Abstract

A scientific evaluation of the carbon emission efficiency is crucial for ensuring the sustainable development of wastewater treatment plants (WWTPs). In this paper, we applied a non-radial data envelopment analysis (DEA) model to calculate the carbon emission efficiency of 225 WWTPs located in China. The results showed that the average carbon emission efficiency of China’s WWTPs was 0.59, indicating that the efficiencies of most samples still require improvement. The carbon emission efficiency of WWTPs from 2015 to 2017 decreased because of the decrease in technology efficiency. Among the influencing factors, different treating scales had positive impact on carbon emission efficiency improvement. WWTPs with anaerobic oxic process and the first-class A standard were likely to have higher carbon emission efficiency in the 225 WWTPs. By incorporating direct and indirect carbon emissions into WWTP efficiency evaluation, this study helped decision-makers and related water authorities to better understand the contribution of WWTPs to the aquatic and atmospheric environments.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Greenhouse gas (GHG) emissions, especially carbon emissions, are the main concern for countries worldwide (Liu et al. 2015; Zaidi et al. 2021). Improving carbon emission efficiency is the common goal of all nations and humanity (Wang et al. 2016; Tenaw and Hawitibo 2021; Zhu et al. 2021). As one of the largest carbon emitters in the world, China faces the severe challenge of carbon reduction (Chang et al. 2017; Li and Cheng 2020; Fang et al. 2021). In 2020, China’s carbon emissions reached 14,400 MMT CO2e despite the COVID-19 lockdown (Koondhar et al. 2021). To proactively respond to climate change and reduce GHG emissions, the Chinese government pledged in 2020 to implement policies and measures to peak carbon emissions by 2030 and achieve carbon neutrality by 2060, also known as the “dual carbon” goal (The State Council Information Office of PRC 2020).

To actively achieve the “dual carbon” goal, the typical high-carbon industries or sectors, such as heavy chemical industries (Lu et al. 2020) and electricity generation sector (Zhao et al. 2020; Banerjee 2022), have developed corresponding plans, recognized the characteristics and efficiency of carbon emissions, and explored measures to improve the efficiency and reduce carbon emission. However, some potential and rapidly growing carbon-emitting sectors in China, such as wastewater treatment plants (WWTPs), have received less attention. While water environment improvement has received increasing attention, many WWTPs have been constructed in China since 2000 (He et al. 2019; Zhang et al. 2019). The number of municipal WWTPs located in cities increased from 427 in 2000 to 2209 in 2017. The processing capacity grew at an average annual rate of 12.72% and reached 157.43 million m3/day in 2017, which was comparable to that of the USA (122.43 million m3/day in 2014) (Shen et al. 2015; Ministry of Housing and Urban–Rural Development of PRC 2018). As one of the largest minor GHG emitters (US EPA 1997), GHG emissions from the waste/wastewater sector have attracted attention. According to the Intergovernmental Panel on Climate Change (IPCC) Fifth Assessment Report, the global GHG emissions from the waste/wastewater sector were 1.4 Gt CO2e in 2010, accounting for about 2.86% of total emissions (IPCC 2015). Regional assessment reports pointed out that the annual GHG of the US wastewater sector reached approximately 19.2 MMT CO2e in 2017 (US EPA 2019). Zhang et al. (2017) reported the average annual GHG emissions of 41 MT CO2e for water utilities in China between 2006 and 2012 and were expected to continue to increase with the expansion of processing capacity. To achieve the “dual carbon” goal, the Chinese government has begun to be concerned about the carbon emissions of WWTPs, emphasizing the promotion of energy-saving and low-carbon development of municipal wastewater (Ministry of Housing and Urban–Rural Development of PRC 2021). The Implementation Plan for the Synergistic Effect of Pollution Reduction and Carbon Reduction, released in 2022, stated that the carbon emission management of WWTPs should be optimized. Assessing the carbon emission efficiency of WWTPs and taking it into consideration in WWTP operation and management will be helpful to achieve China’s “dual carbon” goal and promote low-carbon development of the wastewater treatment industry.

Existing research on improving the efficiency of WWTPs has mainly focused on specific technologies (Bozkurt et al. 2016; Ma et al. 2019; Shin et al. 2022). However, the analysis from the perspective of economics and management has also emerged. In the literature, scientific evaluation and improvement of the efficiency of existing WWTPs have attracted much attention (Mai et al. 2015; Jiang et al. 2020; Yang and Chen 2021), and some studies have evaluated the techno-economic efficiency of WWTPs (Sala-Garrido et al. 2011; Guerrini et al. 2015; Gómez et al. 2017). Most of these studies only used the indicators such as energy, cost, labor, and removed pollutants, without considering GHG. Furthermore, studies evaluated the eco-efficiency of WWTPs, taking into account GHG emissions (Gémar et al. 2018; Torregrossa et al. 2018; Hu et al. 2019). To our knowledge, Molinos-Senante et al. (2016) pioneered the eco-efficiency evaluation of WWTPs. They used a weighted Russell directional distance model (WRDDM), a non-radial DEA model, to assess the eco-efficiency of 30 WWTPs in Spain in 2014. Cost and removed pollutant were selected as inputs and outputs, respectively, and the carbon dioxide (CO2) from electricity consumption was considered an undesirable output. The results showed that half of the facilities need to be improved. Dong et al. (2017) adopted DEA to evaluate the eco-efficiency of WWTPs in China for the first time. Nitrous oxide (N2O) emissions were considered in their study in terms of environmental impact and the results showed that the average efficiency value for WWTPs was between 0.5 and 0.8.

DEA, a non-parametric analysis method, has been widely used to evaluate the efficiency of WWTPs because it can address multiple output/input situations and is not limited by the requirement of large amounts of data. GHG emissions from WWTPs include methane (CH4), CO2, and N2O (Ahn et al. 2010; Polruang et al. 2018; Nguyen et al. 2019). Most scholars often only regard N2O or energy consumption as undesirable outputs (Gémar et al. 2018), but few studies focus on the complete carbon emission from WWTPs. Moreover, previous studies have only focused on evaluating the efficiency of WWTPs at a static moment, ignoring the rate of dynamic efficiency changes over time (e.g., Zeng et al. 2017). To better support decision-making, research on the temporal dynamics of carbon emission efficiency is crucial.

Based on the above, this study was initiated to evaluate the carbon emission efficiency of WWTPs in China. Firstly, it focused on evaluating the carbon emission efficiency in 2017, the dynamic efficiency in 2015–2017 using the non-radial DEA model, and the Malmquist-Luenberger index. Then, this study evaluated the potential factors affecting carbon emission efficiency which includes scale, process, discharge standard, and wastewater treatment fees. This study will provide scientific basis for decision-making to professionals including policymakers as well as wastewater treatment plant managers and operators.

Methodology

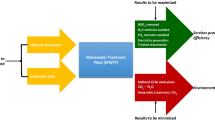

Figure 1 shows the analysis framework of this study. First, relevant data were collected from WWTPs and carbon emissions were calculated. Second, the non-radial DEA model was developed to calculate the relative static efficiency of WWTPs. Then, the Malmquist-Luenberger index was calculated to evaluate the dynamic changes from 2015 to 2017. Finally, potential factors affecting carbon emission efficiency were discussed in details.

The minimum distance to strong efficient frontier DEA model

DEA is a non-parametric technical efficiency analysis method based on mutual comparisons between the evaluated objects (WWTPs in this study). The relative efficiency of each DMU is evaluated according to multiple inputs and outputs. A non-parametric production frontier is formulated and used to compare relative efficiency (Cheng 2014).

To address the issue of slack variables during the measurement in the radial-DEA model, Tone (2001) proposed the slack-based measure (SBM) model. However, each projection point of the evaluated WWTP in SBM model is the farthest point on the frontier. SBM will overestimate the improvement potential of inefficient WWTPs and result in the measured efficiency score lower than its real value. This violates the preferences of decision-makers. Therefore, this paper used the improved DEA model proposed by Aparicio et al. (2007), namely, the minimum distance to strong efficient frontier (MinDS) model. In this method, all the evaluated WWTP reference benchmarks are restricted to the same hyperplane, which make up for the deficiency of the SBM model.

The basic mathematical expression of the MinDS is shown as Eq. (1):

where \({\rho }_{\mathrm{k}}\) is the efficiency value of the evaluated DMU. I, P, and Q are the types of inputs, desirable outputs and undesirable outputs. \({s}_{i}^{x-}\), \({\mathrm{s}}_{p}^{\mathrm{y} + }\), \({\mathrm{s}}_{\mathrm{q}}^{{\mathrm{b}}-}\) are the slack variables of the inputs, desirable outputs, and undesirable outputs. \({\mathrm{y}}_{{\mathrm{p}}{\mathrm{k}}}\) and \({\mathrm{b}}_{\mathrm{qk}}\) are the desirable output (p) and undesirable output (q). \({\lambda }_{\mathrm{j}}\) is the combination coefficient. M is a sufficiently large positive number.

Malmquist-Luenberger index

The Malmquist index calculated the changes in total factor productivity (TFP) over a period. Chung et al. (1997) incorporated the directional distance function including undesired outputs to the Malmquist model, called the Malmquist-Luenberger index (ML index). The index has been widely used because it can be further decomposed to figure out the change of technical efficiency compared to the frontier and its own variation (Wu et al. 2021).

If the input is represented as x, E is the efficiency score. The desirable output is denoted as y, and the undesirable output is denoted as b. The adjustment amount of the desirable output and the undesirable output is denoted as g; the ML index from time t to t + 1 can be defined as

Furthermore, the Malmquist-Luenberger index can be decomposed into the technical efficiency change index (EC) and the technological change index (TC):

When ML index, EC, and TC are larger than 1, they indicate the improvement of productivity, the improvement of efficiency, and the progress of technology, respectively. On the contrary, when ML index, EC, and TC are less than 1, they indicate the decrease in productivity, the deterioration of efficiency, and the deterioration of technology.

Sample data

Data from 225 operating WWTPs were collected from the Urban Drainage Statistics Yearbook (China Urban Water Association 2018), including the operating costs, staffing, scale, pollutant removal, currently used types of processes, and the discharge standards implemented. The sampled dataset was selected and adopted in over 60,000 data, which has included nearly all treatment processes, plant scales, and standards. This can be better represented as the prevailing condition of WWTPs in China.

The carbon emission studies were calculated using the emission factor method recommended by the IPCC (2006, 2019). It provided an internationally acknowledged method for carbon emissions accounting and had been widely accepted. The carbon emissions in the WWTPs were generated from two sources including biological treatment (direct emissions) and electricity consumption (indirect emissions) (Mamais et al. 2015). According to the IPCC guideline, CO2 produced by biological metabolism was considered short-lived biogenic emission and should not be included in the GHG emissions. The global warming potential (GWP) of CH4 and N2O is 21 and 298 times that of CO2, which means that the impact of CH4 and N2O is 21 and 298 times that of CO2. Therefore, CH4 and N2O emissions during the operation of WWTPs were mainly considered in direct emissions. The direct and indirect emissions of each WWTPs were estimated according to Eqs. (4) to (6).

Direct emission

where \({E}_{{\mathrm{CH}}_{4}}\) is the CH4 emissions, kg CH4/day; TOW is the total organic in wastewater, kg COD/day; EF is the emission factor, kg CH4/kg COD; R0 is the recovery of CH4 and the default value is 0. CH4 from wastewater treatment, whose 100-year GWP value was 21 times higher than CO2 (Bassin et al. 2021).

The major contributor to N2O emissions from WWTPs was the incomplete nitrification and denitrification processes during biological nitrogen removal (Ahn et al. 2010). Therefore, using TN in wastewater for N2O accounting was more accurate than using population equivalent (Dong et al. 2017).

where \({\mathrm{E}}_{{\mathrm{N}}_{2}{\mathrm{O}}}\) is the N2O emissions, kg N2O/day; \({\mathrm{TN}}_{\mathrm{influent}}\) and \({\mathrm{TN}}_{\mathrm{effluent}}\) are the influent and effluent TN concentrations (mg /L) of the WWTPs; 0.035 and 0.005 are the emission factors; 298 represents the global warming potential for N2O; 44/28 is the conversion from kg N2O–N to kg N2O; \({\mathrm{Q}}\) is the amount of treated water, m3/day.

Indirect emission

Indirect carbon emissions from WWTPs mainly came from electricity consumption (Larsen 2015). The indirect emissions from WWTPs can be calculated by the CO2 emission factor for power consumption (Zeng et al. 2017). The average value is 0.9224 t/(MW•h), according to the baseline emission factor of the China Regional Network.

where \({\mathrm{x}}\) is the cumulative electricity consumption, kWh/day; EF is the calculation of the CO2 emission factor, t/(MW•h). The descriptive analysis of the input and output indicators in 2017 is shown in Table 1.

Results and discussion

Carbon emission of WWTPs in China

The average carbon emission of 225 Chinese WWTPs was 0.65 kg/m3. Among them, the direct emission was 0.42 kg/m3, and the indirect emission was 0.23 kg/m3. Direct emission accounts for 64.17% (Fig. 2). This result was consistent with the experimental monitoring (Xie and Wang 2012; Bao et al. 2016). Bao et al. (2016) found that direct GHGs from Chinese WWTPs accounted for 49.2–61.8% of total emissions. Overall, in addition to energy consumption, the emissions from biological treatment process also need to be considered. On the one hand, by improving the technology such as using the anammox process, nitrogen removal can be removed by consuming lower energy and carbon emissions (Greenfield and Batstone 2005). On the other hand, the operational management of WWTPs is also critical to improve system efficiency (Castellet-Viciano et al. 2018; Werkneh and Gebru 2023).

Carbon emission efficiency of WWTPs in China

Figure 3 summarizes the efficiency score of 225 WWTPs. There were 103 and 82 WWTPs with medium efficiency (0.4–0.6) and good efficiency (0.6–0.8), respectively, accounting for about 82.22% of the entire sample. The average efficiency value was 0.59, indicating a potential improvement of 41%. In other words, WWTPs could perform better in pollutant removal and carbon reduction under the same operating costs and staffing. The number of efficiencies located on the frontier was 10, accounting for only 4.44% of the total. The pure technical efficiency (PTE) was 0.64 and the scale efficiency (SE) was 0.94, which mean PTE was the main contributing factor to the low technical efficiency. This illustrated the ability to obtain the maximal outputs with given inputs under the actual scale was low. The possible reason for the low PTE may have been that most WWTPs in China still mainly relied on the experience of technicians for management and operation, and there were widespread phenomena of excessive dosage and aeration, which further aggravated carbon emissions (Pan et al. 2020; Chen et al. 2022).

Figure 4 shows the potential improvement of each WWTP including all inputs and outputs. WWTPs could improve performance and efficiency by reducing input and undesirable output and making up for desirable output shortfalls. For the 225 WWTPs, the staffing and operating costs could be reduced by 5 persons and 10,221.1 yuan/day, respectively. Under the current input level, BOD5 and NH3–N could be increased by 1042.92 kg/day and 320.22 kg/day, and the carbon emission could be reduced by 11,569.3 kg/day. Table 2 further compares the characteristics of some efficient and inefficient WWTPs. The most efficient WWTPs produced fewer carbon emissions and removed more pollutants with less capital and labor. This also showed that the inefficient WWTPs should pay attention to the improvement of management and operation under the existing scale to achieve optimized carbon emission efficiency.

Efficiency change

Considering the consistency and availability of data, 43 plants were selected from 225 samples for ML index analysis. The results are shown in Table 3. The average ML index from 2015 to 2017 was 0.98, indicating that the carbon emission efficiency of China’s WWTPs was declining. The decline in technical efficiency was the main reason for the decrease in ML. With the development of China’s economy, wastewater treatment has developed rapidly (Zhang et al. 2019). The environmental pollution control investment and wastewater treatment capacity have increased for years. The treatment processes were basically in line with international standards (Jin et al. 2014). However, the distance from the production frontier has increased, making the technical efficiency decrease.

Influence factors

Process

The status of the primary treatment processes in the WWTPs is shown in Fig. 5. Oxidation ditch was the most widely used process by China’s WWTPs, accounting for about 30.67%. Followed by A2/O, accounting for approximately 27.11%. The third one was sequencing batch reactor–activated sludge process (SBR), accounting for 17.33%. Oxidation ditch and SBR were popular in small- and medium-sized cities because these treatment processes do not require primary settling tank or secondary sedimentation tank and use simple infrastructure construction and convenient management. Large-scale WWTPs had higher requirements for nutrient removal, and nitrogen and phosphorus could be removed by the A2/O process. Therefore, large-scale WWTPs in large cities preferred A2/O process (Jin et al. 2014).

From the perspective of carbon emissions, the results of the Kruskal–Wallis (K-W) test pointed out that the process had the statistically significant influence on the performance of the WWTPs at 5% significance level (p < 0.05). This indicated that treatment processes affected carbon emission efficiency. Among the six processes studied here, AO and activated sludge processes had higher carbon emission efficiency than A2/O, oxidation ditch, and SBR. This was because these processes had the least carbon emissions including direct and indirect carbon emissions. For example, Bao et al. (2015) studied the direct emissions of CO2 from four different treatment processes and the order of emission was SBR (0.347 kg CO2/m3 wastewater) > oxidation ditch (0.344 kg CO2/m3 wastewater) > A2/O (0.176 kg CO2/m3 wastewater) > A/O (0.173 kg CO2/m3 wastewater). For treating 1 m3 wastewater, A2/O had the highest energy use at 0.39 kWh/m3, followed by CASS (0.37 kWh/m3) and A/O (0.28 kWh/m3) processes (Li et al. 2021). It is worth noting that the uneven distribution of the samples may have an impact on the analysis results. Therefore, AO was the best choice when only considering carbon emissions. When the requirements of COD and nutrient removal are considered, A2/O was the more suitable choice.

Scale

In China, WWTPs were divided into small (< 104 t/day), medium (104 t/day ≤ scale < 105 t/day), and large sizes (≥ 105 t/day) (MEE 2015). As shown in Fig. 6, the K-H test showed significant differences in different sizes (p < 0.01). The greater the daily processing capacity, the higher the average efficiency. The average efficiency of large WWTPs was the highest, reaching 0.69, which was significantly higher than the other two types of WWTPs. The result was consistent with previous research (Molinos-Senante et al. 2016; Zeng et al. 2017). In fact, research had already confirmed the economies of scale in WWTPs (Hernández-Sancho et al. 2011a, b; He et al. 2019). Small WWTPs tended to have higher treatment costs, higher unit energy consumption, and difficult management. Therefore, as the core design parameter of WWTPs, scale should be carefully considered in the design or remold for minimizing carbon emissions.

Discharge standard

Standard is also considered to be one of the critical parameters in the design and operation of WWTPs (Borzooei et al. 2020). The Chinese government has been working on tightening wastewater treatment standards for the past decades to control water pollution. Usually, WWTPs were classified into IA, IB, II, and III by the widely used national wastewater standard (GB 18918–2002), of which IA was the highest standard and the III was the lowest standard. The statistical results indicated that about 65.78% of WWTPs implemented IA, 28.44% of WWTPs implemented IB, and only 1.33% of WWTPs implemented standard II.

The results of the K-W test showed that the carbon emission efficiency of WWTPs was also significantly correlated with the emission standards (p < 0.01). The carbon emission efficiency of standard IA was higher than that of standard IB. IA achieved more pollutant removal and its carbon emission efficiency was better than IB (Table 4). There was some debate about whether to raise standards (Wang et al. 2015; Smith et al. 2019). This was because stringent standards reduce water pollution, at the cost of increased resource consumption and carbon emissions (Su et al. 2022). This was confirmed here as well. For instance, the carbon emission of IA was higher than that of IB (Table 4). According to the National Development and Reform Commission (NDRC)’s 14th Five-Year Plan for urban wastewater treatment and resource utilization, cities in the Yangtze River delta, the Greater Bay Area, Beijing-Tianjin-Hebei urban agglomeration, and so on can impose a stricter standard for wastewater discharge. About 45.33% of the WWTPs in the study needed to upgrade their standards. However, this study showed that the upgrade of standards did not mean a regression of the efficiency of WWTPs.

Wastewater treatment fees

Wastewater treatment fees are one of the essential tools to control the discharge of water pollution in China (Liu et al. 2021). In China, it is stipulated that the wastewater treatment fees standard should compensate the operating costs of wastewater treatment and sludge disposal to make reasonable profits (NDRC 2015). However, the results indicated that there was no significant difference between the carbon emission efficiency and the wastewater treatment fees (p = 0.263 > 0.05). This showed that wastewater treatment fees did not include carbon, which may not take effect. Some governments have realized that the wastewater treatment industry may play an essential role in reducing carbon emissions. For example, the Canadian water industry may have experienced a carbon cost levy (MacLeod and Filion 2012). The fact that the WWTPs evaluated in the study were inefficient in terms of carbon emissions showed that China’s water sector has great potential for implementing measures to reduce carbon emissions. Incorporating the cost of carbon emissions into wastewater charges is considered one of the tools.

Data limitation and uncertainty analysis

Although the study used the MinDS model to evaluate the carbon emission efficiency of Chinese WWTPs, this study has certain limitations. The samples selected in the study are consistent with the full sample distribution of WWTPs in China in terms of process distribution, but the geographical distribution may be less representative. This is mainly reflected in the unbalanced geographical distribution of the sample (Fig. 2). Second, this paper introduced the most widely used emission factor method (the IPCC Guidelines) into estimate GHG emissions, but this may result in uncertainty from the lack of sufficient site-specific operational data (Xi et al. 2021). Improving the quality and quantity of data will allow better characterization of uncertainty in the future.

Conclusions

With the requirement of sustainable development, it is necessary to evaluate the carbon emission efficiency of WWTPs. In this study, we applied the MinDS model to evaluate the carbon emission efficiency of Chinese WWTPs. The results showed that only 10 of the 225 WWTPs had high efficiency, with the average efficiency value of 0.59. The dynamic analysis from 2015 to 2017 found that the carbon emission efficiency of WWTPs had decreased, and technical efficiency change was critical to the efficiency decrease. Carbon emission reduction was comprehensive and requires attention from various aspects such as the economy and the environment. In the analysis of identifying potential factors, it was found that the treatment scale affects the carbon emission efficiency of WWTPs. The larger the design’s daily processing capacity, the higher the average efficiency. In addition, different processes and emission discharges also affected the carbon emission efficiency of WWTPs.

Based on the above findings, we proposed the following recommendations: (i) Narrow the difference in carbon emission efficiency between different WWTPs. WWTP managers should also strengthen the plant self-inspection, such as reasonable investment of capital and labor, etc. (ii) With the strengthening of carbon emission reduction, carbon emission cost policy can be introduced into the low carbon policy system in the future.

Data availability

The data that support the findings of this study are available from “the Urban Drainage Statistics Yearbook (2016–2018).”

References

Ahn JH, Kim S, Park H, Rahm B, Pagilla K, Chandran K (2010) N2O Emissions from activated sludge processes, 2008–2009: Results of a national monitoring survey in the United States. Environ Sci Technol 44:4505–4511. https://doi.org/10.1021/es903845y

Aparicio J, Ruiz JL, Sirvent I (2007) Closest targets and minimum distance to the Pareto-efficient frontier in DEA. J Prod Anal 28:209–218

Banerjee S (2022) Theoretical design for ascertaining sustainability of energy systems with special reference to the competing renewable energy schemes. Resour, Environ Sustain 7:100048. https://doi.org/10.1016/j.resenv.2022.100048

Bao Z, Sun S, Sun D (2016) Assessment of greenhouse gas emission from A/O and SBR wastewater treatment plants in Beijing, China. Int Biodeterior Biodegradation 108:108–114. https://doi.org/10.1016/j.ibiod.2015.11.028

Bao Z, Sun S, Sun D (2015) Characteristics of direct CO2 emissions in four full-scale wastewater treatment plants. null 54:1070–1079. https://doi.org/10.1080/19443994.2014.940389

Bassin JP, Castro FD, Valério RR, Santiago EP, Lemos FR, Bassin ID (2021) Chapter 16 - The impact of wastewater treatment plants on global climate change, In: Thokchom B, Qiu P, Singh P, Iyer PK (Eds.), Water Conservation in the Era of Global Climate Change. Elsevier, pp. 367–410. https://doi.org/10.1016/B978-0-12-820200-5.00001-4

Borzooei S, Campo G, Cerutti A, Meucci L, Panepinto D, Ravina M, Riggio V, Ruffino B, Scibilia G, Zanetti M (2020) Feasibility analysis for reduction of carbon footprint in a wastewater treatment plant. J Clean Prod 271:122526. https://doi.org/10.1016/j.jclepro.2020.122526

Bozkurt H, van Loosdrecht MCM, Gernaey KV, Sin G (2016) Optimal WWTP process selection for treatment of domestic wastewater – a realistic full-scale retrofitting study. Chem Eng J 286:447–458. https://doi.org/10.1016/j.cej.2015.10.088

Castellet-Viciano L, Hernández-Chover V, Hernández-Sancho F (2018) Modelling the energy costs of the wastewater treatment process: the influence of the aging factor. Sci Total Environ 625:363–372. https://doi.org/10.1016/j.scitotenv.2017.12.304

Chang X, Li Y, Zhao Y, Liu W, Wu J (2017) Effects of carbon permits allocation methods on remanufacturing production decisions. J Clean Prod 152:281–294. https://doi.org/10.1016/j.jclepro.2017.02.175

Chen Z, He Q, Cai R, Luo H, Luo N, Song C, Cheng H (2022) The development and comprehensive application of mathematical simulation in sewage treatment system under the trend of carbon neutralization (in Chinese). China Environ Sci. https://doi.org/10.19674/j.cnki.issn1000-6923.20220208.003

Cheng G (2014) Data envelopment analysis: methods and MaxDEA software, 1st edn. Intellectual Property Publishing House, Beijing

China Urban Water Association (2018) Urban drainage statistics yearbook. China Urban Water Association, Beijing

Chung YH, Färe R, Grosskopf S (1997) Productivity and undesirable outputs: a directional distance function approach. J Environ Manag 51:229–240. https://doi.org/10.1006/jema.1997.0146

Dong X, Zhang X, Zeng S (2017) Measuring and explaining eco-efficiencies of wastewater treatment plants in China: an uncertainty analysis perspective. Water Res 112:195–207. https://doi.org/10.1016/j.watres.2017.01.026

Fang K, Zhang Q, Song J, Yu C, Zhang H, Liu H (2021) How can national ETS affect carbon emissions and abatement costs? Evidence from the dual goals proposed by China’s NDCs. Resour, Conserv Recycl 171:105638. https://doi.org/10.1016/j.resconrec.2021.105638

Gémar G, Gómez T, Molinos-Senante M, Caballero R, Sala-Garrido R (2018) Assessing changes in eco-productivity of wastewater treatment plants: the role of costs, pollutant removal efficiency, and greenhouse gas emissions. Environ Impact Assess Rev 69:24–31. https://doi.org/10.1016/j.eiar.2017.11.007

Gómez T, Gémar G, Molinos-Senante M, Sala-Garrido R, Caballero R (2017) Assessing the efficiency of wastewater treatment plants: a double-bootstrap approach. J Clean Prod 164:315–324. https://doi.org/10.1016/j.jclepro.2017.06.198

Greenfield PF, Batstone DJ (2005) Anaerobic digestion: impact of future greenhouse gases mitigation policies on methane generation and usage. Water Sci Technol 52:39–47. https://doi.org/10.2166/wst.2005.0496

Guerrini A, Romano G, Leardini C, Martini M (2015) Measuring the efficiency of wastewater services through data envelopment analysis. Water Sci Technol 71:1845–1851. https://doi.org/10.2166/wst.2015.169

He Y, Zhu Y, Chen J, Huang M, Wang P, Wang G, Zou W, Zhou G (2019) Assessment of energy consumption of municipal wastewater treatment plants in China. J Clean Prod 228:399–404. https://doi.org/10.1016/j.jclepro.2019.04.320

Hernández-Sancho F, Molinos-Senante M, Sala-Garrido R (2011a) Techno-economical efficiency and productivity change of wastewater treatment plants: the role of internal and external factors. J Environ Monit 13:3448–3459. https://doi.org/10.1039/C1EM10388A

Hernández-Sancho F, Molinos-Senante M, Sala-Garrido R (2011b) Energy efficiency in Spanish wastewater treatment plants: a non-radial DEA approach. Sci Total Environ 409:2693–2699. https://doi.org/10.1016/j.scitotenv.2011.04.018

Hu W, Guo Y, Tian J, Chen L (2019) Eco-efficiency of centralized wastewater treatment plants in industrial parks: a slack-based data envelopment analysis. Resour Conserv Recycl 141:176–186. https://doi.org/10.1016/j.resconrec.2018.10.020

IPCC (2006) 2006 IPCC Guidelines for National Greenhouse Gas Inventories. Intergovernmental Panel on Climate Change, Japan. https://www.ipcc.ch/report/2006-ipcc-guidelines-for-national-greenhouse-gas-inventories/. Accessed 18 Feb 2022

IPCC (2015) AR5 climate change 2014: mitigation of climate change. Cambridge University Press, New York. https://www.ipcc.ch/report/ar5/wg3/. Accessed 18 Feb 2022

IPCC (2019) 2019 Refinement to the 2006 IPCC Guidelines for national greenhouse gas inventories, Chapter 6-Wastewater Treatment and Discharge. Intergovernmental Panel on Climate Change, Japan

Jiang H, Hua M, Zhang J, Cheng P, Ye Z, Huang M, Jin Q (2020) Sustainability efficiency assessment of wastewater treatment plants in China: a data envelopment analysis based on cluster benchmarking. J Clean Prod 244:118729. https://doi.org/10.1016/j.jclepro.2019.118729

Jin L, Zhang G, Tian H (2014) Current state of sewage treatment in China. Water Res 66:85–98. https://doi.org/10.1016/j.watres.2014.08.014

Koondhar MA, Tan Z, Alam GM, Khan ZA, Wang L, Kong R (2021) Bioenergy consumption, carbon emissions, and agricultural bioeconomic growth: a systematic approach to carbon neutrality in China. J Environ Manag 296:113242. https://doi.org/10.1016/j.jenvman.2021.113242

Larsen TA (2015) CO2-neutral wastewater treatment plants or robust, climate-friendly wastewater management? A systems perspective. Water Res 87:513–521. https://doi.org/10.1016/j.watres.2015.06.006

Li J, Cheng Z (2020) Study on total-factor carbon emission efficiency of China’s manufacturing industry when considering technology heterogeneity. J Clean Prod 260:121021. https://doi.org/10.1016/j.jclepro.2020.121021

Li Y, Xu Y, Fu Z, Li W, Zheng L, Li M (2021) Assessment of energy use and environmental impacts of wastewater treatment plants in the entire life cycle: a system meta-analysis. Enviro Re 198:110458. https://doi.org/10.1016/j.envres.2020.110458

Liu Z, Guan D, Wei W, Davis SJ, Ciais P, Bai J, Peng S, Zhang Q, Hubacek K, Marland G, Andres RJ, Crawford-Brown D, Lin J, Zhao H, Hong C, Boden TA, Feng K, Peters GP, Xi F, Liu J, Li Y, Zhao Y, Zeng N, He K (2015) Reduced carbon emission estimates from fossil fuel combustion and cement production in China. Nature 524:335–338. https://doi.org/10.1038/nature14677

Liu K, Li T, Ma Z (2021) Research on policy analysis and reform of the expense of sewage processing in China——based on the perspective of the polluter-pay principle (in Chinese). Prices Monthly 1–9. https://doi.org/10.14076/j.issn.1006-2025.2021.12.01

Lu C, Li W, Gao S (2020) Driving determinants and prospective prediction simulations on carbon emissions peak for China’s heavy chemical industry. J Clean Prod 251:119642. https://doi.org/10.1016/j.jclepro.2019.119642

Ma XY, Wang Y, Dong K, Wang XC, Zheng K, Hao L, Ngo HH (2019) The treatability of trace organic pollutants in WWTP effluent and associated biotoxicity reduction by advanced treatment processes for effluent quality improvement. Water Res 159:423–433. https://doi.org/10.1016/j.watres.2019.05.011

MacLeod SP, Filion YR (2012) Issues and implications of carbon-abatement discounting and pricing for drinking water system design in Canada. Water Resour Manag 26:43–61. https://doi.org/10.1007/s11269-011-9900-4

Mai Y, Xiao W, Shi L, Ma Z (2015) Evaluation of operating efficiencies of municipal wastewater treatment plants in China (in Chinese). Res Environ Sci 28:1789–1796

Mamais D, Noutsopoulos C, Dimopoulou A, Stasinakis A, Lekkas T (2015) Wastewater treatment process impact on energy savings and greenhouse gas emissions. Water Sci Technol 71:303–308. https://doi.org/10.2166/wst.2014.521.

MEE (2015) Compilation instructions for “Emission Standard of Pollutants for Urban Sewage Treatment Plants” (Draft for Soliciting Opinions). MEE. https://www.mee.gov.cn/gkml/hbb/bgth/201511/t20151111_316837.htm. Accessed 18 Feb 2022

Ministry of Housing and Urban-Rural Development of PRC (2018) China urban and rural construction statistical yearbook. China Statistics Press, Beijing. https://www.mohurd.gov.cn/gongkai/fdzdgknr/sjfb/tjxx/jstjnj/index.html. Accessed 18 Feb 2022

Ministry of Housing and Urban-Rural Development of PRC (2021) Urban wastewater treatment and resource utilization development Plan in the 14th Five-Year Plan, MOHURD. https://www.ndrc.gov.cn/xxgk/zcfb/ghwb/202106/t20210611_1283168_ext.html. Accessed 26 May 2022

Molinos-Senante M, Gémar G, Gómez T, Caballero R, Sala-Garrido R (2016) Eco-efficiency assessment of wastewater treatment plants using a weighted Russell directional distance model. J Clean Prod 137:1066–1075. https://doi.org/10.1016/j.jclepro.2016.07.057

NDRC (2015) Notice on the formulation and adjustment of wastewater treatment charging standards and other related issues, NDRC. http://www.gov.cn/zhuanti/2016-05/22/content_5075616.htm. Accessed 30 May 2022

Nguyen TKL, Ngo HH, Guo W, Chang SW, Nguyen DD, Nghiem LD, Liu Y, Ni B, Hai FI (2019) Insight into greenhouse gases emissions from the two popular treatment technologies in municipal wastewater treatment processes. Sci Total Environ 671:1302–1313. https://doi.org/10.1016/j.scitotenv.2019.03.386

Pan D, Hong W, Kong F (2020) Efficiency evaluation of urban wastewater treatment: evidence from 113 cities in the Yangtze River Economic Belt of China. J Environ Manag 270:110940. https://doi.org/10.1016/j.jenvman.2020.110940

Polruang S, Sirivithayapakorn S, Prateep Na Talang R (2018) A comparative life cycle assessment of municipal wastewater treatment plants in Thailand under variable power schemes and effluent management programs. J Clean Prod 172:635–648. https://doi.org/10.1016/j.jclepro.2017.10.183

Sala-Garrido R, Molinos-Senante M, Hernández-Sancho F (2011) Comparing the efficiency of wastewater treatment technologies through a DEA metafrontier model. Chem Eng J 173:766–772. https://doi.org/10.1016/j.cej.2011.08.047

Shen Y, Linville JL, Urgun-Demirtas M, Mintz MM, Snyder SW (2015) An overview of biogas production and utilization at full-scale wastewater treatment plants (WWTPs) in the United States: challenges and opportunities towards energy-neutral WWTPs. Renew Sustain Energy Rev 50:346–362. https://doi.org/10.1016/j.rser.2015.04.129

Shin J, Choi S, Park CM, Wang J, Kim YM (2022) Reduction of antibiotic resistome in influent of a wastewater treatment plant (WWTP) via a chemically enhanced primary treatment (CEPT) process. Chemosphere 286:131569. https://doi.org/10.1016/j.chemosphere.2021.131569

Smith K, Guo S, Zhu Q, Dong X, Liu S (2019) An evaluation of the environmental benefit and energy footprint of China’s stricter wastewater standards: can benefit be increased? J Clean Prod 219:723–733. https://doi.org/10.1016/j.jclepro.2019.01.204

Su H, Yi H, Gu W, Wang Q, Liu B, Zhang B (2022) Cost of raising discharge standards: a plant-by-plant assessment from wastewater sector in China. J Environ Manag 308:114642. https://doi.org/10.1016/j.jenvman.2022.114642

Tenaw D, Hawitibo AL (2021) Carbon decoupling and economic growth in Africa: evidence from production and consumption-based carbon emissions. Resour, Environ Sustain 6:100040. https://doi.org/10.1016/j.resenv.2021.100040

The State Council Information Office of PRC (2020) Energy in China’s new era. The State Council Information Office of the People’s Republic of China

Tone K (2001) A slacks-based measure of efficiency in data envelopment analysis. Eur J Oper Res 130:498–509. https://doi.org/10.1016/S0377-2217(99)00407-5

Torregrossa D, Marvuglia A, Leopold U (2018) A novel methodology based on LCA + DEA to detect eco-efficiency shifts in wastewater treatment plants. Ecol Ind 94:7–15. https://doi.org/10.1016/j.ecolind.2018.06.031

U.S.EPA (1997) Estimates of global greenhouse gas emissions from industrial and domestic wastewater treatment (No. EPA-600/R-97–091). Office of Policy, Planning, and Evaluation, U.S. Environmental Protection Agency, Washington, DC

U.S.EPA (2019) Inventory of U.S. greenhouse gas emissions and sinks: 1990–2017, USEPA. https://www.epa.gov/ghgemissions/inventory-us-greenhouse-gas-emissions-and-sinks-1990-2017. Accessed 18 Feb 2022

Wang X-H, Wang X, Huppes G, Heijungs R, Ren N-Q (2015) Environmental implications of increasingly stringent sewage discharge standards in municipal wastewater treatment plants: case study of a cool area of China. J Clean Prod 94:278–283. https://doi.org/10.1016/j.jclepro.2015.02.007

Wang S, Chu C, Chen G, Peng Z, Li F (2016) Efficiency and reduction cost of carbon emissions in China: a non-radial directional distance function method. J Clean Prod 113:624–634. https://doi.org/10.1016/j.jclepro.2015.11.079

Werkneh AA, Gebru SB (2023) Development of ecological sanitation approaches for integrated recovery of biogas, nutrients and clean water from domestic wastewater. Resour, Environ Sustain 11:100095. https://doi.org/10.1016/j.resenv.2022.100095

Wu G, Hong J, Tian Z, Zeng Z, Sun C (2021) Assessing the total factor performance of wastewater treatment in China: a city-level analysis. Sci Total Environ 758:143324. https://doi.org/10.1016/j.scitotenv.2020.143324

Xi J, Gong H, Zhang Y, Dai X, Chen L (2021) The evaluation of GHG emissions from Shanghai municipal wastewater treatment plants based on IPCC and operational data integrated methods (ODIM). Sci Total Environ 797:148967. https://doi.org/10.1016/j.scitotenv.2021.148967

Xie T, Wang C (2012) Greenhouse gas emissions from wastewater treatment plants (in Chinese). J Tsinghua Univ (science and Technology) 52:473–477

Yang J, Chen B (2021) Energy efficiency evaluation of wastewater treatment plants (WWTPs) based on data envelopment analysis. Appl Energy 289:116680. https://doi.org/10.1016/j.apenergy.2021.116680

Zaidi SAH, Hussain M, Uz Zaman Q (2021) Dynamic linkages between financial inclusion and carbon emissions: evidence from selected OECD countries. Resour, Environ Sustain 4:100022. https://doi.org/10.1016/j.resenv.2021.100022

Zeng S, Chen X, Dong X, Liu Y (2017) Efficiency assessment of urban wastewater treatment plants in China: considering greenhouse gas emissions. Resour Conserv Recycl 120:157–165. https://doi.org/10.1016/j.resconrec.2016.12.005

Zhang Q, Nakatani J, Wang T, Chai C, Moriguchi Y (2017) Hidden greenhouse gas emissions for water utilities in China’s cities. J Clean Prod 162:665–677. https://doi.org/10.1016/j.jclepro.2017.06.042

Zhang Q, Liu S, Wang T, Dai X, Baninla Y, Nakatani J, Moriguchi Y (2019) Urbanization impacts on greenhouse gas (GHG) emissions of the water infrastructure in China: trade-offs among sustainable development goals (SDGs). J Clean Prod 232:474–486. https://doi.org/10.1016/j.jclepro.2019.05.333

Zhao Y, Cao Y, Shi X, Li H, Shi Q, Zhang Z (2020) How China’s electricity generation sector can achieve its carbon intensity reduction targets? Sci Total Environ 706:135689. https://doi.org/10.1016/j.scitotenv.2019.135689

Zhu R, Zhao R, Sun J, Xiao L, Jiao S, Chuai X, Zhang L, Yang Q (2021) Temporospatial pattern of carbon emission efficiency of China’s energy-intensive industries and its policy implications. J Clean Prod 286:125507. https://doi.org/10.1016/j.jclepro.2020.125507

Funding

This work has been supported by the Outstanding Innovative Talents Cultivation Funded Programs 2021 of Renmin University of China and the National Natural Science Foundation of China (52070192, 51778618).

Author information

Authors and Affiliations

Contributions

Huixin Chen: drafted the manuscript and formal analysis. Yunong Zheng: data curation and investigation. Kai Zhou: formal analysis. Rong Cheng: formal analysis and funding acquisition. Xiang Zheng: formal analysis and funding acquisition. Zhong Ma: contributed to the revision of the manuscript. Lei Shi: methodology and formal analysis. All authors contributed to the interpretation of the results and approved the final version. Special thanks also go to Dr. Zhenxing Zhang (University of Illinois at Urbana-Champaign) for his linguistic assistance during the preparation of this manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: V.V.S.S. Sarma

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, H., Zheng, Y., Zhou, K. et al. Carbon emission efficiency evaluation of wastewater treatment plants: evidence from China. Environ Sci Pollut Res 30, 76606–76616 (2023). https://doi.org/10.1007/s11356-023-27685-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-27685-9