Abstract

Background

Understanding and predicting the behavior of additively manufactured (AM) parts in real-case scenarios is essential for optimizing the design process. Little literature presents a throughout investigation on the influence of the stress state on the anisotropic response of AM materials, and there has not been a great effort to validate the applicability of conventional material models for AM components.

Objective

This work aims to assess the effect of building orientation and the stress state on the mechanical response of as-built laser powder bed fusion (L-PBF) AlSi10Mg and to propose, based on the experimental results, a material model able to represent its mechanical response thoroughly.

Methods

Several mechanical characterization tests, including uniaxial tensile and compressive tests, tensile tests on round-notched bars, and shear tests, were carried out for each investigated building direction (0°, 45°, 90°). The Cazacu-Barlat yield surface was selected to describe the mechanical behavior of the material. Material parameters were identified by inverse calibration and verified using finite element simulation of performed experimental tests.

Results

The results showed a more consistent effect of the building direction on ductility and maximum stress value, while the effect on yield stress was less significant. Under multiaxial stress states, the anisotropic behavior became less noticeable yet present. No anisotropic behavior was observed under shear conditions. In tension and compression, a slight asymmetry in response was noted. Computational results were found in agreement with the experimental data.

Conclusion

The influence of both stress state and of the building direction has been systematically investigated by performing several characterization tests on different sample geometries. In combination with mechanical testing, a material model has been proposed and validated to show the applicability of conventional modeling techniques to AM material.

Similar content being viewed by others

Data Availability

The authors confirm that the data supporting the findings of this study are available within the article [and/or] its supplementary materials.

References

Olakanmi EO, Cochrane RF, Dalgarno KW (2015) A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog Mater Sci 74:401–477. https://doi.org/10.1016/j.pmatsci.2015.03.002

Herzog D, Seyda V, Wycisk E, Emmelmann C (2016) Additive manufacturing of metals. Acta Mater 117:371–392. https://doi.org/10.1016/j.actamat.2016.07.019

Mertens AI, Delahaye J, Lecomte-Beckers J (2017) Fusion-based additive manufacturing for processing aluminum alloys: state-of-the-art and challenges. Adv Eng Mater 19:1700003. https://doi.org/10.1002/adem.201700003

Trevisan F, Calignano F, Lorusso M et al (2017) On the selective laser melting (SLM) of the AlSi10Mg alloy: Process, microstructure, and mechanical properties. Materials (Basel). https://doi.org/10.3390/ma10010076

Zyguła K, Nosek B, Pasiowiec H, Szysiak N (2018) Mechanical properties and microstructure of AlSi10Mg alloy obtained by casting and SLM technique 104:462–472

Shakil SI, Hadadzadeh A, Shalchi Amirkhiz B et al (2021) Additive manufactured versus cast AlSi10Mg alloy: microstructure and micromechanics. Results Mater 10:100178. https://doi.org/10.1016/j.rinma.2021.100178

Kempen K et al (2011) Process optimization and microstructural analysis for selective laser melting of AlSi10Mg. 2011 International Solid Freeform Fabrication Symposium. University of Texas at Austin

Ricci S, Testa G, Iannitti G, Ruggiero A (2022) Laser powder bed fusion of AlSi10Mg alloy: Numerical investigation on the temperature field evolution. Forces Mech 8:100109. https://doi.org/10.1016/j.finmec.2022.100109

Mertens A, Delahaye J, Dedry O et al (2020) Microstructure and properties of SLM AlSi10Mg: Understanding the influence of the local thermal history. In: Procedia Manufacturing. Elsevier B.V., pp 1089–1095

Li X, Yi D, Wu X et al (2021) Effect of construction angles on microstructure and mechanical properties of AlSi10Mg alloy fabricated by selective laser melting. J Alloys Compd 881:160459. https://doi.org/10.1016/j.jallcom.2021.160459

Roth CC, Tancogne-Dejean T, Mohr D (2021) Plasticity and fracture of cast and SLM AlSi10Mg: High-throughput testing and modeling. Addit Manuf 43:101998. https://doi.org/10.1016/j.addma.2021.101998

Dong S, Zhang X, Ma F et al (2020) Research on deposited tracks and microstructures of AlSi10Mg alloy produced by selective laser melting. Appl Phys A Mater Sci Process 126:1–10. https://doi.org/10.1007/s00339-020-03826-6

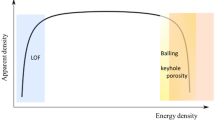

Wu H, Ren Y, Ren J et al (2021) Selective laser melted AlSi10Mg alloy under melting mode transition: Microstructure evolution, nanomechanical behaviors and tensile properties. J Alloys Compd 873:159823. https://doi.org/10.1016/j.jallcom.2021.159823

Pei W, Zhengying W, Zhen C et al (2017) Numerical simulation and parametric analysis of selective laser melting process of AlSi10Mg powder. Appl Phys A Mater Sci Process 123:1–15. https://doi.org/10.1007/s00339-017-1143-7

Samantaray M, Thatoi DN, Sahoo S (2019) Modeling and Optimization of Process Parameters for Laser Powder Bed Fusion of AlSi10Mg Alloy. Lasers Manuf Mater Process 6:356–373. https://doi.org/10.1007/s40516-019-00099-7

Kan WH, Nadot Y, Foley M et al (2019) Factors that affect the properties of additively-manufactured AlSi10Mg: Porosity versus microstructure. Addit Manuf 29:100805. https://doi.org/10.1016/j.addma.2019.100805

Ch SR, Raja A, Nadig P et al (2019) Influence of working environment and built orientation on the tensile properties of selective laser melted AlSi10Mg alloy. Mater Sci Eng A 750:141–151. https://doi.org/10.1016/j.msea.2019.01.103

Maconachie T, Leary M, Zhang J et al (2020) Effect of build orientation on the quasi-static and dynamic response of SLM AlSi10Mg. Mater Sci Eng A 788:139445. https://doi.org/10.1016/j.msea.2020.139445

Wang CG, Zhu JX, Wang GW et al (2022) Effect of building orientation and heat treatment on the anisotropic tensile properties of AlSi10Mg fabricated by selective laser melting. J Alloys Compd 895:162665. https://doi.org/10.1016/j.jallcom.2021.162665

Li W, Li S, Liu J et al (2016) Effect of heat treatment on AlSi10Mg alloy fabricated by selective laser melting: Microstructure evolution, mechanical properties and fracture mechanism. Mater Sci Eng A 663:116–125. https://doi.org/10.1016/j.msea.2016.03.088

Alghamdi F, Song X, Hadadzadeh A et al (2020) Post heat treatment of additive manufactured AlSi10Mg: On silicon morphology, texture and small-scale properties. Mater Sci Eng A 783:139296. https://doi.org/10.1016/j.msea.2020.139296

Schuch M, Hahn T, Bleckmann M (2021) The mechanical behavior and microstructure of additively manufactured AlSi10Mg for different material states and loading conditions. Mater Sci Eng A 813:141134. https://doi.org/10.1016/j.msea.2021.141134

Costas M, Morin D, de Lucio M, Langseth M (2020) Testing and simulation of additively manufactured AlSi10Mg components under quasi-static loading. Eur J Mech A/Solids 81:103966. https://doi.org/10.1016/j.euromechsol.2020.103966

Nalli F, Cortese L, Concli F (2021) Ductile damage assessment of Ti6Al4V, 17–4PH and AlSi10Mg for additive manufacturing. Eng Fract Mech 241:107395. https://doi.org/10.1016/j.engfracmech.2020.107395

Kristoffersen M, Costas M, Koenis T et al (2020) On the ballistic perforation resistance of additive manufactured AlSi10Mg aluminium plates. Int J Impact Eng 137. https://doi.org/10.1016/j.ijimpeng.2019.103476

Gouveia RM, Silva FJG, Atzeni E, Sormaz D, Alves JL, Pereira AB (2020) Effect of scan strategies and use of support structures on surface quality and hardness of L-PBF AlSi10Mg Parts. Materials 13(10):2248. https://doi.org/10.3390/ma13102248

Gray GT, Vecchio KS, Livescu V (2016) Compact forced simple-shear sample for studying shear localization in materials. Acta Mater 103:12–22. https://doi.org/10.1016/j.actamat.2015.09.051

Cazacu O, Barlat F (2004) A criterion for description of anisotropy and yield differential effects in pressure-insensitive metals. Int J Plast 20:2027–2045. https://doi.org/10.1016/j.ijplas.2003.11.021

Kempen K, Thijs L, Van Humbeeck J, Kruth JP (2012) Mechanical Properties of AlSi10Mg Produced by Selective Laser Melting. Phys Procedia 39:439–446. https://doi.org/10.1016/j.phpro.2012.10.059

Cazacu O, Barlat F (2001) Generalization of Drucker’s yield criterion to orthotropy. Math Mech Solids 6(6):613–630. https://doi.org/10.1177/108128650100600603

Chen J, Hou W, Wang X et al (2020) Microstructure, porosity and mechanical properties of selective laser melted AlSi10Mg. Chinese J Aeronaut 33:2043–2054. https://doi.org/10.1016/j.cja.2019.08.017

Thijs L, Kempen K, Kruth JP, Van Humbeeck J (2013) Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater 61:1809–1819. https://doi.org/10.1016/j.actamat.2012.11.052

Larrosa NO, Wang W, Read N et al (2018) Linking microstructure and processing defects to mechanical properties of selectively laser melted AlSi10Mg alloy. Theor Appl Fract Mech 98:123–133. https://doi.org/10.1016/j.tafmec.2018.09.011

Cyr E, Lloyd A, Mohammadi M (2018) Tension-compression asymmetry of additively manufactured Maraging steel. J Manuf Process 35:289–294. https://doi.org/10.1016/j.jmapro.2018.08.015

Rodriguez OL, Allison PG, Whittington WR et al (2018) Strain rate effect on the tension and compression stress-state asymmetry for electron beam additive manufactured Ti6Al4V. Mater Sci Eng A 713:125–133. https://doi.org/10.1016/j.msea.2017.12.062

Ghorbanpour S, Alam ME, Ferreri NC et al (2020) Experimental characterization and crystal plasticity modeling of anisotropy, tension-compression asymmetry, and texture evolution of additively manufactured Inconel 718 at room and elevated temperatures. Int J Plast 125:63–79. https://doi.org/10.1016/j.ijplas.2019.09.002

Adams BM, Bohnhoff WJ, Dalbey KR et al (2022) Dakota, A Multilevel Parallel Object-Oriented Framework for Design Optimization, Parameter Estimation, Uncertainty Quantification, and Sensitivity Analysis: Version 6.16 User’s Manual

Barlat F, Aretz H, Yoon JW et al (2005) Linear transfomation-based anisotropic yield functions. Int J Plast 21:1009–1039. https://doi.org/10.1016/j.ijplas.2004.06.004

Funding

This work was funded by the Italian Ministry of Defense under Grant No. PNRM/a2017.079.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ricci, S., Zucca, G., Iannitti, G. et al. Characterization of Asymmetric and Anisotropic Plastic Flow of L-PBF AlSi10Mg. Exp Mech 63, 1409–1425 (2023). https://doi.org/10.1007/s11340-023-00995-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-023-00995-2