Abstract

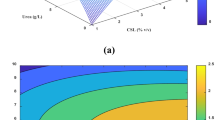

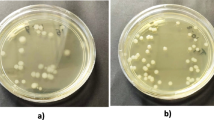

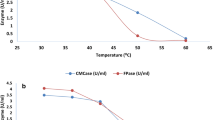

To commercialize the biocementation through microbial induced carbonate precipitation (MICP), the current study aimed at replacing the costly standard nutrient medium with corn steep liquor (CSL), an inexpensive bio-industrial by-product, on the production of urease enzyme by Sporosarcina pasteurii (PTC 1845). Multiple linear regression (MLR) in linear and quadratic forms, adaptive neuro-fuzzy inference system (ANFIS), and genetic programming (GP) were used for modeling of process based on the experimental data for improving the urease activity (UA). In these models, CSL concentration, urea concentration, nickel supplementation, and incubation time as independent variables and UA as target function were considered. The results of modeling showed that the GP model had the best performance to predict the extent of urease, compared to other ones. The GP model had higher R2 as well as lower RSME in comparison with the models derived from ANFIS and MLR. Under the optimum conditions optimized by GP method, the maximum UA value of 3.6 Mm min–1 was also obtained for 5%v/v CSL concentration, 4.5 g L–1 urea concentration, 0 μM nickel supplementation, and 60 h incubation time. A good agreement between the outputs of GP model for the optimal UA and experimental result was obtained. Finally, a series of laboratory experiments were undertaken to evaluate the influence of biological cementation on the strengthening behavior of treated soil. The maximum shear stress improvement between bio-treated and untreated samples was 292% under normal stress of 55.5 kN as a result of an increase in interparticle cohesion parameters.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

Abbreviations

- R 2 :

-

Correlation coefficient

- y :

-

The value (real or normalized) of the independent variable

- X :

-

The value (real or normalized) of output variable

References

Achal V, Mukherjee A, Basu P, Reddy M (2009) Lactose mother liquor as an alternative nutrient source for microbial concrete production by Sporosarcina pasteurii. J Ind Microbiol Biotechnol 36:433–438. https://doi.org/10.1007/s10295-008-0514-7

Al-Thawadi S (2008) High strength in-situ biocementation of soil by calcite precipitating locally isolated ureolytic bacteria. Murdoch University, Dissertation

Amini Kiasari M, Pakbaz MS, Ghezelbash GR (2019) Comparison of effects of different nutrients on stimulating indigenous soil bacteria for biocementation. J Mater Civ Eng 31:04019067. https://doi.org/10.1061/(ASCE)MT.1943-5533.0002693

Asadzadeh F, Maleki-Kakelar M, Shabani F (2019) Predicting cationic exchange capacity in calcareous soils of East-Azerbaijan province, northwest Iran. Commun Soil Sci Plant Anal 50:1106–1116. https://doi.org/10.1080/00103624.2019.1604728

Azarhoosh MJ, Halladj R, Askari S (2017) Presenting a new kinetic model for methanol to light olefins reactions over a hierarchical SAPO-34 catalyst using the Langmuir–Hinshelwood–Hougen–Watson mechanism. J Phys Condens Matter 29:425202

Azarhoosh MJ, Halladj R, Askari S (2018) Application of evolutionary algorithms for modelling and optimisation of ultrasound-related parameters on synthesised SAPO-34 catalysts: crystallinity and particle size. Prog React Kinet Mech 43:236–243. https://doi.org/10.3184/146867818X15233705894446

Azarhoosh MJ, Halladj R, Askari S, Aghaeinejad-Meybodi A (2019) Performance analysis of ultrasound-assisted synthesized nano-hierarchical SAPO-34 catalyst in the methanol-to-lights-olefins process via artificial intelligence methods. Ultrason Sonochem 58:104646. https://doi.org/10.1016/j.ultsonch.2019.104646

Bachmeier KL, Williams AE, Warmington JR, Bang SS (2002) Urease activity in microbiologically-induced calcite precipitation. J Biotechnol 93:171–181. https://doi.org/10.1016/S0168-1656(01)00393-5

Barkouki T, Martinez B, Mortensen B et al (2011) Forward and inverse bio-geochemical modeling of microbially induced calcite precipitation in half-meter column experiments. Transp Porous Media 90:23–39. https://doi.org/10.1007/s11242-011-9804-z

Bingöl D, Inal M, Çetintaş S (2013) Evaluation of copper biosorption onto date palm (Phoenix dactylifera L.) seeds with MLR and ANFIS models. Ind Eng Chem Res 52:4429–4435. https://doi.org/10.1021/ie400484c

Chang I, Cho GC (2019) Shear strength behavior and parameters of microbial gellan gum-treated soils: from sand to clay. Acta Geotech 14:361–375. https://doi.org/10.1007/s11440-018-0641-x

Cheng L, Cord-Ruwisch R (2012) In situ soil cementation with ureolytic bacteria by surface percolation. Ecol Eng 42:64–72. https://doi.org/10.1016/j.ecoleng.2012.01.013

Cheng L, Cord-Ruwisch R (2013) Selective enrichment and production of highly urease active bacteria by non-sterile(open) chemostat culture. J Ind Microbiol Biotechnol 40:1095–1104. https://doi.org/10.1007/s10295-013-1310-6

Cuzman OA, Rescic S, Richter K, Wittig L, Tiano P (2015)Sporosarcina pasteurii use in extreme alkaline conditions for recycling solid industrial wastes. J Biotechnol 214:49–56. https://doi.org/10.1016/j.jbiotec.2015.09.011

DeJong JT, Mortensen BM, Martinez BC, Nelson DC (2010)Bio-mediated soil improvement. Ecol Eng 36:197–210. https://doi.org/10.1016/j.ecoleng.2008.12.029

DeJong JT, Soga K, Banwart SA et al (2011) Soil engineering in vivo: harnessing natural biogeochemical systems for sustainable, multi-functional engineering solutions. J R Soc Interface 8:1–15. https://doi.org/10.1098/rsif.2010.0270

Dupraz S, Parmentier M, Ménez B, Guyot F (2009) Experimental and numerical modeling of bacterially induced pH increase and calcite precipitation in saline aquifers. Chem Geol 265:44–53. https://doi.org/10.1016/j.chemgeo.2009.05.003

Faradonbeh RS, Armaghani DJ, Monjezi M, Mohamad ET (2016) Genetic programming and gene expression programming for flyrock assessment due to mine blasting. Int J Rock Mech Min Sci 88:254–264. https://doi.org/10.1016/j.ijrmms.2016.07.028

Goodman RE (1989) Introduction to rock mechanics. Wiley, New York

Hoek E (2007) Practical rock engineering. Online (ed) Rocscience. https://www.rocscience.com/learning/hoeks-corner/course-notes-books. Accessed 29 Sep 2021

Hull SR, Peters E, Cox C, Montgomery R (1996) Composition of corn steep water during experimental steeping. J Agric Food Chem 44:3521–3527. https://doi.org/10.1021/jf960320v

Jang JS (1993) ANFIS: adaptive-network-based fuzzy inference system. IEEE Trans Syst Man Cybern 23:665–685. https://doi.org/10.1109/21.256541

Joshi S, Goyal S, Reddy MS (2018) Corn steep liquor as a nutritional source for biocementation and its impact on concrete structural properties. J Ind Microbiol Biotechnol 45:657–667. https://doi.org/10.1007/s10295-018-2050-4

Khajeh A, Modarress H (2010) QSPR prediction of flash point of esters by means of GFA and ANFIS. J Hazard Mater 179:715–720. https://doi.org/10.1016/j.jhazmat.2010.03.060

Kiadehi AD, Taghizadeh M, Azarhoosh MJ, Aghaeinejad-Meybodi A (2020) Hydrogen production using ethylene glycol steam reforming in a micro-reformer: experimental analysis, multivariate polynomial regression and genetic programming modeling approaches. J Taiwan Inst Chem Eng 112:20–33. https://doi.org/10.1016/j.jtice.2020.07.012

Koza JR, Bennett FH, Andre D, Keane MA (2002) Genetic programming: biologically inspired computation that creatively solves non-trivial problems. In: Landweber LF, Winfree E (eds) Evolution as Computation, Natural Computing Series. Springer, Berlin, pp 95–124. https://doi.org/10.1007/978-3-642-55606-7_5

Koza JR, Koza JR (1992) Genetic programming: on the programming of computers by means of natural selection. MIT press

Lawford HG, Rousseau JD (1997) Corn steep liquor as a cost-effective nutrition adjunct in high-performanceZymomonas ethanol fermentations. Appl Biochem Biotechnol 63:287–304. https://doi.org/10.1007/BF02920431

Maleki M, Ebrahimi S, Asadzadeh F, Tabrizi ME (2016) Performance of microbial-induced carbonate precipitation on wind erosion control of sandy soil. Int J Environ Sci Technol 13:937–944. https://doi.org/10.1007/s13762-015-0921-z

Martinez B, DeJong J, Ginn T (2014)Bio-geochemical reactive transport modeling of microbial induced calcite precipitation to predict the treatment of sand in one-dimensional flow. Comput Geotech 58:1–13. https://doi.org/10.1016/j.compgeo.2014.01.013

Omoregie AI, Ngu LH, Ong DE, Nissom PM (2019)Low-cost cultivation of Sporosarcina pasteurii strain in food-grade yeast extract medium for microbially induced carbonate precipitation (MICP) application. Biocatal Agric Biotechnol 17:247–255. https://doi.org/10.1016/j.bcab.2018.11.030

Rahman MS, Rashid M, Hussain MA (2012) Thermal conductivity prediction of foods by Neural Network and Fuzzy (ANFIS) modeling techniques. Food Bioprod Process 90:333–340. https://doi.org/10.1016/j.fbp.2011.07.001

Song W, Yang Y, Qi R, Li J, Pan X (2019) Suppression of coal dust by microbially induced carbonate precipitation using Staphylococcus succinus. Environ Sci Pollut Res 26:35968–35977. https://doi.org/10.1007/s11356-019-06488-x

Stabnikov V, Naeimi M, Ivanov V, Chu J (2011) Formation of water-impermeable crust on sand surface using biocement. Cem Concr Res 41:1143–1149. https://doi.org/10.1016/j.cemconres.2011.06.017

Van Paassen L (2009) Biogrout, ground improvement by microbial induced carbonate precipitation. Dissertation. Delft University of Technology

Whiffin VS (2004) Microbial CaCO3 precipitation for the production of biocement. Dissertation. Murdoch University

Whiffin VS, van Paassen LA, Harkes MP (2007) Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol J 24:417–423. https://doi.org/10.1080/01490450701436505

Xiao P, Liu H, Xiao Y, Stuedlein AW, Evans TM (2018) Liquefaction resistance of bio-cemented calcareous sand. Soil Dyn Earthq Eng 107:9–19. https://doi.org/10.1016/j.soildyn.2018.01.008

Yoosathaporn S, Tiangburanatham P, Bovonsombut S, Chaipanich A, Pathom-Aree W (2016) A cost effective cultivation medium for biocalcification of Bacillus pasteurii KCTC 3558 and its effect on cement cubes properties. Microbiol Res 186:132–138. https://doi.org/10.1016/j.micres.2016.03.010

Zhao Y, Yao J, Yuan Z, Wang T, Zhang Y, Wang F (2017) Bioremediation of Cd by strain GZ-22 isolated from mine soil based on biosorption and microbially induced carbonate precipitation. Environ Sci Pollut Res 24:372–380. https://doi.org/10.1007/s11356-016-7810-y

Acknowledgements

The authors are thankful to the Department of Chemical Engineering, Sahand University of Technology, Tabriz, Iran, for the experimental facilities.

Acronyms list

MICPMicrobial induced carbonate precipitation

CSLCorn steep liquor

UAUrease activity

MLRMultiple linear regression

ANFISAdaptive neuro-fuzzy inference system

GPGenetic programming

RMSERoot mean squared error

Greek letter list

ɛRandom error

Author information

Authors and Affiliations

Contributions

MMK and AAM were involved in planning and supervised the work. MMK performed the preliminary experiments to determine effective parameters on economical urease production and carried out the measurements of bacterial growth and urease activity. MMK and SGS prepared the soil samples for bacteria injection and direct shear testing. SGS characterized inherent parameters of shear strength of the biologically treated soil samples and aided in interpreting the results. MJA and AAM processed the experimental data, developed the artificial intelligence methods for modeling the economical production of bacterial urease at high levels, and designed the figures. MMK and MJA drafted the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interests.

Additional information

Responsible Editor: Ta Yeong Wu

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maleki-Kakelar, M., Azarhoosh, M.J., Golmohammadi Senji, S. et al. Urease production using corn steep liquor as a low-cost nutrient source by Sporosarcina pasteurii: biocementation and process optimization via artificial intelligence approaches. Environ Sci Pollut Res 29, 13767–13781 (2022). https://doi.org/10.1007/s11356-021-16568-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-021-16568-6