Abstract

Background

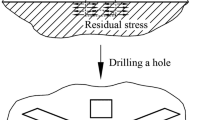

Hole eccentricity is a major source of stress evaluation error when making hole-drilling residual stress measurements. Consequently, tight limits must be applied to the acceptable size of hole eccentricity.

Objective

This research is aimed at developing a compact procedure that can correct for the effects of hole eccentricity and thus enable a larger eccentricity range to be allowed.

Method

A numerical scheme is developed that computes the strain response that would be measured with a centered hole from the experimental strain measurements made with an eccentric hole.

Results

The proposed numerical procedure enables the allowable maximum size limit of hole eccentricity to be increased by a factor of six compared with measurements made without eccentricity error correction.

Conclusions

The proposed method provides a practical method to correct for the effects of hole eccentricity. Its method of computing the corresponding strains for a centered hole makes it compatible for use with the standardized measurement procedure described in ASTM E837-20.

Similar content being viewed by others

References

Schajer GS, Whitehead PS (2018) Hole-Drilling Method for Measuring Residual Stress. Morgan & Claypool, Williston, VT, USA

Grant PV, Lord JD, Whitehead PS (2002) The Measurement of Residual Stresses by the Incremental Hole Drilling Technique. Measurement Good Practice Guide No. 53, National Physical Laboratory, Teddington, UK

Ajovalasit A, Scafidi M, Zuccarello B, Beghini M, Bertini L, Santus C, Valentini E, Benincasa A, Bertelli L (2010) The Hole-Drilling Strain Gauge Method for the Measurement of Uniform or Non-Uniform Residual Stresses, AIAS Residual Stress Working Group, TR01:2010, Florence, Italy. 70

ASTM (2020) Determining Residual Stresses by the Hole-Drilling Strain-Gage Method. Standard Test Method E837–20. American Society for Testing and Materials, West Conshohocken, PA

Sandifer JP, Bowie GE (1978) Residual Stress by Blind-hole Method with Off-center Hole. Exp Mech 18(5):173–179

Ajovalasit A (1979) Measurement of Residual Stresses by the Hole-drilling Method: Influence of Hole Eccentricity. J Strain Anal Eng Design 14(4):171–178

Wang H-P (1979) The Alignment Error of Hole-drilling Method. Proc SESA 36(1):23–28

Wang JY (1990) Refined Analysis of the Relieved Strain Coefficients for the Off-Center Hole-Drilling Case. Exp Mech 30(1):367–371

Vangi D (1997) Residual Stress Evaluation by the Hole-Drilling Method with Off-Center Hole: An Extension of the Integral Method. J Eng Mater Technol 119(1):79–85

Beghini M, Bertini L, Mori LF (2010) Evaluating Non-Uniform Residual Stress by the Hole Drilling Method with Concentric and Eccentric Holes. Part I and Part II, Strain 46(4):324–336 and 46(4):337–346

Nau A, Scholtes B (2012) Experimental and Numerical Strategies to Consider Hole Eccentricity for Residual Stress Measurement with the Hole Drilling Method. Maters Testing 54(5):296–303

Barsanti M, Beghini M, Bertini L, Monelli BD, Santus C (2016) First-order Correction to Counter the Effect of Eccentricity on the Hole-Drilling Integral Method with Strain-Gage Rosettes. J Strain Anal Eng Design 51(6):431–443

Schajer GS (1988) Measurement of Non-Uniform Residual Stresses Using the Hole-Drilling Method. Part I. J Eng Maters Technol 110(4):338–343

Schajer GS (2020) Compact Calibration Data for Hole-Drilling Residual Stress Measurements in Finite-Thickness Specimens. Exp Mech 60(5):665–678

Schajer GS (1993) Use of Displacement Data to Calculate Strain Gauge Response in Non-Uniform Strain Fields. Strain 29(1):9–13

Acknowledgements

This work was financially supported by the Natural Sciences and Engineering Research Council of Canada (NSERC). Juuso Heikkinen and Luc To kindly reviewed the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The author declares that he has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Table 1 lists the polynomial coefficients d1–d4 in equation (21) to calculate the α, β and γ values for a Type A rosette with hole diameters D0 = 0.3D, 0.4D and 0.5D, and for specimen thicknesses W = 0.25D, 0.3D, 0.4D and 0.6D. These hole diameters and specimen thicknesses correspond to those tabulated in ASTM E837-20. The resulting α, β and γ values can then be interpolated using the same procedures described in ASTM E837-20 for interpolating the \(\overline{\mathbf{a} }\) and \(\overline{\mathbf{b} }\) values. Note that ASTM E837-20 limits the maximum hole depth to the minimum of 0.2D or 0.6 W. The latter limit affects specimens of thickness W less than 0.33D.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Schajer, G.S. Hole Eccentricity Correction for Hole-Drilling Residual Stress Measurements . Exp Mech 62, 1603–1613 (2022). https://doi.org/10.1007/s11340-022-00881-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-022-00881-3