Abstract

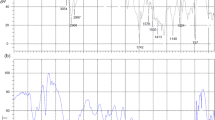

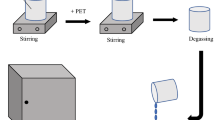

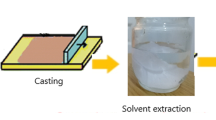

In this study, the polymeric membranes were prepared using discarded polyethylene terephthalate (PET) bottles. The fabrication of the membrane process was carried out using a dope solution composed of polyethylene terephthalate (polymer), O-cresol (as a solvent), and polyethylene glycol 400 (as an additive). The solubility parameters were studied to dissolve the polymer into the solvent at a specific temperature. The melt flow index and thermal analysis were evaluated for the discarded bottles and prepared membranes to ensure the quality and thermal stability of the PET. The porosity of the membranes was determined using scanning electron microscopy. The temperature required to prepare the dope solution was 80 °C with a stirring speed of 350 rpm. Non-solvent-induced phase separation method was used to fabricate the membranes. The coagulation bath was composed of a water–ethanol mixture. The porosity of the prepared membranes ranges between 30 and 50%. The contact angle was determined for the membrane in the range of 40° to 80°. The flux of the membranes was evaluated using membrane testing cell at a specified pressure which ranges from 80 to 150 Lm−2 h−1. The prepared membranes could be used in various industries like dairy, pharmaceutical, juice, and beverages to separate temperature-sensitive substances.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting the findings of this study are available within the article. Raw data that support the findings of this study are available from corresponding author, upon reasonable request.

References

Al-Ani DM, Al-Ani FH, Alsalhy QF, Ibrahim SS (2021) Preparation and characterization of ultrafiltration membranes from PPSU-PES polymer blend for dye removal. Chem Eng Commun 208:41–59. https://doi.org/10.1080/00986445.2019.1683546

Alvi MAUR, Khalid MW, Ahmad NM et al (2019) Polymer concentration and solvent variation correlation with the morphology and water filtration analysis of polyether sulfone microfiltration membrane. Adv Polym Technol 2019:8074626. https://doi.org/10.1155/2019/8074626

Awaja F, Pavel D (2005) Recycling of PET. Eur Polym J 41:1453–1477. https://doi.org/10.1016/j.eurpolymj.2005.02.005

Bildyukevich A, Plisko T, Shustikov A, et al (2020) Effect of the solvent nature on the structure and performance of poly(amide-imide) ultrafiltration membranes. J Mater Sci 55https://doi.org/10.1007/s10853-020-04714-3

Cassano A, Conidi C, Ruby-Figueroa R, Castro-Muñoz R (2018) Nanofiltration and tight ultrafiltration membranes for the recovery of polyphenols from agro-food by-products. Int J Mol Sci 19https://doi.org/10.3390/ijms19020351

Chen J, Shen L, Zhang M et al (2016) Thermodynamic analysis of effects of contact angle on interfacial interactions and its implications for membrane fouling control. Bioresour Technol 201:245–252. https://doi.org/10.1016/j.biortech.2015.11.063

Chen D, Sirkar KK, Jin C et al (2017) Membrane-based technologies in the pharmaceutical industry and continuous production of polymer-coated crystals/particles. Curr Pharm Des 23:242–249

Dhawan G (2020) About ultrafiltration. Applied Membrane Inc. https://appliedmembranes.com/media/wysiwyg/pdf/systems/about_ultrafiltration_technical_article.pdf. Accessed 10 Jan 2022

Elamri A, Abid K, Harzallah O, Lallam A (2015) Characterization of recycled / virgin PET polymers and their composites. 3:11–16 https://doi.org/10.11648/j.nano.s.2015030401.13

Figoli A, Marino T, Galiano F (2016) Polymeric membranes in biorefinery. In: Figoli A, Cassano A, Basile A (eds) Membrane Technologies for Biorefining. Woodhead Publishing, pp 29–59

Fink JK (2012) Chapter 21 - dispersions, emulsions, and foams. In: Fink JK (ed) Petroleum Engineer’s Guide to Oil Field Chemicals and Fluids. Gulf Professional Publishing, Boston, pp 663–694

Geyer R, Jambeck JR, Law KL (2017) Production, use, and fate of all plastics ever made. Sci Adv 3:e1700782. https://doi.org/10.1126/sciadv.1700782

Hansen CM (1967) The three dimensional solubility parameter and solvent diffusion coefficient. Dissertation, The Polytechnic Danish University of Technology

Hendrix K, Vaneynde M, Vankelecom I (2013) Synthesis of modified poly(ether ether ketone) polymer for the preparation of ultrafiltration and nanofiltration membranes via phase inversion. J Memb Sci 447:96–106. https://doi.org/10.1016/j.memsci.2013.07.006

Imdad S, Dohare RK (2022) A critical review on heavy metals removal using ionic liquid membranes from the industrial wastewater. Chem Eng Process - Process Intensif 173:108812. https://doi.org/10.1016/j.cep.2022.108812

Ismail N, Jakariah N, Bolong N, et al (2017) Effect of polymer concentration on the morphology and mechanical properties of asymmetric polysulfone (PSf) membrane. J Appl Membr Sci Technol 21 https://doi.org/10.11113/amst.v21i1.107

Kahrs C, Gühlstorf T, Schwellenbach J (2020) Influences of different preparation variables on polymeric membrane formation via nonsolvent induced phase separation. J Appl Polym Sci 137:48852. https://doi.org/10.1002/app.48852

Kumar V, Singh R, Ahuja IPS (2022) Use of thermosetting polymers for smart civil structures. In: Encyclopedia of materials: plastics and polymers. Elsevier, pp 662–669. https://doi.org/10.1016/B978-0-12-820352-1.00067-5

Kusumocahyo SP, Ambani SK, Marceline S (2021) Improved permeate flux and rejection of ultrafiltration membranes prepared from polyethylene terephthalate (PET) bottle waste. Sustain Environ Res 31:19. https://doi.org/10.1186/s42834-021-00091-x

Latthe SS, Terashima C, Nakata K, Fujishima A (2014) Superhydrophobic surfaces developed by mimicking hierarchical surface morphology of lotus leaf. Molecules 19:4256–4283. https://doi.org/10.3390/molecules19044256

Li P (2017) Effect of polymer dope concentration on the morphology and performance of PES/PDMS hollow fiber composite membrane for gas separation. Juniper Online J Mater Sci 1:1–5. https://doi.org/10.19080/jojms.2017.01.555573

Ma Y, Shi F, Ma J et al (2011) Effect of PEG additive on the morphology and performance of polysulfone ultrafiltration membranes. Desalination 272:51–58. https://doi.org/10.1016/j.desal.2010.12.054

McKeen L (2012) Introduction to the physical, mechanical, and thermal properties of plastics and elastomers. In: McKeen L (ed) The Effect of Sterilization on Plastics and Elastomers, 3rd edn. William Andrew Publishing, Boston, pp 57–84

Mohammad AW, Ng CY, Lim YP, Ng GH (2012) Ultrafiltration in food processing industry: review on application, membrane fouling, and fouling control. Food Bioprocess Technol 5:1143–1156. https://doi.org/10.1007/s11947-012-0806-9

Mulder M (1997) Basic principles of membrane technology, 2nd edn. Kluwer Academic Publishers, Dordrecht, p 564

Plastics Europe, EPRO (2016) Plastics – the facts 2016: an analysis of European plastics production, demand and waste data. PlasticsEurope. https://plasticseurope.org/wp-content/uploads/2021/10/2016-Plastic-the-facts.pdf. Accessed 20 Jan 2022

Pulido BA, Habboub OS, Aristizabal SL et al (2019) Recycled poly(ethylene terephthalate) for high temperature solvent resistant membranes. ACS Appl Polym Mater 1:2379–2387. https://doi.org/10.1021/acsapm.9b00493

Rabiee H, Vatanpour V, Borghei SM (2015) Fouling reduction of emulsion polyvinylchloride ultrafiltration membranes blended by PEG: The effect of additive concentration and coagulation bath temperature. Desalin water Treat 57. https://doi.org/10.1080/19443994.2015.1048739

Rajesh S, Murthy ZVP (2014) Ultrafiltration membranes from waste polyethylene terephthalate and additives: synthesis and characterization. Quim Nova 37:653–657. https://doi.org/10.5935/0100-4042.20140097

Singh R (2015) Introduction to membrane technology. Membrane technology and engineering for water purification, pp 1–80. https://doi.org/10.1016/b978-0-444-63362-0.00001-x

Sofiah H, Nora`aini A, Marinah MA (2010) The influence of polymer concentration on performance and morphology of asymmetric ultrafiltration membrane for lysozyme separation. J Appl Sci 10:3325–3330. https://doi.org/10.3923/jas.2010.3325.3330

Spear MJ, Eder A, Carus M (2015) Wood polymer composites. In: Ansell MP (ed) Wood Composites. Woodhead Publishing, pp 195–249

Sulyman M, Haponiuk J, Formela K (2016) Utilization of recycled polyethylene terephthalate (PET) in engineering materials: a review. Int J Environ Sci Dev 7:100–108. https://doi.org/10.7763/ijesd.2016.v7.749

Tiab D, Donaldson EC (2012) Wettability. In: Tiab D, Donaldson EC (eds) Petrophysics, 3rd edn. Gulf Professional Publishing, Boston, pp 371–418

Wang C, Xiao C, Huang Q, Pan J (2015) A study on structure and properties of poly(p-phenylene terephthamide) hybrid porous membranes. J Memb Sci 474:132–139. https://doi.org/10.1016/j.memsci.2014.09.055

Williams M (2013) The Merck Index: an encyclopedia of chemicals, drugs, and biologicals, 15th Edition Edited by M.J.O’Neil, Royal Society of Chemistry, Cambridge, UK ISBN 9781849736701; 2708 pages. April 2013, $150 with 1-year free access to The Merck Index Online. Drug Dev Res 74:339–339. https://doi.org/10.1002/ddr.21085

Author information

Authors and Affiliations

Contributions

R. K. D. and S. I. contributed to the design and implementation of the research, to the analysis of the results, and to the writing of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

Informed consent was obtained prior to performing the procedure including permission for publication of all images and data included herein.

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Angeles Blanco

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Waste plastic bottles were used to synthesis ultrafiltration membrane using NIPS method.

• Porosity of the membrane lies between 40 andto 50% percent.

• Membrane flux ranges between 80 and 150 Lm−2 h−1 at an operating pressure of 2 bar.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Imdad, S., Dohare, R.K. Preparation of ultrafiltration membrane from discarded polyethylene terephthalate bottles. Environ Sci Pollut Res 30, 42728–42737 (2023). https://doi.org/10.1007/s11356-022-23068-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-23068-8