Abstract

Background

Impact experiments, routinely performed at the macroscale, have long been used to study mechanical properties of materials. Microscale high-velocity impact, relevant to applications such as ballistic drug delivery has remained largely unexplored at the level of a single impact event.

Objective

In this work, we study the mechanical behavior of polymer gels subjected to high-velocity microparticle impact, with strain rates up to 107 s−1, through direct visualization of the impact dynamics.

Methods

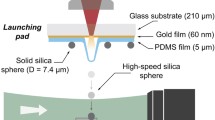

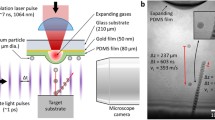

In an all-optical laser-induced particle impact test, 10–24 μm diameter steel microparticles are accelerated through a laser ablation process to velocities ranging from 50 to 1000 m/s. Impact events are monitored using a high-speed multi-frame camera with nanosecond time resolution.

Results

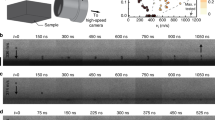

We measure microparticle trajectories and extract both maximum and final penetration depths for a range of particle sizes, velocities, and gel concentrations. We propose a modified Clift-Gauvin model and demonstrate that it adequately describes both individual trajectories and penetration depths. The model parameters, namely, the apparent viscosity and impact resistance, are extracted for a range of polymer concentrations.

Conclusions

Laser-induced microparticle impact test makes it possible to perform reproducible measurements of the single particle impact dynamics on gels and provides a quantitative basis for understanding these dynamics. We show that the modified Clift-Gauvin model, which accounts for the velocity dependence of the drag coefficient, offers a better agreement with the experimental data than the more commonly-used Poncelet model. Microscale ballistic impact imaging performed with high temporal and spatial resolution can serve as direct input for simulations of high-velocity impact responses and high strain rate deformation in gels and other soft materials.

Similar content being viewed by others

References

Christiansen EL, Nagy K, Lear DM, Prior TG (2009) Space station MMOD shielding. Acta Astronaut 65:921–929. https://doi.org/10.1016/j.actaastro.2008.01.046

Christiansen EL, Hyde JL, Bernhard RP (2004) Space shuttle debris and meteoroid impacts. Adv Sp Res 34:1097–1103. https://doi.org/10.1016/j.asr.2003.12.008

Parsi M, Najmi K, Najafifard F, Hassani S, McLaury BS, Shirazi SA (2014) A comprehensive review of solid particle erosion modeling for oil and gas wells and pipelines applications. J Nat Gas Sci Eng 21:850–873. https://doi.org/10.1016/j.jngse.2014.10.001

Pepi M, Squillacioti R, Pfledderer L, Phelps A (2012) Solid particle Erosion testing of helicopter rotor blade materials. J Fail Anal Prev 12:96–108. https://doi.org/10.1007/s11668-011-9531-3

Tilly GP (1969) Erosion caused by airborne particles. Wear 14:63–79. https://doi.org/10.1016/0043-1648(69)90035-0

Moridi A, Hassani-Gangaraj SM, Guagliano M, Dao M (2014) Cold spray coating: review of material systems and future perspectives. Surf Eng 30:369–395. https://doi.org/10.1179/1743294414Y.0000000270

Kendall M, Mitchell T, Wrighton-Smith P (2004) Intradermal ballistic delivery of micro-particles into excised human skin for pharmaceutical applications. J Biomech 37:1733–1741. https://doi.org/10.1016/j.jbiomech.2004.01.032

Hill PF, Edwards DP, Bowyer GW (2001) Small fragment wounds: biophysics, pathophysiology and principles of management. J R Army Med Corps 147:41–51. https://doi.org/10.1136/jramc-147-01-04

Hisley DM, Gurganus JC, Drysdale AW (2011) Experimental methodology using digital image correlation to assess ballistic helmet blunt trauma. J Appl Mech 78:051022. https://doi.org/10.1115/1.4004332

Salisbury CP, Cronin DS (2009) Mechanical properties of ballistic gelatin at high deformation rates. Exp Mech 49:829–840. https://doi.org/10.1007/s11340-008-9207-4

Miller DL, Smith NB, Bailey MR, Czarnota GJ, Hynynen K, Makin IRS, Bioeffects Committee of the American Institute of Ultrasound in Medicine (2012) Overview of therapeutic ultrasound applications and safety considerations. J Ultrasound Med 31:623–634. https://doi.org/10.7863/jum.2012.31.4.623

Mancia L, Vlaisavljevich E, Xu Z, Johnsen E (2017) Predicting tissue susceptibility to mechanical cavitation damage in therapeutic ultrasound. Ultrasound Med Biol 43:1421–1440. https://doi.org/10.1016/j.ultrasmedbio.2017.02.020

Lee T, Luo W, Li Q, Demirci H, Guo LJ (2017) Laser-induced focused ultrasound for cavitation treatment: toward high-precision invisible sonic scalpel. Small 13:1–10. https://doi.org/10.1002/smll.201701555

Gama BA, Lopatnikov SL, Gillespie JW (2004) Hopkinson bar experimental technique: a critical review. Appl Mech Rev 57:223–250

Richler D, Rittel D (2014) On the testing of the dynamic mechanical properties of soft gelatins. Exp Mech 54:805–815. https://doi.org/10.1007/s11340-014-9848-4

Song B, Chen W (2004) Dynamic stress equilibration in split Hopkinson pressure bar tests on soft materials. Exp Mech 44:300–312. https://doi.org/10.1177/0014485104041543

Toyoda Y, Gupta YM (2014) Shockless and shock wave compression of ballistic gel to 1.3 GPa. J Appl Phys 116:. https://doi.org/10.1063/1.4898679

Estrada JB, Barajas C, Henann DL, Johnsen E, Franck C (2018) High strain-rate soft material characterization via inertial cavitation. J Mech Phys Solids 112:291–317. https://doi.org/10.1016/j.jmps.2017.12.006

Panzer MB, Myers BS, Capehart BP, Bass CR (2012) Development of a finite element model for blast brain injury and the effects of CSF cavitation. Ann Biomed Eng 40:1530–1544. https://doi.org/10.1007/s10439-012-0519-2

Marjoribanks RS, Dille C, Schoenly JE, McKinney L, Mordovanakis A, Kaifosh P, Forrester P, Qian Z, Covarrubias A, Feng Y, Lilge L (2012) Ablation and thermal effects in treatment of hard and soft materials and biotissues using ultrafast-laser pulse-train bursts. Photonics Lasers Med 1:155–169. https://doi.org/10.1515/plm-2012-0020

Lee J-H, Veysset D, Singer JP, Retsch M, Saini G, Pezeril T, Nelson KA, Thomas EL (2012) High strain rate deformation of layered nanocomposites. Nat Commun 3:1164. https://doi.org/10.1038/ncomms2166

Veysset D, Hsieh AJ, Kooi S, Maznev AA, Masser KA, Nelson KA (2016) Dynamics of supersonic microparticle impact on elastomers revealed by real-time multi-frame imaging. Sci Rep 6:25577. https://doi.org/10.1038/srep25577

Hassani-Gangaraj M, Veysset D, Nelson KA, Schuh CA (2018) In-situ observations of single micro-particle impact bonding. Scr Mater 145:9–13. https://doi.org/10.1016/j.scriptamat.2017.09.042

Hassani-Gangaraj M, Veysset D, Nelson KA, Schuh CA (2017) Melting can hinder impact-induced adhesion. Phys Rev Lett 119:175701. https://doi.org/10.1103/PhysRevLett.119.175701

Xie W, Alizadeh-Dehkharghani A, Chen Q, Champagne VK, Wang X, Nardi AT, Kooi S, Müftü S, Lee JH (2017) Dynamics and extreme plasticity of metallic microparticles in supersonic collisions /639/166/988 /639/301/1023/1026 /639/301/930/12 /128 article. Sci Rep 7:1–9. https://doi.org/10.1038/s41598-017-05104-7

Hassani-Gangaraj M, Veysset D, Nelson KA, Schuh CA (2019) Impact-bonding with aluminum, silver, and Gold microparticles: toward understanding the role of native oxide layer. Appl Surf Sci 476:528–532. https://doi.org/10.1016/j.apsusc.2019.01.111

Hassani-Gangaraj M, Veysset D, Nelson KA, Schuh CA (2018) Melt-driven erosion in microparticle impact. Nat Commun 9:5077. https://doi.org/10.1038/s41467-018-07509-y

Veysset D, Hsieh AJ, Kooi SE, Nelson KA (2017) Molecular influence in high-strain-rate microparticle impact response of poly(urethane urea) elastomers. Polymer 123:30–38. https://doi.org/10.1016/j.polymer.2017.06.071

Hsieh AJ, Veysset D, Miranda DF, Kooi SE, Runt J, Nelson KA (2018) Molecular influence in the glass/polymer interface design: the role of segmental dynamics. Polymer 146:222–229. https://doi.org/10.1016/j.polymer.2018.05.034

Wu Y-CM HW, Sun Y et al (2019) Unraveling the high strain-rate dynamic stiffening in select model polyurethanes − the role of intermolecular hydrogen bonding. Polymer 168:218–227. https://doi.org/10.1016/j.polymer.2019.02.038

Sun Y, Wu Y-CM, Veysset D, Kooi SE, Hu W, Swager TM, Nelson KA, Hsieh AJ (2019) Molecular dependencies of dynamic stiffening and strengthening through high strain rate microparticle impact of polyurethane and polyurea elastomers. Appl Phys Lett 115:093701. https://doi.org/10.1063/1.5111964

Lee J-H, Loya PE, Lou J, Thomas EL (2014) Dynamic mechanical behavior of multilayer graphene via supersonic projectile penetration. Science 346:1092–1096. https://doi.org/10.1126/science.1258544

Xie W, Tadepalli S, Park SH, Kazemi-Moridani A, Jiang Q, Singamaneni S, Lee JH (2018) Extreme mechanical behavior of nacre-mimetic Graphene-oxide and silk Nanocomposites. Nano Lett 18:987–993. https://doi.org/10.1021/acs.nanolett.7b04421

Hyon J, Lawal O, Fried O, Thevamaran R, Yazdi S, Zhou M, Veysset D, Kooi SE, Jiao Y, Hsiao MS, Streit J, Vaia RA, Thomas EL (2018) Extreme energy absorption in glassy polymer thin films by supersonic micro-projectile impact. Mater Today 21:817–824. https://doi.org/10.1016/j.mattod.2018.07.014

Veysset D, Kooi SE, Мaznev AA, Tang S, Mijailovic AS, Yang YJ, Geiser K, van Vliet KJ, Olsen BD, Nelson KA (2018) High-velocity micro-particle impact on gelatin and synthetic hydrogel. J Mech Behav Biomed Mater 86:71–76. https://doi.org/10.1016/j.jmbbm.2018.06.016

Liu K, Jiang M, Wu Z, Li Z, Ning J (2019) A mechanical model for spherical fragments penetrating gelatine. Int J Impact Eng 131:27–38. https://doi.org/10.1016/j.ijimpeng.2019.04.022

Clift R, Gauvin WH (1971) Motion of entrained particles in gas streams. Can J Chem Eng 49:439–448. https://doi.org/10.1002/cjce.5450490403

Mrozek RA, Leighliter B, Gold CS, Beringer IR, Yu JH, VanLandingham MR, Moy P, Foster MH, Lenhart JL (2015) The relationship between mechanical properties and ballistic penetration depth in a viscoelastic gel. J Mech Behav Biomed Mater 44:109–120. https://doi.org/10.1016/j.jmbbm.2015.01.001

Hassani-Gangaraj M, Veysset D, Nelson KA, Schuh CA (2016) Supersonic impact of metallic micro-particles. arXiv:161208081

Al Khalil M, Frissane H, Taddei L et al (2019) SPH-based method to simulate penetrating impact mechanics into ballistic gelatin: toward an understanding of the perforation of human tissue. Extrem Mech Lett 29:100479. https://doi.org/10.1016/j.eml.2019.100479

Meng S, Taddei L, Lebaal N, Veysset D, Roth S (2020) Modeling micro-particles impacts into ballistic gelatine using smoothed particles hydrodynamics method. Extrem Mech Lett 39:100852. https://doi.org/10.1016/j.eml.2020.100852

Akers B, Belmonte A (2006) Impact dynamics of a solid sphere falling into a viscoelastic micellar fluid. J Nonnewton Fluid Mech 135:97–108. https://doi.org/10.1016/j.jnnfm.2006.01.004

Ansley RW, Smith TN (1967) Motion of spherical particles in a Bingham plastic. AICHE J 13:1193–1196. https://doi.org/10.1002/aic.690130629

Luu L-H, Forterre Y (2009) Drop impact of yield-stress fluids. J Fluid Mech 632:301–327. https://doi.org/10.1017/S0022112009007198

Ovarlez G, Cohen-Addad S, Krishan K, Goyon J, Coussot P (2013) On the existence of a simple yield stress fluid behavior. J Nonnewton Fluid Mech 193:68–79. https://doi.org/10.1016/j.jnnfm.2012.06.009

Tabuteau H, Coussot P, de Bruyn JR (2007) Drag force on a sphere in steady motion through a yield-stress fluid. J Rheol (N Y N Y) 51:125–137. https://doi.org/10.1122/1.2401614

De Bruyn JR, Walsh AM (2004) Penetration of spheres into loose granular media. Can J Phys 82:439–446. https://doi.org/10.1139/p04-025

Goossens WRA (2019) Review of the empirical correlations for the drag coefficient of rigid spheres. Powder Technol 352:350–359. https://doi.org/10.1016/j.powtec.2019.04.075

Yoshitake Y, Mitani S, Sakai K, Takagi K (2008) Surface tension and elasticity of gel studied with laser-induced surface-deformation spectroscopy. Phys Rev E - Stat Nonlinear, Soft Matter Phys 78:1–7. https://doi.org/10.1103/PhysRevE.78.041405

Nakamura T, Hattori M, Kawasaki H et al (1996) Surface tension of the polymer network of a gel. Phys Rev E - Stat Physics, Plasmas, Fluids, Relat Interdiscip Top 54:1663–1668

Jin Y, Mai R, Wu C, Han R, Li B (2018) Comparison of ballistic impact effects between biological tissue and gelatin. J Mech Behav Biomed Mater 78:292–297. https://doi.org/10.1016/j.jmbbm.2017.11.033

Liu M, Hwang HY, Tao H, et al (2012) Terahertz-field-induced insulator-to-metal transition in vanadium dioxide metamaterial. Nature 1–4. https://doi.org/10.1038/nature11231

Dehn J (1987) A unified theory of penetration. Int J Impact Eng 5:239–248. https://doi.org/10.1016/0734-743X(87)90041-8

Liu L, Fan Y, Li W, Liu H (2012) Cavity dynamics and drag force of high-speed penetration of rigid spheres into 10wt% gelatin. Int J Impact Eng 50:68–75. https://doi.org/10.1016/j.ijimpeng.2012.06.004

Segletes SB (2008) Modeling the penetration behavior of rigid spheres into ballistic gelatin. ART-TR-4393

Cross MM (1979) Relation between viscoelasticity and shear-thinning behaviour in liquids. Rheol Acta 18:609–614. https://doi.org/10.1007/BF01520357

Acknowledgments

DV thanks Drs. Bianca Giovanardi and Anwar Koshakji for fruitful discussions. This material is based upon work supported by the U. S. Army Research Office through the Institute for Soldier Nanotechnologies, under Cooperative Agreement Number W911NF-18-2-0048.

Additional image sequences can be found in the supplementary information (Figs. 5-12). The data that support the findings of this work are available from the corresponding author upon request.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

ESM 1

(DOCX 3156 kb)

Rights and permissions

About this article

Cite this article

Veysset, D., Sun, Y., Lem, J. et al. High-Strain-Rate Behavior of a Viscoelastic Gel Under High-Velocity Microparticle Impact. Exp Mech 60, 1179–1186 (2020). https://doi.org/10.1007/s11340-020-00639-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-020-00639-9