Abstract

The COVID-19 pandemic forced use of face masks up to billions of masks per day globally. Though an important and necessary measure for control of the pandemic, use of masks also poses some inherent risks. One of those risks is inhalation of microplastics released from the mask materials. Since most of the mask materials are made from plastic/polymers, they always have the potential to expose the user to fragmented microplastics. To estimate the amount of inhalable microplastic exuded from masks, an experiment simulating real-life scenario of mask usage was performed. The study included collection of microplastics oozed out from the masks on to a filter paper followed by staining and fluorescence detection of the total number of microplastics using a microscope. Both used and new masks were studied. Based on the emission wavelength, the microplastics were found to be belonging to three different categories, namely blue, green and red emitting microplastics respectively. The number of microplastic particles emitted per mask over a period of usage of 8 h was about 5000 to 9000 for new masks and about 6500 to 15,000 for used masks respectively. The estimation of polymer type of plastic in the mask fabrics was also carried out using Raman and FTIR spectroscopy.

Similar content being viewed by others

Introduction

COVID-19 pandemic has spread all over the globe in the last couple of years. The coronavirus causing COVID-19 was detected and genetically sequenced at the very beginning of the pandemic. Being a very contagious virus, all the health advisories had advised to wash hands, use sanitiser, keep physical distance and wear mask to contain the spread of the disease. All over the world, wearing masks became a necessity during this time (Chu et al. 2020; Greenhalgh and Howard 2022). According to Deng et al. (2022), about 4 billion masks were used daily during the pandemic. Since nearly every person of the world was forced to wear a mask, amongst the worldwide population of 7.95 billion (Worldometers.info 2022), monthly consumption of masks reached to approximately about 129 billion masks in 2020 itself (Prata et al. 2020).

Different types of masks are used by people depending upon availability, protection level, affordability etc. The most popular and mostly used masks are surgical, N95, cotton and nonwoven masks. All these masks are commercially available and commonly used. Amongst all the types of masks, surgical and cotton masks are the most popular. Wearing of the masks has its benefits, but it has been observed that prolonged use of masks can also have some harmful health effects. One of the adverse effects of mask usage is exposure to microplastics. Because nearly all types of masks use some kind of plastic material, the use of masks could potentially result in inhalation of microplastic that is released from the fabric/material of the masks. The material of surgical and N95 masks is fabricated from synthetic or natural polymers or their composites, which are mostly polypropylene (PP), polyethylene (PE), glass papers and woollen felt (Chellamani et al. 2013; Neupane and Giri 2020). The middle layer of surgical masks is made from melt-blown fabric, while the N95 respirators contain five PP layers of which the three middle layers are made of melt-blown fabric (Li et al. 2021). Polypropylene is the most commonly used polymer in manufacturing of the masks. For obtaining smaller and denser filter material for better efficiency, the filter layer and external layers are fabricated using nonwoven melt-blown polypropylene and spun-bond polypropylene, respectively (Deng et al. 2022). These layers are delicate enough to get degraded over the time of use and thus pose the user a risk of inhaling broken microplastics.

Why microplastics study is important?

Microplastics are the most recent emerging pollutants of concern due to their expected potential of causing health hazard (Prata 2018). Though no direct health effect of microplastic is known yet, the most important concern due to microplastics is owed to their ability to adsorb various organic pollutants and toxic metals (Wang et al. 2021), which are defined as priority pollutants in the Stockholm and Basel Convention (Gallo et al. 2018). Microplastics are spread in the environment all over the world (Rocha-Santos and Duarte, 2015). The term microplastics was first coined in 2004 to describe small-sized particles of plastic generated due to breaking or weathering of plastic articles (Thompson et al. 2004). The material plastic was firstly fabricated from synthetic polymers in the early nineteenth century (Andrady and Neal 2009). Due to its useful properties, plastic production increased drastically from 1.5 million tonnes in 1950 to about 368 million tonnes in 2019 (Verla et al. 2019; PlasticEurope 2018).

Plastics are polymerized organic compounds extracted from oil or gas (Cole et al. 2013). According to the size of the plastics, they can be categorized in five groups, namely, megaplastics (> 1 m), macroplastics (< 1 m), mescoplastics (< 2.5 cm), microplastics (MPs) (< 5 mm) and nanoplastics (NPs) (< 1 μm) (Chatterjee and Sharma 2019). MPs and NPs are ubiquitous in the environment and are found in the air and ocean, and on land all over the globe (Horton and Clark 2018). MPs are important in pollution point of view since they are persistent and pose a potential threat to all living beings as well as to the environment (Horton and Clark 2018).

Some studies have reported harmful effects of MPs on marine organisms, which also implies that MPs generated from use or disposal of the huge number of masks in the COVID-19 pandemic are a potential ecological risk (eSilva et al. 2016; Welden and Cowie 2016; Gray and Weinstein 2017). Furthermore, due to consumption of seafood, the MPs in marine organisms can find their way to human beings too. Also, MPs were found to pass through the epidermis of the mammalian gut and translocate to other tissues (Wang et al. 2019; Bisht and Negi 2020; Wang et al. 2020a, b). Above this, in recent studies, microplastic concentrations as high as 12 µg/ml have been reported in human blood (Heather et al. 2022) as well as in human lung tissues (Jenner et al. 2022), suggesting that the MP pollution is no more just a probable health risk, rather it has already reached to human blood stream. Wearing masks potentially results in microplastic inhalation, including microplastics inhaled from the air and also from the materials of the masks. Masks are worn over both the mouth and nose. Thus, during respiration, the microplastic particles emanated from masks are very likely to be inhaled by the user. A recent study conducted by Li et al. (2021) also showed that inhalation risks of MPs increased with improper use of masks.

Although advised otherwise, most people use the masks multiple times. Except cotton and fashion masks, other masks are not meant to be washed, cleaned and reused. However, due to factors like availability and affordability, it is a very common practice to reuse the masks. The cleaning or disinfection of masks is performed usually by simple washing, ultraviolet (UV) light irradiation, alcohol disinfection etc. (Chua et al. 2020). Since the melt-blown fabric made of polypropylene (PP) (Pu et al. 2018) used in masks is a fragile material, washing it with water or disinfecting with alcohol can lead to its degradation creating loose fibers or fractions in its structure. Due to this damage to the fabric, the risk of inhaling microplastics generated from masks increases. Still it has become a very common practice to reuse the masks after cleaning and disinfection (Song et al. 2020). It is this practice of cleaning and reusing the masks or using them for prolonged times than intended that can result in generation of micro/nanoplastics from their material (Aragaw 2020; Fadare and Okoffo 2020) which can ultimately be inhaled by the user.

Some recent studies have reported microplastics in the material of disposed and new masks (Jie et al. 2021). However, very few studies have reported the inhalable amount of microplastic from the use of masks (Li et al. 2021). This study was undertaken to estimate inhalable microplastics exuded from various types of masks using real life-like respiration simulation experimental setup. Owing to the huge extent of mask usage all over the world in last couple of years and still continuing, this study will be very helpful for future studies on effect and risks of mask-generated MPs on human health.

Materials and methods

For assessing the microplastics exudation from face masks, five types of commonly used COVID masks were selected. For each type of mask, two categories were considered, namely, new masks and used masks. The new category masks were brand new unused masks while the used category masks were reused. The 5 types of masks were the following: cloth masks, N95 masks with plastic breathing valve, N95 mask without valve, 3-ply surgical masks and 2-ply surgical masks. Experiments were repeated seven times for each type of face mask (n = 7). Surgical masks were reused for 3–4 times, while N95 and cloth masks were reused for 5–6 times. The number of usage times for sampling was decided based on a small survey amongst the volunteers on number of maximum times the masks were used (it was 6–7 times for surgical and about 12 times for cloth and N95). Because the masks were discarded after using for these maximum no. of times, they were posing no inhalation risk to user after that. So, in order to account for the exposure of user to microplastics exuded from used masks, it was decided to sample the masks at halfway the maximum usage time. It may be noted that the used N95 and cloth masks were water washed, while surgical masks were reused without any cleaning.

Experimental setup

A sample collection chamber (mouth piece) was designed for holding the sample mask (Fig. 1). The sample masks were tied firmly on the spherical end of the holder which had grooves for inlet of air in the chamber. The inner side of the chamber was connected by tubing to an air pump with flow rate of 15 LPM, representing normal breathing rate via a hollow cylindrical chamber. A glass fiber filter paper preheated at 300 °C was placed at the end of the sampling holder to collect the microplastics released from masks. To ensure that there is no another possible source of MPs in the system due to leakage etc., it was tested with a leak-proof leather fabric. Also, the metallic chamber was preheated at 300 °C and checked for plastic contamination before the experiment to ensure no pre-contamination. Additionally, for few samples, we put a backup filter paper for collecting the MPs leaching from the set up if any, and did not detect any using fluorescence microscopy. The sampling was carried out for 8 h for each sample mask. The microplastics collected on filter paper were then stained using Nile Red (NR) dye with concentration of 10 μg mL−1 (in acetone) with an exposure time of 30 min. NR was chosen for staining due to its high solubility and strong fluorescence yield in a wide range of organic solvents (Sitepu et al. 2012). Other details of the sample preparation were as given by Tiwari et al. (2019) and Maes et al. (2017).

Fluorescence microscopy

Fluorescence staining method can be easily and efficiently used for detection of most common polymer fragments (i.e. microplastics). Magnified fluorescence images of microplastic particles of size as low as few micrometres can be obtained with a fluorescence microscope. Additionally, this method also rules out interference due to non-plastic items.

Each NR-stained filter paper was counted under microscope (Zeiss make: Model-Axio imager Z2). The samples were exited with UV rays and emission wavelengths were processed using 4′,6-diamidino-2-phenylindole (DAPI), fluorescein isothiocyanate (FITC) and Texas red filters. The images were post processed with MetaSystem: ISIS software. Blank filter papers were also processed using same method and the blank values were corrected for in the final count.

Results and discussion

Total number of microplastics

The samples were observed under a fluorescence microscope using 3 colour filters, namely green, blue and red (FITC, DAPI, Texas Red), since different types of microplastics emit different coloured fluorescence (Shruti et al. 2022). There was large variation observed in number of MPs in different types of masks as well as in samples of same type of masks under different filters. Depending upon number of the observed MPs, fifteen to twenty microscope images for each filter paper were taken at random spots covering the entire filter paper. The total number of MPs was then calculated for total filter paper area, using average of those observed microscope images. The microscopic images of samples with combined images of all three filters are shown in Fig. 2 and Fig. 7 (In supplimentary material).

Table 1 shows the total number of microplastic particles observed per mask over a period of 8 h of sampling. Amongst all the studied masks, the total number of MPs ranged from 5421 ± 1417 to 15,113 ± 3532. The number of MPs emitting green, blue and red fluorescence ranged from 1354 ± 510 to 7916 ± 1215, 566 ± 161 to 3452 ± 926 and 662 ± 167 to 5672 ± 2110 respectively. Amongst all the masks, used 2-ply surgical masks showed the highest number of exuded MPs while 3-ply new surgical masks showed the lowest. It was noted that the standard deviations are high. However, they are in similar range as reported by Chen et al. (2021) for MPs emitted from masks in the environment. The largest average standard deviation was observed for red emitting MPs, whereas average standard deviations for other two colours as well as for total MPs were similar to or less than Chen et al. (2021).

In order to corroborate the findings, Student’s t test was used for significance testing. The statistic t was calculated using Eq. (1), assuming that the two populations under consideration have the same standard deviation (Boddy and Smith 2009).

Here, x1 and x2 are means, Sx1x2 is the pooled standard deviation given by Eq. 2, and n1 and n2 are the sample sizes (number of replicate analyses = 7)

The calculated values of t for different mask types studied are shown in Table 1. The testing was done at the significance level of 0.05 and 12 degrees of freedom which corresponds to tcritical value of 2.179. The test results show that there was no significant difference (t < tcritical) between results obtained for new and used cloth masks. This is expected since cloth masks have shown decrease in the number of MPs in used masks. However, the results obtained for all the other types of masks differ significantly (t > tcritical) at confidence level of 95% as shown in Table 1.

The number of MPs emitting green fluorescence were maximum amongst the three colours, and were slightly more in total number than red and blue emitting microplastics combined. It is reported that different types of microplastics emit different coloured fluorescence (Shim et al. 2016; Shruti et al. 2022). Thus, different colour data can be useful for source identification as well as for tracing of the microplastics trail from its origin to target. Below is the compilation of fluorescence colour data according to type of the microplastics stained with NR dye (Table 2). The types of microplastics covered are LDPE: low-density polyethylene, HDPE: high-density polyethylene, PE: polyethylene, PP: polypropylene, EPS: expanded polystyrene, PVC: polyvinylchloride, PET: polyethylene-tere-phthalate and PA: polyamide.

It is evident from the observed data that most of the microplastic types emit at least two different colours, though with varying intensities (Shruti et al. 2022). None of the microplastic type is observed to give fluorescence in all three colours. Green emitting microplastics were found the most in this study (average #4800), followed by red (average #2600) and blue (average #2300). Thus, it can be said that LDPE, HDPE, PE, PP, EPS and PVC are the most dominating types of MP polymers released from face masks. All the types of masks were observed to contain MPs emitting the all three colours of fluorescence. However, cloth masks were an exception in which the MPs emitting red fluorescence were not observed in both new as well as used cloth masks. Since cloth masks do not have any plastic layer, the microplastics observed might have been due to impurity in the material or due to plastic contamination during manufacture. With reference to Table 2, it can be inferred that the MPs exuded from cloth masks could dominantly be PE, PP and EPS, whereas from other types of masks, all the listed MPs types are exuded.

Confirmation of plastic types using Raman and FTIR spectra

The fabric materials of the masks were tested for their polymer content using Raman and FTIR spectroscopy. It was found that there was no difference in used and new mask materials in terms of their Raman and FTIR spectra. This is expected since the mask material only deteriorates in strength, but its overall composition remains nearly same. Raman spectra were recorded using 532 nm laser excitation line with power on the sample ~ 1 mW. Appropriate edge filter and a CCD-based 0.75 m (Andor Technology) spectrometer with entrance slit width of ~ 50 µm were used to detect the scattered light. The Raman spectra of all the sample mask materials are shown in Fig. 3. The spectra were matched with Raman frequencies provided for polymers by Furukawa et al. (2006) and Nikolaeva et al. (2017) and it was found that both surgical and N95 masks showed polypropylene (PP) as the principle material of these masks. This also matches with the coloured fluorescence data obtained by fluorescence microscopy in this study. However, other polymers were not identified using Raman spectra, and thus, FTIR analysis was carried out for their determination using an IR Affinity-1 spectrometer (Shimadzu, Japan).

The FTIR spectra of cloth, surgical and N95 mask fabrics are shown in Fig. 4. The spectra were matched using inbuilt instrument library to identify possible polymer content. Same as that of Raman spectra, the FTIR spectra too did not show any quantifiable polymer in cloth masks. This shows that the microplastics emitted from cloth masks could mostly be due to some minor external contamination or trace impurity. The absence of polymer spectra in cloth masks can be attributed to a basic difficulty we faced in the Raman and FTIR spectroscopy for polymer detection in fabric. The detection is surface based in these two techniques. So, for other masks, where the whole fabric is made of plastic polymers, placing the probe at any spot can detect their polymer types. However, this becomes difficult for cotton masks since these masks are mainly made of cotton fibres. In reality, most of the masks claiming to be made of cotton may have slight percentage of polyester so as to give some water-resistant property to the fabric, but these plastic polymers are present either as trace level impurity or as external contamination in the fabric. Since it was observed that the microplastics are in micrometer sizes, it is nearly impossible to find one attached to the surface of cotton mask and then positioning the probe there to get its FTIR/Raman spectra. It may be noted that this does not mean that the cotton masks do not contain plastic polymers, only that they are too low in concentration to be detected as such.

The FTIR spectra of surgical masks showed polypropylene (PP) and polyamide (PA) as the most probable polymers in its fabric. These two plastic types were also accompanied with detection of probable polymer additives which are mostly used for increasing the strength of plastic materials during its manufacture. This detection also matches with the fluorescent detection in which surgical masks showed all three colour emitting MPs. It may be noted that both inner side and outer side layers of both the surgical masks showed same FTIR spectra.

For N95 masks, it was observed that the mask had multiple layers. Thus, the spectra were obtained for the outer fabric as well as the largest inner fabric layer (since middle layer fabric is made of melt-blown PP similar to surgical masks, the spectra were same as surgical masks). Both the spectra are shown in Fig. 4.

The outer layer (both fabrics, i.e. the one facing mouth and the outward fabric, were found to be made from same material) showed PP as the most possible polymer content in the fabric. This result is in accordance with Chellamani et al. (2013), Neupane and Giri (2020), Li et al. (2021) and Deng et al. (2022). The inner fabric layer showed three possible polymer frequencies, viz. PET, PE and PA. This observation also matches with fluorescence microscopic data and thus it can be inferred that the N95 material itself is the source of different types of MPs exuded from the mask.

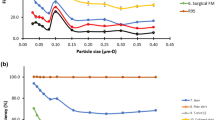

Percentage distribution of MPs in new and used masks

Figure 5 shows the percentage distribution of different types of microplastics in used and new masks of each type. The percent distribution of different colour emitting microplastics was observed to be nearly same in both used and new masks for cloth, N95 with valve and N95 without valve masks. The percentage of green emitting microplastics in these three types of masks was approximately between 55 and 69%. N95 mask with valve had higher percentage of blue emitting MPs than red emitting MPs while N95 without valve had high percentage of red than blue. A noticeable difference of percentage distribution amongst three types of MPs between used and new masks was observed for the 2-ply and 3-ply surgical masks. In 3-ply surgical masks, the red emitting MPs increased from 30% in new masks to about 51% in used ones while blue emitting MPs reduced from about 45% in new to 27% in used. The green MP percentage remained nearly unchanged. In 2-ply surgical masks, percentage of red MPs remained nearly unchanged, while green MPs increased from 32% in new masks to 53% in used, and blue MPs reduced from 30% in new to 12% in used. Of the five types of masks, surgical masks have the most delicate and poor-quality fabric. Thus, using them multiple times over could result in different patterns of MPs released from them.

Change in total amount of MPs in used and new masks

It is clear from the data that over the time, there is change in total amount of MPs released from the masks. Figure 6 shows the change in percentage of MPs exuded from used masks vs those exuded from new masks. All the masks except cloth masks were observed to exude higher number of MPs in used masks than the new ones. It is evident from the observation that multiple time use of masks results into degradation and weathering of the mask material leading to higher emission of MPs from the masks (Aragaw 2020; Fadare and Okoffo 2020).

Cloth masks showed average 14% decrease in exuded MPs in used masks than new ones for both green and blue MPs. Red emitting MPs were not observed in either of the used or new cloth masks. This shows that the MPs exuded from the cloth masks could be just a contamination or impurity attached to the mask fabric during time of manufacture/transfer etc. The N95 masks with valve showed lowest average increase of 32% for all the three colour emitting MPs in used masks. The highest percentage change in exuded MPs was observed for both the 2- and 3-ply surgical mask types. For 3-ply masks, the percentage of red emitting MPs increased by about 254% in used masks followed by an increase of 80% in green and 20% in blue emitting MPs. In 2-ply masks, the highest increase was of around 245% in the green emitting MPs followed by 105% increase in the red emitting MPs. Surprisingly, the percentage of blue emitting MPs was found to reduce by about 15% in the 2-ply used masks than new ones. In case of absolute number of total exuded MPs, the highest increase was observed in 2-ply surgical masks followed by 3-ply surgical masks, N95 masks and lastly N95 masks with valve respectively. Cloth masks on the contrary showed decrease in absolute number of exuded MPs after use.

Conclusion

Use of face masks as a preventive measure for spread of the coronavirus. However, it could lead to inhalation of microplastics particles by the user. It was found that over the period of 8 h of usage, all the types of commonly used masks exude microplastics in thousands of numbers. The number of microplastics exuded increases even more in multiple times used masks. It was also concluded that different types of masks exude different types of microplastics. It can be said that the fluorescence detection method is a very simple and easy method for both qualitative and quantitative measurements of the microplastics.

Data availability

The datasets generated during and/or analysed during the current study are not publicly available due to departmental policy, but are available from the corresponding author strictly on reasonable request only.

References

Andrady AL, Neal MA (2009) Applications and societal benefits of plastics. Phil Trans R Soc B Biol Sci 364(1526):1977–1984. https://doi.org/10.1098/rstb.2008.0304

Aragaw TA (2020) Surgical face masks as a potential source for microplastic pollution in the COVID-19 scenario. Mar Pollut Bull 159:111517. https://doi.org/10.1016/j.marpolbul.2020.111517

Bisht VS, Negi D (2020) Microplastics in aquatic ecosystem: sources, trophic transfer and implications. Int J Fish Aquat Stud 8:227–234

Boddy R, Smith G (2009) Statistical methods in practice: for scientists and technologists. John Wiley & Sons, Chichester, West Sussex, UK

Chatterjee S, Sharma S (2019) Microplastics in our oceans and marine health. Field Actions Sci Rep J Field Actions (Special Issue 19): 54–61

Chellamani K, Veerasubramanian D, Balaji RV (2013) Surgical face masks: manufacturing methods and classification. J Acad Ind Res 2(6):320–324

Chen X, Xi C, Liu Q, Zhao Q, Xiong X, Wu C (2021) Used disposable face masks are significant sources of microplastics to environment. Environ Poll 285:117485

Chu DK, Akl EA, Duda S, Solo K, Yaacoub S, Schünemann HJ (2020) Physical distancing, face masks, and eye protection to prevent person-to-person transmission of SARS-CoV-2 and COVID-19: a systematic review and meta-analysis. The Lancet. https://doi.org/10.1016/S0140-6736(20)31142-9

Chua MH, Cheng W, Goh SS, Kong J, Li B, Lim JY, Mao L, Wang S, Xue K, Yang L, Ye E, Zhang K, Cheong WCD, Tan BH, Li Z, Tan BH, Loh XJ (2020) Face masks in the new COVID-19 normal: materials, testing, and perspectives. Research (Wash D C) 2020https://doi.org/10.34133/2020/7286735

Cole M, Lindeque P, Fileman E, Halsband C, Goodhead R, Moger J, Galloway TS (2013) Microplastic ingestion by zooplankton. Environ Sci Technol 47(12):6646–6655. https://doi.org/10.1021/es400663f

Deng W, Sun Y, Yao X, Ka S, Ling C, Wang H, Chopra SS, Xu BB, Wang JX, Chen JF, Wang D, Amancio H, Pramana S, Ye R, Wang S (2022) Masks for COVID-19. Adv Sci 9:2102189. https://doi.org/10.1002/advs.202102189

eSilva PPG, Nobre CR, Resaffe P, Pereira CDS, Gusmão F (2016) Leachate from microplastics impairs larval development in brown mussels. Water Res 106:364–370. https://doi.org/10.1016/j.watres.2016.10.016

Erni-Cassola G, Gibson MI, Thompson RC, Christie-Oleza JA (2017) Lost, but found with Nile red: a novel method for detecting and quantifying small microplastics (1 mm to 20 μm) in environmental samples. Environ Sci Technol 51:13641–13648

Fadare OO, Okoffo ED (2020) Covid-19 face masks: a potential source of microplastic fibers in the environment. Sci Tot Environ 737:140279. https://doi.org/10.1016/j.scitotenv.2020.140279

Furukawa T, Sato H, Kita Y, Matsukawa K, Yamaguchi H, Ochiai S, Siesler HW, Ozaki Y (2006) Molecular structure, crystallinity and morphology of polyethylene/polypropylene blends studied by Raman mapping, scanning electron microscopy, wide angle X-ray diffraction, and differential scanning calorimetry. Polym J 38(11):1127–1136

Gallo F, Fossi C, Weber R, Santillo D, Sousa J, Ingram I, Nadal A, Romano D (2018) Marine litter plastics and microplastics and their toxic chemicals components: the need for urgent preventive measures. Environ Sci Eur 30(13). https://doi.org/10.1186/s12302-018-0139-z.

Gray AD, Weinstein JE (2017) Size-and shape-dependent effects of microplastic particles on adult daggerblade grass shrimp (Palaemonetes pugio). Environ Toxicol Chem 36(11):3074–3080. https://doi.org/10.1002/etc.3881

Greenhalgh T, Howard J (2022) Masks for all? The science says yes. Available from: https://www.fast.ai/2020/04/13/masks-summary/. Accessed 24 June 2022

Heather AL, Martin JM, vanVelzen SHB, Vethaak AD, Garcia-Vallejo JJ, Lamoree MH (2022) Discovery and quantification of plastic particle pollution in human blood. Environ Int 163:107199

Horton A, Clark A (2018) Microplastic Methods Workshop Report. In: Organised and facilitated by the NERC UK Microplastics Network and the Royal Society of Chemistry Water Science Forum. Royal Society of Chemistry, London, UK, pp 1–19. https://www.rsc.org/images/Microplastic%20methods%20workshop%20report%202018_tcm18-252110.pdf. Accessed 16 June 2022

Jenner LC, Rotchell JM, Bennett RT, Cowen M, Tentzeris V, Sadofsky LR (2022) Detection of microplastics in human lung tissue using μFTIR spectroscopy. Sci Tot Environ 831:154907. https://doi.org/10.1016/j.scitotenv.2022.154907

Jie M, Fengyuan C, Huo X, Hao J, Jingli L, Ping L, Chun CC, Ke P (2021) Face masks as a source of nanoplastics and microplastics in the environment: quantification, characterization, and potential for bioaccumulation. Environ Poll 288:117748

Li L, Zhao X, Li Z, Song K (2021) COVID-19: Performance study of microplastic inhalation risk posed by wearing masks. J Haz Mat 411:124955

Maes T, Jessop R, Wellner N, Haupt K, Mayes AG (2017) A rapid-screening approach to detect and quantify microplastics based on fluorescent tagging with Nile Red. Sci Rep 7:1–10

Neupane B, Giri B (2020) Current understanding on the effectiveness of face masks and respirators to prevent the spread of respiratory viruses. Engineering engrxiv archive. https://doi.org/10.31224/osf.io/h3wgc

Nikolaeva GY, Sagitova EA, Prokhorov KA, Pashinin PP, Nedorezova PM, Klyamkina AN, Guseva MA, Gerasin VA (2017) Using Raman spectroscopy to determine the structure of copolymers and polymer blends. IOP Conf Series: J Phys: Conf Series 826:012002. https://doi.org/10.1088/1742-6596/826/1/012002

PlasticEurope, Plastics-the Facts (2018) An analysis of European plastics production, demand, and waste data. https://plasticseurope.org/wp-content/uploads/2021/10/2018-Plastics-the-facts.pdf. Accessed on 15 June 2022

Prata JC (2018) Airborne microplastics: consequences to human health? Environ Pollut 234:115–126. https://doi.org/10.1016/j.envpol.2017.11.043

Prata JC, Reis V, Matos JT, da Costa JP, Duarte AC, Rocha-Santos T (2019) A new approach for routine quantification of microplastics using Nile Red and automated software (MP-VAT). Sci Tot Environ 690:1277–1283

Prata JC, Silva ALP, Walker TR, Duarte AC, Rocha-Santos T (2020) COVID-19 pandemic repercussions on the use and management of plastics. Environ Sci Technol 54(13):7760–7765. https://doi.org/10.1021/acs.est.0c02178

Pu Y, Zheng J, Chen F, Long Y, Wu H, Li Q, Ning X (2018) Preparation of polypropylene micro and nanofibers by electrostatic-assisted melt blown and their application. Polymers 10(9):959

Rocha-Santos T, Duarte AC (2015) A critical overview of the analytical approaches to the occurrence, the fate and the behavior of microplastics in the environment. Trends Anal Chem 65:47–53. https://doi.org/10.1016/j.trac.2014.10.011

Shim WJ, Song YK, Hong SH, Jang M (2016) Identification and quantification of microplastics using Nile Red staining. Mar Pollut Bull 113:469–476

Shruti VC, Pérez GF, Roy PD, Kutralam MG (2022) Analyzing microplastics with Nile Red: Emerging trends, challenges, and prospects. J Haz Mat 423:127171

Sitepu IR, Ignatia L, Franz AK, Wong DM, Faulina SA, Tsui M, Kanti A, Boundy-Mills K (2012) An improved high-throughput Nile red fluorescence assay for estimating intracellular lipids in a variety of yeast species. J Microbiol Methods 91(2):321–328. https://doi.org/10.1016/j.mimet.2012.09.001

Song W, Pan B, Kan H, Xu Y, Yi Z (2020) Heat inactivating and reusing of virus- contaminated disposable medical mask. medRxiv. https://doi.org/10.1101/2020.07.01.20144527

Sturm MT, Horn H, Schuhen K (2021) The potential of fluorescent dyes-comparative study of Nile red and three derivatives for the detection of microplastics. Anal Bioanal Chem 413:1059–1071

Thompson RC, Olson Y, Mitchell RP, Davis A, Rowland SJ, John AWG, McGonigle D, Russell AE (2004) Lost at sea: where is all the plastic? Sci 304(5672):838. https://doi.org/10.1126/science.1094559

Tiwari M, Rathod TD, Ajmal PY, Bhangare RC, Sahu SK (2019) Distribution and characterization of microplastics in beach sand from three different Indian coastal environments. Mar Poll Bull 140:262–273

Verla AW, Enyoh CE, Verla EN, Nwarnorh KO (2019) Microplastic–toxic chemical interaction: a review study on quantified levels, mechanism and implication. SN Appl Sci 1(11):1400. https://doi.org/10.1007/s42452-019-1352-0

Wang W, Gao H, Jin S, Li R, Na G (2019) The ecotoxicological effects of microplastics on aquatic food web, from primary producer to human: a review. Ecotoxicol Environ Saf 173:110–117. https://doi.org/10.1016/j.ecoenv.2019.01.113

Wang YL, Lee YH, Chiu IJ, Lin YF, Chiu HW (2020a) Potent impact of plastic nanomaterials and micromaterials on the food chain and human health. Int J Mol Sci 21(5):1727. https://doi.org/10.3390/ijms21051727

Wang Y, Zhou J, Gao X (2020b) Numerical analysis of airflow fields from new meltblowing dies for dual-slot jets. ACS Omega 5(22):13409–13415. https://doi.org/10.1021/acsomega.0c01668

Wang Y, Wang X, Li Y, Li J, Liu Y, Xia S, Zhao J (2021) Effects of exposure of polyethylene microplastics to air, water and soil on their adsorption behaviors for copper and tetracycline. Chem Eng J 404:126412. https://doi.org/10.1016/j.cej.2020.126412

Welden NA, Cowie PR (2016) Long-term microplastic retention causes reduced body condition in the langoustine, Nephrops norvegicus. Environ Pollut 218:895–900. https://doi.org/10.1016/j.envpol.2016.08.020

Worldometers.info (2022) Worldometer From: Dover, Delaware, U.S.A https://www.worldometers.info/world-population/. Accessed on 31 May 2022

Acknowledgements

Authors would like to thank Mr. Rajesh Chaurasia and Mr. Kapil Shirsath of RP&AD, BARC for their invaluable help in carrying out fluorescence microscopy of the samples. We also extend our gratitude to Dr. Nilanjal Misra of RTDD, BARC and Dr. Himal Bhatt of HP&SRPD, BARC for their help in FTIR and Raman spectroscopy.

Funding

This work is funded by Government of India at Bhabha Atomic Research Centre Mumbai.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Conceptualisation and planning were done by R.C. Bhangare, M. Tiwari and S.K. Sahu. Material preparation, data collection and analysis were performed by R.C. Bhangare, M. Tiwari, P.Y. Ajmal and T.D. Rathod. The first draft of the manuscript was written by R.C. Bhangare and all authors commented on previous versions of the manuscript. All authors have read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

This is an observational study. No human or animal subjects were involved. The authors confirm that no ethical approval is required.

Consent for publication

All authors affirm consent for publication of the manuscript.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Supplementary file1 (MP4 1538 KB)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bhangare, R.C., Tiwari, M., Ajmal, P.Y. et al. Exudation of microplastics from commonly used face masks in COVID-19 pandemic. Environ Sci Pollut Res 30, 35258–35268 (2023). https://doi.org/10.1007/s11356-022-24702-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-24702-1