Abstract

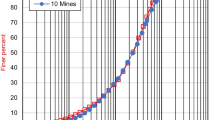

Given that many mines around the world are located in areas where fresh water is scarce, and companies are being held to increasingly stringent sustainability and environmental responsibility standards, many mines are looking to use locally available saline groundwater or seawater as mixing water in cemented paste backfill (CPB). However, the impacts of this decision on key engineering properties of CPB (e.g. strength and self-desiccation) that affect its mechanical stability need to be better understood to allow confident selection of this practical and more sustainable solution. Thus, the effect of mixing water salinity and binder type on the strength (unconfined compressive strength, UCS) development and self-desiccation (measured by suction and volumetric water content) of CPB is explored in this research. NaCl concentrations from 0 to 300 g/L were used in CPB made with silica tailings and Portland cement type I (PC). Concentrations of 10 and 35 g/L were found to moderately increase UCS, while a concentration of 100 g/L had comparable UCS to non-saline CPB and a concentration of 300 g/L was found to significantly decrease UCS over all curing times. The overall trend is 10 g/L > 35 g/L > 0 g/L > 100 g/L > 300 g/L. The UCS of the 60-day-old CPB with a NaCl of 300 g/L is significantly lower, registering a 26% decrease compared to the UCS of the 60-day-old CPB without salt. In contrast, the UCS of the 60-day-old CPBs containing 10 g/L and 35 g/L of salt exhibits a notable improvement, being 15% and 10% higher, respectively, than the UCS of the 60-day-old CPB without salt. Water content and suction monitoring were conducted up to 28 days of curing time, and it was found that suction only slightly contributed to UCS gain of the saline CPB, and high salt contents (100 and 300 g/L) significantly inhibited the self-desiccation ability of CPB due to inhibition of cement hydration by the excessive amount of salt. The increase in strength of both saline and non-saline samples was attributed primarily to the increase in cement hydration products, while the increased strength of the samples with salinities of 10 and 35 g/L was mainly attributed to the enhancement of the binder hydration due to the low amount of salt and the presence of Friedel’s salt in the pores. The effect of PC replacement by 25 to 75% with slag on CPB with 35 g/L mixing water salinity was also studied. Slag replacement of 50% and higher resulted in significantly higher UCS over most curing times. Suction likely moderately contributed to UCS of the saline CPB with slag, in addition to the presence of Friedel’s salt in the pores and the acceleration of cement and slag hydration by the presence of NaCl.

Similar content being viewed by others

Data availability

The data can be available upon request.

References

Abdul-Hussain N, Fall M (2011) Unsaturated hydraulic properties of cemented tailings backfill that contains sodium silicate. Eng Geol 123(4):288–301. https://doi.org/10.1016/j.enggeo.2011.07.011

Alarcon-Ruiz L, Platret G, Massieu E, Ehrlacher A (2005) The use of thermal analysis in assessing the effect of temperature on a cement paste. Cement Concrete Res 35:609–613

Aldhafeeri A, Fall M (2017) Sulphate induced changes in the reactivity of cemented tailings backfill. Int J Miner Process 166(10):13–23

Ali G, Fall M, Alainachi I (2021) Time-and temperature-dependence of rheological properties of cemented tailings backfill with sodium silicate. J Mater Civ Eng 33(3):04020498

Allen AD (1995) Availability of groundwater in the Goldfields-Esperance region. Hydrogeology Reports, Series Number: 1995/21, Geology Survey of Western Australia, Department of Minerals and Energy, MGR80996, 16

Basista M, Weglewski W (2008) Micromechanical modeling of sulphate corrosion in concrete: influence of ettringite forming reaction. Theoret Appl Mech 35(2008):29–52

Beaudoin JJ, Marchand J (2001) Pore structure. In: Ramachandran VS, Beaudoin JJ (eds) Handbook of analytical techniques in concrete science and technology: Principles, techniques and applications. William Andrew Inc

Belem T, Aatar O El, Bussière B, Benzaazoua M, Fall M, Yilmaz E (2006) Characterisation of self-weight consolidated paste backfill. in R Jewell, S Lawson & P Newman (eds), Paste 2006: Proceedings of the Ninth International Seminar on Paste and Thickened Tailings, Australian Centre for Geomechanics, Perth, pp. 333–345. https://doi.org/10.36487/ACG_repo/663_29

Benzaazoua M, Fall M, Belem T (2004) A contribution to understanding the hardening process of cemented pastefill. Min Eng 17(2):141–152. https://doi.org/10.1016/j.mineng.2003.10.022

Beya FK, Mbonimpa M, Belem T, Benzaazoua, M, Kalonji K Ouellet S (2015) Preliminary study of the influence of temperature and salinity on the thermal properties of hardening cemented paste backfill. In: Proceedings of the 68th Canadian Geotechnical Conference and 7th Canadian Permafrost Conference, Quebec, QC, Canada. 20–23

Bullard JW, Jennings HM, Livingston RA, Nonat A, Scherer GW, Schweitzer JS, Scrivener KL, Thomas JJ (2011) Mechanisms of cement hydration. Cem Concr Res 41(12):1208–1223. https://doi.org/10.1016/j.cemconres.2010.09.011

Chen S, Du Z, Zhang Z, Zhang H, Xia Z, Feng F (2020) Effects of chloride on the early mechanical properties and microstructure of gangue-cemented paste backfill. Const and Build Mat 235:117504. https://doi.org/10.1016/j.conbuildmat.2019.117504

Cook RA, Hover KC (1999) Mercury porosimetry of hardened cement pastes. Cem Concr Res 29(6):933–943. https://doi.org/10.1016/S0008-8846(99)00083-6

Cui L, Fall M (2018) Multiphysics modeling and simulation of strength development and distribution in cemented tailings backfill structures. Int J Concrete Struct Mater 12(1):1–22

Douglas M, Clark ID, Raven K, Bottomley D (2000) Groundwater mixing dynamics at a Canadian Shield mine. J Hydrol 235(2000):88–103

Fall M, Belem T, Samb S, Benzaazoua M (2007) Experimental characterization of the stress-strain behaviour of cemented paste backfill. J Mater Sci 42:3914–3922

Fall M, Benzaazoua M (2005) Modeling the effect of sulphate on strength development of paste backfill and binder mixture optimization. Cem and Conc Res 35(2):301–314. https://doi.org/10.1016/j.cemconres.2004.05.020

Fall M, Benzaazoua M, Sae E (2008) Mix proportioning of underground cemented paste backfill. J Tunn Undergr Space Technol 23:80–90

Fall M, Célestin JC, Pokharel M, Touré M (2010) A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill. Eng Geol 114(3–4):397–413. https://doi.org/10.1016/j.enggeo.2010.05.016

Fang K, Fall M (2019) Chemically induced changes in shear behaviour of interface between rock and tailings backfill undergoing cementation. Rock Mech Rock Eng 2(9):3047–3062

Fang K, Fall M (2020) Shear behavior of the interface between rock and cemented backfill: effect of curing stress, drainage condition and backfilling rate. Rock Mech Rock Eng 53:325–336

Feldman RF, Beaudoin JJ (1991) Pretreatment of hardened hydrated cement pastes for mercury intrusion measurements. Cem Concr Res 21(2–3):297–308. https://doi.org/10.1016/0008-8846(91)90011-6

Fernanda RL, Goncalves JP, Dweck J, da Cunha ALC (2017) Evaluation of influence of salt in the cement hydration to oil wells. Mater. Res. 20(2):7430747. https://doi.org/10.1590/1980-5373-MR-2017-0049

Fredlund DG, Rahardjo H (1993) Soil mechanics for unsaturated soils. John Wiley & Sons

Gabrovšek R, Vuk T, Kaučič V (2006) Evaluation of the hydration of Portland cement containing various carbonates by means of thermal analysis. Acta Chim Slov 53:159–165

Ghirian A, Fall M (2014) Coupled thermo-hydro-mechanical–chemical behaviour of cemented paste backfill in column experiments: Part II: mechanical, chemical and microstructural processes and characteristics. Eng Geol 170:11–23. https://doi.org/10.1016/j.enggeo.2013.12.004

Hargis CW, Telesca A, Monteiro PJM (2014) Calcium sulfoaluminate (Ye’elimite) hydration in the presence of gypsum, calcite, and vaterite. Cement Concrete Res 65(2014):15–20

Haruna S, Fall M (2021) Strength development of cemented tailings materials containing polycarboxylate ether-based superplasticizer: experimental results on the effect of time and temperature. Can J Civ Eng 48(4):429–442. https://doi.org/10.1139/cjce-2019-0809

Helinski M, Fourie A, Fahey M, Ismail M (2007) Assessment of the self-desiccation process in cemented mine backfills. Can Geotech J 44(10):1148–1156. https://doi.org/10.1139/T07-051

Hivon EG, Sego DC (1993) Distribution of saline permafrost in the Northwest Territories. Canada Canad Geotech J 30(3):506–514. https://doi.org/10.1139/t93-043

Ishikawa M, Ichikuni M (1984) Uptake of sodium and potassium by calcite. Chem Geol 42(1–4):137–146. https://doi.org/10.1016/0009-2541(84)90010-X

Jiang H, Fall M (2017a) Yield stress and strength of saline cemented tailings in sub-zero environments: Portland cement paste backfill. Int J Min Proc 160:68–75. https://doi.org/10.1016/j.minpro.2017.01.010

Jiang H, Fall M (2017b) Yield stress and strength of saline cemented tailings materials in sub-zero environments: slag-paste backfill. J Sust Cement-Based Mat 6(5):314–331. https://doi.org/10.1080/21650373.2017.1280428

Jiang H, Fall M, Li Y, Han J (2019) An experimental study on compressive behaviour of cemented rockfill. Constr Build Mater 213:10–19

Kang C, Kim T (2020) Pore and strength characteristics of alkali-activated slag paste with seawater. Mag Concr Res 72(10):499–508. https://doi.org/10.1680/jmacr.18.00390

Ke-rui Y, Cai-wen Z, Zhi-gang L, Zhi G, Cong N (2004) A study on alkali-fixation ability of C-S-H gel. Proceedings of the 12th International Conference on Alkali-Aggregate Reaction in Concrete, Beijing, China, p. 221–225

Komljenović MM, Baščarević Z, Marjanović N, Nikolić V (2012) Decalcification resistance of alkali-activated slag. J Hazard Mater 233:112–121

Lambert P, Page CL, Short NR (1985) Pore solution chemistry of the hydrated system tricalcium silicate/sodium chloride/water. Cem Concr Res 15:675–680

Li L, Aubertin M (2003) A general relationship between porosity and uniaxial strength of engineering materials. Can J Civ Eng 30(4):644–658. https://doi.org/10.1139/l03-012

Li W, Fall M (2016) Sulphate effect on the early age strength and self-desiccation of cemented paste backfill. Constr Build Mater 106:296–304. https://doi.org/10.1016/j.conbuildmat.2015.12.124

Li W, Fall M (2018) Strength and self-desiccation of slag-cemented paste backfill at early ages: link to initial sulphate concentration. Cement Concr Compos 89:160–168. https://doi.org/10.1016/j.cemconcomp.2017.09.019

Li WW, Jiang ZL, Lu MY, Long WJ, Xing F, Liu J (2021) Effects of seawater, NaCl, and Na2SO4 solution mixing on hydration process of cement paste. J Mater Civ Eng 33(5):04021057

Mehta PK, Monteiro PJ (2006) Concrete: microstructure, properties, and materials. 3rd McGraw-Hill Education

Neville AM (2011) Properties of concrete, London Pearson Education Limited, Technology & Engineering, p 846

O’Farrell M, Wild S, Sabir B (2001) Pore size distribution and compressive strength of waste clay brick mortar. Cement Concr Compos 23(1):81–91

Oey T, Kumar A, Bullard JW, Neithalath N, Sant G (2013) The filler effect: the influence of filler content and surface area on cementitious reaction rates. J Am Ceram Soc 96(6):1978–1990. https://doi.org/10.1111/jace.12264

Orejarena L, Fall M (2008) Mechanical response of a mine composite material to extreme heat. Bull Eng Geol Env 67:387–396

Ouellet S, Bussière B, Aubertin M, Benzaazoua M (2007) Microstructural evolution of cemented paste backfill: mercury intrusion porosimetry test results. Cem Concr Res 37(12):1654–1665. https://doi.org/10.1016/j.cemconres.2007.08.016

Persson B (1997) Self-desiccation and its importance in concrete technology. Mat and Struct 30(5):293–305. https://doi.org/10.1007/BF02486354

Persson B (2000) Consequence of cement constituents, mix composition and curing conditions for self-desiccation in concrete. Mater Struct 33(6):352–362. https://doi.org/10.1007/BF02479644

Pokharel M (2008) Geotechnical and environmental responses of paste tailings systems to coupled thermo-chemical loadings. [MASc thesis, Ottawa, ON: University of Ottawa.] https://doi.org/10.20381/ruor-18910.

Poon CS, Wong YL, Lam L (1997) The influence of different curing conditions on the pore structure and related properties of fly-ash cement pastes and mortars. Constr Build Mater 11(7–8):383–393. https://doi.org/10.1016/S0950-0618(97)00061-5

Prasad J, Jain D, Ahuja A (2006) Factors influencing the sulphate resistance of cement concrete and mortar. Asian Journal of Civil Engineering (BUILDING AND HOUSING) 7(3):259–268

Rocha CAA, Cordeiro GC, Toledo Filho RD (2015) Use of thermal analysis to determine the hydration products of oil well cement pastes containing NaCl and KCl. J Therm Anal Calorim 122:1279–1288

Rodrigues LF, Pereira GJ, Jo D, da Cunha ALC (2017) Evaluation of influence of salt in the cement hydration to oil wells. Mater Res 20(2):743–747. https://doi.org/10.1590/1980-5373-MR-2017-0049

Roessler M, Odler I (1985) Investigations on the relationship between porosity, structure and strength of hydrated Portland cement pastes.I. Effect of porosity. Cement Concrete Res 15(2):320–330. https://doi.org/10.1016/0008-8846(85)90044-4

Roessler M, Odler I (1985) Investigations on the relationship between porosity, structure and strength of hydrated Portland cement pastes. II. Effect of pore structure and of degree of hydration. Cement Concrete Res 15(3):401–410. https://doi.org/10.1016/0008-8846(85)90113-9

Roshani A, Fall M (2020) Rheological properties of cemented paste backfill with nano-silica: link to curing temperature. Concrete Cement Compos 114:103785

Shehata MH, Thomas MD (2010) The role of alkali content of Portland cement on the expansion of concrete prisms containing reactive aggregates and supplementary cementing materials. Cem Concr Res 40(4):569–574. https://doi.org/10.1016/j.cemconres.2009.08.009

Shi D, Winslow DN (1985) Contact angle and damage during mercury intrusion into cement paste. Cem Concr Res 15(4):645–654. https://doi.org/10.1016/0008-8846(85)90064-X

Simon D, Grabinsky MW (2012) Electromagnetic wave-based measurement techniques to study the role of Portland cement hydration in cemented paste backfill materials. Int J Min Reclam Environ 26(1):3–28. https://doi.org/10.1080/17480930.2012.639193

Sugiyama D (2008) Chemical alteration of calcium silicate hydrate (C–S–H) in sodium chloride solution. Cem Concr Res 38(2008):1270–1275

Suryavanshi A, Scantlebury J, Lyon S (1995) The binding of chloride ions by sulphate resistant Portland cement. Cem Concr Res 25:581–592

Suzuki K, Nishikawa T, Ikenaga H, Ito S (1986) Effect of NaCl or NaOH on the formation of C-S-H. Cem Concr Res 16:333–340

Taylor HF (1997) Cement chemistry, 2nd edn. Thomas Telford, London, UK

Tian X, Fall M (2021) Non-isothermal evolution of mechanical properties, pore structure and self-desiccation of cemented paste backfill. Constr Build Mater 297:123657. https://doi.org/10.1016/j.conbuildmat.2021.123657

De la Vergne JN (2003) Hard Rock Miner’s Handbook. Stantec Engineering. pp. i–ii

Wang Y, Fall M, Wu A (2016) Initial temperature-dependence of strength development and self-desiccation in cemented paste backfill that contains sodium silicate. Cem and Conc Comp 67:101–110. https://doi.org/10.1016/j.cemconcomp.2016.01.005

Wang J, Xie J, Wang Y, Liu Y, Ding Y (2020) Rheological properties, compressive strength, hydration products and microstructure of seawater-mixed cement pastes. Cem and Conc Comp 114:103770. https://doi.org/10.1016/j.cemconcomp.2020.103770

Wang C, Villaescusa E (2000) Backfill research at the western Australian school of mines. Proceedings of MassMin 2000, Brisbane, (Chitombo, G.) (ed.),The Australian Institute of Mining and Metallurgy, Melbourne, 2000. pp. 735–743

Van Weert F, Van der Gun J, Reckman J (2009) Global overview of saline groundwater occurrence and genesis. International Groundwater Resources Assessment Centre, Report nr. GP 2009-1. p 107

Wu D, Fall M, Cai S (2014) Numerical modelling of thermally and hydraulically coupled processes in hydrating cemented tailings backfill columns. Int J Min Reclam Environ 28(3):173–199

Yilmaz E, Fall M (2017) Paste tailings management Springer International Publishing Switzerland. https://doi.org/10.1007/978-3-319-39682-8

Young JF, Tong HS, Berger RL (1977) Compositions of solutions in contact with hydrating tricalcium silicate pastes. J Am Ceram Soc 60(5–6):193–198. https://doi.org/10.1111/j.1151-2916.1977.tb14104.x

Zhou X, Lin X, Huo M, Zhang Y (1996) The hydration of saline oil-well cement. Cem Concr Res 26(12):1753–1759. https://doi.org/10.1016/S0008-8846(96)00176-7

Zhu Q, Linhua Jiang L, Chen Y, Xu J, Lili Mo L (2012) Effect of chloride salt type on chloride binding behavior of concrete. Constr Build Mater 37:512–517

Zhou YF, Lu JX, Li JS, Cheeseman C, Chi SP (2021) Effect of NaCl and MgCl2 on the hydration of lime-pozzolan blend by recycling sewage sludge ash. J Clean Prod 313:127759

Zhou Y, Fall M, Haruna S (2022) Flow ability of cemented paste backfill with chloride-free antifreeze additives in sub-zero environments. Cement Concr Compos 126:104359

Zhu G, Zhu W, You Fu, Yan B, Jiang H (2023a) Effects of chloride salts on strength, hydration, and microstructure of cemented tailings backfill with one-part alkali-activated slag. Constr Build Mater 374:130965

Zhu G, Zhu W, Hou C, Jiang H (2023) Use of saline water in cemented fine tailings backfill with one-part alkali-activated slag. J Mater Civil Eng 35(03):04022440

Acknowledgements

The authors also thank Lafarge Canada for providing the Slag used in this research.

Funding

Natural Sciences and Engineering Research Council of Canada

Author information

Authors and Affiliations

Contributions

Elizabeth A. Carnogursky: investigation, methodology, and writing — original draft preparation. Mamadou Fall: conceptualization, methodology, resources, writing — review and editing, supervision, project administration, and funding acquisition. Sada Haruna: investigation, methodology, and review and editing.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

The authors declare that they have no known competing financial interests or personal relationships that seem to affect the work reported in this article. We declare that we have no human participants, human data, or human tissues.

Consent for publication

All of the authors have read and approved the paper for publication.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Carnogursky, E.A., Fall, M. & Haruna, S. Strength development and self-desiccation of saline cemented paste backfill. Environ Sci Pollut Res 31, 14894–14911 (2024). https://doi.org/10.1007/s11356-024-32200-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-024-32200-9