Abstract

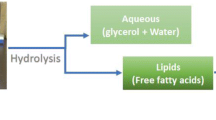

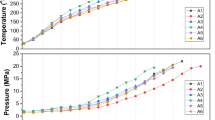

Biodiesel production from the transesterification of triglycerides produces crude glycerol as a by-product with a percentage of glycerol typically 20–80% (w/w) depending on the specific conditions of the transesterification process. This crude glycerol requires further purification in order to achieve commercial value and to increase the profitability of biodiesel production. For this reason, the main objective of this work was to obtain glycerol with a purity greater than 90% (w/w) starting from water-free crude glycerine as obtained from the IPN-GBD-1000® transesterification process and treating it via single-step neutralization according to green chemistry principles. For this purpose, sulphuric (H2SO4) and citric (C6H8O7) acids were evaluated as neutralizers by adding dilute acid solutions to crude glycerine under mild conditions. The physicochemical characterization of both crude and purified glycerol was carried out by means of infrared spectroscopy (FTIR), 1H and 13C nuclear magnetic resonance (NMR) and thermogravimetric analysis (TGA). The results indicated that the neutralization method herein developed allowed the obtaining of glycerol with purities of 98.5% and 84.37% (w/w) and treatment efficiencies of 98.5% and 46.7% for sulphuric and citric acid treatments, respectively. In addition, the environmental viability of the sulphuric acid process was evaluated through the calculation of green metrics such as environmental factor, water factor and mass intensity, through which significant environmental advantages were confirmed. The one-step neutralization process reported herein generates zero waste when sulphuric acid is used; it also decreases the water consumption 17-fold and reduces 3-fold the use of raw materials per mass unit of purified glycerol compared to the conventional acidification-neutralization process.

Similar content being viewed by others

References

Almazrouei M, Elagroudy S, Janajreh I (2019) Transesterification of waste cooking oil: quality assessment via thermogravimetric analysis. Energy Procedia 158:2070–2076

Ambat I, Srivastava V, Sillanpää M (2018) Recent advancement in biodiesel production methodologies using various feedstock: a review. Renew Sust Energ Rev 90:356–369

Anitha M, Kamarudin SK, Kofli NT (2016) The potential of glycerol as a value-added commodity. Chem Eng J 295:119–130

Ardi MS, Aroua MK, Hashim NA (2015) Progress, prospect and challenges in glycerol purification process: a review. Renew Sust Energ Rev 42:1164–1173

Bagnato G, Iulianelli A, Sanna A, Basile A (2017) Glycerol production and transformation: a critical review with particular emphasis on glycerol reforming reaction for producing hydrogen in conventional and membrane reactors. Membranes 7(2):17

Bilck AP, Müller CMO, Olivato JB, Mali S, Grossmann MVE, Yamashita F (2015) Using glycerol produced from biodiesel as a plasticiser in extruded biodegradable films. Polímeros 25(4):331–335

Capello C, Fischer U, Hungerbühler K (2007) What is a green solvent? A comprehensive framework for the environmental assessment of solvents. Green Chem 9(9):927–934

Chi Z, Pyle D, Wen Z, Frear C, Chen S (2007) A laboratory study of producing docosahexaenoic acid from biodiesel-waste glycerol by microalgal fermentation. Process Biochem 42(11):1537–1545

Chol CG, Dhabhai R, Dalai AK, Reaney M (2018) Purification of crude glycerol derived from biodiesel production process: experimental studies and techno-economic analyses. Fuel Process Technol 178:78–87

Ciriminna R, Pina C, Della Rossi M, Pagliaro M (2014) Understanding the glycerol market. Eur J Lipid Sci Technol 116:1432–1439

Contreras Andrade I, Avella Moreno E, Sierra Cantor JF, Guerrero Fajardo CA, Sodre JR (2015) Purification of glycerol from biodiesel production by sequential extraction monitored by 1H NMR. Fuel Process Technol 132:99–104

Curzons AD, Constable DJ, Mortimer DN, Cunningham VL (2001) So you think your process is green, how do you know?—using principles of sustainability to determine what is green–a corporate perspective. Green Chem 3(1):1–6

Dhabhai R, Ahmadifeijani E, Dalai AK, Reaney M (2016) Purification of crude glycerol using a sequential physico-chemical treatment, membrane filtration, and activated charcoal adsorption. Sep Purif Technol 168:101–106

Dos Santos Ferreira J, Volschan I, Cammarota MC (2018) Co-digestion of sewage sludge with crude or pretreated glycerol to increase biogas production. Environ Sci Pollut Res 25(22):21811–21821

Dou B, Dupont V, Williams PT, Chen H, Ding Y (2009) Thermogravimetric kinetics of crude glycerol. Bioresour Technol 100(9):2613–2620

Gao W, Chen K, Yang R, Yang F (2015) Process for coating of reconstituted tobacco sheet with citrates. J Anal Appl Pyrolysis 114:138–142

Hájek M, Skopal F (2010) Treatment of glycerol phase formed by biodiesel production. Bioresour Technol 101(9):3242–3245

Hernández Altamirano R, Mena Cervantes VY (2018) MX Patent Application 015832

International Energy Agency (2019) Renewables 2019: analysis and forecasts to 2024. IEA, Paris

Javani A, Hasheminejad M, Tahvildari K, Tabatabaei M (2012) High quality potassium phosphate production through step-by-step glycerol purification: a strategy to economize biodiesel production. Bioresour Technol 104:788–790

Kongjao S, Damronglerd S, Hunsom M (2010) Purification of crude glycerol derived from waste used-oil methyl ester plant. Korean J Chem Eng 27(3):944–949

Maina S, Kachrimanidou V, Ladakis D, Papanikolaou S, de Castro AM, Koutinas A (2019) Evaluation of 1,3-propanediol production by two Citrobacter freundii strains using crude glycerol and soybean cake hydrolysate. Environ Sci Pollut Res 1–10

Manosak R, Limpattayanate S, Hunsom M (2011) Sequential-refining of crude glycerol derived from waste used-oil methyl ester plant via a combined process of chemical and adsorption. Fuel Process Technol 92(1):92–99

Martínez A, Mijangos GE, Romero-Ibarra IC, Hernández Altamirano R, Mena Cervantes VY, Gutiérrez S (2018) A novel green one-pot synthesis of biodiesel from Ricinus communis seeds by basic heterogeneous catalysis. J Clean Prod 196:340–349

Muniru OS, Ezeanyanaso CS, Akubueze EU, Igwe CC, Elemo GN (2019) Review of different purification techniques for crude glycerol from biodiesel production. J Energy Res Rev 1–6

Quispe CA, Coronado CJ, Carvalho JA Jr (2013) Glycerol: production, consumption, prices, characterization and new trends in combustion. Renew Sust Energ Rev 27:475–493

San Kong P, Aroua MK, Daud WMAW (2016) Conversion of crude and pure glycerol into derivatives: a feasibility evaluation. Renew Sust Energ Rev 63:533–555

Sheldon RA (1992) Organic synthesis-past, present and future. Chem Ind 23:903–906

Sheldon RA (2017) The E factor 25 years on: the rise of green chemistry and sustainability. Green Chem 19(1):18–43

Tamošiūnas A, Valatkevičius P, Gimžauskaitė D, Jeguirim M, Mėčius V, Aikas M (2017) Energy recovery from waste glycerol by utilizing thermal water vapor plasma. Environ Sci Pollut Res 24(11):10030–10040

Tan HW, Abdul Aziz AR, Aroua MK (2013) Glycerol production and its applications as a raw material: a review. Renew Sust Energ Rev 27:118–127

Wan Isahak WNR, Che Ramli ZA, Ismail M, Mohd Jahim J, Yarmo MA (2015) Recovery and purification of crude glycerol from vegetable oil transesterification. Sep Purif Rev 44(3):250–267

Xiao Y, Xiao G, Varma A (2013) A universal procedure for crude glycerol purification from different feedstocks in biodiesel production: experimental and simulation study. Ind Eng Chem Res 52(39):14291–14296

Yong K, Ooi T, Dzulkefly K, Wan Yunus W, Hazimah A (2001) Characterization of glycerol residue from a palm kernel oil methyl ester plant. J Oil Palm Res 13(2):1–6

Živković S, Veljković M (2018) Environmental impacts the of production and use of biodiesel. Environ Sci Pollut Res 25(1):191–199

Acknowledgements

The authors give particular acknowledgement to the Laboratorio Nacional de Desarrollo y Aseguramiento de la Calidad de Biocombustibles (LaNDACBio) and Centro Mexicano para la Producción más Limpia (CMP+L) for allowing the use of laboratory infrastructure and to the National Council of Science and Technology (CONACYT) for its financial support through the projects CONACyT 293981 and CONACyT 255107. In addition, special acknowledgement is given to the Secretary of Science, Technology and Innovation of Mexico City (SECITI-CDMX) through the project SECITI/044/2018 “Innovación del proceso de producción de biodiesel para la comercialización de la tecnología sustentable IPN-GBD-1000 bajo el enfoque de traje a la medida del usuario”, and SIP-IPN multidisciplinary Project No. 2019-2011-SIP-20195299 for the funding and support to carry out this work.

Alejandra Tiscareño gratefully acknowledges the financial support of the Institutional Program of Postgraduate Scholarships of the IPN, the CONACyT-SENER National Fund Scholarship Program as well as the Institutional Training Scholarship for Researchers (BEIFI) Scholarship.

Author information

Authors and Affiliations

Corresponding author

Additional information

Responsible editor: Ta Yeong Wu

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mena-Cervantes, V.Y., Hernández-Altamirano, R. & Tiscareño-Ferrer, A. Development of a green one-step neutralization process for valorization of crude glycerol obtained from biodiesel. Environ Sci Pollut Res 27, 28500–28509 (2020). https://doi.org/10.1007/s11356-019-07287-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-019-07287-0