Abstract

Given the immense threats of microplastics, we herein investigate photodegrading the debris of polyethylene bags (PBs) by sulfur-doped titanium dioxide. The optimization of operating parameters showed that controlling the water pH at 3 and introducing PBs by 0.10 g/L under a catalyst dose of 1.25 g/L reduced the polyethylene mass by 3.10% in 7 h, whereas raising the catalyst dose to 3 g/L improved the mass reduction to 4.72%. The extension of degradation time to 100 h at pH 3, catalyst dosage of 3 g/L, and PBs concentration of 0.10 g/L increased the mass loss ratio to 21.74%. Scanning electron microscopy of PBs after 100 h of photodegradation showed cracks on the surface accompanied by the increase of carbonyl index from 0.52 to 1.41 confirming the breakdown of the polymeric chain. Total organic carbon increased from 0.80 to 7.76 mg/L in the first 10 h of photodegradation, then decreased to 1 mg/L after extending the reaction time to 100 h due to the mineralization of organic intermediates generated from the photodegradation of PBs. Trapping tests exhibited the major role of hydroxyl radicals in the degradation system, and the catalyst showed high stability under five repetitive runs. This study proposes an efficient treatment system that can be implemented on a wider scale utilizing the synthesized catalyst to degrade plastics efficiently before their release to water streams.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Due to the large-scale production of plastic, plastic waste can be detected in the environment which has lured global worries due to the detrimental effects of plastic waste on the ecosystem (Ariza-tarazona et al. 2020). Plastic items can remain in the environment for long periods due to their low biodegradability (Geyer et al. 2017). Thus, large items can be broken into smaller plastic particles such as mesoplastics (< 2.50 cm), microplastics (< 5 mm), and nanoplastics (< 1 µm) via the environmental degradation processes (e.g., abrasion, hydrolysis, oxidation, UV radiation, microbial decomposition) (Hamd et al. 2022). The annual production of plastic is over 380 million tons, and it is expected to reach 2 billion tons by 2050 (Paço et al. 2017; Janaswamy et al. 2022). Around 79% of plastic and its fragments could be disposed of in landfills which is harmful to bacteria, plants, and humans due to the leaching of these plastics into the soil and groundwater (Ahmad et al. 2023). Plants can uptake plastic, especially with smaller size which could lead to the accumulation of these compounds in the food chain (Ahmad et al. 2023). Further, plastic’s surface can act as a carrier for toxic pollutants which may lead to the transfer of these pollutants to the food web (Tang et al. 2020). Further, greenhouse gases can be produced due to the accumulation of plastics in landfills (Tang et al. 2020). On the other hand, plastic waste can be managed by incineration which results in the production of greenhouse gases (e.g., CO2) and the increase of risks related to global warming leading to the environmental pollution (Ahmad et al. 2023).

On the other hand, plastic fragments (meso, micro, and nanoplastics) can exist in aquatic life via the release of treated effluents from wastewater treatment plants (WWTPs), as WWTPs could not efficiently remove plastic fragments (Enfrin et al. 2020). For instance, over 4 million microplastics (MPs) can be released daily from each WWTP into water streams in the USA (Mason et al. 2016). Further, plastic can exist in seas, oceans, and lakes due to the direct disposal of plastic in water streams or/and owing to the natural transfer of plastic to water streams due to their low density (Jiang et al. 2018). Plastic and its fragments can migrate long distances in the aquatic environment by the marine currents which could damage aquatic life (Ariza-tarazona et al. 2019). Aquatic organisms can ingest plastic and its fragments which may result in the blockage of the digestive tract followed by death (Eerkes-medrano et al. 2015; Ateia et al. 2022). Additionally, the consumption of plastic by marine organisms can contribute to the accumulation of plastic in the human body via the food chain (Ariza-tarazona et al. 2020). According to recent reports, 5 g of plastic fragments can enter human body every week (Ariza-tarazona et al. 2020). The impacts of plastic and its fragments on human health are still mysterious. Howbeit, some studies reported that plastics could cause physical damage and biological stress in humans (Revel et al. 2018; Dong et al. 2020). Therefore, tertiary treatment unit has to be added to conventional WWTPs to efficiently and completely degrade plastic fragments prior the release to water streams as well as strict measures have to be executed to prevent the direct release of plastics into the aquatic life.

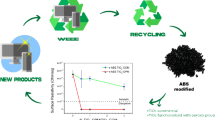

Biological, physical, and chemical techniques are not efficient for the degradation of plastic and its fragments due to the produced sludge, long treatment time, production of secondary microplastics (MPs), and high chemical consumption (Dey et al. 2021). Recently, advanced oxidation processes have shown remarkable effectiveness in the degradation of plastics and their fragments such as photocatalysis, Fenton, and ozonation processes (Li et al. 2022; Liu et al. 2022; Ortiz et al. 2022). Fenton and ozonation processes suffer from some demerits such as the use of hazards and expensive chemicals as well as the generation of large volumes of sludge in the case of Fenton process which obstruct the full-scale application of the aforementioned processes (Hamd et al. 2022). Photocatalysis, an advanced oxidation process, is featured by its high degradation performance, ability to utilize solar light, and green nature (Ariza-tarazona et al. 2020). In photocatalysis process, the degradation of plastic and its fragments can take place via the generated reactive species resulting in breaking polymer chain in plastics followed by forming short chain intermediaries and mineralization to water and carbon dioxide (Lu et al. 2021). Nonetheless, the photocatalysis process suffers from some defects such as the wide bandgap and the fast reunite between electrons and holes in the traditional catalysts such as TiO2 and ZnO which suppressed the accelerated degradation (Cui et al. 2020). To overcome the above-mentioned issues, bare photocatalysts have been modified by doping with metals or/and non-metals (Murillo-Sierra et al. 2018; Karim and Shriwastav 2020). Zinc et al. (2019) employed platinum/zinc oxide nanorod for the photodegradation of polyethylene film (1 cm × 1 cm) in 175 h using a halogen lamp (Zinc et al. 2019). They reported an increase in the carbonyl index by 2.10 times in the case of doped-ZnO compared to pure ZnO (Zinc et al. 2019). Llorente-García et al. (2020) degraded microplastics (3 mm × 3 mm and 5 mm × 5 mm) by N-TiO2 under UV irradiation for 50 h at pH 3 (Llorente-García et al. 2020). The mass loss ratios were 1.38% and 0.97% in the case of microplastics with 3 mm × 3 mm and 5 mm × 5 mm, respectively indicating that the increase of plastic’s size could decrease the degradation rate. Herein, an efficient photocatalyst (sulfur-doped TiO2 (S-TiO2)) that was previously employed in our previous studies for the degradation of emerging pollutants such as trimethoprim and 2,4-dichlorophenol was utilized for the degradation of polyethylene bags (Samy et al. 2023b, a). Doping with sulfur reduced the bandgap to 2.85 eV which improved the absorption in the visible light region as well as sulfur ions could trap electrons inhibiting the recombination between charge carriers, thereby enhancing the photocatalytic performance and the generation of reactive species. The efficient degradation of plastic waste using the fabricated photocatalyst can participate in reducing the reliance on landfilling and incineration and decreasing the release of plastic waste to water streams which decrease the aforementioned environmental hazards related to plastic waste.

In this study, polyethylene bags (PBs) were collected and cut into 1 cm × 1 cm pieces, and the photocatalytic degradation of PBs was performed using S-TiO2. The morphological changes as well as the alterations on PBs surface were investigated as a result of the photodegradation process using scanning electron microscopy and Fourier transform infrared spectroscopy. Further, the degradation of PBs was monitored under different operating parameters such as pH, PBs concentration, reaction time, and catalyst dose. Additionally, the degradation mechanism of PBs was investigated as well as the recyclability performance of the photocatalyst was assessed.

Materials and methods

Materials

p-Benzoquinone (C6H4O2, 99%), tert-butyl alcohol (C4H10O, 99%), and ammonium oxalate (C2H8N2O4, 99%) were purchased from Sigma-Aldrich.

Experimental procedures

The preparation of S-TiO2 was conducted as previously described in the previous study (Gar Alalm et al. 2018). Polyethylene bags (PBs) were compiled from the household garbage of a residential area, washed with distilled water, left for drying at room temperature, and cut into small pieces (1 cm × 1 cm). The collected PBs are characterized by their low density and transparency. The degradation of PBs was attained in a photoreactor using a 400 W metal halide lamp as a light source, a 250 mL beaker that contains 100 mL of distilled water, and a magnetic stirrer for achieving excellent contact between plastic pieces and catalyst particles. The spectra of the lamp were provided in the supplementary file (Fig. S1). The distance between the lamp and water surface was 10 cm with an intensity of 45,000 lux. Initially, control experiments were performed using light only, catalyst only, light with catalyst, and PBs without light and catalyst. The effect of light intensity was tested by changing the distance between the lamp and the solution surface (10–40 cm) to specify the intensity that could attain the highest degradation. The light intensity was measured by a lux meter (Milwaukee SM700). Further, the effect of pH (2–9), PBs concentration (0.10–0.30 g/L), and catalyst dosage (0.25–5 g/L) was studied. The experiments were conducted at room temperature 30 °C, whereas the temperature increased to 40 °C during the reaction as a result of the heat emitted by the lamp.

The optimization of operating parameters was performed by varying their values as shown in Table 1. Twenty experiments were selected to attain interaction between the operating parameters based on the response surface method (RSM) coupled with central composite design (CCD). A polynomial model was developed to relate the mass loss ratio of PBs after 7 h with the independent parameters such as pH, catalyst dose, and PBs concentration. The suitability of the model to predict the mass loss ratio was examined by performing analysis of variance (ANOVA). According to the developed model, the decrease of pH values to 2 and 3 and the raising of catalyst dosage to 3 and 5 g/L as well as the extension of reaction time to 100 h were performed to enhance the degradation efficacy. The effectiveness of the synthesized catalyst was validated via measuring the comparison factor (CF) in our study (Eq. (1)), then our comparison factor was compared with other studies.

where efficiency is the mass loss ratio, PBs concentration and photocatalyst dose are in g/L, and the time is in hours.

The primary reactive species were specified using trapping experiments in which tert-butyl alcohol, benzoquinone, and ammonium oxalate were employed as quenchers of hydroxyl radicals, superoxide radicals, and holes, respectively. The quenchers’ concentrations were 50 mM. Also, in the recyclability test, the solution was left 1 h to allow the catalyst particles to settle after each cycle, then the supernatant was decanted. Subsequently, the catalyst particles were compiled from the bottom of the reactor after drying for reusing the catalyst particles in succeeding cycles.

Analytical methods

The morphology and particle size of the fabricated S-TiO2 were explored by a transmission electron microscopy (TEM), and the crystallinity of S-TiO2 was investigated using an X-ray diffraction spectroscopy (XRD). The chemical elements of the prepared S-TiO2 were determined using an energy-dispersive X-ray (EDX) spectroscopy. Further, the bandgap of S-TiO2 was estimated via a UV-Vis spectrophotometer via Kubelka-Munk equation by plotting photon energy (hv) versus (F(R)hv)0.5, where F(R) means the function of reflectance (Ariza-tarazona et al. 2020). Moreover, the separation of electrons and holes was evaluated using fluorescence spectrophotometer by recording the photoluminescence (PL) spectra. Regarding the PBs, scanning electron microscopy (SEM) was performed before and after the degradation to evaluate the morphological changes. Additionally, Fourier transform infrared spectroscopy (FTIR) was conducted before and after degradation to investigate the changes in surface functional groups and confirm the degradation of PBs based on carbonyl index (CI). CI is equal to the proportion of carbonyl peak (1550–1810 cm−1) to reference peak (1368 cm−1) (Ortiz et al. 2022). CI is an index of the degradation of PBs, where the increase of CI means the efficient degradation of plastics. FTIR spectra were recorded between 4000 and 400 cm−1 with a spectral resolution of 4 cm−1. The models of the aforementioned equipment were mentioned in our previous studies (Samy et al. 2023b, a).

After the degradation process, the treated solution was filtered to collect PBs followed by drying at room temperature to measure the mass loss ratio using a sensitive balance as shown in Eq. (2). Additionally, the mineralization of PBs was explored using total organic carbon analyzer (TOC, Shimadzu).

where ML is the mass loss ratio (%) of PBs, M0 is the initial mass of PBs (g), and Mt is the mass of PBs at the end of reaction (g).

Results and discussion

Characterizations of S-TiO2 and PBs

The TEM image in Fig. 1a shows that the particles have spherical-like morphology with a particle size range (10–21 nm). The XRD pattern in Fig. 1b depicts a main peak at 25.3° which is indexed to anatase TiO2. Further, the peaks at nearly 38°, 48°, 53.9°, 55.4°, and 62.7° are imputed to the anatase TiO2 (JCPDS no. 21-1272) (Ramos-Delgado et al. 2013). The sulfur in the doped TiO2 did not show any unique peaks due to its low content as well as the regular distribution of its ions with anatase crystallite (Hamadanian et al. 2009). EDX pattern in Fig. 1c depicts the growth of Ti, O, and S confirming the chemical composition of S-TiO2. Figure 1d shows the bandgap of the synthesized S-TiO2 using the function of reflectance (F(R)). F(R) was measured as described in our previous work (Samy et al. 2020b). The bandgap was 2.85 eV which is lower than that of pure TiO2 (3.20 eV) affirming the role of sulfur ions in narrowing the bandgap and boosting the utilization of broad area of the solar light, thereby improving the generation of reactive radicals. Figure S2 shows the PL spectra of pure TiO2 and S-TiO2 with a maximum emission at nearly 385 nm. The intensity in the case of S-TiO2 was lower than that of TiO2 confirming the improvement of the separation of charge carriers in the case of doped TiO2.

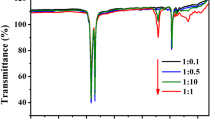

Figure 2a shows the FTIR spectra of PBs before and after the photodegradation. The comparison between the FTIR spectra of PBs before and after degradation clearly shows significant changes in the chemical structure after the photodegradation by S-TiO2. The observed peaks at 2915, 2848, 1471, and 719 cm−1 are due to the vibrations of the alkyl groups in the plastic (Ariza-Tarazona et al. 2020). Specifically, the peaks at 2915 and 2848 cm−1 are imputed to C–H bond stretching vibrations, while the peaks at 1471 and 719 cm−1 are indexed to –C=C– bond stretching and CH2 rocking deformation, respectively. A peak appeared at 1368 cm−1, indicating a slight deformation of the –CH3 group, which remained relatively stable after irradiation (Tofa et al. 2019b; Ariza-Tarazona et al. 2020). In addition, notable changes were observed in the range of 1650 to 1750 cm−1, where significant peaks associated with carbonyl groups (C=O bonds) appeared in the case of PBs after degradation. This suggests the increase of carbonyl functional groups during the photocatalytic degradation process.

The observed changes in the FTIR spectrum confirm the successful breakdown of the plastic by the S-TiO2 photocatalyst. To further evaluate the extent of degradation, the carbonyl index (CI) was calculated, which is an indicator of the degradation of plastic. By comparing the absorbance of the carbonyl peak (1743 cm−1) with the reference peak (1368 cm−1), the CI before irradiation was determined to be 0.52, indicating a relatively low concentration of carbonyl functional groups. However, after irradiation, the CI increased to 1.41, indicating a higher concentration of carbonyl groups resulting from the breakdown of polymer chains and the formation of new carbonyl groups.

Figure 2b, c shows the SEM micrographs of PBs before and after the degradation for 100 h. Figure 2b demonstrates a smooth and homogenous surface of PBs before degradation. In the case of PBs after the degradation as given in Fig. 2c, the surface becomes rougher as well as cracks or fractures appear on the surface which affirmed the breakdown of polymer chains in PBs as a result of the degradation.

Control experiments

Figure 3 shows the mass loss ratios of PBs in the case of using light only without catalyst, catalyst only without light, catalyst with light, and PBs without light and catalyst at pH 7, catalyst dose of 0.25 g/L, PBs concentration of 0.20 g/L, light intensity of 45000 lux, and reaction time of 7 h. In the case of PBs degradation without catalyst and light, there was no change in the mass of PBs after mixing for 7 h. Further, in the case of light only, the mass loss ratio was only 0.05%. The limited mass loss in the case of photolysis and PBs without catalyst and light affirmed the stability of polyethylene bags under natural environmental conditions. In the case of catalyst only, no change in mass was observed, as the degradation of PBs by the catalyst could not take place without illumination (Ariza-tarazona et al. 2019). On the other hand, the mass loss ratio increased to 0.31% after 7 h due to the illumination of catalyst which resulted in the production of reactive oxygen species, thereby degrading PBs polymer chain (Ariza-tarazona et al. 2020). The obtained mass loss ratio was attained under low catalyst dose, short reaction time, and large plastic size compared to previous studies. Ariza-Tarazona et al. (2020) reported a mass loss ratio of 0.15% at a temperature of 20 °C, nitrogen-doped TiO2 dose of 4 g/L, microplastic concentration of 4 g/L, and reaction time of 50 h (Ariza-tarazona et al. 2020). Figure S3 shows the effect of light intensity in the presence of the catalyst (0.25 g/L) on the mass loss ratio. The intensities were 45,000, 30,000, 25,000, and 20,000 lux corresponding to the distances between the lamp and water surface of 10, 20, 30, and 40 cm, respectively. The highest mass loss ratio was attained at a light intensity of 45,000 lux (0.31%), as the increase of light intensity could enhance the generation of reactive radicals (Gogoi et al. 2022). Thus, all the next experiments were performed at this light intensity. In the next experiments, the optimization of operating parameters such as pH, catalyst dose, and PBs concentration was performed to achieve higher mass loss ratios.

Optimization of operating parameters

A polynomial model shown in Eq. (3) with R2 of 0.97 was developed to link the mass loss ratio with the independent parameters (pH, catalyst dose, and plastic concentration) using Minitab@20. Table 2 shows the experimental mass loss ratios and the expected mass ratios using the model under different operating parameters. Additionally, analysis of variance (ANOVA) in Table 3 affirms the convenience of the model due to the low P and high F values.

where X, Y, and Z are PBs concentration (g/L), catalyst dose (g/L), and pH, respectively.

Figure 4 shows the effects of operating parameters on mass loss ratios. The results indicated that the increase of catalyst dose enhanced the degradation of polymeric chain; therefore, the optimal catalyst dose was 1.25 g/L. Elevating the catalyst dose could contribute to the generation of more hydroxyl radicals that would attack the weak points in the polymeric chain resulting in the generation of polyethylene alkyl radicals (Kriston 2010). Further, peroxy radicals could be formed via reacting alkyl radicals with oxygen that might abstract H from another polymeric chain forming hydroperoxide (Ariza-tarazona et al. 2020). Subsequently, hydroperoxide could be disassociated due to the weak O–O bond into two radicals (oxy and hydroxyl radicals) that could abstract unstable hydrogens from other polymeric chains (Tofa et al. 2019a). Therefore, the raising of the produced hydroperoxide as a result of the increase of catalyst dose could participate in accelerating the polymeric chain decomposition.

The effect of pH was also explored by varying pH (5–9) stating that pH 5 was the optimum. In the case of acidic conditions, H+ ions would be available which could accelerate the formation of hydroperoxide leading to the elevation of oxy and hydroxyl radicals with high reactivity than peroxy radicals, thereby improving plastic degradation (Kriston 2010). Further, the zeta potential of TiO2 is high at low pH which suppressed the agglomeration of catalyst particles (Mikulášek et al. 1997). The deagglomeration of catalyst particles could contribute to the increase of active surface area and the interaction between TiO2 nanoparticles and PBs resulting in the improvement of degradation efficacy. On the other hand, at high pH values, the mass loss ratio decreased might be due to the possible agglomeration of catalyst particles leading to the decline of active sites and the decrease of interaction between the catalyst particles and PBs. The point of zero charge of S-TiO2 is 6.25 as reported by Jafari et al. (2020), so the catalyst’s charge is positive at acidic condition (pH < 6.25) and negative at alkaline condition (pH > 6.25) (Jafari et al. 2020). On the other hand, the surface charge of plastics (e.g., PBs) can be negative due to the environmental weathering (Fotopoulou and Karapanagioti 2012; Liu et al. 2020b). Thus, the degradation performance was higher at acidic condition due to the attractive forces between the positively charged S-TiO2 and negatively charged PBs, whereas the mass loss ratio decreased at high pH values owing to the repulsive forces.

Regarding the effect of PBs concentration, the raising of PBs concentration above 0.10 g/L could contribute to the decrease of the mass loss ratio. The increase of PBs concentration requires more radicals and a longer time, so the mass loss of PBs would be higher at lower PBs concentrations compared to higher concentrations at the same reaction time. Table 4 shows the optimum operating parameters and the expected mass loss ratio under the optimum value.

To check the appropriateness of the model to predict the mass loss ratio, the model’s validity was assessed by experimenting with the optimum condition as shown in Table 4, and the mass loss ratio was compared with the value obtained from the model under the optimum condition. The difference between the expected and experimental mass loss ratio under the optimum condition was low which affirmed the applicability of the model.

Improvement of the mass loss ratio

Despite the high stability of PBs, especially with their large size (1 cm × 1 cm), we continued our endeavors to improve the degradation efficiency. Thus, decreasing pH, increasing catalyst dose, and prolonging the reaction time were performed. The mass loss ratio increased from 2.70% under the optimal condition (pH 5, catalyst dose of 1.25 g/L, and PBs concentration of 0.10 g/L) to 3.10% after decreasing pH value to 3 due to the abundance of H+ ions that could drive the reaction towards the generation of hydroperoxide which enhanced the degradation of PBs as shown in Fig. 5a (Tofa et al. 2019a). Howbeit, the mass loss percentage was only 2.90% at pH 2. The declined mass loss in the case of pH 2 compared to pH 3 could be owing to the quenching nature of H+ ions towards the generated hydroxyl radicals at very low pH values as described in Eq. (4). Radwan et al. (2018) reported the same conclusion during the removal of phenol in an electro-Fenton system (Radwan et al. 2018).

On the other hand, increasing the catalyst dose to 3 g/L at pH 3 and PBs concentration of 0.10 g/L improved the mass loss ratio to 4.72% due to the increase of the generated radicals that could abstract more hydrogens from the polymeric chain, thereby improving the decomposition performance as depicted in Fig. 5b. However, the increase of catalyst dose to 5 g/L showed a mass loss ratio of 4.89%. The raising of catalyst dosage did not frequently enhance the degradation performance due to the tendency of catalyst particles to agglomerate at higher doses which decreased the number of active sites (Liu et al. 2020a). Also, the increase of catalyst dose might result in scattering the photons which could deprive many active sites from illumination resulting in the decline of the degradation efficiency (Samy et al. 2020a, 2021a).

To increase the mass loss ratio and check the stability of the photocatalyst under long reaction time, the degradation of PBs was conducted over 100 h under pH 3, catalyst dosage of 3 g/L, and PBs concentration of 0.10 g/L. The mass loss ratio jumped to 21.74% after the long reaction time because of the continuous generation of reactive radicals that could attack the polymeric chain (Ariza-tarazona et al. 2019). The improvement of mass loss ratio with time affirmed the stability of the catalyst and its potential to generate reactive species under long operational time. Figure 5c demonstrates the changes in PBs before and after photodegradation for 100 h.

On the other hand, total organic carbon (TOC) was monitored during the reaction time (100 h) as given in Fig. 6. The results demonstrated that the TOC value increased to 7.76 mg/L with time due to the organic intermediates generated because of the degradation of PBs. However, the TOC started to decrease after 10 h and reached 1 mg/L after 100 h due to the attack of the produced radicals on the organic by-products. Full mineralization could not be achieved due to the frequent generation of organic intermediates as a result of the degradation of polymeric chain in PBs.

A comparison between the results in our study and the results in the previous studies is provided in Table 5. Based on the comparison factor, the degradation performance in our study is dazzling, and the synthesized catalyst is efficient, as it can achieve high mass loss ratio under the optimal conditions in the case of polyethylene plastics (1 cm × 1 cm) compared to lower mass loss ratio in other studies.

Degradation mechanism

The illumination of S-TiO2 by the metal-halide lamp could generate electrons and holes. Text S1 shows the potential of valence and conduction bands. According to the valence and conduction bands positions, electrons in the conduction band (CB) and holes in the valence band (VB) could generate superoxide radicals and hydroxyl radicals, respectively as a result of the reaction with oxygen and hydroxyl ions, respectively. The sulfur ions doped into the lattice structure of TiO2 could trap the excited electrons which enhanced the charge carriers separation as affirmed by the PL spectra in Fig. S2. The generated •OH could attack on the weak places in the polymeric chain generating polyethylene alkyl radicals (Eq. (5)) (Tofa et al. 2019a). Then, peroxy radicals could be produced via reacting the alkyl radicals with oxygen as shown in Eq. (6). Subsequently, peroxy radicals could abstract hydrogen from another polymeric chain to generate hydroperoxide species as described in Eq. (7). The generated hydroperoxide could be converted to two radicals (oxy and hydroxyl radicals) due to the cleavage of the weak O–O bond as given in Eq. (8). Oxy and hydroxyl radicals could abstract hydrogens from other polymeric chains as shown in Eq. (9) which accelerated the degradation of PBs leading to the alteration of its molecular weight. All the generated radicals could depolymerize PBs to monomers and finally would be mineralized to CO2 and H2O.

The primary radicals were specified using quenching experiments. Tert-butyl alcohol (TBA), benzoquinone (BQ), and ammonium oxalate (AO) were used for quenching hydroxyl radicals, superoxide radicals, and holes, respectively as shown in Fig. 7 at reaction time of 7 h, pH 3, catalyst dosage of 3 g/L, and PBs concentration of 0.10 g/L. The mass loss ratio decreased to 1.21%, 3.10%, and 4.12% in the case of TBA, BQ, and AO, respectively compared to 4.72% in the absence of quenchers (Blank) affirming the vital contribution of hydroxyl radicals to degrading PBs. This also ensures that superoxide radicals and holes slightly participate in the degradation process.

Recyclability of S-TiO2

The recyclability of the catalyst was examined under five cycles (Time of each cycle = 7 h) as depicted in Fig. 8 at pH 3, catalyst dosage of 3 g/L, and PBs concentration of 0.10 g/L. The catalyst was gathered after each cycle and dried before the next cycle. The mass loss ratios were 4.72%, 4.57%, 4.42%, 4.36%, and 4.19% in the five subsequent runs. The decline in mass loss ratio in successive cycles could be owing to the loss of the catalyst, as some particles could be adsorbed on the PBs surface in each cycle leading to the decrease of catalyst dose (Venkataramana et al. 2021). Further, the generated by-products could cover the active sites of the catalyst in successive cycles which decreased the generated radicals (Samy et al. 2021b).

Conclusions

The synthesized photocatalyst’s bandgap is 2.85 eV indicating the ability of S-TiO2 to generate radicals under visible light radiation. Using 1.25 g/L of the catalyst and 0.10 g/L of PBs at pH 5 and reaction time of 7 h attained a mass loss ratio of 2.70%. To improve the weight loss ratios, the degradation of PBs was also examined under pH 2 and 3 showing that the weight loss ratio increased to 3.10% in the case of pH 3 compared to 2.90% in the case of pH 2. Additionally, the increase of catalyst dose to 3 g/L and 5 g/L raised the mass loss ratios to 4.72% and 4.89%, respectively. Further, prolonging the reaction time to 100 h at pH 3, catalyst dose of 3 g/L, and PBs concentration of 0.10 g/L resulted in attaining a mass loss ratio of 21.74%. The presence of cracks on PBs surface after photodegradation for 100 h as depicted in the SEM micrograph and the increase of carbonyl index from 0.52 in the case of pristine PBs to 1.41 in the case of degraded PBs assured the photodegradation of the polymeric chain in PBs. TOC analysis affirmed the degradation of PBs to organic intermediates and the ability of the generated reactive species to mineralize the organic by-products. Hydroxyl radicals were the dominant reactive species, and the synthesized catalyst could be reused efficiently for five runs. The prepared catalyst proves its effectiveness and stability towards the degradation of PBs. Therefore, it can be employed in a large-scale system to efficiently degrade plastics.

Data availability

All data generated or analyzed during this study are included in this published article [and its supplementary information files].

References

Ahmad M, Dubey A, Kumar A, Yadav S (2023) Unlocking the biotechnological and environmental perspectives of microplastic degradation in soil-ecosystems using metagenomics. Process Saf Environ Prot 170:372–379. https://doi.org/10.1016/j.psep.2022.11.084

Ariza-tarazona MC, Villarreal-chiu JF, Barbieri V et al (2019) New strategy for microplastic degradation : green photocatalysis using a protein-based porous N-TiO2 semiconductor. Ceram Int 45:9618–9624. https://doi.org/10.1016/j.ceramint.2018.10.208

Ariza-tarazona MC, Villarreal-chiu JF, Hernández-lópez JM et al (2020) Microplastic pollution reduction by a carbon and nitrogen-doped TiO2: effect of pH and temperature in the photocatalytic degradation process. J Hazard Mater 395:122632. https://doi.org/10.1016/j.jhazmat.2020.122632

Asghar W, Qazi IA, Ilyas H, Khan AA, Awan MA, Rizwan Aslam M (2011) Comparative solid phase photocatalytic degradation of polythene films with doped and undoped TiO2 nanoparticles. J Nanomater 2011. https://doi.org/10.1155/2011/461930

Ateia M, Ersan G, Alalm MG et al (2022) Emerging investigator series: microplastic sources, fate, toxicity, detection, and interactions with micropollutants in aquatic ecosystems—a review of reviews. Environ Sci Process Impacts 24:172–195. https://doi.org/10.1039/d1em00443c

Cui J, Gao P, Deng Y (2020) Destruction of per- and polyfluoroalkyl substances (PFAS) with advanced reduction processes (ARPs): a critical review. Environ Sci Technol 54:3752–3766. https://doi.org/10.1021/acs.est.9b05565

Dey TK, Uddin E, Jamal M (2021) Detection and removal of microplastics in wastewater : evolution and impact. Env Sci Poll Res 28:16925–16947. https://doi.org/10.1007/s11356-021-12943-5

Dong C, Chen C, Chen Y et al (2020) Polystyrene microplastic particles : in vitro pulmonary toxicity assessment. J Hazard Mater 385:121575. https://doi.org/10.1016/j.jhazmat.2019.121575

Eerkes-medrano D, Thompson RC, Aldridge DC (2015) Microplastics in freshwater systems : a review of the emerging threats, identification of knowledge gaps and prioritisation of research needs. Water Res 75:63–82. https://doi.org/10.1016/j.watres.2015.02.012

Enfrin M, Lee J, Gibert Y et al (2020) Release of hazardous nanoplastic contaminants due to microplastics fragmentation under shear stress forces. J Hazard Mater 384:121393. https://doi.org/10.1016/j.jhazmat.2019.121393

Fotopoulou KN, Karapanagioti HK (2012) Surface properties of beached plastic pellets. Mar Environ Res 81:70–77. https://doi.org/10.1016/j.marenvres.2012.08.010

Gar Alalm M, Samy M, Ookawara S, Ohno T (2018) Immobilization of S-TiO2 on reusable aluminum plates by polysiloxane for photocatalytic degradation of 2,4-dichlorophenol in water. J Water Process Eng 26:329–335. https://doi.org/10.1016/j.jwpe.2018.11.001

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv 3:25–29. https://doi.org/10.1126/sciadv.1700782

Gogoi R, Dohling HM, Singh A et al (2022) Visible light enhanced photosynthesis of C-C bonds using PdO/Pd@PEDOT nanocomposite. J Catal 414:109–124. https://doi.org/10.1016/j.jcat.2022.08.027

Hamadanian M, Reisi-Vanani A, Majedi A (2009) Preparation and characterization of S-doped TiO2 nanoparticles, effect of calcination temperature and evaluation of photocatalytic activity. Mater Chem Phys 116:376–382. https://doi.org/10.1016/j.matchemphys.2009.03.039

Hamd W, Daher EA, Tofa TS, Dutta J (2022) Recent advances in photocatalytic removal of microplastics : mechanisms, kinetic degradation, and reactor design. Front Mar Sci 9:1–28. https://doi.org/10.3389/fmars.2022.885614

Jafari A, Sadeghi M, Tirgir F, Mehdi S (2020) Sulfur and nitrogen doped-titanium dioxide coated on glass microspheres as a high performance catalyst for removal of naphthalene (C10H8) from aqueous environments using photo oxidation in the presence of visible and sunlight. 192:195–212. https://doi.org/10.5004/dwt.2020.25659

Janaswamy S, Yadav MP, Hoque M et al (2022) Cellulosic fraction from agricultural biomass as a viable alternative for plastics and plastic products. Ind Crop Prod 179:114692. https://doi.org/10.1016/j.indcrop.2022.114692

Jiang P, Zhao S, Zhu L, Li D (2018) Microplastic-associated bacterial assemblages in the intertidal zone of the Yangtze Estuary. Sci Total Environ 624:48–54. https://doi.org/10.1016/j.scitotenv.2017.12.105

Karim AV, Shriwastav A (2020) Degradation of ciprofloxacin using photo, sono, and sonophotocatalytic oxidation with visible light and low-frequency ultrasound: degradation kinetics and pathways. Chem Eng J 392:124853. https://doi.org/10.1016/j.cej.2020.124853

Kriston I (2010) Some aspects of the degradation and stabilization of Phillips type polyethylene. PhD Thesis Budapest Univ Technol Econ. http://hdl.handle.net/10890/1051

Li Y, Li J, Ding J et al (2022) Degradation of nano-sized polystyrene plastics by ozonation or chlorination in drinking water disinfection processes. Chem Eng J 427:131690. https://doi.org/10.1016/j.cej.2021.131690

Liu G, Zhu D, Zhou W, Liao S, Cui J, Wu K, Hamilton D (2010) Solid-phase photocatalytic degradation of polystyrene plastic with goethite modified by boron under UV – vis light irradiation. Appl Surf Sci 256:2546–2551. https://doi.org/10.1016/j.apsusc.2009.10.102

Liu G, Liao S, Zhu D, Hua Y, Zhou W (2012) Innovative photocatalytic degradation of polyethylene film with boron-doped cryptomelane under UV and visible light irradiation. Chem Eng J 213:286–294. https://doi.org/10.1016/j.cej.2012.09.105

Liu C, Lü H, Yu C et al (2020) Novel FeWO4/WO3 nanoplate with p–n heterostructure and its enhanced mechanism for organic pollutants removal under visible-light illumination. J Environ Chem Eng 8:104044. https://doi.org/10.1016/j.jece.2020.104044

Liu P, Zhan X, Wu X et al (2020) Chemosphere effect of weathering on environmental behavior of microplastics : properties, sorption and potential risks. Chemosphere 242:125193. https://doi.org/10.1016/j.chemosphere.2019.125193

Liu F, Zhuang X, Du Z et al (2022) Applied Catalysis B : Environmental enhanced photocatalytic performance by polarizing ferroelectric KNbO3 for degradation of plastic wastes under mild conditions. Appl Catal B Environ 318:121897. https://doi.org/10.1016/j.apcatb.2022.121897

Llorente-García BE, Hernández-López JM, Zaldívar-Cadena AA et al (2020) First insights into photocatalytic degradation of HDPE and LDPE microplastics by a mesoporous N-TiO2 coating: effect of size and shape of microplastics. Coatings 10. https://doi.org/10.3390/coatings10070658

Lu E, Cedillo-gonz EI, David J et al (2021) Boosting visible-light photocatalytic degradation of polystyrene nanoplastics with immobilized CuxO obtained by anodization. J Env Chem Eng 9. https://doi.org/10.1016/j.jece.2021.106208

Mason SA, Garneau D, Sutton R et al (2016) Microplastic pollution is widely detected in US municipal wastewater treatment plant effluent. Environ Pollut 218:1045–1054. https://doi.org/10.1016/j.envpol.2016.08.056

Mikulášek P, Wakeman RJ, Marchant JQ (1997) The influence of pH and temperature on the rheology and stability of aqueous titanium dioxide dispersions. Chem Eng J 67:97–102. https://doi.org/10.1016/S1385-8947(97)00026-0

Murillo-Sierra JC, Sirés I, Brillas E et al (2018) Advanced oxidation of real sulfamethoxazole + trimethoprim formulations using different anodes and electrolytes. Chemosphere 192:225–233. https://doi.org/10.1016/j.chemosphere.2017.10.136

Ortiz D, Munoz M, Nieto-sandoval J et al (2022) Insights into the degradation of microplastics by Fenton oxidation : from surface modification to mineralization. Chemosphere 309:136809. https://doi.org/10.1016/j.chemosphere.2022.136809

Paço A, Duarte K, João P et al (2017) Biodegradation of polyethylene microplastics by the marine fungus Zalerion maritimum. Sci Total Environ 586:10–15. https://doi.org/10.1016/j.scitotenv.2017.02.017

Radwan M, Gar Alalm M, Eletriby H (2018) Optimization and modeling of electro-Fenton process for treatment of phenolic wastewater using nickel and sacrificial stainless steel anodes. J Water Process Eng 22:155–162. https://doi.org/10.1016/j.jwpe.2018.02.003

Ramos-Delgado NA, Gracia-Pinilla MA, Maya-Treviño L et al (2013) Solar photocatalytic activity of TiO2 modified with WO3 on the degradation of an organophosphorus pesticide. J Hazard Mater 263:36–44. https://doi.org/10.1016/j.jhazmat.2013.07.058

Revel M, Châtel A, Mouneyrac C (2018) Micro ( nano ) plastics : a threat to human health ? Curr Opin Environ Sci Heal 1:17–23. https://doi.org/10.1016/j.coesh.2017.10.003

Samy M, Ibrahim MG, Gar Alalm M, Fujii M (2020) Effective photocatalytic degradation of sulfamethazine by CNTs/LaVO4 in suspension and dip coating modes. Sep Purif Technol 235:35516. https://doi.org/10.1016/j.seppur.2019.116138

Samy M, Gar M, Fujii M, Ibrahim MG (2021) Doping of Ni in MIL-125 ( Ti ) for enhanced photocatalytic degradation of carbofuran : reusability of coated plates and effect of different water matrices. J Water Process Eng 44:102449. https://doi.org/10.1016/j.jwpe.2021.102449

Samy M, Ibrahim MG, Fujii M et al (2021) CNTs/MOF-808 painted plates for extended treatment of pharmaceutical and agrochemical wastewaters in a novel photocatalytic reactor. Chem Eng J 406:7. https://doi.org/10.1016/j.cej.2020.127152

Samy M, Gar Alalm M, Khalil MN et al (2023) Treatment of hazardous landfill leachate containing 1,4 dioxane by biochar-based photocatalysts in a solar photo-oxidation reactor. J Environ Manage 332:117402. https://doi.org/10.1016/j.jenvman.2023.117402

Samy M, Mensah K, El-Fakharany EM et al (2023) Green valorization of end-of-life toner powder to iron oxide-nanographene nanohybrid as a recyclable persulfate activator for degrading emerging micropollutants. Environ Res 223:115460. https://doi.org/10.1016/j.envres.2023.115460

Samy M, Ibrahim MG, Alalm MG, Fujii M (2020a) Modeling and optimization of photocatalytic degradation of methylene blue using lanthanum vanadate. 1008:97–103.https://doi.org/10.4028/www.scientific.net/MSF.1008.97

Tang S, Lin L, Wang X et al (2020) Pb (II) uptake onto nylon microplastics: interaction mechanism and adsorption performance. J Hazard Mater 386:121960. https://doi.org/10.1016/j.jhazmat.2019.121960

Tofa TS, Kunjali KL, Paul S, Dutta J (2019) Visible light photocatalytic degradation of microplastic residues with zinc oxide nanorods. Environ Chem Lett 17:1341–1346. https://doi.org/10.1007/s10311-019-00859-z

Tofa TS, Ye F, Kunjali KL, Dutta J (2019b) Enhanced visible light photodegradation of microplastic fragments with plasmonic platinum/zinc oxide nanorod photocatalysts. Catalysts 9. https://doi.org/10.3390/catal9100819

Venkataramana C, Botsa SM, Shyamala P, Muralikrishna R (2021) Photocatalytic degradation of polyethylene plastics by NiAl2O4 spinels-synthesis and characterization. Chemosphere 265:129021. https://doi.org/10.1016/j.chemosphere.2020.129021

Zinc P, Nanorod O, Tofa TS et al (2019) Enhanced visible light photodegradation of microplastic fragments with plasmonic. Catalysts 9:819. https://doi.org/10.3390/catal9100819

Acknowledgements

The second and last authors are supported by the Faculty of Engineering, Mansoura University.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). The Open access funding of this work was sponsored through the Transformative Agreement between Springer Nature and Science, Technology and Innovation Funding Authority (STDF) in cooperation with Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

AS: conceptualization, formal analysis, visualization, methodology, writing—original draft, editing. MS: conceptualization, writing—original draft, investigation, formal analysis, visualization, review and editing, supervision. MM: writing—review and editing, supervision. MGA: investigation, methodology, formal analysis, supervision, writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All authors have checked the manuscript and have agreed to the publication of this work in Environmental Science and Pollution Research.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Sami Rtimi

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Sharara, A., Samy, M., Mossad, M. et al. Photodegradation of polyethylene debris in water by sulfur-doped TiO2: system optimization, degradation mechanism, and reusability. Environ Sci Pollut Res 31, 3951–3963 (2024). https://doi.org/10.1007/s11356-023-31460-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-31460-1