Abstract

Organosiloxanes are industrially produced worldwide in millions of tons per annum and are widely used by industry, professionals, and consumers. Some of these compounds are PBT (persistent, biaccumulative and toxic) or vPvB (very persistent and very bioaccumulative). If organosiloxanes react at all in the environment, Si–O bonds are hydrolyzed or Si–C bonds are oxidatively cleaved, to result finally in silica and carbon dioxide. In strong contrast and very unexpectedly, recently formation of new Si–CH3 bonds from siloxanes and methane by the action of microorganisms under mild ambient conditions was proposed (in landfills or digesters) and even reported (in a biotrickling filter, 30 °C). This is very surprising in view of the harsh conditions required in industrial Si–CH3 synthesis. Here, we scrutinized the pertinent papers, with the result that evidence put forward for Si–C bond formation from siloxanes and methane in technical microbiological systems is invalid, suggesting such reactions will not occur in the environment where they are even less favored by conditions. The claim of such reactions followed from erroneous calculations and misinterpretation of experimental results. We propose an alternative explanation of the experimental observations, i.e., the putative observation of such reactions was presumably due to confusion of two compounds, hexamethyldisiloxane and dimethylsilanediol, that elute at similar retention times from standard GC columns.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Organosiloxanes, compounds that contain C–Si–O subunits in their molecular structure, are man-made emerging ubiquitous pollutants now detected in many environmental compartments. Their structure is basically made of –Si–O– chains or rings, where each silicon atom additionally bears two organic moieties, in most cases methyl (CH3, Me) groups (–SiMe2–O–), occasionally higher or halogenated alkyl or phenyl groups. These compounds are produced worldwide in millions of tons per annum and are used by industry, professionals and consumers, so that they find their way into the environment (Rücker and Kümmerer 2015). In particular, octamethylcyclotetrasiloxane (D4), decamethylcyclopentasiloxane (D5), and dodecamethylcyclohexasiloxane (D6) are HPV (high production volume) chemicals according to the Organisation for Economic Co-operation and Development and the US Environmental Protection Agency, and are classified as PBT (persistent, bioaccumulative and toxic) and/or vPvB (very persistent and very bioaccumulative) under the European REACH regulation. These compounds are therefore substances of very high concern (SVHC) and are subjected to increasingly restrictive regulation, e.g., in Europe (ECHA 2018a, b, 2019, 2021; EU 2018, 2019). For structures and explanation of shorthand names of some important organosiloxanes, see Scheme 1.

For these reasons, degradation of organosiloxanes in the environment is an important issue. Complete degradation (mineralization) requires cleavage of both Si–O and Si–C bonds. Si–O–Si bond cleavage in organosiloxanes by hydrolysis to produce silanols is slow in most cases but is catalyzed by acid, base, or Lewis acid (Xu 1998; Xu et al. 1998, 2017; Ducom et al. 2013; Gatidou et al. 2016; ECHA database www.echa.europa.eu). In contrast, the only well-documented environmental Si–CH3 cleavage is by reaction with OH radicals in the atmosphere (Alton and Browne 2020, 2022), whereby in a series of reaction steps not known in detail a Si–CH3 is replaced by a Si–OH substructure. Repetition of this sequence in combination with hydrolysis will finally lead to silicic acid, Si(OH)4, or its oligomers or its polymeric anhydride silica, SiO2. Reaction with OH radicals may occur also in water (Xu et al. 2017; Han et al. 2020).

Since Si–C bonds do not occur in living nature, it is still an open question whether there exist microorganisms able to cleave such bonds (Rücker and Kümmerer 2015; Petkowski et al. 2020; Rücker et al. 2023).

During the last 20 years, degradation of organosiloxanes has become a hot research topic in the context of biogas valorization (Braganca et al. 2020; Golmakani et al. 2022; Rivera-Montenegro et al. 2022; Rücker et al. 2023). Biogases, mixtures of mostly methane and carbon dioxide, are an upcoming power resource advantageous in terms of greenness, sustainability, and climate protection. There are three kinds of biogases (Rasi et al. 2011), those from anaerobic digestion of wastewater treatment sludge (Bougrier et al. 2006; Appels et al. 2008; De Arespacochaga et al. 2020), those released from landfills (Bolan et al. 2013; Kuhn et al. 2017; Li et al. 2019; De Arespacochaga et al. 2020; Braganca et al. 2020; Wang et al. 2020), and those produced from agricultural wastes (Rasi et al. 2013; Akhavan et al. 2014; Foppiano et al. 2020; Oliveira et al. 2022). Digester gas contains siloxanes that were adsorbed to sludge out of sewage, coming from use of personal care products containing, e.g., D4 and D5. Landfill gas contains siloxanes that probably are hydrolysis products of polydimethylsiloxanes (PDMS) present, e.g., in waste building materials, or residues in not quite empty containers of personal care products. Even in some biogases from agricultural waste traces of siloxanes of unknown origin were detected. Whenever biogas is combusted, e.g., for power generation, siloxanes therein are transformed into solid SiO2 particles that cause serious damage of equipment (Gersen et al. 2019; De Arespacochaga et al. 2020) and may threaten human health. Fuel cells are extremely sensitive to siloxane traces in feed biogas (Madi et al. 2015; Papurello and Lanzini 2018). Therefore, siloxanes have to be removed from crude biogas, a task of immediate economic relevance (Golmakani et al. 2022). For this purpose, adsorption to porous materials such as active carbon is state of the art, but alternative technologies are in high demand (De Arespacochaga et al. 2020; Braganca et al. 2020; Gaj 2020; Das et al. 2022; Rivera-Montenegro et al. 2022; Alves et al. 2023; Pascual et al. 2023; Gaj and Cichuta 2023). As such, recently biodegradation of siloxanes is an active field of research (Grabitz et al. 2021; Rücker et al. 2023). For example, in a biotrickling filter (BTF) a gas stream is brought into intimate contact with biodegrading microorganisms in the presence of an aqueous mineral solution. For exploring this technology, N2 or air were spiked with siloxane traces (D4 and/or D5) to serve as model gases in laboratory-size BTFs (Santos-Clotas et al. 2019, 2020; Boada et al. 2020; Pascual et al. 2020, 2021a).

Despite all uncertainty on details of degradation, for many years, it was generally accepted that if Si–CH3 bonds in siloxanes are at all reactive in the environment, then methylsiloxanes will finally be oxidatively degraded into silica, carbon dioxide and water. This view was and is plausible in our environment rich in oxygen and is based on thermodynamics that favor Si–O over Si–C moieties due to the Si–O bond being far stronger than the Si–C bond. This is of course in line with the usual environmental mineralization of organic pollutants into carbon dioxide and water.

All organosiloxanes are industrially synthesized in a sequence comprising as the first step the Müller–Rochow process, in which Si–CH3 bonds are formed from elemental silicon and chloromethane (2 CH3Cl + Si → (CH3)2SiCl2), requiring harsh conditions (300 °C, 3 bar) even under CuO catalysis (Beck et al. 2022). It was therefore very unexpected and contra-intuitive when in 2014 Tansel and Surita declared formation of new Si–CH3 bonds from siloxanes and methane thermodynamically favorable, and moreover suggested such reactions to occur under the mild conditions in landfills or digesters, for example hypothetical reaction (1) (Scheme 2) (Tansel and Surita 2014).

Detailed view of putative reaction (1)

This hypothetical reaction comprises formation of a Si–CH3 bond under cleavage of a Si–O bond. Tansel and Surita estimated the free energy of this reaction as − 251 kJ/mol, meaning an exothermic, thermodynamically favored reaction. This suggestion did not find much resonance until 2020, when Zhang et al. reported on an experiment in which for the first time they treated a real biogas containing traces of D5 and D4 in a (micro)aerobic BTF (Zhang et al. 2020). Most surprisingly to us, they interpreted their experimental results in terms of reaction (1), reporting formation of L2, a condensation product of Me3SiOH, as the major product. Such an accidental Si–CH3 bond formation seems questionable in view of what is known of pertinent bond enthalpies, see Table 1 that represents the current knowledge of organosilicon chemistry, obtained from a large body of experimental evidence. Zhang et al.’s interpretation contradicts general experience of organosiloxane behavior in the environment (Rücker and Kümmerer 2015; Homem and Ratola 2020; Rücker et al. 2023), and would have far-reaching consequences not only for biogas purification, but also for understanding the fundamental chemistry of organosilicon compounds, and last not least for industrial organosiloxane synthesis. Therefore, the putative Si–CH3 bond formation under mild conditions deserved a detailed investigation, the more so since it seems to be gaining acceptance as shown by the following quotations: “… the likely formation of L2 as an intermediate metabolite of D4 degradation” (Pascual et al. 2021b, no reference given), and “methane utilization may be a possible reaction mechanism for trimethylsilanol formation” (Xiang et al. 2021, referencing Tansel and Surita 2014). These authors obviously took for granted the possibility of Si–CH3 bond formation under mild conditions. The title question is asked here for the first time, to the best of our knowledge. The objectives of the present work were (i) to decide whether Si–C bond formation from siloxanes and methane under mild condition is real or erroneous, (ii) in the latter case, to understand what really may have happened in Zhang et al.’s experiment. So, we investigated the issue by scrutinizing the Tansel and Surita (2014) paper (“Consideration of reaction enthalpy” section) and the Zhang et al. (2020) paper (“Consideration of experimental evidence” section). From that a more realistic explanation of Zhang et al.’s experimental results evolved as a hypothesis that was shown to be in concordance with current knowledge (“Test of hypothesis” section).

Consideration of reaction enthalpy

Tansel and Surita (2014) roughly estimated reaction enthalpies as differences between enthalpies of products and reactants. Neglecting any ring strain effects or entropy terms, the enthalpy of a compound was expressed as the sum of its (average) bond enthalpies. This is equivalent to a reaction enthalpy being the difference of bond enthalpies on the left- and on the right-hand side of a reaction equation, or the difference of enthalpies of bonds formed and bonds broken. Attempting to reproduce their calculations, we followed the same approach, counting the bonds on the left-hand side of Eq. (1), 10 Si–O, 10 Si–C, 34 C–H bonds, and on the right-hand side, 9 Si–O, 11 Si–C, 33 C–H, 1 O–H bonds (Scheme 2). As a result, in this reaction one Si–O and one C–H bond are broken and one Si–C and one O–H bond are newly formed.

There are several sets of average bond enthalpies available; six sets are shown in Table 1. Using the set of bond enthalpies given in Tansel and Surita’s paper (set 1), we find reaction (1) to be endothermic by 17 kJ/mol, in obvious contradiction to their result of 251 kJ/mol exothermicity. If alternatively set 2, 3, 4, or 5 is used, reaction (1) turns out to be endothermic by 91, 31, 58–137, or 82 kJ/mol, respectively. Set 6 is the result of recent high-level ab initio calculations (Zhu and Zhou 2022); using these numbers, reaction (1) is endothermic by 86 kJ/mol. According to all these six sets, this hypothetical reaction is more or less endothermic and therefore not very likely to occur spontaneously or under catalysis to a reasonable extent. This is understandable since a very strong Si–O bond is broken in favor of a less strong Si–C bond, while the O–H bond formed, though stronger than the broken C–H bond, is unable to overcompensate.

If we additionally take into account ring strain of cyclosiloxanes, the conclusion is even stronger since ring-shrinking will build up further strain. Unfortunately, the only available numerical values of ring strain in Dn are rather old and contradictory. The most recently published values of strain energies of D3, D4 and D5 are 10.5, 1.01, and 1.05 kJ/mol, respectively (Voronkov 1996). Thereby an effect on reaction (1) is negligible, while the analogous hypothetical reaction (2) below, where D3 is formed from D4, suffers from an additional ring strain effect of 9.5 kJ/mol. Using older ring strain estimates for D3, D4, and D5 (80, 60, and 40 kJ/mol, Voronkov et al. 1991), reactions (1) and (2) are both disfavored by an additional ring strain effect of 20 kJ/mol.

Similar discrepancies are found between Tansel and Surita’s vs our calculations for all other hypothetical reactions mentioned in their paper. One obvious error in their calculations is the number of Si–C bonds in Me3SiOH given in their Table 2 as 1 instead of 3. Due to this error, all their calculations for reactions involving Me3SiOH (including reaction (1)) must be considered erroneous. However, even after correction of this error we are still unable to reproduce the G values given in their Table 2, we suspect that these numbers resulted from actually using bond energies other than those in set 1. For example, in their Fig. 3a and c, the Si–O bond energy is depicted about 450 kJ/mol, strangely with the same source given as that for set 1. Finally, in calculating the ΔG values for reactions (their Table 3, based on the numbers in their Table 2), the plus/minus signs or the directions of reactions seem to be confused.

Consideration of experimental evidence

In Zhang et al.’s (2020) experiment, a stream of biogas from an anaerobic digester (mostly CH4 and CO2) containing traces of D5, D4, and H2S was mixed with air (final O2 concentration 1%) and was treated at 30 °C in a BTF (Zhang et al. 2020). The BTF contained a circulating aqueous mineral nutrient solution and a biofilm (developing from an anaerobic digested sludge inoculum) and was continuously run for six months. Thereby, the H2S in the biogas was oxidized to sulfuric acid, the pH fell to 1.5, removal of H2S from the gas stream was almost complete (> 95%) while removal of siloxanes was partial (D5 removal up to 52%). At day 180, the aqueous reaction broth was analyzed for organosiloxanes by extraction into THF followed by GC/MS analysis using a 60 m HP-5MS capillary GC column. The gas chromatogram (shown in Zhang et al. (2020) as Fig. 7, red trace) showed a major product (retention time ~ 11.28 min) and a minor product (retention time 12.89 min) that the authors interpreted as L2 (hexamethyldisiloxane) and D3 (hexamethylcyclotrisiloxane), respectively. However, both these attributions are problematic.

Interpretation of the major product as L2 is subject to doubt for at least two reasons.

First, it is known that L2 suffers hydrolysis according to the equation Me3SiOSiMe3 + H2O \(\rightleftharpoons\) Me3SiOH + HOSiMe3 (Scheme 3). This is a hydrolysis equilibrium dominated in dilute aqueous solution by Me3SiOH (Spivack and Dorn 1994), and the experimental half-life of L2 in aqueous solution due to this reaction is ~ 4 days at pH 7 and 25 °C, and ~ 1.5 h at pH 5 and 25 °C (ECHA database www.echa.europa.eu). This fact alone renders presence of L2 in any reasonable amount at the end of Zhang et al.’s experiment (aqueous solution, pH down to 1.5, 30 °C, 180 days) extremely unlikely.

Second, the starting siloxanes D4 and D5 as well as their hydrolysis products and product D3 are made of D groups exclusively, whereas L2 (MM) consists of M groups.

To explain the putative formation of L2 (via condensation of Me3SiOH, the reverse of the above hydrolysis), Zhang et al. postulated the occurrence of reactions, called by them “ring-shrinking polyreactions”, that had been theoretically proposed by Tansel and Surita (2014), their “methane consuming siloxane reactions”:

The essence of reactions (1)–(3) is formation of a third Si–C bond at a silicon atom that is already engaged in two Si–C bonds, under cleavage of a Si–O bond, that is, formation of M from D groups and methane. These reactions according to Tansel and Surita are exothermic, ΔG0 = − 251 kJ/mol for both (1) and (2), and − 753 kJ/mol for (3), see, however, the “Consideration of reaction enthalpy” section above.

Additionally, Zhang et al. treated the crude product mixture (THF extract after drying with anhydrous Na2SO4) with bis(trimethylsilyl)trifluoroacetamide (BSTFA) in order to transform silanols into their trimethylsilyl derivatives for better GC/MS behavior (Scheme 3). The gas chromatogram after that treatment (shown in Zhang et al. (2020) as Fig. 7, blue trace) showed a peak of medium intensity at retention time 11.28 min, a peak of high intensity at 15.12 min, and peaks at 21.86 (low intensity) and 28.08 min (minute intensity). Zhang et al. (2020) attributed these peaks to L2, L3, L4 and L5, respectively. The latter three compounds presumably were the silylation products of dimethylsilanediol (DMSD), tetramethyldisiloxane-1,3-diol (dimerdiol), and hexamethyltrisiloxane-1,5-diol (trimerdiol), all these silanols are hydrolysis products of D4 and D5 (Scheme 3). There is another serious problem in this data interpretation, the absence of DMSD in the crude reaction mixture before silylation, where according to the silylation result it should be the dominant product.

In view of these problems, Zhang et al.’s data interpretation seemed highly questionable. Our hypothesis is that the major peak in the GC trace of Zhang et al.’s crude THF extract (retention time close to 11.28 min) does not correspond to L2 but to Me2Si(OH)2 (dimethylsilanediol, DMSD), whereas the peak at 11.28 min in the silylated sample does correspond to L2. In other words, L2 and DMSD may appear at similar retention times on Zhang et al.’s GC column and therefore may have been confused.

Our hypothesis is based on facts:

-

D4 and D5 in acidic aqueous solution are readily hydrolyzed to mostly DMSD, with trimerdiol and dimerdiol being obvious intermediates (Spivack and Dorn 1994; Kozerski and Durham 2006; ECHA database www.echa.europa.eu).

-

DMSD is extracted into THF from aqueous solution (Varaprath et al. 1998, 2006).

-

DMSD is analyzable by GC without decomposition, Table S1 in the Supplementary Material presents retention times of DMSD measured on various capillary GC columns under various conditions.

If our hypothesis is correct, the problems mentioned above are resolved, and questionable reactions such as (1)–(3) are not required to explain Zhang et al.’s experimental results.

For the presence of L2 in the silylated sample, there are several possible explanations. (i) Silylation by BSTFA of a water trace still present in the dried THF extract or newly diffused into it during handling in laboratory air, due to THF’s hygroscopicity. (ii) L2 contamination in reagent BSTFA due to moisture contact during its production, storage or handling. (iii) Traces of Me3SiOH may be present in the real biogas in concentration too low to be detected, are enriched in the reaction broth by continuous entry during the 180 day experiment, are extracted into THF and then silylated by BSTFA resulting in L2.

Test of hypothesis

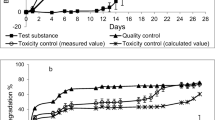

Our hypothesis essentially is the possibility of confusing L2 and DMSD if GC retention times only are considered. To test this hypothesis, the GC retention times of both compounds should be known under identical conditions. The type of GC column used for such a comparison should be similar (not necessarily the same) to that used by Zhang et al. (2020).

Table S1 in the Supplementary Material presents all retention times of DMSD that we were able to find in the literature reported up to mid-2022. Table S2 is a similar compilation for L2. These measurements were performed using various column materials, various column dimensions and under various conditions. A single paper provides GC retention times for both DMSD and L2 (3.02 and 3.88 min, respectively), but capillary columns used and conditions were not specified and may have been different for the two compounds (Varaprath 1999). Measurements using the most prevalent column material (5% diphenyl 95% dimethylpolysiloxane, the one used by Zhang et al.) and the most common column length (30 m) are highlighted in Tables S1 and S2 by italics. Restricting attention to these reports, retention times of DMSD still extend from 2.43 to 4.3 min, those of L2 vary between 1.65 and 6.4 min depending on conditions (temperature, carrier gas flow, solvent etc.) in a not quite transparent manner. Though the retention time range for DMSD is completely covered by that for L2, this data alone does not mean that under a particular set of conditions the retention times of both compounds are similar. However, in a most recent article (Geng et al. 2022) retention times of DMSD and L2 under identical conditions were published for the first time, 7.86 min for DMSD and 7.65 min for L2 (TG-5 column, 60 m × 0.25 mm × 0.25 μm, 1.00 mL/min He, temperature program 3 min at 40 °C, 5 °C/min up to 90 °C). This result (2.7% difference in retention times) strongly supports our hypothesis. Similarly, preliminary measurements of retention times of both compounds in our lab resulted in 4.54 min for DMSD and 3.88 min for L2 (Optima 5MS Accent capillary column (30 m × 0.25 mm × 0.25 μm), 1.5 mL/min He, temperature program 5 min at 35 °C, 10 °C/min up to 70 °C, 30 °C/min up to 260 °C) when running a mixture of both compounds dissolved in THF (M. Winkelmann, unpublished). This result (17% difference in retention times) is at least compatible with our hypothesis.

Discussion

Meanwhile, Zhang et al. in a control experiment monitored the transformation of D5 in dilute sulfuric acid (pH 2.0) at 30 °C for 30 days, conditions similar to those of their original experiment but without any added inoculum. The major observed product GC peak eluted at a retention time close to that of the major product in the original experiment, Zhang et al. now interpreted it as DMSD, though they did not report a mass spectrum of this peak. Consequently, they withdrew their claim for L2 formation, and thus for Me3SiOH and Si–C bond formation in their BTF (Zhang et al. 2021a). They also revoked a one-step reaction D5 → MD3M (L5) that appeared in the Graphical Abstract of their 2020 paper without any comment and that again comprised formation of M from D groups. In another subsequent study they confirmed that D5 removal in such an acidic BTF is due to acid-catalyzed hydrolysis (Zhang et al. 2021b). However, Zhang et al. (2021a, b) did not discuss reasons for the original erroneous claim.

As an aside, Zhang et al.’s identification of their original minor product (peak at 12.89 min) as D3 is also doubtful. D3 is subject to rapid hydrolysis as well (t1/2 = 2 min at pH 4, 23 min at pH 7, 25 °C, ECHA database www.echa.europa.eu; Gerhards et al. 2022). So the minor product probably was hexamethyltrisiloxane-1,5-diol (trimerdiol), which in the subsequent silylation step gave rise to L5. Mass spectra of Dn and the corresponding n-merdiol under EI (70 eV) ionization are nearly identical (Varaprath and Lehmann 1997; Varaprath et al. 2006).

An anonymous reviewer requested us to “comment on the hydrophilicity of each bond”.

Hydrophilicity of a compound roughly parallels the polarity of a molecule that in turn is the vector sum of polarities of all bonds present. In a simple siloxane, the only highly polar bonds are the Si–O bonds. Numerically, with the electronegativities of C, Si, O, and H being 2.55, 1.90, 3.44, and 2.20, respectively, the bond polarities (electronegativity differences of atoms) are as follows: Si–O 1.54, Si–C 0.65, C–H 0.35 (dimensionless). In a cyclic siloxane the bond dipole vectors add to zero, and in a linear siloxane nearly so. So, siloxanes (unless carrying highly polar functional groups) are nonpolar and therefore hydrophobic compounds, as described by the octanol/water partition coefficients KOW or log KOW. The experimental log KOW values of D3 (4.4), D4 (6.89), D5 (8.07), and Me3SiOH (1.19) (ECHA database www.echa.europa.eu) mean that the cyclic siloxanes are extremely hydrophobic, and even Me3SiOH prefers the octanol phase to the water phase by a factor of 15. Thus, hypothetical reaction (1) would transform extremely hydrophobic compounds into somewhat less hydrophobic ones.

An anonymous reviewer suggested a discussion of the influence of “super/sub-critical waters and also the energy provided by explosion of micro/nano-bubbles formed during some reactions”.

Hydrolysis of siloxanes (that is, Si–O bond cleavage) strongly depends on temperature, for example, hydrolyses of D4 and D5 are 22 and 17 times faster at 35 °C than at 10 °C (ECHA database www.echa.europa.eu). In hydrolysis experiments of Dn or Ln in water at these moderate temperatures Si–C cleavage or Si–C formation was never observed. However, in supercritical water (390 °C, 27 MPa), several organosilicon compounds including siloxanes underwent Si–C cleavage (Itami et al. 2004). Silicone wastes under subcritical or supercritical water conditions (250–390 °C, 50–280 bar) were even reported to decompose down to CH4 and/or a solid inorganic material containing SiO2 (Ulbrich et al. 2022).

Low-density polyethylene crosslinked with siloxane moieties, on the other hand, when treated with supercritical water (~ 350 °C), lost the crosslinks by cleavage of siloxane Si–O bonds; additionally, polyethylene chains were cut (Goto et al. 2008; Baek et al. 2016; Elmanovich et al. 2022). In all these experiments, no hints to formation of Si–C bonds were reported. Moreover, supercritical or very hot subcritical water does not play a role in landfills, digesters, biotrickling filters or in the free environment, to the best of our knowledge.

Micro/nanobubble technology is an emerging opportunity in wastewater treatment (Nair et al. 2022; Zhou et al. 2022a, b); however, no information on the behavior of siloxanes under such conditions seems to be available.

Conclusion and outlook

Scrutiny of the pertinent papers clearly shows that there is no evidence for formation of Si–C bonds from methane and siloxanes under mild conditions, neither theoretical nor experimental. The calculations put forward in favor of such reactions are incomprehensible, while the only case of such reactions putatively observed (in a biotrickling filter) most likely was erroneous, in that a product GC peak corresponding to DMSD seems to be misinterpreted as corresponding to L2. On a slightly polar GC column L2 and DMSD elute at similar retention times, so that they may easily be confused if retention times only are considered. This explains Zhang et al.’s (2020) experimental observations, and thus both objectives of our work were reached.

Reactions such as (1)–(3) should be favored by conditions in the technical microbiological systems discussed here (landfills, anaerobic digesters, biotrickling filters for biogas cleaning): Siloxane substrates and methane and bacteria are present in relatively high concentrations for durations long enough to allow for adaptation and selection of microorganisms. If under these conditions such Si–C bond forming reactions do not occur, then their occurrence under the less favorable conditions in the environment (in the field) is even less probable.

According to a recent review (Braganca et al. 2020), in analyses of biogases the presence of L2 was often reported, that of Me3SiOH sometimes, while Me2Si(OH)2 (DMSD) was not only never reported, but also never looked for. This is surprising since at least in cases of proven Me3SiOH formation by hydrolysis of oligo- or polymeric linear dimethylsiloxanes (PDMS), formation of large amounts of Me2Si(OH)2 should be expected. Moreover, the major hydrolysis product of cyclic dimethylsiloxanes such as D4 or D5 also is Me2Si(OH)2, a compound both well-soluble in water and volatile. As expected, in leachates from waste deposit sites both Me3SiOH and Me2Si(OH)2 were found (Grümping and Hirner 1999). So, it seems possible that L2 reported in biogases at least in some cases or in part actually was DMSD.

Data availability

All data and materials are included in the main text and the Supplementary Material.

References

Akhavan O, Bijanzad K, Mirsepah A (2014) Synthesis of graphene from natural and industrial carbonaceous wastes. RSC Adv 4:20441–20448. https://doi.org/10.1039/c4ra01550a

Alton MW, Browne EC (2020) Atmospheric chemistry of volatile methyl siloxanes: kinetics and products of oxidation by OH radicals and Cl atoms. Environ Sci Technol 54:5992–5999. https://doi.org/10.1021/acs.est.0c01368

Alton MW, Browne EC (2022) Atmospheric degradation of cyclic volatile methyl siloxanes: radical chemistry and oxidation products. ACS Environ Au 2:263–274. https://doi.org/10.1021/acsenvironau.1c00043

Alves CMAC, Abreu FOMS, Araujo RS, Oliveira MLM (2023) Recent advances in siloxanes removal from biogas and their efficiency: a short review. Chem Pap 77:1–9. https://doi.org/10.1007/s11696-022-02460-1

Appels L, Baeyens J, Degreve J, Dewil R (2008) Principles and potential of the anaerobic digestion of waste-activated sludge. Prog Energy Combust Sci 34:755–781. https://doi.org/10.1016/j.pecs.2008.06.002

Baek BK, La YH, Lee AS, Han H, Kim SH, Hong SM, Koo CM (2016) Decrosslinking reaction kinetics of silane-crosslinked polyethylene in sub- and supercritical fluids. Polymer Degrad Stab 130:103–108. https://doi.org/10.1016/j.polymdegradstab.2016.05.025

Beck AD, Schäffer L, Haufe S, Waldvogel SR (2022) Assessment of the electrochemical synthesis route to silicones starting from silica as feedstock. Eur J Org Chem 2022:e202201253. https://doi.org/10.1002/ejoc.202201253

Boada E, Santos-Clotas E, Bertran S, Cabrera-Codony A, Martin MJ, Baneras L, Gich F (2020) Potential use of Methylibium sp. as a biodegradation tool in organosilicon and volatile compounds removal for biogas upgrading. Chemosphere 240:124908. https://doi.org/10.1016/j.chemosphere.2019.124908

Bolan NS, Thangarajan R, Seshadri B, Jena U, Das KC, Wang H, Naidu R (2013) Landfills as a biorefinery to produce biomass and capture biogas. Bioresource Technol 135:578–587. https://doi.org/10.1016/j.biortech.2012.08.135

Bougrier C, Delgenes JP, Carrere H (2006) Combination of thermal treatments and anaerobic digestion to reduce sewage sludge quantity and improve biogas yield. Process Saf Environ Protect 84:280–284. https://doi.org/10.1205/psep.05162

Braganca I, Sanchez-Soberon F, Pantuzza GF, Alves A, Ratola N (2020) Impurities in biogas: Analytical strategies, occurrence, effects and removal technologies. Biomass Bioenergy 143:105878. https://doi.org/10.1016/j.biombioe.2020.105878

Brook MA (2000) Silicon in organic, organometallic, and polymer chemistry. Wiley, New York

Clayden J, Greeves N, Warren SG (2012) Organic chemistry, 2nd edn. Oxford University Press, Oxford

Das J, Ravishankar H, Lens PNL (2022) Biological biogas purification: recent developments, challenges and future prospects. J Environ Manag 304:114198. https://doi.org/10.1016/j.jenvman.2021.114198

De Arespacochaga N, Raich-Montiu J, Crest M, Cortina JL (2020) Presence of siloxanes in sewage biogas and their impact on its energetic valorization. In: Homem V, Ratola N (eds.) Volatile Methylsiloxanes in the Environment, Handbook of Environmental Chemistry, Springer, pp 131–157. https://doi.org/10.1007/698_2018_372

Ducom G, Laubie B, Ohannessian A, Chottier C, Germain P, Chatain V (2013) Hydrolysis of polydimethylsiloxane fluids in controlled aqueous solutions. Water Sci Technol 68:813–820. https://doi.org/10.2166/wst.2013.308

ECHA (2018a) Annex XV report – Proposal for identification of a substance of very high concern on the basis of the criteria set out in REACH Article 57 – Substance Name Octamethylcyclotetrasiloxane, D4. https://www.echa.europa.eu/documents/10162/50488161-546d-2048-828a-b6d9ef29f310. Accessed 14 Feb 2023

ECHA (2018b) Annex XV report – Proposal for identification of a substance of very high concern on the basis of the criteria set out in REACH Article 57 – Substance Name Decamethylcyclopentasiloxane, D5. https://www.echa.europa.eu/documents/10162/2ad6bb2e-3eca-dd87-e705-db5c71ac4ffe. Accessed 14 Feb 2023

ECHA (2019) Annex XV restriction report, proposal for a restriction, version number 1, 11 January 2019. https://www.echa.europa.eu/documents/10162/13641/rest_d4d5d6_axvreport_en.pdf/c4463b07-79a3-7abe-b7a7-5c816e45bb98. Accessed 14 Feb 2023

ECHA (2021) Recommendation of the European Chemicals Agency of 14 April 2021 for the inclusion of substances in Annex XIV to REACH (List of substances subject to authorization), https://www.echa.europa.eu/documents/10162/13640/10th_axiv_recommendation_april2021_en.pdf/e84c6688-d038-fc8f-41dd-874535ac7a82. Accessed 14 Feb 2023

Elmanovich IV, Sizov VE, Zefirov VV, Kalinina AA, Gallyamov MO, Papkov VS, Muzafarov AM (2022) Chemical recycling of high-molecular-weight organosilicon compounds in supercritical fluids. Polymers 14:5170. https://doi.org/10.3390/polym14235170

EU (2018) Commission regulation (EU) 2018/35 of 10 January 2018 amending Annex XVII to Regulation (EC) No 1907/2006 of the European Parliament and of the Council concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) as regards octamethylcyclotetrasiloxane (‘D4’) and decamethylcyclopentasiloxane (‘D5’). Off J Europ Union L6:45–47. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32018R0035&from=EN. Accessed 14 Feb 2023

EU (2019) Commission regulation (EU) 2019/831 of 22 May 2019 amending annexes II, III and V to regulation (EC) No 1223/2009 of the European Parliament and of the Council on cosmetic products. Off J Europ Union L137:29–63. https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019R0831&from=EN. Accessed 14 Feb 2023

Foppiano D, Tarik M, Schneebeli J, Calbry-Muzyka A, Biollaz S, Ludwig C (2020) Siloxane compounds in biogas from manure and mixed organic waste: Method development and speciation analysis with GC-ICP-MS. Talanta 208:120398. https://doi.org/10.1016/j.talanta.2019.120398

Gaj K (2020) Adsorptive biogas purification from siloxanes – a critical review. Energies 13:2605. https://doi.org/10.3390/en13102605

Gaj K, Cichuta K (2023) Combined biological method for simultaneous removal of hydrogen sulphide and volatile methylsiloxanes from biogas. Energies 16:100. https://doi.org/10.3390/en16010100

Gatidou G, Arvaniti OS, Stasinakis AS, Thomaidis NS, Andersen HR (2016) Using mechanisms of hydrolysis and sorption to reduce siloxanes occurrence in biogas of anaerobic sludge digesters. Bioresource Technol 221:205–213. https://doi.org/10.1016/j.biortech.2016.09.018

Geng H, Chen L, Wang S, Wu Y, Gao P, Jiang Q, Yang F, Xia W (2022) Analysis of volatile compounds contributing to distinctive odour of silver carp (Hypophthalmichthys molitrix) surimi. Int J Food Sci Technol 57:7774–7786. https://doi.org/10.1111/ijfs.16141

Gerhards R, Seston RM, Kozerski GE, McNett DA, Boehmer T, Durham JA, Xu S (2022) Basic considerations to minimize bias in collection and analysis of volatile methyl siloxanes in environmental samples. Sci Total Environ 851:158275. https://doi.org/10.1016/j.scitotenv.2022.158275

Gersen S, Visser P, van Essen M, Brown M, Lewis A, Levinsky H (2019) Impact of silica deposition on the performance of gas-fired domestic appliances caused by the combustion of siloxanes in the fuel. Renew Energy 132:575–586. https://doi.org/10.1016/j.renene.2018.07.143

Golmakani A, Ali Nabavi S, Wadi B, Manovic V (2022) Advances, challenges, and perspectives of biogas cleaning, upgrading, and utilisation. Fuel 317:123085. https://doi.org/10.1016/j.fuel.2021.123085

Goto T, Yamazaki T, Sugeta T, Okajima I, Sako T (2008) Selective decomposition of the siloxane bond constituting the crosslinking element of silane-crosslinked polyethylene by supercritical alcohol. J Appl Polymer Sci 109:144–151. https://doi.org/10.1002/app.27928

Grabitz E, Olsson O, Kümmerer K (2021) Towards the design of organosilicon compounds for environmental degradation by using structure biodegradability relationships. Chemosphere 279:130442. https://doi.org/10.1016/j.chemosphere.2021.130442

Grümping R, Hirner AV (1999) HPLC/ICP-OES determination of water-soluble silicone (PDMS) degradation products in leachates. Fresenius J Anal Chem 363:347–352. https://doi.org/10.1007/s002160051201

Han W, Sun H, Zhang S, Zhao Q, Zhang X, Ma Y, Chen J, Li H (2020) Hydroxyl radical oxidation of cyclic methylsiloxanes D4–D6 in aqueous phase. Chemosphere 242:125200. https://doi.org/10.1016/j.chemosphere.2019.125200

Homem V, Ratola N (eds) (2020) Volatile methylsiloxanes in the environment Handbook of Environmental Chemistry. Springer Nature, Cham. https://doi.org/10.1007/978-3-030-50135-8

Itami K, Terakawa K, Yoshida JI, Kajimoto O (2004) The carbon–silicon bond cleavage of organosilicon compounds in supercritical water. Bull Chem Soc Jpn 77:2071–2080. https://doi.org/10.1246/bcsj.77.2071

Kozerski GE, Durham JA (2006) Kinetics and mechanism of the abiotic hydrolysis reactions of permethylated cyclosiloxanes in dilute aqueous solution. Abstracts, 38th central regional meeting of the American Chemical Society, Frankenmuth, MI, United States, May 16–20, 2006, CRM-051

Kuhn JN, Elwell AC, Elsayed NH, Joseph B (2017) Requirements, techniques, and costs for contaminant removal from landfill gas. Waste Manag 63:246–256. https://doi.org/10.1016/j.wasman.2017.02.001

Li Y, Alaimo CP, Kim M, Kado NY, Peppers J, Xue J, Wan C, Green PG, Zhang R, Jenkins BM, Vogel CFA, Wuertz S, Young TM, Kleeman MJ (2019) Composition and toxicity of biogas produced from different feedstocks in California. Environ Sci Technol 53:11569–11579. https://doi.org/10.1021/acs.est.9b03003

Madi H, Lanzini A, Diethelm S, Papurello D, Van herle J, Lualdi M, Gutzon Larsen J, Santarelli M (2015) Solid oxide fuel cell anode degradation by the effect of siloxanes. J Power Sources 279:460–471. https://doi.org/10.1016/j.jpowsour.2015.01.053

Nair SS, Pinedo-Cuenca R, Stubbs T, Davis SJ, Ganesan PB, Hamad F (2022) Contemporary application of microbubble technology in water treatment. Water Sci Technol 86:2138–2156. https://doi.org/10.2166/wst.2022.328

Oliveira LG, Cremonez PA, Machado B, Soares da Silva E, Silva FEB, Correa GCG, Lopez TFM, Alves HJ (2022) Updates on biogas enrichment and purification methods: A review. Can J Chem Eng 2022:1–30. https://doi.org/10.1002/cjce.24671

Papurello D, Lanzini A (2018) SOFC single cells fed by biogas: experimental tests with trace contaminants. Waste Manag 72:306–312. https://doi.org/10.1016/j.wasman.2017.11.030

Pascual C, Cantera S, Lebrero R (2021a) Volatile siloxanes emissions: Impact and sustainable abatement perspectives. Trends Biotechnol 39:1245–1248. https://doi.org/10.1016/j.tibtech.2021.05.003

Pascual C, Cantera S, Munoz R, Lebrero R (2021b) Siloxanes removal in a two-phase partitioning biotrickling filter: Influence of the EBRT and the organic phase. Renew Energy 177:52–60. https://doi.org/10.1016/j.renene.2021.05.144

Pascual C, Cantera S, Munoz R, Lebrero R (2020). Comparative assessment of two biotrickling filters for siloxanes removal: Effect of the addition of an organic phase. Chemosphere 251:126359. https://doi.org/10.1016/j.chemosphere.2020.126359

Pascual C, Lebrero R, Cantera S (2023) Toward a sustainable and cost-efficient biological-based platform for siloxanes removal. Crit Rev Environ Sci Technol 53:70–86. https://doi.org/10.1080/10643389.2022.2044254

Petkowski JJ, Bains W, Seager S (2020) On the potential of silicon as a building block for life. Life 10:84. https://doi.org/10.3390/life10060084

Rasi S, Läntelä J, Rintala J (2011) Trace compounds affecting biogas energy utilisation – a review. Energy Convers Manag 52:3369–3375. https://doi.org/10.1016/j.enconman.2011.07.005

Rasi S, Seppälä M, Rintala J (2013) Organic silicon compounds in biogases produced from grass silage, grass and maize in laboratory batch assays. Energy (Oxford) 52:137–142. https://doi.org/10.1016/j.energy.2013.01.015

Riedel E, Janiak C (2022) Anorganische Chemie, 10th edn. De Gruyter, Berlin

Rivera-Montenegro L, Valenzuela EI, Gonzalez-Sanchez A, Munoz R, Quijano G (2022) Volatile methyl siloxanes as key biogas pollutants: Occurrence, impacts and treatment technologies. Bioenerg Res. https://doi.org/10.1007/s12155-022-10525-y

Rücker C, Grabitz E, Kümmerer K (2023) Are Si–C bonds cleaved by microorganisms? A critical review on biodegradation of methylsiloxanes. Chemosphere 321:137858. https://doi.org/10.1016/j.chemosphere.2023.137858

Rücker C, Kümmerer K (2015) Environmental chemistry of organosiloxanes. Chem Rev 115:466–524. https://doi.org/10.1021/cr500319v

Santos-Clotas E, Cabrera-Codony A, Boada E, Gich F, Munoz R, Martin MJ (2019) Efficient removal of siloxanes and volatile organic compounds from sewage biogas by an anoxic biotrickling filter supplemented with activated carbon. Bioresource Technol 294:122136. https://doi.org/10.1016/j.biortech.2019.122136

Santos-Clotas E, Cabrera-Codony A, Martin MJ (2020) Coupling adsorption with biotechnologies for siloxane abatement from biogas. Renew Energy 153:314–323. https://doi.org/10.1016/j.renene.2020.02.026

Sarai NS, Levin BJ, Roberts JM, Katsoulis DE, Arnold FH (2021) Biocatalytic transformations of silicon – the other group 14 element. ACS Cent Sci 7:944–953. https://doi.org/10.1021/acscentsci.1c00182

Spivack J, Dorn SB (1994) Hydrolysis of oligodimethylsiloxane-α, ω-diols and the position of hydrolytic equilibrium. Environ Sci Technol 28:2345–2352. https://doi.org/10.1021/es00062a019

Tansel B, Surita SC (2014) Differences in volatile methyl siloxane (VMS) profiles in biogas from landfills and anaerobic digesters and energetics of VMS transformations. Waste Manag 34:2271–2277. https://doi.org/10.1016/j.wasman.2014.07.025

Ulbrich M, Tillmann J, Voit H (2022) Process of reacting silicone with hydrothermal or supercritical water. WO2022214176 A1 (in German)

Varaprath S (1999) Synthesis of 14C-labeled cyclic and linear siloxanes. J Organomet Chem 572:37–47. https://doi.org/10.1016/S0022-328X(98)00916-4

Varaprath S, Lehmann RG (1997) Speciation and quantitation of degradation products of silicones (silane/siloxane diols) by gas chromatography-mass spectrometry and stability of dimethylsilanediol. J Environ Polym Degrad 5:17–31. https://doi.org/10.1007/BF02763565

Varaprath S, Salyers KL, Plotzke KP, Nanavati S (1998) Extraction of octamethylcyclotetrasiloxane and its metabolites from biological matrices. Anal Biochem 256:14–22. https://doi.org/10.1006/abio.1997.2475

Varaprath S, Stutts DH, Kozerski GE (2006) A primer on the analytical aspects of silicones at trace levels – challenges and artifacts – A review. Silicon Chem 3:79–102. https://doi.org/10.1007/s11201-006-9005-8

Voronkov MG (1996) Energy of the Si–O bond and ring strain in permethylcyclosiloxanes. Russ J Gen Chem 66:165

Voronkov MG, Klyuchnikov VA, Mironenko EV, Shvets GN, Danilova TF, Khudobin YI (1991) Thermochemistry of organosilicon compounds V. Thermochemical properties of perorganyloligocyclosiloxanes. J Organomet Chem 406:91–97. https://doi.org/10.1016/0022-328X(91)83174-3

Wang N, Tan L, Xie L, Wang Y, Ellis T (2020) Investigation of volatile methyl siloxanes in biogas and the ambient environment in a landfill. J Environ Sci 91:54–61. https://doi.org/10.1016/j.jes.2020.01.005

Wilbraham AC, Staley DD, Matta MS (2008) Chemistry. Pearson Prentice Hall, Upper Saddle River, New Jersey (Chapter 8)

Xiang X, Liu N, Xu L, Cai Y (2021) Review of recent findings on occurrence and fates of siloxanes in environmental compartments. Ecotoxicol Environ Safety 224:112631. https://doi.org/10.1016/j.ecoenv.2021.112631

Xu S (1998) Hydrolysis of poly(dimethylsiloxanes) on clay minerals as influenced by exchangeable cations and moisture. Environ Sci Technol 32:3162–3168. https://doi.org/10.1021/es980338h

Xu S, Lehmann RG, Miller JR, Chandra G (1998) Degradation of polydimethylsiloxanes (silicones) as influenced by clay minerals. Environ Sci Technol 32:1199–1206. https://doi.org/10.1021/es9708676

Xu L, Xu S, Zhi L, He X, Zhang C, Cai Y (2017) Methylsiloxanes release from one landfill through yearly cycle and their removal mechanisms (especially hydroxylation) in leachates. Environ Sci Technol 51:12337–12346. https://doi.org/10.1021/acs.est.7b03624

Zhang Y, Oshita K, Kusakabe T, Takaoka M, Kawasaki Y, Minami D, Tanaka T (2020) Simultaneous removal of siloxanes and H2S from biogas using an aerobic biotrickling filter. J Hazard Mater 391:122187. https://doi.org/10.1016/j.jhazmat.2020.122187

Zhang Y, Oshita K, Kusakabe T, Takaoka M, Kawasaki Y, Minami D, Tanaka T (2021a) Corrigendum to „Simultaneous removal of siloxanes and H2S from biogas using an aerobic biotrickling filter” [J. Hazard. Mater. 391 (2020) 122187]. J Hazard Mater 409:125032. https://doi.org/10.1016/j.jhazmat.2020.125032

Zhang Y, Oshita K, Takaoka M, Kawasaki Y, Minami D, Inoue G, Tanaka T (2021b) Effect of pH on the performance of an acidic biotrickling filter for simultaneous removal of H2S and siloxane from biogas. Water Sci Technol 83:1511–1521. https://doi.org/10.2166/wst.2021.083

Zhou S, Marcelino KR, Wongkiew S, Sun L, Guo W, Khanal SK, Lu H (2022a) Untapped potential: Applying microbubble and nanobubble technology in water and wastewater treatment and ecological restoration. ACS EST Engg 2:1558–1573. https://doi.org/10.1021/acsestengg.2c00117

Zhou S, Liu M, Chen B, Sun L, Lu H (2022) Microbubble and nanobubble-aeration for upgrading conventional activated sludge process: a review. Bioresource Technol 362:127826. https://doi.org/10.1016/j.biortech.2022.127826

Zhu S, Zhou CW (2022) Theoretical study on the kinetics and thermodynamics of H-atom abstractions from tetramethylsilane-related species. Int J Chem Kinet 54:243–255. https://doi.org/10.1002/kin.21554

Funding

Open Access funding enabled and organized by Projekt DEAL.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by Christoph Rücker and Magnus Winkelmann. The first draft of the manuscript was written by Christoph Rücker. Klaus Kümmerer and Magnus Winkelmann commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

All authors consented to publication.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: George Z. Kyzas

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Rücker, C., Winkelmann, M. & Kümmerer, K. Are Si–C bonds formed in the environment and/or in technical microbiological systems?. Environ Sci Pollut Res 30, 91492–91500 (2023). https://doi.org/10.1007/s11356-023-28528-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-28528-3