Abstract

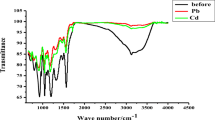

The present study discusses the effect of the addition of nano-sized arc stabilizing materials on fume emissions and its solubility characteristics. Micro and nano-sized sodium/potassium titanates were added to the SMAW electrode flux as a substitute for the conventional sodium and potassium silicate compounds. The total and soluble metal concentration of fumes from the newly developed electrodes were estimated and compared with that of commercially available electrodes. The estimation of fume formation rate and breathing zone concentration of fumes followed the ISO 15011–1 and ISO 10882–1 standard. An average 50% reduction in the soluble fraction of fumes was observed from the electrodes containing micro-sized potassium-titanate compounds, and the reduction was further improved by 60% when nano-sodium titanate was added to the flux. Whereas, the reduction in soluble metal concentration for potassium titanate coated electrodes were 45% and 55%, in that order, for their micro and nano-structured forms. The soluble fraction of hexavalent chromium from the electrodes containing 100% nano sodium/potassium titanates was reduced up to 50% in each impactor stage. The inclusion of nano-sized sodium titanate in the flux resulted in a reduction in fume formation rate up to 55% and breathing zone concentration of fumes by 58% compared to the conventional sodium silicate coated electrodes. The electrode assaying 100% nano-potassium titanate showed a reduction of 59% in fume formation rate and 61% in breathing zone concentration compared to that of conventional potassium silicate-coated electrodes.

Similar content being viewed by others

Data availability

Not applicable.

References

Baune E (2005) Coated electrode with low fume emission and low hexavalent chromium for welding stainless steels. (U.S. Patent No. 20050189337A1) U.S. Patent and Trade mark office. https://patents.google.com/patent/US20050189337A1/en

Berlinger B, Weinbruch S, Ellingsen DG, Zibarev E, Chashchin V, Chashchin M, Thomassen Y (2019) On the bio-accessibility of 14 elements in welding fumes. Environ Sci Process Impacts 21(3):497–505

Cena LG, Chisholm WP, Keane MJ, Cumpston A, Chen BT (2014) Size distribution and estimated respiratory deposition of total chromium, hexavalent chromium, manganese, and nickel in gas metal arc welding fume aerosols. Aerosol Sci Technol 48(12):1254–1263

Chen B, Han F, Huang Y, Lu K, Liu Y, Li L (2009) Influence of nanoscale marble (calcium carbonate CaCO3) on properties of D600R surfacing electrode. Weld J 88:99s–103s

Dean TC, Youngstown NY (1992) Moisture resistant sodium titanate and potassium titanate. W.O. Patent No. 91/01355, European Patent office. https://patents.google.com/patent/WO1991001355A1/en

Dennis JH, French MJ, Hewitt PJ, Mortazavi SB, Redding AJ (1996) Reduction of hexavalent chromium concentration in fumes from metal cored arc welding by addition of reactive metals. J Ann Occup Hyg 40(3):339–344

Donahey JW (1955) Potassium-supplying welding flux ingredient. U.S. Patent No. 720473A, U.S. Patent and Trademark office. https://patents.google.com/patent/US2720473A/en

Donahey JW Pa P (1955) Potassium-supplying welding flux ingredient. US2720473

Fattahi M, Nabhani N, Vaezi MR, Rahimi E (2011) Improvement of impact toughness of AWS E6010 weld metal by adding TiO2 nanoparticles to the electrode coating. Mater Sci Eng A 528(27):8031–8039

Fellman A, Kujanpää V (2006) The effect of shielding gas composition on welding performance and weld properties in hybrid CO2 laser–gas metal arc welding of carbon manganese steel. J Laser Appl 18(1):12–20

Gomes J, Miranda R, Esteves H, Albuquerque P (2022) Risk Assessment of welding operations and processes in terms of ultrafine particles emissions in Ramos D, Almeida L (Eds), Risk management: An Overview. Nova Science Publishers. https://doi.org/10.52305/HNYO7041

Gomes J, Miranda R (2017) Determination of “safe” and “critical” nanoparticles exposure to welders in a workshop. J Tox Env Health Part A 80:767–775

Guerreiro C, Gomes JF, Carvalho P, Santos TJG, Miranda RM, Albuquerque P (2014) Characterization of airborne particles generated from metal active gas welding process. Inhalation Toxicol 26(6):345–352

Han BC, Liu I, Chuang HC, Pan CH, Chuang KJ (2016) Effect of welding fume on heart rate variability among workers with respirators in a shipyard. Sci Rep 6(1):1–6

IARC Working Group on the Evaluation of Carcinogenic Risks to Humans (2018) Welding, molybdenum trioxide, and indium tin oxide. International Agency for Research on Cancer, Lyon, FR. https://pubmed.ncbi.nlm.nih.gov/31268644/

International Agency for Research on Cancer (1990) Chromium, nickel and welding. In: IARC monographs on the evaluation of carcinogenic risks to humans, vol 49. International Agency for Research on Cancer, Lyon, FR. https://www.ncbi.nlm.nih.gov/books/NBK519250/

ISO 10822–1–2001 (2001) Health and safety in welding and allied process – sampling of airborne particulates and gases in the operator’s breathing zone. International Organization for Standardization, Geneva. https://www.iso.org/standard/43385.html

ISO 15202-2-2021 (2021) International organization for standardization, work place air- determination of metals and metalloids in airborne particulate matter by inductively coupled plasma atomic emission spectrometry- part 2: sample preparation. Switzerland, ISO, Geneva

ISO 15011–1 (2009) Health and safety in welding and allied processes-laboratory method for sampling fume and gases generated by arc welding-Part 1: Determination of emission rate and sampling for analysis of particulate fume. International Organization for Standardization, Geneva

Jenkins NT, Pierce WMG, Eagar TW (2005) Particle size distribution of gas metal and flux cored arc welding fumes. Welding J 84(10):156–163

Kimura S, Kobayashi M, Godai T et al (1979) Investigationson chromium in stainless steel welding fumes. Weld J 59:195–204

Knowles JC, Franks K, Abrahams I (2001) Investigation of the solubility and ion release in the glass system K2O–Na2O–CaO–P2O5. Biomaterials 22(23):3091–3096

Koponen M, Gustafsson T, Kalliomäki PL, Lauri PYY (1981) Chromium and nickel aerosols in stainless steel manufacturing, grinding and welding. Am Ind Hyg Assoc J 42(8):596–601

Leese E, Morton J, Gardiner PH, Carolan VA (2017) The simultaneous detection of trivalent & hexavalent chromium in exhaled breath condensate: A feasibility study comparing workers and controls. Int J Hyg Environ Health 220:415–423

Lin CC, Chen MR, Chang SL, Liao WH, Chen HL (2015) Characterization of ambient particles size in workplace of manufacturing physical fitness equipments. Industr Health 53(1):78–84

Maltman C, Yurkov V (2019) Extreme environments and high-level bacterial tellurite resistance. Microorganisms 7(12):601

Mao L, Gao B, Deng N, Zhai J, Zhao Y, Li Q, Cui H (2015) The role of temperature on Cr (VI) formation and reduction during heating of chromium-containing sludge in the presence of CaO. Chemosphere 138:197–204

NIOSH (1994) National institute for occupational safety and health. In: Manual of analytical methods, method 7600, 4th edn. NIOSH. https://www.cdc.gov/niosh/docs/2003-154/pdfs/7600.pdf

OccupationalSafetyand Health Administration (2006) Occupational exposure to hexavalent chromium. Final Rule Federal Register 71:10099–10385

Pal TK, Maity UK (2011) Effect of nano size TiO2 particles on mechanical properties of AWS E 11018M type electrode. Mater Sci Appl 2(09):1285

Pesch B, Kendzia B, Hauptmann K, Van Gelder R, Stamm R, Hahn JU, Brüning T (2015) Airborne exposure to inhalable hexavalent chromium in welders and other occupations: Estimates from the German MEGA database. Int J Hyg Environ Health 218:500–506

Rahul M, Sivapirakasam SP, Vishnu BR, Balasubramanian KR, Mohan S (2021) Health issue owing to exposure with welding fumes and their control strategies at the source–A review. Mater Today Proc 46:9239–9245

Rahul M, Sivapirakasam SP, Mohan S, Vishnu BR, Gomes JFP (2022) Study on mass concentration and morphology of SMAW fume particles with a new covered electrode using nano-CaTiO3 as an arc stabilizer. J Manuf Process 84:230–239

Riccelli MG, Goldoni M, Poli D, Mozzoni P, Cavallo D, Corradi M (2020) Welding fumes, a risk factor for lung diseases. Int J Environ Res 17(7):2552

Sivapirakasam SP, Mohan S, Kumar MS, Surianarayanan M (2015) Welding fume reduction by nano-alumina coating on electrodes–towards green welding process. J Clean Prod 108:131–144

Sreejith M, Sivapirakasam SP, Kumar MS, Surianarayanan M (2015) Welding fumes reduction by coating of nano-TiO2 on electrodes. J Mater Process Technol 219:237–247

Vishnu BR, Sivapirakasam SP, Satpathy KK, Albert SK, Chakraborty G (2018a) Cr6+ reduction in welding fumes by nano composite coatings on stainless steel manual metal arc welding electrodes. Process Saf Environ Prot 114:334–346

Vishnu BR, Sivapirakasam SP, Satpathy KK, Albert SK, Chakraborty G (2018b) Influence of nano-sized flux materials in the reduction of the Cr (VI) in the stainless-steel welding fumes. J Manuf Proces 34:713–720

Vishnu BR, Paramashivan SS, Mohan S, Albert SK, Rahul M (2020) Effect of substituting fine rutile of the flux with nano TiO2 on the improvement of mass transfer efficiency and the reduction of welding fumes in the stainless steel SMAW electrode. High Temp Mater Process 39(1):117–123

Voitkevich V (1995) Welding fumes: formation, properties and biological effects. Woodhead Publishing Limited. https://books.google.co.in/books/about/Welding_Fumes.html?id=U0ZRAAAAMAAJ&redir_esc=y

Weman K (2012) Manual metal arc (MMA) welding with coated electrodes. Woodhead Publishing Series in Welding and Other Joining Technologies, Welding Processes Handbook (Second Edition), Woodhead Publishing, pp 99–103

Yang SY, Lin JM, Young LH, Chang CW (2018) Mass-size distribution and concentration of metals from personal exposure to arc welding fume in pipeline construction: a case report. Industr Health 56(4):356–363

Yoon CS, Paik NW, Kim JH, Chae HB (2009) Total and soluble metal contents in flux-cored arc welding fumes. Aerosol Sci Technol 43(6):511–521

Zatka VJ, Warner JS, Maskery D (1992) Chemical Speciation of Nickel in Airborne Dusts: Analytical Method and Results of An Interlaboratory Test Program. Environ Sci Technol 26:138

Zeidler-Erdely PC, Meighan TG, Erdely A, Battelli LA, Kashon ML, Keane M, Antonini JM (2013) Lung tumor promotion by chromium-containing welding particulate matter in a mouse model. Part Fibre Toxicol 10(1):1–10

Acknowledgements

The authors are grateful to the Director, National Institute of Technology (NIT), Tiruchirappalli for her continual encouragement and support for this work.

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

Mr. Rahul M: Conceptualization, Methodology, Investigation, Writing -Original Draft, Dr. S.P. Sivapirakasam: Formal analysis, Supervision, Resources, Writing -Review & Editing, Dr. Sreejith Mohan: Methodology, Validation, Formal analysis, Investigation, Dr. Vishnu B. R: Formal analysis, Investigation.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Responsible Editor: Ioannis A. Katsoyiannis

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Madhusoodhanan, R., Paramashivan, S.S., Mohan, S. et al. Study on the soluble and insoluble fume and hexavalent chromium emitted from a new covered electrode with micro and nano sized-sodium and potassium titanate–based flux. Environ Sci Pollut Res 30, 95550–95565 (2023). https://doi.org/10.1007/s11356-023-29079-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-29079-3