Abstract

Cemented tailings backfill (CTB) is widely adopted to ensure the safety of underground goafs and mitigate environmental risks. Fly ash (FA) and calcium formate (CF) are common industrial by-products that improve the mechanical performance of CTB. How the coupling of the two components affects the strength development is not yet well-understood. Neural network modelling was conducted to predict the strength development, including the static indicator of uniaxial compressive strength (UCS) and the dynamic indicator of ultrasonic pulse velocity (UPV). Sobol’ sensitivity analysis was carried out to reveal the contributions of FA, CF and curing time to CTB strength. SEM microstructure investigation on CTB samples was implemented to reveal the mechanism of strength development and justify the predictions by neural network modelling and sensitivity analysis. Results show that the combination of FA content, CF content and curing time can be used to predict both UCS and UPV while providing adequate accuracy. The maximum of UCS of 6.1215 MPa is achieved at (FA content, CF content, curing time) = (13.78 w%, 3.76 w%, 28 days), and the maximum of UPV of 2.9887 km/s is arrived at (FA content, CF content, curing time) = (11.67 w%, 3.08 w%, 10 days). It is also implicated that prediction of UCS using UPV alone, although common in field application is not recommended. However, UPV measurement, in combination with the information of FA dosage, CF dosage and curing time, could be used to improve UCS prediction. The rank of variable significance for UCS is curing time > FA content > CF content, and for UPV is FA content > curing time > CF content; variable interaction is strongest for FA with CF for UCS development, and for FA with curing time for UPV evolution. Influence of FA on CTB strength development is due to improved polymerisation and consumption of Ca(OH)2. Influence of CF on strength development is a result of accelerated hydration and increased combined-water content in calcium silicate hydrate (CSH). Effect of curing time is attributed to the evolution of CSH product and pore-water content during cement hydration.

Similar content being viewed by others

Data availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

Abbiati G, Marelli S, Tsokanas N, Sudret B, Stojadinović B (2021) A global sensitivity analysis framework for hybrid simulation. Mech Syst Signal Process 146:106997. https://doi.org/10.1016/j.ymssp.2020.106997

Behera SK, Ghosh CN, Mishra DP, Singh P, Mishra K, Buragohain J, Mandal PK (2020) Strength development and microstructural investigation of lead-zinc mill tailings based paste backfill with fly ash as alternative binder. Cement Concr Compos 109:103553. https://doi.org/10.1016/j.cemconcomp.2020.103553

Belibi Tana AE, Yin S, Wang L (2021) Investigation on mechanical characteristics and microstructure of cemented whole tailings backfill. Minerals 11(6):592

Benzaazoua M, Belem T, Bussière B (2002) Chemical factors that influence the performance of mine sulphidic paste backfill. Cem Concr Res 32(7):1133–1144. https://doi.org/10.1016/S0008-8846(02)00752-4

Cao S, Xue G, Yilmaz E, Yin Z, Yang F (2021a) Utilizing concrete pillars as an environmental mining practice in underground mines. J Clean Prod 278:123433. https://doi.org/10.1016/j.jclepro.2020.123433

Cao S, Yilmaz E, Yin Z, Xue G, Song W, Sun L (2021b) CT scanning of internal crack mechanism and strength behavior of cement-fiber-tailings matrix composites. Cement Concr Compos 116:103865. https://doi.org/10.1016/j.cemconcomp.2020.103865

Chen L, Jiang L, Liu X, Xu P, Meng Y, Ben X, Jin W, Chen C, Zhi F (2021) Understanding the role of calcium formate towards hydration and deformation property of light-burned magnesia cement. Constr Build Mater 289:122995. https://doi.org/10.1016/j.conbuildmat.2021.122995

Ercikdi B, Yılmaz T, Külekci G (2014) Strength and ultrasonic properties of cemented paste backfill. Ultrasonics 54(1):195–204. https://doi.org/10.1016/j.ultras.2013.04.013

Fall M, Benzaazoua M, Saa EG (2008) Mix proportioning of underground cemented tailings backfill. Tunn Undergr Space Technol 23(1):80–90. https://doi.org/10.1016/j.tust.2006.08.005

Galaa AM, Thompson BD, Grabinsky MW, Bawden WF (2011) Characterizing stiffness development in hydrating mine backfill using ultrasonic wave measurements. Can Geotech J 48(8):1174–1187. https://doi.org/10.1139/t11-026

Guo Z, Qiu J, Jiang H, Xing J, Sun X, Ma Z (2021) Flowability of ultrafine-tailings cemented paste backfill incorporating superplasticizer: Insight from water film thickness theory. Powder Technol 381:509–517. https://doi.org/10.1016/j.powtec.2020.12.035

He Y, Chen Q, Qi C, Zhang Q, Xiao C (2019) Lithium slag and fly ash-based binder for cemented fine tailings backfill. J Environ Manage 248:109282. https://doi.org/10.1016/j.jenvman.2019.109282

Heikal M (2004) Effect of calcium formate as an accelerator on the physicochemical and mechanical properties of pozzolanic cement pastes. Cem Concr Res 34(6):1051–1056. https://doi.org/10.1016/j.cemconres.2003.11.015

Hu C, Li Z (2015) A review on the mechanical properties of cement-based materials measured by nanoindentation. Constr Build Mater 90:80–90. https://doi.org/10.1016/j.conbuildmat.2015.05.008

Huang Z, Yilmaz E, Cao S (2021) Analysis of strength and microstructural characteristics of mine backfills containing fly ash and desulfurized gypsum. Minerals 11(4):409

Jiang H, Han J, Li Y, Yilmaz E, Sun Q, Liu J (2020a) Relationship between ultrasonic pulse velocity and uniaxial compressive strength for cemented paste backfill with alkali-activated slag. Nondestruct Test Eval 35(4):359–377. https://doi.org/10.1080/10589759.2019.1679140

Jiang H, Yi H, Yilmaz E, Liu S, Qiu J (2020b) Ultrasonic evaluation of strength properties of cemented paste backfill: Effects of mineral admixture and curing temperature. Ultrasonics 100:105983. https://doi.org/10.1016/j.ultras.2019.105983

Li J, Cao S, Yilmaz E (2022) Characterization of macro mechanical properties and microstructures of cement-based composites prepared from fly ash, gypsum and steel slag. Minerals 12(1):6

Ma BG, Chen FJ, Zhang BL, Lin CL (2014) The design and application of ballastless track enhanced concrete mineral admixture. Appl Mech Mater 638–640:1427–1430. https://doi.org/10.4028/www.scientific.net/AMM.638-640.1427

Marelli S, Lamas C, Konakli K, Mylonas C, Wiederkehr P, Sudret B (2021) UQLab user manual – sensitivity analysis, Report # UQLab-V1.4–106, Chair of Risk, Safety and Uncertainty Quantification, ETH Zurich, Switzerland.

Miao X, Gerke KM, Sizonenko TO (2017) A new way to parameterize hydraulic conductances of pore elements: a step towards creating pore-networks without pore shape simplifications. Adv Water Resour 105:162–172. https://doi.org/10.1016/j.advwatres.2017.04.021

Orejarena L, Fall M (2011) Artificial neural network based modeling of the coupled effect of sulphate and temperature on the strength of cemented paste backfill. Can J Civ Eng 38(1):100–109. https://doi.org/10.1139/l10-109

Qi C, Fourie A, Chen Q, Zhang Q (2018) A strength prediction model using artificial intelligence for recycling waste tailings as cemented paste backfill. J Clean Prod 183:566–578. https://doi.org/10.1016/j.jclepro.2018.02.154

Qiu J, Guo Z, Yang L, Jiang H, Zhao Y (2020) Effect of tailings fineness on flow, strength, ultrasonic and microstructure characteristics of cemented paste backfill. Constr Build Mater 263:120645. https://doi.org/10.1016/j.conbuildmat.2020.120645

Sadrossadat E, Basarir H, Karrech A, Durham R, Fourie A, Bin H (2020) The optimization of cemented hydraulic backfill mixture design parameters for different strength conditions using artificial intelligence algorithms. In: Topal E (Hrsg.), the 28th International Symposium on Mine Planning and Equipment Selection - MPES 2019. Springer Series in Geomechanics and Geoengineering. Springer

Sasmal S, Anoop MB (2019) 7 - Nanoindentation for evaluation of properties of cement hydration products. In: Pacheco-Torgal F et al. (Editors), Nanotechnology in Eco-efficient Construction (Second Edition). Woodhead Publishing, pp. 141-161

Singh NB, Abha K (1983) Effect of calcium formate on the hydration of tricalcium silicate. Cem Concr Res 13(5):619–625. https://doi.org/10.1016/0008-8846(83)90050-9

Sobol IM (1993) Sensitivity estimates for nonlinear mathematical models. Math Model Comput Exp 4:407–414

Sun W, Wang H, Hou K (2018) Control of waste rock-tailings paste backfill for active mining subsidence areas. J Clean Prod 171:567–579. https://doi.org/10.1016/j.jclepro.2017.09.253

Wang B, Li L, Yu Y, Huo B, Liu J, Liu J (2021a) Analysis of damage failure in uniaxial compressive of cemented paste backfill by ultrasonic pulse velocity test. Rev Int Métodos Numér Cálc Diseño Ing 37(2):27

Wang J, Fu J, Song W, Zhang Y (2021b) Viscosity and strength properties of cemented tailings backfill with fly ash and its strength predicted. Minerals 11(1):78

Wang S, Song X, Wei M, Liu W, Wang X, Ke Y, Tao T (2021c) Strength characteristics and microstructure evolution of cemented tailings backfill with rice straw ash as an alternative binder. Constr Build Mater 297:123780. https://doi.org/10.1016/j.conbuildmat.2021.123780

Wu D, Zhang Y, Liu Y (2016) Mechanical performance and ultrasonic properties of cemented gangue backfill with admixture of fly ash. Ultrasonics 64:89–96. https://doi.org/10.1016/j.ultras.2015.08.004

Wu J, Jing H, Yin Q, Yu L, Meng B, Li S (2020) Strength prediction model considering material, ultrasonic and stress of cemented waste rock backfill for recycling gangue. J Clean Prod 276:123189. https://doi.org/10.1016/j.jclepro.2020.123189

Wu J, Jing H, Gao Y, Meng Q, Yin Q, Du Y (2022) Effects of carbon nanotube dosage and aggregate size distribution on mechanical property and microstructure of cemented rockfill. Cement Concrete Comp 127:104408. https://doi.org/10.1016/j.cemconcomp.2022.104408

Xu W, Li Q, Haruna S (2019) The effect of calcium formate, sodium sulfate, and cement clinker on engineering properties of fly ash-based cemented tailings backfill. Advances in Materials Science and Engineering 2019: 5370360https://doi.org/10.1155/2019/5370360

Xu W, Zhang Y, Zuo X, Hong M (2020) Time-dependent rheological and mechanical properties of silica fume modified cemented tailings backfill in low temperature environment. Cement Concr Compos 114:103804. https://doi.org/10.1016/j.cemconcomp.2020.103804

Xu W, Chen W, Tian M, Guo L (2021) Effect of temperature on time-dependent rheological and compressive strength of fresh cemented paste backfill containing flocculants. Constr Build Mater 267:121038. https://doi.org/10.1016/j.conbuildmat.2020.121038

Yan B, Zhu W, Hou C, Yilmaz E, Saadat M (2020) Characterization of early age behavior of cemented paste backfill through the magnitude and frequency spectrum of ultrasonic P-wave. Constr Build Mater 249:118733. https://doi.org/10.1016/j.conbuildmat.2020.118733

Yılmaz T, Ercikdi B, Karaman K, Külekçi G (2014) Assessment of strength properties of cemented paste backfill by ultrasonic pulse velocity test. Ultrasonics 54(5):1386–1394. https://doi.org/10.1016/j.ultras.2014.02.012

Yin S, Chen W, Wang Y (2021) Effect of mixed bacteria on cemented tailings backfill: Economic potential to reduce binder consumption. J Hazard Mater 411:125114. https://doi.org/10.1016/j.jhazmat.2021.125114

Yu Z, Shi X-z, Chen X, Zhou J, Qi C-c, Chen Q-s, Rao D-j (2021) Artificial intelligence model for studying unconfined compressive performance of fiber-reinforced cemented paste backfill. Trans Nonferrous Met Soc China 31(4):1087–1102. https://doi.org/10.1016/S1003-6326(21)65563-2

Zhao Y, Taheri A, Soltani A, Karakus M, Deng A (2019) Strength development and strain localization behavior of cemented paste backfills using portland cement and fly ash. Materials 12(20):3282

Zhao Y, Taheri A, Karakus M, Chen Z, Deng A (2020) Effects of water content, water type and temperature on the rheological behaviour of slag-cement and fly ash-cement paste backfill. Int J Min Sci Technol 30(3):271–278. https://doi.org/10.1016/j.ijmst.2020.03.003

Funding

This work is supported by the National Natural Science Foundation of China projects (52004272, 52061135111, 52122404), Natural Science Foundation of Jiangsu Province project (BK20200660), China Postdoctoral Science Foundation projects (2020M680073, 2019M661987), Fundamental Research Funds for the Central Universities (2022QN1035) and Open Sharing Fund for the Large-scale Instruments and Equipment of China University of Mining and Technology project (DYGX-2021–079).

Author information

Authors and Affiliations

Contributions

Xiuxiu Miao: Software—programming and validation, visualisation and formal analysis, writing—original draft. Jiangyu Wu: Conceptualisation and methodology—experiment, Data curation, writing—original draft, funding acquisition. Yiming Wang: Implementation of the experiment. Da Ma: Conceptualisation and methodology—numerical modelling. Hai Pu: Resources, funding acquisition, writing—review and editing, supervision.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent to publish

All authors approved the version to be published.

Competing interests

The authors no competing interests.

Additional information

Responsible Editor: Philippe Garrigues

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix 1 Primary experimental results

Appendix 1 Primary experimental results

Presented in Table

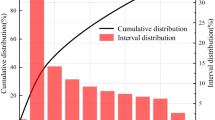

Table 4 is the raw data of UPV and UCS measurements on 256 cement specimens produced under different levels of fly ash dosage, calcium formate dosage and curing time. Figure 2 is produced from Table 4.

Rights and permissions

About this article

Cite this article

Miao, X., Wu, J., Wang, Y. et al. Coupled effects of fly ash and calcium formate on strength development of cemented tailings backfill. Environ Sci Pollut Res 29, 59949–59964 (2022). https://doi.org/10.1007/s11356-022-20131-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-022-20131-2