Abstract

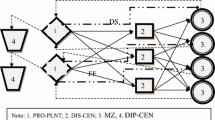

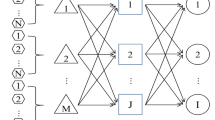

This paper presents a novel decentralized decision support system to optimally design a general global closed-loop supply chain. This is done through an original risk-based robust mixed-integer linear programming that is formulated based on an initial uncertain bi-level programming. Addressing the decision-maker’s (DM’s) attitude toward risk, a scenario-based conditional value-at-risk is used to deal with demand and return uncertainty. Also, the Karush–Kuhn–Tucker (KKT) conditions are employed to transform the model into its single-level counterpart. The results obtained from solving a numerical example through the proposed framework are compared with those of the corresponding centralized system, which is formulated through deterministic multi-objective programming and solved by the Lp-metric method. The results show that the use of the proposed framework improves the robustness of profit, income, and cost by about 28%, 34%, and 36% on average. However, a more conservative DM faces a larger cost of robustness than an optimistic DM while experiencing a more significant improvement in the system responsiveness. Using the proposed framework, the manager can measure the advantages, disadvantages, and consequences of their decisions before their actual implementation. This is because the model is capable of establishing fundamental trade-offs among risk, cost, profit, income, robustness, and responsiveness according to the DM’s attitude toward risk.

Similar content being viewed by others

Data availability

I confirm that all relevant data are included in the article and information file.

Abbreviations

- RQ:

-

Research question

- SC:

-

Supply chain

- RO:

-

Robust optimization

- CLSC:

-

Closed-loop supply chain

- CLSCND:

-

Closed-loop supply chain network design

- GCLSC:

-

Global closed-loop supply chain

- DSS:

-

Decision support system

- GCLSCND:

-

Global closed-loop supply chain network design

- GSCN:

-

Global supply chain network

- VaR:

-

Value-at-risk

- CVaR:

-

Conditional value-at-risk

- DM:

-

Decision-maker

- MILP:

-

Mixed integer-linear programming

- BLP:

-

Bi-level programming

- KKT:

-

Karush–Kuhn–Tucker

- \(s\in \left\{1,\cdots s,\cdots ,S\right\}\) :

-

Index of suppliers

- \(p\in \left\{1,\cdots p,\cdots ,P\right\}\) :

-

Index of products

- \(f\in \left\{1,\cdots f,\cdots ,F\right\}\) :

-

Index of manufacturers

- \(b\in \left\{1,\cdots b,\cdots ,B\right\}\) :

-

Index of distribution centers

- \(m\in \left\{1,\cdots m,\cdots ,M\right\}\) :

-

Index of markets

- \(g\in \left\{1,\cdots g,\cdots ,G\right\}\) :

-

Index of collection centers

- \(n\in \left\{1,\cdots n,\cdots ,N\right\}\) :

-

Index of countries

- \(t\in \left\{1,\cdots t,\cdots ,T\right\}\) :

-

Index of times

- \(o\in \left\{1,\cdots o,\cdots ,O\right\}\) :

-

Index of disposal centers

- \(\tau \in \left\{1,\cdots o,6\right\}\) :

-

Index of cost functions

- \({q}_{sfpt}^{(1)}\) :

-

Number of product p purchased for manufacturer f from supplier s at time t

- \({q}_{fbpt}^{(2)}\) :

-

Number of product p produced by manufacturer f for distribution center b at time t

- \({q}_{bmpt}^{(3)}\) :

-

Number of product p distributed from distribution center b to market m at time t

- \({q}_{mgpt}^{(4)}\) :

-

Number of returned product p from market m to collection center g at time t

- \({q}_{gopt}^{(5)}\) :

-

Number of returned product p from collection center g to disposal center o at time t

- \({q}_{gfpt}^{(6)}\) :

-

Number of returned product p from collection center g to manufacturer f at time t

- \({X}_{f}\) :

-

Binary variable to define whether manufacturer f is opened

- \({Y}_{b}\) :

-

Binary variable to define whether distribution center b is opened

- \({Z}_{g}\) :

-

Binary variable to define whether disposal center g is opened

- Income:

-

System’s total income

- \({\Psi }_{1}\) :

-

Facilities’ total opening cost

- \({\Psi }_{2}\) :

-

Products’ total purchasing, transportation, and customs duties cost

- \({\Psi }_{3}\) :

-

Total production and logistics cost from manufacturers to distribution centers

- \({\Psi }_{4}\) :

-

Returned products’ total cost of transportation to collection centers

- \({\Psi }_{5}\) :

-

Products’ total disposal and the relative transportation cost

- \({\Psi }_{6}\) :

-

Sum of saved and transportation costs of returned products to manufacturers

- \(\begin{array}{c}{Z}^{leader}\\ {Z}^{lead{er}^{*}}\end{array}\) :

-

Leader’s objective function/optimal objective function value

- \(\begin{array}{c}{Z}^{follower}\\ {Z}^{follow{er}^{*}}\end{array}\) :

-

Follower’s objective function/optimal objective function value

- \(\begin{array}{c}{\gamma }_{leader}\\ {\gamma }_{follower}\end{array}\) :

-

Objectives’ importance weights

- \(Z\) :

-

The objective function of the mono-objective model resulting from the initial bi-objective one

- \({t}_{sfp}^{de}\) :

-

Delivery time of product p from supplier s to manufacturer f (Month)

- \({\rho }_{p}^{se}\) :

-

The selling price of product p ($)

- \({c}_{f}^{mnu}\) :

-

Opening cost of manufacturer f ($)

- \({c}_{b}^{dis}\) :

-

Opening cost of distribution center b ($)

- \({c}_{g}^{col}\) :

-

Opening cost of collection center g ($)

- \({c}_{spn}^{pu}\) :

-

The unit purchasing cost of product p from supplier s in country n ($)

- \({r}_{bspn}^{cd}\) :

-

Customs duty rate of product p from supplier s in country n

- \({c}_{psfn}^{tr (1)}\) :

-

Unit transportation cost of product p from supplier s to manufacturer f in country n ($)

- \({c}_{pfb}^{tr (2)}\) :

-

Unit transportation cost of product p from manufacturer f to distribution center b ($)

- \({c}_{pbm}^{tr (3)}\) :

-

Unit transportation cost of product p from distribution center b to market center m ($)

- \({c}_{pmg}^{tr (4)}\) :

-

Unit transportation cost of product p from market center m to collection center g ($)

- \({c}_{pgo}^{tr (5)}\) :

-

Unit transportation cost of product p from collection center g to disposal center o ($)

- \({c}_{pgf}^{tr (6)}\) :

-

Unit transportation cost of product p from collection center g to manufacturer f ($)

- \({c}_{p}^{pr}\) :

-

The unit production cost of product p ($)

- \({c}_{p}^{o}\) :

-

Unit disposal cost of product p ($)

- \({d}_{sfn}^{(1)}\) :

-

Distance between supplier s and manufacturer f in country n (× 100 km)

- \({d}_{fb}^{(2)}\) :

-

Distance between manufacturer f and distribution center b (× 100 km)

- \({d}_{bm}^{(3)}\) :

-

Distance between distribution center b and market center m (× 100 km)

- \({d}_{mg}^{(4)}\) :

-

Distance between market m and collection center g (× 100 km)

- \({d}_{go}^{(5)}\) :

-

Distance between collection center g and disposal center o ( x 100 km)

- \({d}_{gf}^{(6)}\) :

-

Distance between collection center g and manufacturer f (× 100 km)

- \({a}_{p}\) :

-

Cost-saving of product p due to its recovery ($)

- \({o}_{p}\) :

-

Minimum disposal fraction of product p

- \({{\boldsymbol{v}}}_{fp}^{(1)}\) :

-

The capacity of manufacturer f for product p

- \({{\boldsymbol{v}}}_{bp}^{(2)}\) :

-

The capacity of distribution center b for product p

- \({{\boldsymbol{v}}}_{gp}^{(3)}\) :

-

The capacity of collection center g for product p

- \({r}_{n}^{ex}\) :

-

Exchange rate of country n

- \(\mathcal{X}\) :

-

Returned products ratio

- \({\widetilde{\delta }}_{mpt}\) :

-

Uncertain demand of product p from market m at time t

References

Agrawal VV, Atasu A, Van Wassenhove LN (2019) OM Forum—new opportunities for operations management research in sustainability. Manuf Serv Oper Manag 21(1):1–12

Almaktoom AT, Krishnan KK, Wang P, Alsobhi S (2016) Cost efficient robust global supply chain system design under uncertainty. Int J Adv Manuf Technol 85(1–4):853–868

Altmann M, Bogaschewsky R (2014) An environmentally conscious robust closed-loop supply chain design. J Bus Econ 84(5):613–637

Amin SH, Baki F (2017) A facility location model for global closed-loop supply chain network design. Appl Math Model 41:316–330

Amin SH, Zhang G (2012) An integrated model for closed-loop supply chain configuration and supplier selection: multi-objective approach. Expert Syst Appl 39(8):6782–6791

Amin SH, Zhang G, Eldali MN (2020) A review of closed-loop supply chain models. J Data Inf Manag 2(4):279–307

Amirian J, Amoozad Khalili H, Mehrabian A (2022) Designing an optimization model for green closed-loop supply chain network of heavy tire by considering economic pricing under uncertainty. Environ Sci Pollut Res 29:53107–53120. https://doi.org/10.1007/s11356-022-19578-0

Amirtaheri O, Zandieh M, Dorri B, Motameni A (2017) A bi-level programming approach for production-distribution supply chain problem. Comput Ind Eng 110:527–537

Asadabadi A, Miller-Hooks E (2018) Co-opetition in enhancing global port network resiliency: a multi-leader, common-follower game theoretic approach. Transp Res B Method 108:281–298

Asl-Najafi J, Yaghoubi S, Azaron A (2018) Coordination of a bi-level closed-loop supply chain considering economic and green transportation modes. Int J Ind Eng Prod Res 29(4):429–441

Autry CW (2005) Formalization of reverse logistics programs: a strategy for managing liberalized returns. Ind Mark Manag 34(7):749–757

Babaveisi V, Paydar MM, Safaei AS (2018) Optimizing a multi-product closed-loop supply chain using NSGA-II, MOSA, and MOPSO meta-heuristic algorithms. J Ind Eng Int 14(2):305–326

Baptista S, Barbosa-Póvoa AP, Escudero LF, Gomes MI, Pizarro C (2019) On risk management of a two-stage stochastic mixed 0–1 model for the closed-loop supply chain design problem. Eur J Oper Res 274(1):91–107

Battini D, Bogataj M, Choudhary A (2017) Closed loop supply chain (CLSC): economics, modelling, management and control. Int J Prod Econ 183:319–321

Ben-Tal A, Bertsimas D, Brown DB (2010) A soft robust model for optimization under ambiguity. Oper Res 58(4-part-2):1220–1234

Ben-Tal A, Nemirovski A (1998) Robust convex optimization. Math Oper Res 23(4):769–805

Bertsimas D, Brown DB (2009) Constructing uncertainty sets for robust linear optimization. Oper Res 57(6):1483–1495

Butner K (2010) The smarter supply chain of the future. Strategy & Leadership 38(1)

Cagliano R, Caniato F, Golini R, Kalchschmidt M, Spina G (2008) Supply chain configurations in a global environment: a longitudinal perspective. Oper Manag Res 1(2):86–94

Caniato F, Golini R, Kalchschmidt M (2013) The effect of global supply chain configuration on the relationship between supply chain improvement programs and performance. Int J Prod Econ 143(2):285–293

Chalmardi MK, Camacho-Vallejo J-F (2018) A bi-level programming model for sustainable supply chain network design that considers incentives for using cleaner technologies. J Clean Prod

Chen J, Wang H, Fu Y (2022) A multi-stage supply chain disruption mitigation strategy considering product life cycle during COVID-19. Environ Sci Pollut Res:1–15. https://doi.org/10.1007/s11356-022-18931-7

Chen Y-W, Wang L-C, Wang A, Chen T-L (2017) A particle swarm approach for optimizing a multi-stage closed loop supply chain for the solar cell industry. Robot Comput Integr Manuf 43:111–123

Cheng X, Yang G, Fan L (2018) Global supply chain network design problem with rules of origin and limited import quotas. Kybernetes. Int J Syst Cyber 48.5:930–948

Cheraghalipour A, Roghanian E (2022) A bi-level model for a closed-loop agricultural supply chain considering biogas and compost. Environ Dev Sustain 1–47. https://doi.org/10.1007/s10668-022-02397-1

Choi S, RuszczyńSki A (2008) A risk-averse newsvendor with law invariant coherent measures of risk. Oper Res Lett 36(1):77–82

Choi TM, Lo CK, Wong CW, Yee RW, Ho HPY (2012) A Five‐R analysis for sustainable fashion supply chain management in Hong Kong: a case analysis. J Fash Mark Manag 16(2):161–175

Cohen MA, Lee HL (2020) Designing the right global supply chain network. Manuf Serv Oper Manag 22(1):15–24

Collette Y, Siarry P (2013) Multiobjective optimization: principles and case studies: Springer Science & Business Media

Crowley J, Fleming C, Cooper C (1982) A computer model for the refraction of non-linear waves. In Coastal Engineering 18:384–403. https://doi.org/10.9753/icce.v18.26

Dantzig GB (1955) Linear programming under uncertainty. Manag Sci 1(3–4):197–206

Dehghan E, Nikabadi MS, Amiri M, Jabbarzadeh A (2018) Hybrid robust, stochastic and possibilistic programming for closed-loop supply chain network design. Comput Ind Eng 123:220–231

Dornier P-P, Ernst R, Fender M, Kouvelis P (2008) Global operations and logistics: text and cases. John Wiley & Sons

Du Z-J, Chen Z-X, Yu S-M (2022) Commercial-risk joint analysis with probabilistic linguistic assessments. Knowl-Based Syst 247:108737

Duong ATB, Vo VX, Carvalho MDS, Sampaio P, Truong H Q (2022) Risks and supply chain performance: globalization and COVID-19 perspectives. Int J Prod Perform Manag

El Ghaoui L, Lebret H (1997) Robust solutions to least-squares problems with uncertain data. SIAM J Matrix Anal Appl 18(4):1035–1064

Fallah H, Eskandari H, Pishvaee MS (2015) Competitive closed-loop supply chain network design under uncertainty. J Manuf Syst 37:649–661

Fan Y, Zhang X, Zhu L (2010) Estimating the macroeconomic costs of CO2 emission reduction in China based on multi-objective programming. Adv Clim Chang Res 1(1):27–33

Fleischmann M, Beullens P, Bloemhof-Ruwaard JM, Van Wassenhove LN (2001) The impact of product recovery on logistics network design. Prod Oper Manag 10(2):156–173

Garg K, Kannan D, Diabat A, Jha P (2015) A multi-criteria optimization approach to manage environmental issues in closed loop supply chain network design. J Clean Prod 100:297–314

Ghomi-Avili M, Naeini SGJ, Tavakkoli-Moghaddam R, Jabbarzadeh A (2018) A fuzzy pricing model for a green competitive closed-loop supply chain network design in the presence of disruptions. J Clean Prod 188:425–442

Goh M, Lim JY, Meng F (2007) A stochastic model for risk management in global supply chain networks. Eur J Oper Res 182(1):164–173

Golpîra H (2016) A robust bi-objective uncertain green supply chain network management. Serb J Manag 11(2):211–222

Golpîra H (2017a) Robust bi-level optimization for an opportunistic supply chain network design problem in an uncertain and risky environment. Oper Res Decisions 27(1):1–41. https://doi.org/10.5277/ord170102

Golpîra H (2017b) Robust bi-level optimization for an opportunistic supply chain network design problem in an uncertain and risky environment. Oper Res Decisions 27(1):21–41

Golpîra H (2017c) Supply chain network design optimization with risk-averse retailer. Int J Inform Syst Supply Chain Manag 10(1):16–28

Golpîra H (2018) A novel Multiple Attribute Decision Making approach based on interval data using U2P-Miner algorithm. Data Knowl Eng 115:116–128

Golpîra H (2020a) Optimal integration of the facility location problem into the multi-project multi-supplier multi-resource Construction Supply Chain network design under the vendor managed inventory strategy. Expert Syst Appl 139:112841. https://doi.org/10.1016/j.eswa.2019.112841

Golpîra H (2020b) Smart energy-aware manufacturing plant scheduling under uncertainty: a risk-based multi-objective robust optimization approach. Energy 209:118385

Golpîra H, Javanmardan A (2021) Decentralized decision system for closed-loop supply chain: a bi-level multi-objective risk-based robust optimization approach. Comput Chem Eng 154:107472. https://doi.org/10.1016/j.compchemeng.2021.107472

Golpîra H, Javanmardan A (2022) Robust optimization of sustainable closed-loop supply chain considering carbon emission schemes. Sustain Prod Consump 30:640–656. https://doi.org/10.1016/j.spc.2021.12.028

Golpîra H, Khan SAR, Safaeipour S (2021) A review of logistics internet-of-things: current trends and scope for future research. J Ind Inf Integr 22:100194. https://doi.org/10.1016/j.jii.2020.100194

Golpîra H, Najafi E, Zandieh M, Sadi-Nezhad S (2017) Robust bi-level optimization for green opportunistic supply chain network design problem against uncertainty and environmental risk. Comput Ind Eng 107:301–312. https://doi.org/10.1016/j.cie.2017.03.029

Golpîra H, Tirkolaee EB (2019) Stable maintenance tasks scheduling: a bi-objective robust optimization model. Comput Ind Eng 137:106007

Govindan K, Fattahi M (2017) Investigating risk and robustness measures for supply chain network design under demand uncertainty: a case study of glass supply chain. Int J Prod Econ 183:680–699

Govindan K, Soleimani H, Kannan D (2015) Reverse logistics and closed-loop supply chain: a comprehensive review to explore the future. Eur J Oper Res 240(3):603–626

Guan G, Jiang Z, Gong Y, Huang Z, Jamalnia A (2020) A bibliometric review of two decades’ research on closed-loop supply chain: 2001–2020. Ieee Access 9:3679–3695

Guan Z, Mou Y, Sun M (2022) Hybrid robust and stochastic optimization for a capital-constrained fresh product supply chain integrating risk-aversion behavior and financial strategies. Comput Ind Eng 169:108224

Gupta N, Rajesh R, Daultani Y (2021) Investigation on supply chain vulnerabilities and risk management practices in Indian manufacturing industries. In Computational management. Springer, 535–552

Hajipour V, Tavana M, Di Caprio D, Akhgar M, Jabbari Y (2019) An optimization model for traceable closed-loop supply chain networks. Appl Math Model 71:673–699

Hammami R, Frein Y (2013) An optimisation model for the design of global multi-echelon supply chains under lead time constraints. Int J Prod Res 51(9):2760–2775

Hasani A (2021) Resilience cloud-based global supply chain network design under uncertainty: resource-based approach. Comput Ind Eng 158:107382

Hasani A, Khosrojerdi A (2016) Robust global supply chain network design under disruption and uncertainty considering resilience strategies: a parallel memetic algorithm for a real-life case study. Transp Res E Logist Transp Rev 87:20–52

Hasani A, Zegordi SH, Nikbakhsh E (2015) Robust closed-loop global supply chain network design under uncertainty: the case of the medical device industry. Int J Prod Res 53(5):1596–1624

Hasani A, Zegordi SHJ (2015) A robust competitive global supply chain network design under disruption: the case of medical device industry. Int J Ind Eng Prod Res 26(1):63–84

Hassanpour A, Bagherinejad J, Bashiri M (2018) A robust bi-level programming model to design a closed loop supply chain considering government collection’s policy. Sci Iran

Huang E, Goetschalckx M (2014) Strategic robust supply chain design based on the Pareto-optimal tradeoff between efficiency and risk. Eur J Oper Res 237(2):508–518

Huang L, Murong L, Wang W (2020) Green closed-loop supply chain network design considering cost control and CO2 emission. Modern Supply Chain Research and Applications 2(1):42–59

Irawan CA, Akbari N, Jones DF, Menachof D (2018) A combined supply chain optimisation model for the installation phase of offshore wind projects. Int J Prod Res 56(3):1189–1207

Jabbarzadeh A, Haughton M, Khosrojerdi A (2018) Closed-loop supply chain network design under disruption risks: a robust approach with real world application. Comput Ind Eng 116:178–191

Jalil SA, Hashmi N, Asim Z, Javaid S (2018a) A de-centralized bi-level multi-objective model for integrated production and transportation problems in closed-loop supply chain networks. Int J Manag Sci Eng Manag 14(3):206–217

Jalil SA, Javaid S, Muneeb SM (2018b) A decentralized multi-level decision making model for solid transportation problem with uncertainty. Int J Syst Assur Eng Manag 9(5):1022–1033

Karakama T, Kainuma Y (2013) Design of a global closed-loop supply chain model. J Jpn Ind Manag Assoc 64(2E):366–375

Kaya O, Urek B (2016) A mixed integer nonlinear programming model and heuristic solutions for location, inventory and pricing decisions in a closed loop supply chain. Comput Oper Res 65:93–103

Keyvanshokooh E, Ryan SM, Kabir E (2016) Hybrid robust and stochastic optimization for closed-loop supply chain network design using accelerated Benders decomposition. Eur J Oper Res 249(1):76–92

Khan SAR, Yu Z, Golpira H, Sharif A, Mardani A (2021) A state-of-the-art review and meta-analysis on sustainable supply chain management: future research directions. J Clean Prod 278:123357

Khan SAR, Yu Z, Sharif A, Golpîra H (2020) Determinants of economic growth and environmental sustainability in South Asian Association for Regional Cooperation: evidence from panel ARDL. Environ Sci Pollut Res 27(36):45675–45687

Khattry B, Rao JM (2002) Fiscal faux pas?: an analysis of the revenue implications of trade liberalization. World Dev 30(8):1431–1444

Kim J, Do Chung B, Kang Y, Jeong B (2018) Robust optimization model for closed-loop supply chain planning under reverse logistics flow and demand uncertainty. J Clean Prod 196:1314–1328

Krug Z, Guillaume R, Battaïa O (2021) Exploring the opportunities in establishing a closed-loop supply chain under uncertainty. Int J Prod Res 59(5):1606–1625

Kwak D-W, Rodrigues VS, Mason R, Pettit S, Beresford A (2018) Risk interaction identification in international supply chain logistics. Int J Oper Prod Manag 38(2)

Li H (2015) A genetic algorithm using a finite search space for solving nonlinear/linear fractional bilevel programming problems. Ann Oper Res 235(1):543–558

Li S, Wang L (2010) Outsourcing and capacity planning in an uncertain global environment. Eur J Oper Res 207(1):131–141

Liu P, Hendalianpour A, Hafshejani MF, Yaghoobi F, Feylizadeh M (2022) System dynamics model: developing model for supplier selection with a focus on CSR criteria. Complex Intell. Syst. https://doi.org/10.1007/s40747-022-00788-5

Longinidis P, Georgiadis MC, Kozanidis G (2015) Integrating operational hedging of exchange rate risk in the optimal design of global supply chain networks. Ind Eng Chem Res 54(24):6311–6325

Lotfi R, Nazarpour H, Gharehbaghi A, Sarkhosh SMH, Khanbaba A (2022) Viable closed-loop supply chain network by considering robustness and risk as a circular economy. 29:70285–70304. https://doi.org/10.1007/s11356-022-20713-0

Ma L, Liu Y, Liu Y (2020) Distributionally robust design for bicycle-sharing closed-loop supply chain network under risk-averse criterion. J Clean Prod 246:118967

Magazzino C, Alola AA, Schneider N (2021) The trilemma of innovation, logistics performance, and environmental quality in 25 topmost logistics countries: a quantile regression evidence. J Clean Prod 322:129050

MahmoumGonbadi A, Genovese A, Sgalambro A (2021) Closed-loop supply chain design for the transition towards a circular economy: a systematic literature review of methods, applications and current gaps. J Clean Prod 323:129101

Mahmud P, Paul SK, Azeem A, Chowdhury P (2021) Evaluating supply chain collaboration barriers in small-and medium-sized enterprises. Sustainability 13(13):7449

Manuj I, Mentzer JT (2008) Global supply chain risk management strategies. Int J Phys Distrib Logist Manag 38.3:192

Mao X, Zhang J, Cheng TE, Liu Y (2022) How to choose a downstream partner for a manufacturer considering firms’ personal traits? IEEE Trans Eng Manag. 1–13. https://doi.org/10.1109/TEM.2022.3160279

Meixell MJ, Gargeya VB (2005) Global supply chain design: a literature review and critique. Transp Res E Logist Transp Rev 41(6):531–550

Mele M, Magazzino C (2021) Pollution, economic growth, and COVID-19 deaths in India: a machine learning evidence. Environ Sci Pollut Res 28(3):2669–2677

Mele M, Magazzino C, Schneider N, Gurrieri AR, Golpira H (2022) Innovation, income, and waste disposal operations in Korea: evidence from a spectral granger causality analysis and artificial neural networks experiments. 39:427–459. https://doi.org/10.1007/s40888-022-00261-z

Mirzapour Al-E-Hashem S, Malekly H, Aryanezhad M (2011) A multi-objective robust optimization model for multi-product multi-site aggregate production planning in a supply chain under uncertainty. Int J Prod Econ 134(1):28–42

Mishra M, Hota SK, Ghosh SK, Sarkar B (2020) Controlling waste and carbon emission for a sustainable closed-loop supply chain management under a cap-and-trade strategy. Mathematics 8(4):466

Nagao T, Ijuin H, Yamada T, Nagasawa K, Zhou L (2021) COVID-19 disruption strategy for redesigning global supply chain network across TPP countries. Logistics 6(1):2

Nagurney A, Besik D, Nagurney LS (2019) Global supply chain networks and tariff rate quotas: equilibrium analysis with application to agricultural products. J Glob Optim 75(2):439–460

Nakamura K, Ijuin H, Yamada T, Ishigaki A, Inoue M (2018) Modeling of global supply chain network with trans-pacific partnership. J Soc Plant Eng Jpn 30(3):69–81

Nakamura K, Yamada T, Tan KH (2019) The impact of Brexit on designing a material-based global supply chain network for Asian manufacturers. Manag Environ Qual Intern J 30(5)

Oliveira LS, Machado RL (2021) Application of optimization methods in the closed-loop supply chain: a literature review. J Comb Optim 41(2):357–400

Özkır V, Başlıgil H (2013) Multi-objective optimization of closed-loop supply chains in uncertain environment. J Clean Prod 41:114–125

Panchal GB, Mirzahosseinian H, Tiwari S, Kumar A, Mangla SK (2022) Supply chain network redesign problem for major beverage organization in ASEAN region. Ann Oper Res 1–32. https://doi.org/10.1007/s10479-022-04571-0

Phetsuksiri B, Srisungngam S, Rudeeaneksin J, Boonchu S, Klayut W, Norrarat R, . . . Kasetjaroen Y (2018) QuantiFERON-TB Gold In-Tube test in active tuberculosis patients and healthy adults. Rev Inst Med trop S Paulo 60. https://doi.org/10.1590/S1678-9946201860056

Pourjavad E, Mayorga R (2018) Optimization of a sustainable closed loop supply chain network design under uncertainty using multi-objective evolutionary algorithms. Adv Prod Eng Manag 13(2):216–228

Prakash S, Kumar S, Soni G, Jain V, Rathore APS (2018) Closed-loop supply chain network design and modelling under risks and demand uncertainty: an integrated robust optimization approach. Ann Oper Res1–28

Quintens L, Pauwels P, Matthyssens P (2006) Global purchasing: state of the art and research directions. J Purch Supply Manag 12(4):170–181

Rad RS, Nahavandi N (2018) A novel multi-objective optimization model for integrated problem of green closed loop supply chain network design and quantity discount. J Clean Prod 196:1549–1565

Rahimi M, Ghezavati V (2018) Sustainable multi-period reverse logistics network design and planning under uncertainty utilizing conditional value at risk (CVaR) for recycling construction and demolition waste. J Clean Prod 172:1567–1581

Rahimi M, Ghezavati V, Asadi F (2019) A stochastic risk-averse sustainable supply chain network design problem with quantity discount considering multiple sources of uncertainty. Comput Ind Eng 130:430–449

Rahmanzadeh S, Pishvaee MS, Govindan K (2022) Emergence of open supply chain management: the role of open innovation in the future smart industry using digital twin network. Ann Oper Resh 1–29. https://doi.org/10.1007/s10479-021-04254-2

Ras PJ, Vermeulen WJ (2009) Sustainable production and the performance of South African entrepreneurs in a global supply chain. The case of South African table grape producers. Sustain Dev 17(5):325–340

Reich J, Kinra A, Kotzab H, Brusset X (2021) Strategic global supply chain network design–how decision analysis combining MILP and AHP on a Pareto front can improve decision-making. Int J Prod Res 59(5):1557–1572

Rezapour S, Farahani RZ, Fahimnia B, Govindan K, Mansouri Y (2015) Competitive closed-loop supply chain network design with price-dependent demands. J Clean Prod 93:251–272

Rockafellar RT, Uryasev S (2002) Conditional value-at-risk for general loss distributions. J Bank Finance 26(7):1443–1471

Rogers DS, Tibben-Lembke R (2001) An examination of reverse logistics practices. J Bus Logist 22(2):129–148

Rogers L (2009) Going in reverse to move forward. Mod Mater Handl 64(9):28–31

Rubio S, Corominas A (2008) Optimal manufacturing–remanufacturing policies in a lean production environment. Comput Ind Eng 55(1):234–242

Ruimin M, Lifei Y, Maozhu J, Peiyu R, Zhihan L (2016) Robust environmental closed-loop supply chain design under uncertainty. Chaos Solitons Fractals 89:195–202

Saedinia R, Vahdani B, Etebari F, Nadjafi BA (2019) Robust gasoline closed loop supply chain design with redistricting, service sharing and intra-district service transfer. Transp Res E Logist Transp Rev 123:121–141

Safaei S, Ghasemi P, Goodarzian F, Momenitabar M (2022) Designing a new multi-echelon multi-period closed-loop supply chain network by forecasting demand using time series model: a genetic algorithm. Environ Sci Pollut Res 1–15. https://doi.org/10.1007/s11356-022-19341-5

Sahling F, Kayser A (2016) Strategic supply network planning with vendor selection under consideration of risk and demand uncertainty. Omega 59:201–214

Salema MIG, Barbosa-Povoa AP, Novais AQ (2007) An optimization model for the design of a capacitated multi-product reverse logistics network with uncertainty. Eur J Oper Res 179(3):1063–1077

Saraeian S, Shirazi B, Motameni H (2019) Adaptive control of criticality infrastructure in automatic closed-loop supply chain considering uncertainty. Int J Crit Infrastruct Prot 25:102–124

Sharif A, Afshan S, Chrea S, Amel A, Khan SAR (2020) The role of tourism, transportation and globalization in testing environmental Kuznets curve in Malaysia: new insights from quantile ARDL approach. Environ Sci Pollut Res 27(20):25494–25509

Singh AR, Mishra P, Jain R, Khurana M (2012) Design of global supply chain network with operational risks. Int J Adv Manuf Technol 60(1–4):273–290

Singh RK, Kumar R (2020) Strategic issues in supply chain management of Indian SMEs due to globalization: an empirical study. Benchmarking Int J 27(3):913–932

Soleimani H, Kannan G (2015) A hybrid particle swarm optimization and genetic algorithm for closed-loop supply chain network design in large-scale networks. Appl Math Model 39(14):3990–4012

Soyster AL (1973) Convex programming with set-inclusive constraints and applications to inexact linear programming. Oper Res 21(5):1154–1157

Srinivasan M, Hamdani M, Ma S (2021) Four supply chain management systems: from supply chain strategies to human resource management. Bus Horiz 64(2):249–260

Sun H, Li J, Wang T, Xue Y (2022) A novel scenario-based robust bi-objective optimization model for humanitarian logistics network under risk of disruptions. Transp Res E Logist Transp Rev 157:102578

Talaei M, Moghaddam BF, Pishvaee MS, Bozorgi-Amiri A, Gholamnejad S (2016) A robust fuzzy optimization model for carbon-efficient closed-loop supply chain network design problem: a numerical illustration in electronics industry. J Clean Prod 113:662–673

Taleizadeh AA, Mamaghan MK, Torabi SA (2018) A possibilistic closed-loop supply chain: pricing, advertising and remanufacturing optimization. Neural Comput Applic 32:1195–1215. https://doi.org/10.1007/s00521-018-3646-3

Tan E, Smith G, Saad M (2006) Managing the global supply chain: a SME perspective. Prod Plan Control 17(3):238–246

Thiele A (2004) A robust optimization approach to supply chains and revenue management. Massachusetts Institute of Technology. http://hdl.handle.net/1721.1/16693

Tosarkani BM, Amin SH (2019) An environmental optimization model to configure a hybrid forward and reverse supply chain network under uncertainty. Comput Chem Eng 121:540–555

Tsiakis P, Papageorgiou LG (2008) Optimal production allocation and distribution supply chain networks. Int J Prod Econ 111(2):468–483

Urata T, Yamada T, Itsubo N, Inoue M (2017a) Global supply chain network design and Asian analysis with material-based carbon emissions and tax. Comput Ind Eng 113:779–792

Validi S, Bhattacharya A, Byrne P (2014) A case analysis of a sustainable food supply chain distribution system—a multi-objective approach. Int J Prod Econ 152:71–87

Vicente LN, Calamai PH (1994) Bilevel and multilevel programming: a bibliography review. J Global Optim 5(3):291–306

Wang Q, Chen K, Wang S, Cao X (2022) Optimal decisions in a closed-loop supply chain: fairness concerns, corporate social responsibility and information value. Ann Oper Res 309(1):277–304

Wu M, Zhu SX, Teunter RH (2013) The risk-averse newsvendor problem with random capacity. Eur J Oper Res 231(2):328–336

Xu Z, Elomri A, Pokharel S, Zhang Q, Ming X, Liu W (2017) Global reverse supply chain design for solid waste recycling under uncertainties and carbon emission constraint. Waste Manag 64:358–370

Yang T, Fu C, Liu X, Pei J, Liu L, Pardalos PM (2018) Closed-loop supply chain inventory management with recovery information of reusable containers. J Comb Optim 35(1):266–292

Yildizbaşi A, Çalik A, Paksoy T, Farahani RZ, Weber G-WJT, Economy EDo (2018) Multi-level optimization of an automotive closed-loop supply chain network with interactive fuzzy programming approaches. Technol Econ Dev Econ 24(3):1004–1028

Yousefi A, Pishvaee M, Teimoury E (2021) Adjusting the credit sales using CVaR-based robust possibilistic programming approach. Iran J Fuzzy Syst 18(1):117–136

Yousefi A, Pishvaee MS (2018) A fuzzy optimization approach to integration of physical and financial flows in a global supply chain under exchange rate uncertainty. Int J Fuzzy Syst 20(8):2415–2439

Yu Z, Waqas M, Tabish M, Tanveer M, Haq IU, Khan SAR (2022) Sustainable supply chain management and green technologies: a bibliometric review of literature. Environ Sci Pollut Res 29:58454–58470. https://doi.org/10.1007/s11356-022-21544-9

Zeballos LJ, Méndez CA, Barbosa-Povoa AP, Novais AQ (2014) Multi-period design and planning of closed-loop supply chains with uncertain supply and demand. Comput Chem Eng 66:151–164

Zeng AZ, Rossetti C (2003) Developing a framework for evaluating the logistics costs in global sourcing processes. Int J Phys Distrib Logist Manag 33(9/10):785

Zhang A, Luo H, Huang GQ (2013) A bi-objective model for supply chain design of dispersed manufacturing in China. Int J Prod Econ 146(1):48–58

Zhen L, Huang L, Wang W (2019) Green and sustainable closed-loop supply chain network design under uncertainty. J Clean Prod 227:1195–1209

Author information

Authors and Affiliations

Contributions

The author confirms sole responsibility for the study conception and design, data collection, analysis and interpretation of results, and manuscript preparation.

Corresponding author

Ethics declarations

Ethical approval

The manuscript has not been submitted to any other publication for simultaneous consideration. The submitted work is original and it has not been published elsewhere in any form or language (partially or in full), unless the new work concerns an expansion of previous work. A single study has not been split up into several parts to increase the number of submissions and submitted to various publications or one publication over time. Results have been presented clearly, honestly, and without fabrication, falsification, or inappropriate data manipulation. I adhere to discipline-specific rules for acquiring, selecting, and processing data. No data, text, or theories by others are presented as if they were the author’s own (“plagiarism”).

Conflict of interest

I wish to confirm that there are no known conflicts of interest associated with this publication and there has been no significant financial support for this work that could have influenced its outcome.

Additional information

Responsible Editor: Arshian Sharif

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Golpîra, H. Closing the loop of a global supply chain through a robust optimal decentralized decision support system. Environ Sci Pollut Res 30, 89975–90005 (2023). https://doi.org/10.1007/s11356-022-23176-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-23176-5