Abstract

This study underlines a latest approach of preparing nitrogen carbon nanoparticles fused on zinc oxide nanoparticle nanocomposite (N-CNPs/ZnONP nanocomposite) for the uptake of copper ions (Cu2+) from wastewater using a sol gel method. The metal loaded adsorbent was then applied in the latent fingerprint application. N-CNPs/ZnONP nanocomposite proved to be a good sorbent for the optimal adsorption of Cu2+ at pH 8 and 1.0 g/L dosage. Langmuir isotherm best fitted the process with the maximum adsorption capacity of 285.71 mg/g that was superior to most values reported in other studies for the removal of Cu2+. At 25 °C, the adsorption was spontaneous and endothermic. Furthermore, Cu2+-N-CNPs/ZnONP nanocomposite revealed to be sensitive and selective for latent fingerprint (LFP) identification on a variety of porous surfaces. As a result, it is an excellent identifying chemical for latent fingerprint recognition in forensic science.

Graphical Abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Heavy metals are pollutants that have a harmful effect on the environment when they are in high concentration. In developed and developing countries, where industries such as electroplating, tanning, electronics, batteries, manures, and defoliants are expanding, wastewater containing heavy cations is usually discarded into the environment. When released improperly, these ions pose a threat to both the surroundings and human health (Briffa et al. 2020). Copper is counted among these metals that is usually observed in wastewater (Benzaoui et al. 2018; Izydorczyk et al. 2021). This metal is widely distributed in the environment owing to its naturally occurring and primarily human-caused emission. When consumed in water at a dosage of 0.8 mg/L, it can cause acrodynia in newborns. Copper can kill all fish and marine plants if it is discharged into the water (Royer and Sharman 2022; Malhotra et al. 2020). The Environmental Protection Agency (EPA) sets recommended levels for metals and the allowed amount of Cu2+ in water consumption is 1 mg/L (Benzaoui et al. 2018). A number of treatment procedures have been proposed and used to remove heavy metals from aqueous solutions, including solvent extraction, ion exchange, and precipitation (Renu et al. 2017; Zamora-Ledezma et al. 2021; Chai et al. 2021). These methods produce pollutants in addition to being expensive. Sewage containing metals has additional issues (Babbitt 2022). One of the simplest and most economical treatment methods is adsorption, although some adsorbents that are utilized might be very expensive. As a result, effective and affordable materials are required for usage as appropriate adsorbents.

Pineapple is the second largest produced tropical fruit worldwide with the Johor-Sarawak-Pineapple (longer and broader leaves) and the Morris (shorter and narrower leaves), (Prado and Spinacé 2019). In South Africa, pineapple is mostly produced in the coastal areas namely Eastern Cape, Kwazulu Natal, and the Northern Cape (South Africa. National Department of Agriculture. Directorate Communication. and Institute for Tropical and Subtropical Crops (South Africa) 2000). Pineapples have presented some health benefits including digestion facilitation and cancer risk limitation and possess illness fighting-antioxidant (South Africa. National Department of Agriculture. Directorate Communication. and Institute for Tropical and Subtropical Crops (South Africa) 2000). However, the waste produced from pineapples and the leaves when discharged to dumping ground cause the formation of methane gas which contributes to the greenhouse effect and is therefore toxic to human health.

Recently, carbon-based materials coated on metal oxides (CBMs-MO) including carbon dots coated on aluminum oxide nanofiber nanocomposites (CDs/Al2O3) (Fouda-Mbanga et al. 2020), nitrogen carbon nanoparticle coated on zinc oxide nanoparticles (N-CNPs/ZnONPs) (Prabakaran and Pillay 2020), and graphene oxide-tungsten oxide nanocomposite (Umejuru et al. 2021) have been significantly applied for the removal of heavy metals from wastewater. CBMs-MO have demonstrated the aptitude to strengthen the adsorption capacity owing to their immense surface area and availability of binding sites (Xu et al. 2018). However, several of these studies have remained only at the level of heavy metal removal and the fate of the metal-loaded adsorbent is usually overlooked and the metal-loaded adsorbent when discharged inappropriately becomes a pollutant which constitutes a secondary pollution.

Latent fingerprint (LFP) could be an application amongst others to solve the issue of secondary pollution. LFP detection research is a distinctive area of forensic science since it recognizes substances that aid in favorably identifying a criminal. The recognition of concise and unnoticeable latent fingerprint images is thus critical in the investigation of crimes. Various techniques have been applied in the development of LFP application among including powder dusting method (PDM). The powder dusting method has demonstrated to be very effective because it is inexpensive and facile to conduct. Additionally, PDM provides concise ridge trends that are acquired, and contrast between fingerprint sweat and the background substrate is increased (Prabakaran and Pillay 2020). However, the drawbacks of the PDM are low image resolution, less sensitivity, and background. On the other hand, metal-ion-loaded powder adsorbent has shown to be more efficient as LFP markers on diverse surfaces (porous and non-porous) due to the electrostatic and connection between the ridges and the powder (Prabakaran and Pillay 2021).

In this work, endeavors have been made to tackle this secondary pollution issue through latent fingerprint application. The aim of this study was to prepare novel zinc oxide nanoparticle (ZnONPs)–coated carbon nanoparticles (CNPs) from pineapple leaf powder (PLP) for the removal of Cu2+ from wastewater and the reuse of the metal loaded adsorbent in latent fingerprint (LFP) application.

Materials and methods

Materials

Pineapple leaves were acquired from Summerpride Foods (Pty) Ltd in East London, Eastern Cape, South Africa. ZnC4H10O6, polyvidone (C6H9NO)n, CuH2N2O7, CH4N2O, PbN2O6, CdH8N2O10, and NiH12O12N2 were are procured from Sigma-Aldrich (USA), and NaOH, HCl (hydrochloric acid), and ethanol were secured from Merck (USA). All the above chemicals were used without any further processing. Deionized water (DI) was applied in all synthesis.

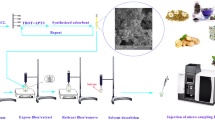

Synthesis of N-CNPs from PLP and CNPs/ZnONP nanocomposite

After being reduced into chunks, pineapple leaves (PL) were washed with DI and then were exposed to air to dry. Additionally, for an additional 2 days of searing, the seared PL were placed in an oven set at 80 °C. The powdered dry PL was maintained in a covered beaker until proper use. N-CNPs was prepared using a method as previously reported in literature (Prabakaran and Pillay 2020), where 5.0 g of PLP was mixed with 2.0 g of urea in 120 mL DI. The mixture was vigorously stirred at 50 °C for 3 h to get a gel mixture that was further dried at 50 °C for another 3 h before introducing the product into a furnace to be calcinated at 450 °C for 2 h.

In attempt to develop the N-CNPs/ZnONP nanocomposite, 16 g of ZnONPs and 50 mg of N-CNPs were combined with 25 mL of DI in a beaker and swirled for 12 h on a heated magnetic stirrer. The combination was also centrifuged at 6000 rpm for 30 min, and any impurity was removed by repeatedly cleaning the solution with water and ethanol. Following centrifugation, the residue was collected, placed into a hot air oven for 12 h to dry, and a dark gray N-CNPs/ZnONP nanocomposite was obtained. The preparation of the nanocomposite mentioned above is illustrated in Scheme 1.

Characterizations

Using a Bruker Vertex 70 (PerkinElmer, USA), the Fourier transform infrared (FTIR) spectrum of CNPs and N-CNPs/ZnONP nanocomposite was examined in order to identify the functioning groups (FGs). We used a mechanical shaker to stir the solutions. X-ray diffraction (XRD) was achieved with the aid of PANalytical X’Pert Pro X-ray diffractometer (Malvern PANalytical, Malvern, UK) and Philips PW1729 diffractometer (Phillips and Company, Amsterdam, Netherlands) with working systems of Cu Kα radiation (λ = 1.5406 Å) operating at 45 kV and 40 mA. The simultaneous TGA/DSC (SDT) was conducted using SDT-Q600 (Advanced lab solution). The shape and elemental configuration of the nanomaterials N-CNPs/ZnONPs and Cu2+-N-CNPs/ZnONPs were examined with a scanning electron microscope (SEM) (TESCAN, VEGA SEM, Brno, Czech Republic). Transmission electron microscopy (TEM JEOL, JEM-2100F, Tokyo, Japan) with a controlling electron voltage of 90 kV was applied to approximate the size of nanocomposites. The synthesized N-CNPs/ZnONP nanocomposite’s surface charge was determined using the Malvern Nano zeta sizer 90 (Malvern, UK). This was accomplished by sonicating a solution containing 30 mg of N-CNPs/ZnONP nanocomposite in 50 mL of distilled water for 30 min prior to testing. Thermo Scientific China’s ICP-OES system was used to assess the molarity of the Cu2+ ions following adsorption at a flow rate of 0.5 mL per minute. An OHAUS carried out the pH tests to control the solution’s pH. Impressions of latent fingerprints (LFP) were obtained using a phone camera in the presence of regular visible light.

Adsorption studies

Using proper dilutions from the concentrated solutions, Cu2+ ion solutions were created. Fifty milliliters of 50 mg L−1 Cu2+ ion combination at pH 8.0 ± 0.2 and 50 mg of the nanocomposite was used for the uptake analysis in triplicate, which was then stirred with a mechanical shaker at 200 rpm for 120 min. By varying the beginning pH (3–10) while using 50 mg L−1 of a Cu2+ ions solution, the impact of pH was assessed (composed from deionized water and copper nitrate trihydrate). Both 0.1 M hydrochloric acid and sodium hydroxide solution were used to regulate pH.

The amount of Cu2+ adsorbed onto N-CNPs/ZnONP nanocomposite was examined making use of the below Eqs. 1, 2, and 3:

where qe denotes the sorption capacity, qt is the optimum equilibrium at time t, Ct is the molarity of Cu2+ ions at time t, V denotes the volume of the solution, m denotes the mass in grams of the N-CNPs/ZnONP nanocomposite, and Co and Ce denote, respectively, the initial and equilibrium molarities of Cu2+.

Graphs and tables illustrate mean values ± SD (error bars). The standard deviation was calculated using Eq. 4 below:

where n is the number of data points from the trial; xi is the value of exclusive data point; and x is the average data points.

Impact of coexisting ions

In the regular water system, no single ion can be detected. The significance of the accessible divalent ions on the binding site of the N-CNPs/ZnONP nanocomposite must be investigated. To achieve this, precursor salts of the various ions Pb2+, Cd2+, and Ni2+ were mixed with Cu2+ ions at different concentrations of 10, 50, 100, and 200 mg L−1 in DI.

Reusability of the N-CNPs/ZnONP nanocomposite in latent fingerprint application

Latent fingerprint application was explored utilizing powder dusting method (PDM) with Cu2+-N-CNPs/ZnONP nanocomposite identifying powder. Fingerprint volunteers initially had their hands washed and dried. The thumb impression was then used on diversified surfaces after the fingers had been applied neatly to the foreheads and noses. Afterwards, the labelling powder of Cu2+-N-CNPs/ZnONP nanocomposite spread on the fingerprint and the excess powder was wiped off with a squirrel brush. A good phone with a high-resolution camera was utilized to capture the fingerprint images under daylight conditions.

Results and discussion

XRD characterization

XRD sequences of N-CNPs and N-CNPs/ZnONP nanocomposite are displayed in Fig. 1A. The planes of (002) and (100), distinctively, are represented by 2 significant peaks of N-CNPs as demonstrated in Fig. 1A(a), which were seen at diffraction values of 24.93° and 43.34°, sequentially, and they are well aligned with the JCPDS No.: 75–1621 (Jayachandiran et al. 2018; Shanmugam et al. 2015). In Fig. 1A(b), the apexes observed at 23.14° (002) and 41.77° (100) corresponded to N-CNPs and this slight difference compared to Fig. 1A(a) could be due to the short-range stacking arrangement (Fu et al. 2013). The pinnacles with the following numbers represent zinc oxide nanoparticles: 31.67° (100), 34.14° (002), 35.93° (101), 47.37° (102), 56.58° (110), 62.63° (103), 67.79° (112), 72.46° (004), and 76.54° (202). The sequences best fitted with the JCPDS No.: 79–0207 (Jayachandiran et al. 2018; Abdessemed et al. 2019). Since the ZnO-related crests are more intense than the N-CNPs-related peaks, the apexes in the XRD sequence showed that the ZnONPs in the produced nanocomposite are extremely crystalline. In addition, diffraction peaks from the XRD study proved that the nanocomposite contained ZnO nanoparticles and N-CNPs. The crystallite size of N-CNPs/ZnONP nanocomposite was found to be 10.39 nm and was calculated using the Scherrer equation below:

where D = average size of particles, K = Scherrer’s constant (0.90), λ = radiation wavelength (1.5406 Å), β = full width at half maximum intensity (FWHM) given in radians, and θ = Braggs diffraction angle in radians.

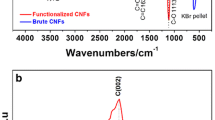

FTIR characterization

The FTIR spectrum of N-CNPs, N-CNPs/ZnONP nanocomposite, and Cu2+-N-CNPs/ZnONP nanocomposite is shown in Fig. 1B. The bands at 3426, 2953, 1630, 1404, 1092, and 685 cm−1 are ascribed to the O–H, C-H, C = O/C = N, C = C, C-O/C-N, and = C-H stretching vibration as shown in Fig. 1B (Zhang et al. 2022; Kumar et al. 2017; Wan et al. 2016). Those perceived at 619 and 612 cm−1 correlated with Zn–O band for N-CNPs/ZnONP nanocomposite and Cu2+-N-CNPs/ZnONP nanocomposite (Balogun et al. 2020). Furthermore, the slight shift noted in the two spectrum is due to adsorption of Cu2+ onto N-CNPs/ZnONP nanocomposite.

SDT characterization

SDT was explored to determine the thermal steadiness and weight loss of -OH group adsorbed on N-CNPs and N-CNPs/ZnONP nanocomposite. Figure 1C(a) illustrates the weight loss of N-CNPs versus temperature. A peak at approximately 180 °C with a weight loss of 6.92% was observed due to the elimination of water molecules, poor interaction of bonds, and volatile organic solvent. Another peak at approximately 275 °C with a weight loss of 18.15% was noted due to probably the combustion of carbon and hydroxylated groups. No further change was observed afterwards. N-CNPs/ZnONP nanocomposite showed no major peaks as seen in Fig. 1C(b). The decreasing line indicated that the reaction was exothermic, and the weight loss of 6.3% and 10.91% occurred at 200 and 300 °C, respectively (Zhang et al. 2020).

XPS characterization

XPS extensive scanning spectra of N-CNPs/ZnONP nanocomposite and Cu2+-N-CNPs/ZnONP nanocomposite were acquired to explore the adjustment of the adsorbent mainly after adsorption. Figure 2A illustrates the survey scan spectra and component configuration of N-CNPs/ZnONP nanocomposite and Cu2+ loaded on N-CNPs/ZnONPs. The spectrum of N-CNPs/ZnONP nanocomposite consists of energy bands for C 1 s (280.92 eV), N 1 s (392.97 eV), O 1 s (527.65 eV), Zn 2p1 (1041.94 eV), Zn 2p2 (1019.06 eV), Zn 3 s (139.30 eV), Zn 3p (89.18 eV), and Zn 3d (8.99 eV) (Chang et al. 2019; Xu et al. 2013). The uptake of Cu2+ ions on N-CNPs/ZnONP nanocomposite was validated by the presence of Cu 2p (934.50 eV) core level peak with the deconvolution peaks of Cu 2p1/2 (940.73 eV) and Cu 2p3/2 (931.65 eV) binding energy in the XPS scan spectra after adsorption, as demonstrated in Fig. 2A and B, respectively. Additionally, there was a satellite peak at 951. 87 eV associated probably to CuO. This revealed that the valency of Cu2+ was not affected. Figure 2C displays a C 1 s spectrum of N-CNP/ZnONP nanocomposite with double peak formation indicating better oxidation. The C–C peak of C 1 s spectrum is found at 282.84 eV. The deconvolution of the high resolution of N-CNP/ZnONP nanocomposite resulted in 4 peaks centered at 282.55, 283.31, 284.56, and 286.49 eV which respectively corresponded to the hydrocarbon, Zn–O-C, Zn-C, and CO2 groups. The presence of these oxygen functional groups facilitated the attachment of ZnO onto the N-CNPs (Chang et al. 2019). Figure 2D shows the C 1 s spectrum of Cu2+ loaded onto the adsorbent. A single peak was observed at 283.44 eV, and the deconvolution of this peak leads to two main peaks namely C–C and C-O centered at 283.31 and 285.52 eV (Sun et al. 2014; Chen et al. 2018), respectively. Moreover, the broadening of the C peak after adsorption could be related to the carboxylic group producing a complex COO-Cu(II) (Jiang et al. 2019). The disappearance of the peak observed in Fig. 2D could be due to the loss of energy during the interactions of photoelectrons and other electrons (Malvankar et al. 2020). Figure 2E and F show the deconvolution of N 1 s peak before and after Cu2+ ions onto N-CNPs/ZnONPs. The findings reveal the presence of sp2C-N, sp3C-N, and O-N peaks. The slight increase in binding energy as demonstrated in Fig. 2D confirms the presence of interaction of Cu2+ ion interaction with the adsorbent (Chang et al. 2019). Figure 3A and B display the Zn 2p spectrum of N-CNPs/ZnONP nanocomposite and Cu2+-N-CNPs/ZnONP nanocomposite. It was noticed two significant peaks in both figures corresponding to Zn 2p1/2 (1043.01 eV) and Zn 2p3/2 (1019.88 eV) for N-CNPs/ZnONP nanocomposite and Zn 2p1/2 (1042.86 eV) and Zn 2p3/2 (1019.69 eV) in Cu2+-N-CNPs/ZnONP nanocomposite. There was a slight difference in binding energy from 23.13 to 23.17 eV confirming the oxidation state of zinc to be (+ 2) in the wurtzite structure (Ahmed et al. 2018).

SEM characterization

Scanning electron spectroscopy was used to investigate the framework of N-CNPs, N-CNPs/ZnONP nanocomposite, and Cu2+-N-CNPs/ZnONP nanocomposite, depicted in Fig. 4A–F. At different amplifications of 100 and 50 μm, the surface image of N-CNPs, N-CNPs/ZnONP nanocomposite, and Cu2+-CNPs/ZnONP nanocomposite was detected and demonstrated the presence of spherical shape-like nanoparticles (Santhoshkumar et al. 2017). Furthermore, the appearance of white particles (ZnONPs) onto the black N-CNPs observed mainly in Fig. 4C–F confirmed the formation of N-CNPs/ZnONP nanocomposite. The elemental composition of N-CNPs, N-CNPs/ZnONP nanocomposite, and Cu2+-N-CNPs/ZnONP nanocomposite derived from EDAX indicated the appearance of C (68.6%) and O (23.5%) for N-CNPs (Fig. 5A); Zn (45%), O (28%), and C (26.1%) for N-CNPs/ZnONPs (Fig. 5B); and Zn (66.6%), C (16.5%), O (13.9%), and Cu (2.3%) for Cu2+-N-CNPs/ZnONP nanocomposite (Fig. 5C). Elemental mapping of Cu2+-N-CNPs/ZnONP nanocomposite as shown in Fig. 6A–E was investigated to further reinforce the presence of Cu2+ bound onto the binding site of the adsorbent after adsorption. Additionally, Fig. 6A–E demonstrate a constant disposition of C, Zn, O, and Cu elements at the surface of Cu2+-N-CNPs/ZnONP nanocomposite after uptake (Chigondo et al. 2018).

TEM characterization

The shape of N-CNPs/ZnONP nanocomposite was explored using TEM analysis. Figure 7A presents the micrograph of N-CNPs at 100 nm, and Fig. 7A and B present the micrograph of the nanocomposite. The black dot observed in Fig. 7A confirmed the existence of carbon nanoparticles. Figure 7A and B demonstrate a spherical morphology of the nanocomposite. Additionally, the presence of the combination of white particle (ZnONPs) with the black carbon nanoparticles attested to the formation of the N-CNPs/ZnONP nanocomposite.

Batch adsorption studies

Effect of pH on the removal of Cu2+ ions and pHPZC

Solution pH is a critical parameter influencing the adsorption procedure. Its impact on Cu2+ ions removal was investigated from pH 3 to 11 using 1 g/L of adsorbent mass of 50 mg/L Cu2+ ions solution. As illustrated in Fig. 8A, a slight decline of sorption was noticed from pH 3 to 4 and thereafter sorption gradually increased until it became constant. The sorption occurred over a range of pH 8 to 11 from which a percentage removal was between 99 and 99.67% with the optimum pH established at pH 8. Additionally, the adsorption capacity of the adsorbent had a similar trend as the effect of pH as shown in Fig. 8A with the maximum adsorption capacity was 25 mg/g.

The point-of-zero charge is a parameter that characterizes the surface of the adsorbent; hence, it was determined. The pH(PZC) of N-CNPs/ZnONP nanocomposite was found to be 8.86 as displayed in Fig. 8C. This information signifies that below pHPZC 8.86, N-CNPs/ZnONP nanocomposite surface is positively charged. This implies that there will be repulsion of Copper ions from the adsorbent sites due to the competition between the latter and proton H+. Above pHPZC 8.86, N-CNPs/ZnONP nanocomposite surface becomes negatively charged and sorption of copper ions becomes hence favorable.

Effect of weight adsorbent on the uptake of Cu2+

The effect of N-CNPs/ZnONP nanocomposite dose on the obliteration of Cu2+ ions at pH 8 was explored. Figure 8B demonstrates sorption was stable from 99.56 to 99.78% as the adsorbent increased from 0.05 to 0.06 g and from 99.14 to 99.53% as the adsorbent increased from 1.2 to 2.4 g/L. From 2.4 to 3.6 g/L, a considerable decline of the percentage removal of Cu2+ was observed from 99.53 to 94.48%. The significant decrease could be explained by the fact that at greater dosage, the active sites of the adsorbent overlap or become full, resulting to less available binding site for sorption (Chigondo et al. 2018). The optimum dosage for the ongoing study was therefore established at 1 g/L for all tests. The maximum adsorption capacity was found to be 49.81 mg/g and declined gradually as the dosage increased.

Adsorption isotherms

Understanding the interrelation between the adsorbate and adsorbent is necessary for the configuration and operation of an excellent sorption system. Evaluating the sorption isotherms is a common way to accomplish this. Consequently, the influence of temperature on the adsorption of Cu2+ ions onto N-CNPs/ZnONP nanocomposite was investigated at 25, 35, and 45 °C; the findings are shown in Fig. 9A–E. The increment in temperature demonstrates an increment in the binding capacity of Cu2+ ions onto the adsorbent surface, so as to strengthen the adsorption. Furthermore, an increase in concentration resulted in an increase of the equilibrium adsorption capacity as shown in Fig. 9A. The experimental data was adapted onto Langmuir, Freundlich, Temkin, and D-R isotherm models. Langmuir model (Fig. 9B) supposes monolayer coverage, and the adsorbate can be equally adsorbed on all sorption sites (Chigondo et al. 2018; Parashar et al. 2016). The Langmuir linear form is displayed in Eq. 6.

where Ce in milligrams per liter is the equilibrium concentration, qe in milligrams per gram is the equilibrium uptake amount, qm is the highest uptake amount, and b or KL is the Langmuir constant which is associated with adsorption capacity and adsorption energy. The non-dimensional factor RL was considered in order to determine whether sorption was suitable and could be approximated as given in Eq. 7. When RL < 1, the adsorption is advantageous; when RL > 1, the adsorption is not advantageous; and when RL = 0, the adsorption is irreversible. In this study, RL value was between 0 and 1 at 25 °C implying a convenient adsorption.

Freundlich isotherm (Fig. 9C) assumes multilayer coverage on the adsorbent surface and was evaluated using Eq. 8 below

where Kf is the Freundlich constant describing the uptake capacity and n is the adsorption intensity. The values of n in the range of 1 to 10 revealed a favorable adsorption.

Temkin isotherm, as presented in Fig. 9D, was taken advantage to explain how N-CNPs/ZnONP nanocomposite and Cu2+ uptake interactions differ with adsorbent surface coverage based on the free adsorption capacity. Temkin isotherm linear form was represented with Eq. 9 as presented below:

where B is the Temkin isotherm constants obtain from the slope and kT from the intercept (kJ/mol). Temkin parameters are shown in Table 1.

Dubinin-Radushkevich’s (D-R) isotherm model shown in Fig. 9E enhances the uptake process and provides as well the mean free energy through the adsorption process. The linear form of the D-R isotherm is given in Eq. 10 where lnqe was plotted against ε2:

From the above Eqs. 10 and 11, R is the gas constant, T is the temperature in Kelvin, qs is the D-R theoretical saturation capacity, ε is the Polanyi potential, and β is the activity coefficient linked to the uptake energy.

D-R parameters are depicted in Table 1. The mean free energy, E (kJ mol−1), is determined from KDR (β) and is represented as illustrated in Eq. 12:

This amount E is helpful because it gives knowledge regarding the adsorption process mechanisms. When E is between 8 and 16 kJ mol−1, the adsorption process form is chemical; however, if E < 8 kJ mol−1, the process is physically occurring. In this work, the mean uptake energy was between 3.98 and 15.33 kJ/mol which suggests that the process may be occurring chemically.

When contrasting the 4 adsorption isotherm models, the R2 values for Langmuir (R2linear = 0.938–0.995) were higher than the Freundlich (R2linear = 0.929–0.979), Temkin (R2linear = 0.885–0.963), and D-R (R2linear = 0.865–0.968). This implies that Cu2+ ions adsorption onto N-CNPs/ZnONP nanocomposite surface was homogeneous and occurred through a monolayer coverage. The maximum adsorption capacity found was 285.71 mg/g. The effectiveness of N-CNPs/ZnONPs for Cu2+ adsorption was evaluated by contrasting with other reported materials in literature as demonstrated in Table 2. The results, displayed in Table 2, show that N-CNPs/ZnONPs were very effective with a rapid uptake and higher adsorption capacity than the reported ones in literature (Zhang et al. 2022).

Adsorption kinetic studies

Adsorption kinetics is essential because it clarifies adsorption design and modeling based on water treatment strategy. Additionally, for the adsorbent to be considered for a potential practical use, fast adsorption kinetics are required. To describe well the adsorption of Cu2+ onto N-CNPs/ZnONP nanocomposite, kinetics that is pseudo-first-order, pseudo-second-order, and intraparticle diffusion were investigated using Eqs. 13, 14, and 15 respectively as shown below:

where qe and qt are the amounts of Cu2+ adsorbed onto N-CNPs/ZnONP nanocomposite at equilibrium and time t in mg g−1; k1 and k2 are the rates constant in g mg−1·min−1; and kint (mg g−1 min−1/2) and Ci (mg g−1) are the intra-particle diffusion rate constants related to the magnitude of the boundary layer thickness, respectively. Figure 10B–D show the linear curve fittings from which different parameters evaluated are demonstrated in Table 3. The R2 values obtained in second-order kinetics (R2Linear = 0.9999–1.000) were higher than the ones obtained in first-order kinetics (R2Linear = 0.4927–0.8479). The experimental and modelled qe values resulting from the second-order kinetic model corresponded well. Cu2+ ion adsorption by N-CNPs/ZnONPs thus was best fitted by the second-order kinetics model. Furthermore, it was as well observed a decline in k2 values (0.2459–0.0273) as the concentration increases. This was caused by the rapid adsorption from dilute solution, as less Cu2+ ions migrate to the adsorption sites compared to concentrated solutions (Ghosh et al. 2014; Mahmoud et al. 2013; Zhang et al. 2016). The intraparticle diffusion (ID) model was investigated to establish the presence of a rate-limiting phase. The process is said to be governed by ID if the graph of qt vs. t1/2 becomes linear. Additionally, when the graph goes through zero, it confirms that ID is the primary process affecting uptake. If it does not pass through zero, then it might not be the sole rate-controlling step. In Fig. 10D, it is shown that the linear fittings do not pass through zero confirming that the ID was not the only rate-controlling step in Cu2+ adsorption onto N-CNPs/ZnONP nanocomposite (Debnath et al. 2014).

Adsorption thermodynamics of Cu2+ by N‑CNPs/ZnONPs

Gibbs free energy, enthalpy, and entropy were determined using Eqs. 16 and 17 below:

where R and T are as described earlier; the equilibrium constant k = mqe/ce is calculated from the N-CNPs/ZnONP nanocomposite adsorbate proportion (qe) to that of the solution in equilibrium (Ce). A linear fitting is presented in Fig. 11, and the values of ∆G° and ∆H° as displayed in Table 4 were obtained using the slope and the intercept of lnk against 1/T. The positive value of the enthalpy stipulates an endothermic process during the sorption of Cu2+ by N-CNPs/ZnONPs (Liu et al. 2016). The adsorption was spontaneous as supported by the negative values of the free Gibbs energy. Furthermore, the adsorption occurred with expanding entropy as shown by the positive value, implying an increase of randomness with a surge of Cu2+ (Kanrar et al. 2016).

Investigation of kinetic viability

A normalized standard deviation ∆qe (%) was calculated to test the quantitative validity of the kinetic models applied in this investigation using Eq. 18 (Song et al. 2013):

where n is the number of data points, qe,exp. (mg/g) is the experimental value observed, qe,calc. (mg/g) is the calculated qe from the models, and the computed findings are shown in Table 3. Under all situations assessed, the results of ∆qe (%) found for the pseudo second-order model were lower than those found for the pseudo-first-order and intra-particle diffusion models (Li et al. 2016). As a result of the greater correlation coefficient and strong agreement between the experimental and computed qe values, the adsorption of Cu(II) ions onto N-CNPs/ZnONP nanocomposite adsorbent can be best represented by the pseudo-second-order kinetic model.

Effect of interfering ions and competing adsorption

It is almost impossible for an ion to exist alone in drinking water or wastewater. Usually, a number of ions along Cu2+ could be present which will therefore contend for the binding sites, hence interfering with Cu2+ adsorption (Chen et al. 2017; Almohammadi and Mirzaei 2016). The effect of co-existing ions (Cd2+, Pb2+, Ni2+) during the sorption process is illustrated in Fig. 12. The concentration of the competing ions was varied from 10 to 200 mg/L, while the concentration of Cu2+ was kept constant throughout. The outcome shows that Pb2+ had less impact on the adsorption, while Cd2+ and Ni2+ had an impact declining from 73.88 to 52.81% and 86.57 to 67.75%, respectively. The interference order was Cd2+ (2/0.95) > Ni2+ (2/0.70) > Pb2+(2/1.19). The observed trend could be evaluated around the charge per radius value (Z/R). The attraction of the ion to the adsorbent’s binding site increases with the ratio of charge to radius. This interference order is strongly associated with cation Z/R values. Pb2+ has less influence on the intake of Cu2+ owing to repulsive forces due to an electron affinity identical to Cu2+ (Fouda-Mbanga et al. 2022).

Adsorption mechanism

XPS was taken advantage of to explore the interconnection between Cu2+ and the functional groups of N-CNPs/ZnONPs. Figure 2 demonstrates the survey scan of N-CNPs/ZnONP nanocomposite before and after adsorption. Figure 3C illustrates that O 1 s spectra of N-CNPs/ZnONP nanocomposite comprise mainly of two peaks with binding energy at 529.57 eV and 529.65 eV, which corresponded to O2− and O1− of ZnO and the -OH separately (Joshi et al. 2019). Figure 3D demonstrates that after Cu2+ adsorption, O2− and O1− peaks area ratio and intensity increased in contrast to similar peaks before adsorption. This increase in peaks and binding energy of O2− and O1− attested the implication of -OH group in the adsorption process (Zhao et al. 2021). The point of zero charge as mentioned earlier is a critical factor. From Fig. 8A, it was noted that adsorption was effective at wide range pH 8–10. At pH < pHpzc, the surface charge was predominantly positively charged owing to the presence of more protons. Therefore, repelling of the adsorbent with Cu2+ ions occurred. At pH > pHpzc, the surface charge of the adsorbent was predominantly negatively charged due to the presence of hydroxyl groups and there could be uptake of Cu2+ through electrostatic binding with OH−. In summary, various functional groups including OH− and O-C = O (as explained in the C 1 s spectrum) contributed to the uptake of Cu2+ see Fig. 13.

The following reactions could explain the adsorption mechanism with the expectations that the proton in the carboxyl and hydroxyl group will be interchanged:

Reusability investigation of Cu2+‑N‑CNPs/ZnONP nanocomposite in latent fingerprint

It was necessary to investigate the reusability of metal loaded onto the adsorption to avert secondary pollution. To succeed in this task, latent fingerprint detection was conducted using distinctive impermeable surfaces such as paper foil, aluminum sheets, transparent plastic, and bottle lids as exhibited in Fig. 14. Clear fingerprint patterns were observed on the surfaces using Cu2+-N-CNPs/ZnONPs powder and better ridges were acquired using aluminum sheets. Aluminum sheet ridges were used to examine the distinctive minutiae of the fingerprint as presented in Fig. 14. In the investigation, 3 main features were identified including dot, Island, and scar. These 3 stages could be helpful in identifying a suspect.

Conclusion

A novel adsorbent of N-CNPs/ZnONP nanocomposite was synthesized from pineapple leaves and zinc oxide nanoparticles. This material was applied for the uptake of copper ions from water samples. The utmost percentage uptake efficiency for copper was 99.67 and 99.78% for pH and dosage, respectively. The adsorption process of copper was best fitted by the Langmuir isotherm with a superior adsorption capacity of 285.71 mg/g. The pseudo-second-order model fitted this uptake technique as highlighted by the high R-square values and computed qe values. The thermodynamics parameters provided evidence that the adsorption process was spontaneous and endothermic. The powder dusting approach using Cu2+-N-CNPs/ZnONP nanocomposite was utilized as a marking material for LFP identification under normal light. This recyclable nanocomposite was developed to identify fingerprints on a variety of surfaces and was established to be an efficient labelling agent for LFP sensing in forensic research. As a result, rather than being dumped into the environment as secondary waste after reaching its maximum copper loading, this material can be commercialized and supplied to law enforcement personnel for LFP detection.

Data availability

Not applicable.

References

Abdessemed A, Rasalingam S, Abdessemed S et al (2019) Impregnation of ZnO onto a vegetal activated carbon from algerian olive waste: a sustainable photocatalyst for degradation of ethyl violet dye. Int J Photoenergy 2019. https://doi.org/10.1155/2019/4714107

Ahmed G, Hanif M, Mahmood K et al (2018) Lattice defects of ZnO and hybrids with GO: characterization. EPR and Optoelectronic Properties AIP Adv 8:025218

Almohammadi S, Mirzaei M (2016) Removal of copper (II) from aqueous solutions by adsorption onto granular activated carbon in the presence of competitor ions. Adv Environ Technol 2:85–94. https://doi.org/10.22104/aet.2016.392

Babbitt H (2022) Sewerage and sewage treatment

Balogun SW, James OO, Sanusi YK, Olayinka OH (2020) Green synthesis and characterization of zinc oxide nanoparticles using bashful (Mimosa pudica), leaf extract: a precursor for organic electronics applications. SN Appl Sci 2:1–8. https://doi.org/10.1007/S42452-020-2127-3/FIGURES/10

Benzaoui T, Selatnia A, Djabali D (2018) Adsorption of copper (II) ions from aqueous solution using bottom ash of expired drugs incineration. Adsorpt Sci Technol 36:114–129. https://doi.org/10.1177/0263617416685099

Briffa J, Sinagra E, Blundell R (2020) Heavy metal pollution in the environment and their toxicological effects on humans. Heliyon 6:e04691. https://doi.org/10.1016/J.HELIYON.2020.E04691

Chai WS, Cheun JY, Kumar PS et al (2021) A review on conventional and novel materials towards heavy metal adsorption in wastewater treatment application. J Clean Prod 296:126589. https://doi.org/10.1016/J.JCLEPRO.2021.126589

Chang QQ, Cui YW, Zhang HH et al (2019) C-doped ZnO decorated with Au nanoparticles constructed from the metal-organic framework ZIF-8 for photodegradation of organic dyes. RSC Adv 9:12689–12695. https://doi.org/10.1039/C8RA09985E

Chen H, Chen Z, Zhao G et al (2018) Enhanced adsorption of U(VI) and 241Am(III) from wastewater using Ca/Al layered double hydroxide@carbon nanotube composites. J Hazard Mater 347:67–77. https://doi.org/10.1016/J.JHAZMAT.2017.12.062

Chen Q, Zhou K, Hu Y et al (2017) Effect of competing ions and causticization on the ammonia adsorption by a novel poly ligand exchanger (PLE) ammonia adsorption reagent. Water Sci Technol 75:1294–1308. https://doi.org/10.2166/WST.2016.548

Chigondo M, Paumo HK, Bhaumik M et al (2018) Rapid high adsorption performance of hydrous cerium-magnesium oxides for removal of fluoride from water. J Mol Liq 265:496–509. https://doi.org/10.1016/j.molliq.2018.06.015

Debnath S, Kitinya J, Onyango MS (2014) Removal of Congo red from aqueous solution by two variants of calcium and iron based mixed oxide nano-particle agglomerates. J Ind Eng Chem 20:2119–2129. https://doi.org/10.1016/J.JIEC.2013.09.041

Fouda-Mbanga B, Prabakaran E, Pillay K (2022) Cd2+ ion adsorption and re-use of spent adsorbent with N-doped carbon nanoparticles coated on cerium oxide nanorods nanocomposite for fingerprint detection. Chem Phys Impact 5:100083. https://doi.org/10.1016/J.CHPHI.2022.100083

Fouda-Mbanga BG, Prabakaran E, Pillay K (2020) Synthesis and characterization of CDs/Al2O3 nanofibers nanocomposite for Pb2+ ions adsorption and reuse for latent fingerprint detection. Arab J Chem 13:6762–6781. https://doi.org/10.1016/j.arabjc.2020.06.030

Fu C, Zhao G, Zhang H (2013) Evaluation and characterization of reduced graphene oxide nanosheets as anode materials for lithium-ion batteries. Int J Electrochem Sci 8:6269–6280

Ghosh A, Chakrabarti S, Biswas K, Ghosh UC (2014) Agglomerated nanoparticles of hydrous Ce(IV) + Zr(IV) mixed oxide: preparation, characterization and physicochemical aspects on fluoride adsorption. Appl Surf Sci 307:665–676. https://doi.org/10.1016/J.APSUSC.2014.04.095

Izydorczyk G, Mikula K, Skrzypczak D et al (2021) Potential environmental pollution from copper metallurgy and methods of management. Environ Res 197:111050. https://doi.org/10.1016/J.ENVRES.2021.111050

Jayachandiran J, Raja A, Arivanandhan M et al (2018) A facile synthesis of hybrid nanocomposites of reduced graphene oxide/ZnO and its surface modification characteristics for ozone sensing. J Mater Sci Mater Electron 29:3074–3086. https://doi.org/10.1007/S10854-017-8239-X/FIGURES/12

Jiang DB, Yuan S, Cai X et al (2019) Magnetic nickel chrysotile nanotubes tethered with pH-sensitive poly(methacrylic acid) brushes for Cu(II) adsorption. J Mol Liq 276:611–623. https://doi.org/10.1016/J.MOLLIQ.2018.12.048

Joshi N, da Silva LF, Shimizu FM et al (2019) UV-assisted chemiresistors made with gold-modified ZnO nanorods to detect ozone gas at room temperature. Microchim Acta 186:1–9. https://doi.org/10.1007/S00604-019-3532-4

Kanrar S, Debnath S, De P et al (2016) Preparation, characterization and evaluation of fluoride adsorption efficiency from water of iron-aluminium oxide-graphene oxide composite material. Chem Eng J 306:269–279. https://doi.org/10.1016/J.CEJ.2016.07.037

Kumar R, Oves M, Ameelbi T et al (2017) Hybrid chitosan/polyaniline-polypyrrole biomaterial for enhanced adsorption and antimicrobial activity. J Colloid Interface Sci 490:488–496. https://doi.org/10.1016/J.JCIS.2016.11.082

Li K, Cao J, Li H et al (2016) Nitrogen functionalized hierarchical microporous/mesoporous carbon with a high surface area and controllable nitrogen content for enhanced lead( ii ) adsorption. RSC Adv 6:92186–92196. https://doi.org/10.1039/C6RA19166E

Liu L, Cui Z, Ma Q et al (2016) One-step synthesis of magnetic iron–aluminum oxide/graphene oxide nanoparticles as a selective adsorbent for fluoride removal from aqueous solution. RSC Adv 6:10783–10791. https://doi.org/10.1039/C5RA23676B

Mahmoud HR, El-Molla SA, Saif M (2013) Improvement of physicochemical properties of Fe2O3/MgO nanomaterials by hydrothermal treatment for dye removal from industrial wastewater. Powder Technol 249:225–233. https://doi.org/10.1016/J.POWTEC.2013.08.021

Malhotra N, Ger TR, Uapipatanakul B et al (2020) Review of copper and copper nanoparticle toxicity in fish. Nanomaterials 10:1–28. https://doi.org/10.3390/nano10061126

Malvankar S, Doke S, Gahlaut R et al (2020) Co-doped SnO2 nanocrystals: XPS, Raman, and magnetic studies. J Electron Mater 49:1872–1880. https://doi.org/10.1007/S11664-019-07865-5

Parashar K, Ballav N, Debnath S et al (2016) Rapid and efficient removal of fluoride ions from aqueous solution using a polypyrrole coated hydrous tin oxide nanocomposite. J Colloid Interface Sci 476:103–118. https://doi.org/10.1016/j.jcis.2016.05.013

Prabakaran E, Pillay K (2020) Synthesis and characterization of fluorescent N-CDs/ZnONPs nanocomposite for latent fingerprint detection by using powder brushing method. Arab J Chem 13:3817–3835. https://doi.org/10.1016/J.ARABJC.2019.01.004

Prabakaran E, Pillay K (2021) Nanomaterials for latent fingerprint detection: a review. J Mater Res Technol 12:1856–1885. https://doi.org/10.1016/J.JMRT.2021.03.110

Prado KS, Spinacé MAS (2019) Isolation and characterization of cellulose nanocrystals from pineapple crown waste and their potential uses. Int J Biol Macromol 122:410–416. https://doi.org/10.1016/J.IJBIOMAC.2018.10.187

Renu NA, Agarwal M, Singh K (2017) Methodologies for removal of heavy metal ions from wastewater: an overview. Interdiscip Environ Rev 18:124. https://doi.org/10.1504/IER.2017.087915

Royer A, Sharman T (2022) Copper toxicity. StatPearls, Tampa

Santhoshkumar J, Kumar SV, Rajeshkumar S (2017) Synthesis of zinc oxide nanoparticles using plant leaf extract against urinary tract infection pathogen. Resour Technol 3:459–465. https://doi.org/10.1016/J.REFFIT.2017.05.001

Shanmugam M, Alsalme A, Alghamdi A, Jayavel R (2015) Enhanced photocatalytic performance of the graphene-V2O5 nanocomposite in the degradation of methylene blue dye under direct sunlight. ACS Appl Mater Interfaces 7:14905–14911. https://doi.org/10.1021/ACSAMI.5B02715/ASSET/IMAGES/MEDIUM/AM-2015-02715W_0013.GIF

Song ST, Saman N, Johari K, Mat H (2013) Removal of Hg(II) from aqueous solution by adsorption using raw and chemically modified rice straw as novel adsorbents. Ind Eng Chem Res 52:13092–13101. https://doi.org/10.1021/IE400605A/SUPPL_FILE/IE400605A_SI_001.PDF

South Africa. National Department of Agriculture. Directorate Communication., Institute for Tropical and Subtropical Crops (South Africa) (2000) Cultivating pineapples. 7

Sun WL, Xia J, Shan YC (2014) Comparison kinetics studies of Cu(II) adsorption by multi-walled carbon nanotubes in homo and heterogeneous systems: Effect of nano-SiO2. Chem Eng J 250:119–127. https://doi.org/10.1016/J.CEJ.2014.03.094

Umejuru EC, Prabakaran E, Pillay K (2021) Coal fly ash decorated with graphene oxide–tungsten oxide nanocomposite for rapid removal of Pb2+ ions and reuse of spent adsorbent for photocatalytic degradation of acetaminophen. ACS Omega 6:11155–11172. https://doi.org/10.1021/ACSOMEGA.0C04194

Wan S, He F, Wu J et al (2016) Rapid and highly selective removal of lead from water using graphene oxide-hydrated manganese oxide nanocomposites. J Hazard Mater 314:32–40. https://doi.org/10.1016/J.JHAZMAT.2016.04.014

Xu D, Fan D, Shen W (2013) Catalyst-free direct vapor-phase growth of Zn1-xCuxO micro-cross structures and their optical properties. Nanoscale Res Lett 8:1–9. https://doi.org/10.1186/1556-276X-8-46

Xu J, Cao Z, Zhang Y et al (2018) A review of functionalized carbon nanotubes and graphene for heavy metal adsorption from water: preparation, application, and mechanism. Chemosphere 195:351–364. https://doi.org/10.1016/J.CHEMOSPHERE.2017.12.061

Zamora-Ledezma C, Negrete-Bolagay D, Figueroa F et al (2021) Heavy metal water pollution: a fresh look about hazards, novel and conventional remediation methods. Environ Technol Innov 22:101504. https://doi.org/10.1016/J.ETI.2021.101504

Zhang W, Ou J, Tang M et al (2022) Physically-crosslinked activated CaCO3/polyaniline-polypyrrole-modified GO/alginate hydrogel sorbent with highly efficient removal of copper(II) from aqueous solution. Chem Eng J 431:133375. https://doi.org/10.1016/J.CEJ.2021.133375

Zhang W, Song J, He Q et al (2020) Novel pectin based composite hydrogel derived from grapefruit peel for enhanced Cu(II) removal. J Hazard Mater 384:121445. https://doi.org/10.1016/J.JHAZMAT.2019.121445

Zhang Y, Lin X, Zhou Q, Luo X (2016) Fluoride adsorption from aqueous solution by magnetic core-shell Fe3O4@alginate-La particles fabricated via electro-coextrusion. Appl Surf Sci 389:34–45. https://doi.org/10.1016/J.APSUSC.2016.07.087

Zhao P, Geng T, Zhao Y et al (2021) Removal of Cu(II) ions from aqueous solution by a magnetic multi-wall carbon nanotube adsorbent. Chem Eng J Adv 8:100184. https://doi.org/10.1016/J.CEJA.2021.100184

Acknowledgements

The authors would like to thank the Nelson Mandela University and the National Research Foundation for funding the projects as well as the Chemistry Department at Nelson Mandela University and the Chemical Sciences Department at University of Johannesburg for providing the facilities. A sincere thanks is extended to Prof. Bryan Doyle for conducting the XPS analysis.

Funding

Open access funding provided by Nelson Mandela University. Partial fundings was received from the Nelson Mandela University and University of Johannesburg for the preparation of this manuscript.

Author information

Authors and Affiliations

Contributions

All authors made substantial contributions to the conception or design of the work: Bienvenu-Gael Fouda-Mbanga for conceptualization, data acquisition, visualization, and interpretation of data; Kriveshini Pillay and Zikhona Tywabi-Ngeva for guidance and supervision; and Kriveshini Pillay and Zikhona Tywabi-Ngeva approved the version to be published and agree to be accountable for all aspects of the work in ensuring that questions related to the accuracy or integrity of any part of the work are appropriately investigated and resolved.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Tito Roberto Cadaval Jr

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fouda-Mbanga, BG., Pillay, K. & Tywabi-Ngeva, Z. Novel development of zinc oxide–coated carbon nanoparticles from pineapple leaves using sol gel method for optimal adsorption of Cu2+ and reuse in latent fingerprint application. Environ Sci Pollut Res 31, 38801–38820 (2024). https://doi.org/10.1007/s11356-023-25474-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-25474-y