %), with machinery contributing 10.2 %. Irrigation impact is dominated by electricity consumption and agricultural machinery, which are responsible for 27.1 and 10.8 % of the total environmental impact, respectively. The fertilizer impact is predominantly due to the use of nitrogen-phosphorus-potassium (N-P-K) compounds and calcium ammonium nitrate, which cause 30.5 and 5.22 % of the total environmental impact. The high value attributed to N-P-K arises from (i) the direct adverse effects of N-P-K emissions to the environment including eutrophication and (ii) the large quantities of energy and natural resources consumed in their production (Worrell and Blok 1994).

For organic pepper cultivation, the key contributor to environmental impact is irrigation (68.5 %) which consumes electricity (37.4 %) from the Greek energy mix and relies on machinery (17.9 %) including pumps and pipe networks for groundwater extraction (Fig. 4). Machinery used for ploughing, harrowing, hoeing and manure application provides 23.5 % of the total environmental impact. In organic cultivation, fertilizing is responsible for only 7.98 % of the total environmental impact, which is mainly attributed to the transport of manure to the field.

Figure 5 presents the contributions at each stage (i.e. irrigation, fertilizing and machinery) to ReCiPe’s three damage categories. Results are weighted to highlight the most important environmental impacts of each cultivation system. In both cultivation systems, the ‘human health’ damage category yields the highest score. This damage category is the aggregated result of the following endpoint impact categories: ‘climate change human health’, ‘ozone depletion’, ‘human toxicity’, ‘photochemical oxidant formation’, ‘particulate matter formation’ and ‘ionizing radiation’. For conventional cultivation (Fig. 5), the ‘human health’ damage category is primarily affected by irrigation (electricity consumption from the Greek grid), secondarily by fertilizing (emissions originating from the underlying production processes) and finally by machinery use (combustion of diesel fuel). For organic cultivation, irrigation is again the main contributor to ‘human health’ damage, followed by machinery use, which is to be expected because machinery is more intensively used in organic than in conventional cultivation. Finally, fertilizing only makes a small contribution to this category, which is attributed to airborne emissions originating from transport of manure to the field.

The second most affected damage category in both cultivation systems is ‘resources’. This damage category is a combination of ReCiPe’s endpoint impact categories: ‘metal depletion’ and ‘fossil depletion’. For conventional cultivation (Fig. 5), the main areas of concern for ‘resources’ damage are irrigation (again due to the energy mix) and fertilizing. In the latter case, the production of chemical fertilizers consumes large quantities of natural resources and is also energy intensive, thus also providing stress to the impact category on ‘fossil depletion’. Machinery makes a small contribution, owing to the burning of fossil fuels (diesel) during ploughing and harrowing and to the metals used for machinery construction. For organic cultivation, the ‘resources’ damage category is primarily affected by irrigation (electricity from the Greek energy grid). Moreover, the greater use of machinery in organic cultivation contributes to both metal and fossil depletion. Fertilizing makes the smallest contribution, which is attributed to the diesel fuel burned during the transport of manure.

For both cultivation systems, the damage category with the lowest score is ‘ecosystems’ which derives from combining the following endpoint impact categories: ‘climate change ecosystems’, ‘terrestrial acidification’, ‘freshwater eutrophication’, ‘terrestrial ecotoxicity’, ‘freshwater ecotoxicity’, ‘marine ecotoxicity’, ‘agricultural land occupation’, ‘urban land occupation’ and ‘natural land transformation’. In conventional cultivation, the main contributors include fertilizing (i.e. impacts on freshwater eutrophication) and irrigation (i.e. indirect emissions from fossil fuel extraction and electricity production). In organic cultivation, the main contributor is irrigation, followed by machinery (i.e. indirect emissions from machinery construction affecting mainly ecotoxicity impact categories).

By aggregating ReCiPe’s three damage categories into a single score, the total environmental footprint is estimated in terms of Eco-indicator point (Pt) units, i.e. one thousandth of the yearly environmental load of an average European citizen. Figure 6 indicates that both cultivation systems exhibit similar environmental performance per product unit (1 t of marketable fruit yield). In particular, the environmental footprint per tonne of conventional pepper cultivation is 11 Pt, slightly lower than that of organic pepper cultivation, which is 11.5 Pt. Figure 6 shows that the damage category ‘ecosystems’ attains a slightly lower score for organic cultivation than conventional agriculture. This lower score could be attributed to the government ban on use of synthetic pesticides and nitrogen-based fertilizers, which positively impacts on wildlife conservation and the landscape (Stolze et al. 2000). Nonetheless, conventional cultivation achieves lower scores in the ‘resources’ and ‘human health’ damage categories, which may be attributed to the higher irrigation requirement and associated electricity consumption by organic agriculture. Combustion of fossil fuels to produce electricity has a high impact on ‘human health’; this is particularly the case for lignite which is the main constituent of the Greek energy mix. The ‘human health’ damage category is also affected, to a lesser degree, by diesel consumption in the machinery stage and by the manure spreading process that both result in airborne emissions. Organic irrigation scores more highly for ‘resources’, again because of fossil fuel usage by the irrigation system and cultivation machinery. It should be noted that particularly machinery highlycontributes to ‘resources’ damage because of the resources consumed during manufacture (e.g. metals, fossil fuels) and operation (e.g. diesel consumption).

Therefore, even though conventional pepper cultivation strongly depends on chemical fertilizers, it exhibits an overall slightly lower total environmental footprint, which is attributed to its higher (i.e. 4 t/year) marketable fruit yield, compared to organic cultivation (2.5 t/year). In other words, organic cultivation requires more land, and hence more irrigation and machinery to hoe and plough the land, to produce the same amount of pepper fruit product. Expressing the results per unit area of farmland, then the environmental footprint of organic pepper cultivation is about 35 % lower than the conventional system. This is in accordance with previous LCA studies comparing agricultural products from conventional and organic farming systems, which have shown that impacts per area of farmed land are usually lower in organic systems, but, when related to the quantity of products, the impacts often turn out to be higher (Tuomisto et al. 2012; Meier et al. 2015; Foteinis and Chatzisymeon 2016).

Potential limitations arise from the level of uncertainty of data collected during the LCI stage, data availability and the impact assessment methodology. First, the spatial scale is limited to Northern Greece and its climate conditions. Moreover, the temporal scale of the collected data refers to 2015, when the prevailing climate conditions were temperate, meaning that weather extremes lay outside the boundaries of the study. Even though typical farms were examined, it is quite possible that a few farmers in the area use non-typical types and quantities of pesticides/fertilizers and follow different cultivation practices, e.g. surface irrigation, which could potentially lead to different environmental impacts. Nonetheless, the vast majority of conventional and organic farmers are described by the data obtained from the farmers surveyed, whilst typical climate conditions existed during the selected reference period, making results robust. Another limitation is the absence of certain data from proprietary LCI databases. Data on equivalent rather than exact machinery are used and only the main ingredients of pesticides are available in existing databases.

3.3 Sensitivity analyses

A sensitivity analysis dealing with the marketable pepper fruit yield is carried out to investigate the effect of changed assumptions regarding yields on the environmental sustainability of both cultivation systems. In conventional agriculture the marketable pepper fruit yield ranges from 3 to 5 tons, whilst in organic it ranges from 2 to 3 tons (Table 1). The worst case and best case scenarios are therefore examined for each cultivation system, corresponding respectively to minimum and maximum marketable yields. For the best case scenario (maximum yield), the environmental impacts of both cultivation systems reduce compared to the original scenario (mean yield). In the best case scenario, the total environmental footprint of conventional agriculture is 9.66 Pt, whereas that of organic is 10.84 Pt per tonne of marketable pepper fruit. Thus, for the highest yield, the conventional system has a total environmental footprint per product unit about 11 % lower than for the organic system. This is attributed to conventional system having a higher maximum yield than the organic system. Both systems have similar environmental footprints for the worst case scenario of minimum marketable yield, with values of 16.09 (conventional) and 16.27 (organic) Pt per tonne of marketable pepper fruit. For the worst case scenario, both cultivation systems have increased environmental impacts compared to the original scenario (mean yield). For both cultivation systems, the total environmental footprint is affected by marketable yield changes, with conventional cultivation being more sensitive than organic. Weather has the greatest influence on pepper yield, and so its influence is likely to be similar in both systems. However, pests could restrict total marketable yield in organic cultivation, unlike conventional pepper systems where pests are controlled by chemical means.

A second sensitivity analysis is carried out concerning electricity consumption during irrigation, one of the main environmental hotspots experienced by both cultivation systems. Irrigation makes a high contribution to the total environmental footprint of conventional and organic pepper cultivation systems. First, irrigation relies on infrastructure and machinery for water withdrawal and transfer. Second, irrigation consumes electricity for water pumping and distribution. In the present case studies, water is directly withdrawn from wells; electricity driving the irrigation process is supplied by the Greek grid, which is heavily dependent on fossil fuels and thus increases environmental impact. This effect is also discernible in the total environmental footprint of organic pepper cultivation which is slightly higher than conventional cultivation, because organic cultivation requires larger quantities of water per unit product. Hence, the sensitivity of both cultivation systems is assessed with respect to the energy mix. For this reason, the best and worst case scenarios are employed and the response assessed of the conventional and organic pepper cultivation systems. As the best case scenario, an electricity mix totally comprising wind and solar renewable energy sources (RES) is examined; both of these RES are readily available in Greece and could provide the electricity needed for water pumping. As the worst case scenario, an electricity mix comprising lignite is considered, noting that lignite is amongst the least environmentally friendly choices. The original scenario is where electricity is provided by the existing grid.

Scenario S1 entails use of wind energy for irrigation, instead of electricity imported from the Greek grid. It is assumed that electricity generated by an onshore wind turbine (capacity in the range from 1 to 3 MW) could cover the energy needs of the irrigation process for both systems; the results are different to those from the original scenario (i.e. electricity from the Greek grid). In scenario S1, the total environmental footprint of conventional cultivation reduces by about 26 %, to 8.09 Pt (c.f. 11 Pt in the original scenario). For the 8.09 Pt case, irrigation, machinery and fertilizing stages contribute 31.3, 13.9 and 54.8 % to the total environmental footprint. For the original scenario, electricity consumption during irrigation contributes 2.99 Pt per tonne of conventional pepper yield or 27.1 % of the total environmental footprint. In scenario S1, electricity from wind energy results in a much lower value of 0.055 Pt per tonne of conventional pepper yield (i.e. 0.68 % of the total environmental footprint of scenario S1). The remaining 30.62 % or 2.475 Pt of the irrigation stage in scenario S1 is attributed to infrastructure and machinery required for irrigation; the values of which are similar for both organic and conventional pepper cultivation.

The total environmental footprint for organic pepper cultivation amounts to 7.29 Pt per pepper fruit tonne, achieving a 37 % reduction compared to the original scenario, where the total environmental footprint is 11.5 Pt. In scenario S1, irrigation, machinery and fertilizing stages are responsible for 50.2, 37.2 and 12.6 % of the total environmental footprint. Moreover, electricity from wind energy contributes only 1.09 % or 0.0792 Pt to the total environmental footprint, compared to 4.31 Pt or 37.4 % for the original scenario. The remaining 49.1 % of the irrigation stage in scenario S1 is again attributed to infrastructure and machinery required for irrigation. Overall, the use of wind energy substantially reduces the predicted total environmental footprint of conventional and organic pepper cultivation systems by 26 and 37 % respectively, the higher reduction of the organic system owing to its higher irrigation needs. As a result, in scenario S1, the organic system results in about 10 % lower total environmental footprint per product unit, compared to conventional pepper cultivation. Moreover, when wind energy is used, organic pepper cultivation yields a lower score in all three of ReCiPe’s damage categories, compared to conventional cultivation (Fig. 7).

Sensitivity analysis for both conventional (red) and organic (green) cultivation systems undertaken by exploring alternative energy source scenarios for electricity usage from (a) the Greek mix (original scenario), (b) wind energy (scenario S1), (c) solar energy (scenario S2) and (d) lignite (scenario S3)

Scenario S2 examines use of solar energy. Figure 7 shows the results. In scenario S2, photovoltaic (PV) systems (3KWp single-Si panels mounted on slanted roofs) are used to provide electricity during irrigation. The results are similar to those obtained for wind energy (scenario S1). According to ReCiPe’s endpoint method, the total environmental footprint of conventional agriculture, when using solar energy, is 8.27 Pt per pepper fruit tonne. In scenario S2, irrigation contributes 32.8 %, machinery 13.7 % and fertilizing 53.6 % to the total environmental footprint of conventional pepper cultivation. In this case, electricity consumption during the irrigation stage amounts to 2.81 % (0.23 Pt) of the total environmental footprint. This higher contribution reflects the fact that, in general, wind turbines have lower environmental impact than solar PVs.

The environmental footprint of organic cultivation in scenario S2 is 7.54 Pt, with irrigation, machinery and fertilizing responsible for 51.9, 35.9 and 12.2 % of the total environmental footprint. In this case, electricity consumption from solar energy contributes 4.44 % (0.34 Pt) to the total environmental footprint. Overall, use of solar energy again leads to substantial reductions in the total environmental footprints of the conventional and organic pepper cultivation systems (by 25 and 34 %, respectively). Therefore, in scenario S2, organic cultivation exhibits 8.8 % lower environmental footprint per unit of product, compared to conventional cultivation. For both solar and wind energy, organic pepper cultivation yields a lower score in all three of ReCiPe’s damage categories, compared to conventional cultivation (Fig. 7).

Finally, the worst case scenario (S3) is examined, where electricity originates solely from lignite combustion. As expected, scenario S3 exhibits the highest environmental footprint, and the highest score in all three damage categories considered (Fig. 7). According to ReCiPe’s endpoint method, the total environmental footprint of conventional agriculture amounts to 12.07 Pt per pepper fruit tonne in scenario 3, of which 53.9 % is attributed to irrigation, 9.4 % to machinery use and 36.7 % to fertilizing. Electricity consumption during irrigation amounts to 33.4 % (~4 Pt) of the total environmental footprint, reflecting the high environmental impact of lignite extraction and combustion as part of electricity production. For organic cultivation, scenario S3 yields a score of 13.01 Pt per pepper fruit tonne, with irrigation, machinery and fertilizing being responsible for 72.1, 20.8 and 7.1 % of the total environmental footprint. Electricity consumption originating from lignite contributes by 44.6 % (5.8 Pt) to the total environmental footprint. As a result, conventional cultivation in scenario S3 exhibits ~7 % lower environmental footprint per unit of product, compared to organic cultivation. For both cultivation systems, the use of lignite led to a higher score in all three of ReCiPe’s damage categories, compared to the foregoing scenarios (Fig. 7). Overall, the use of lignite increases the environmental impact of both systems, highlighting the importance of the electricity mix composition on the total environmental sustainability of agricultural cultivation systems.

4 Conclusions

The environmental footprint and key environmental hotspots of organic and conventional open field pepper cultivation systems have been identified by LCA methodology using information from a case study in the Anthemountas basin (Northern Greece). The main conclusions are listed below:

-

At midpoint level, the highest normalized environmental impact of both cultivation systems is in the ‘freshwater eutrophication’ impact category. Owing to direct emissions from the much greater use of chemical fertilizers, conventional cultivation attains a score three times larger than organic cultivation.

-

At endpoint level, irrigation provides the major impact for both cultivation systems, mainly due to the high consumption of electricity supplied from the Greek energy mix. It should be noted that the Greek mix is dominated by fossil fuels (i.e. 54 % lignite, 11 % crude oil, 17 % natural gas and 18 % renewable energy) and therefore yields high environmental impact.

-

Overall, both cultivation systems have similar total environmental impacts. Organic cultivation achieves a slightly lower score for the ‘ecosystems’ damage category, whereas conventional cultivation performs better in the ‘resources’ and ‘human health’ damage categories. In total, conventional cultivation exhibits a slightly better environmental performance due to its higher crop yield and to Greece’s fossil-fuel-dependent electricity mix used during the irrigation stage. If results are expressed per unit of area, then organic pepper cultivation has about 35 % lower total environmental impacts in the resources, ecosystems and human health damage categories.

-

When wind and solar energy are used to meet the electricity needs of the irrigation stage, both systems have decreased environmental footprint. Organic agriculture has a lower total environmental footprint (about 10 and 9 % in the case of wind and solar energy, respectively) and also a lower score in all three damage categories (i.e. ‘ecosystems’, ‘resources’ and ‘human health’) compared to conventional agriculture. In short, the introduction of renewable energy sources (RES) is likely to improve the sustainability of conventional and organic pepper cultivation systems, especially the latter. On the other hand, if a fossil-fuel-oriented energy mix such as lignite is introduced, then both systems will exhibit higher environmental impact, with organic cultivation being affected the most due to its higher water inputs per unit of product.

References

Andreadakis A, Gavalakis E, Kaliakatsos L, Noutsopoulos C, Tzimas A (2007) The implementation of the water framework directive (WFD) at the river basin of Anthemountas with emphasis on the pressures and impacts analysis. Desalination 210:1–15

Atilgan B, Azapagic A (2015) Life cycle environmental impacts of electricity from fossil fuels in Turkey. J Clean Prod 106:555–564

Björklund A (2002) Survey of approaches to improve reliability in lca. Int J Life Cycle Assess 7(2):64–72

Bot A, Benites J (2005) The importance of soil organic matter. Key to drought-resistant soil and sustained food production. Food and Agriculture Organization of the United Nations, Rome

Chatzisymeon E, Foteinis S, Mantzavinos D, Tsoutsos T (2013) Life cycle assessment of advanced oxidation processes for olive mill wastewater treatment. J Clean Prod 54:229–234

De Ponti T, Rijk B, Van Ittersum MK (2012) The crop yield gap between organic and conventional agriculture. Agric Syst 108:1–9

Del Amor FM (2007) Yield and fruit quality response of sweet pepper to organic and mineral fertilization. Renew Agr Food Syst 22:233–238

Delioglou A (2010) Organic pepper and eggplant cultivation in the prefecture of Thessaloniki. Department of Crop Science, Alexander Technological Educational Institute of Thessaloniki, Greece

EC - European Commission (1998) State of application of regulation (EEC) No.2078/92: evaluation of agri-environment programmes. European Commission, DGVI Commission working document VI/7655/98: 1–150

EC - European Commission (2007) Council regulation (EC) No 834/2007 of 28 June 2007 on organic production and labelling of organic products and repealing regulation (EEC) No 2092/91. Official Journal of the Europe L189:1–23

EC - European Commission (2013) Facts and figures on organic agriculture in the European Union. European Commission, Agriculture and Rural Development, pp 46

EC - European Commission (2014) The rapid growth of EU organic farming—key facts and figures. EU Agricultural Markets Briefs, No 3, July 2014, pp 7

FAO (2016) Organic agriculture, FAO inter-departmental working group on organic agriculture. Food and Agriculture Organization of the United Nations. Rome, Italy

Foteinis S, Chatzisymeon E (2016) Life cycle assessment of organic versus conventional agriculture. A case study of lettuce cultivation in Greece. J Clean Prod 112(4):2462–2471

Foteinis S, Kouloumpis V, Tsoutsos T (2011) Life cycle analysis for bioethanol production from sugar beet crops in Greece. Energ Policy 39:4834–4841

Fusi A, Castellani V, Bacenetti J, Cocetta G, Fiala M, Guidetti R (2016) The environmental impact of the production of fresh cut salad: a case study in Italy. Int J Life Cycle Assess 21:162–175

Hole DG, Perkins AJ, Wilson JD, Alexander IH, Grice PV, Evans AD (2005) Does organic farming benefit biodiversity? Biol Conserv 122:113–130

Kassam A, Basch G, Friedrich T, Shaxson F, Goddard T, Amado TJC, Crabtree B, Hongwen L, Mello I, Pisante MSM (2013) Sustainable soil management is more than what and how crops are grown. Principles of sustainable soil management in agroecosystems. CRC Press, p 337–400

Laini A, Bartoli M, Lamastra L, Capri E, Balderacchi M, Trevisan M (2012) Herbicide contamination and dispersion pattern in lowland springs. Sci Total Environ 438:312–318

López A, Fenol J, Hellín P, Flores P (2014) Cultivation approach for comparing the nutritional quality of two pepper cultivars grown under different agricultural regimes. LWT - Food Sci Technol 58:299–305

Margni M, Rossier D, Crettaz P, Jolliet O (2002) Life cycle impact assessment of pesticides on human health and ecosystems. Agric Ecosyst Environ 93:379–392

Mathiesen BV, Münster M, Fruergaard T (2009) Uncertainties related to the identification of the marginal energy technology in consequential life cycle assessments. J Clean Prod 17(15):1331–1338

Meier MS, Stoessel F, Jungbluth N, Juraske R, Schader C, Stolze M (2015) Environmental impacts of organic and conventional agricultural products—are the differences captured by life cycle assessment? J Environ Manag 149:193–208

Nemecek T, Kagi T, (2007) Life cycle inventories of agricultural production systems. Agroscopereckenholz-tänikon research station ART, Zurich and Dubendorf

Noponen MRA, Edwards-Jones G, Haggar JP, Soto G, Attarzadeh N, Healey JR (2012) Greenhouse gas emissions in coffee grown with differing input levels under conventional and organic management. Agric Ecosyst Environ 151:6–15

O’Brien D, Brennan P, Humphreys J, Ruane E, Shalloo L (2014) An appraisal of carbon footprint of milk from commercial grass-based dairy farms in Ireland according to a certified life cycle assessment methodology. Int J Life Cycle Assess 19:1469–1481

PRé (2014) SimaPro database manual—methods library. PRé, various authors, © 2002–2015, some rights reserved

PRé (2016) SimaPro database manual. https://www.pre-sustainability.com/introduction-to-lca. Accessed 19 Sept 2016

Stalikas CD, Chaidou CI, Pilidis GA (1997) Enrichment of PAHs and heavy metals in soils in the vicinity of the lignite-fired power plants of West Macedonia (Greece). Sci Total Environ 204:135–146

Stolze M, Piorr A, Haring A, Dabbert S (2000) The environmental impacts of organic farming in Europe. Organic Farming in Europe: Economics and Policy, Volume 6:1–143 ISBN 3-933403-05-7

Szafirowska A, Elkner K (2009) The comparison of yielding and nutritive value of organic and conventional pepper fruits. Veg Crop Res Bull 71:111–121

Tuomisto HL, Hodge ID, Riordan P, Macdonald DW (2012) Does organic farming reduce environmental impacts?—a meta-analysis of European research. J Environ Manag 112:309–320

Worrell E, Blok K (1994) Energy savings in the nitrogen fertilizer industry in the Netherlands. Energy 19:195–209

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Niels Jungbluth

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Chatzisymeon, E., Foteinis, S. & Borthwick, A.G.L. Life cycle assessment of the environmental performance of conventional and organic methods of open field pepper cultivation system. Int J Life Cycle Assess 22, 896–908 (2017). https://doi.org/10.1007/s11367-016-1204-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11367-016-1204-8