Abstract

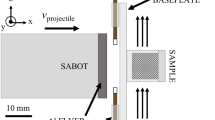

We describe a laser-launched micro-flyer apparatus designed for spall strength measurement. The launcher uses a single pulse from a pulsed laser that is stretched in time to nominally 20 nanoseconds using an optical ring cavity, while inexpensive multi-lens arrays are used to spatially homogenize the beam. The velocimetry technique that we developed for the experiment provides the required sub-nanosecond time resolution. We demonstrate the capability of the apparatus to interrogate the spall strength of AZ31B Mg alloy thin foils, a material system with potential applications as a lightweight protection material. Numerical simulations and fractography are very useful to determine the quality of the experimental data and help to interpret our results. The simulations and fractography analyses of the experiments suggest that the short shock pulse duration in the experiment causes incipient spallation. The short pulse also likely introduces stochasticity to the measured spall strength through limited activation of failure mechanisms within the samples. The shocked AZ31B Mg alloy has spall strengths that are greater than previously reported figures for fine grained Mg alloys, likely because the laser based system achieves higher strain rates than in prior work on this material.

Similar content being viewed by others

References

Fowles GR, Duvall GE, Asay J, Bellamy P, Feistmann F, Grady D, Michaels T, Mitchell R (1970) Gas gun for impact studies. Rev Sci Instrum 41(7):984. https://doi.org/10.1063/1.1684739

Antoun T, Seaman L, Curran DR, Kanel GI, Razorenov SV, Utkin AV (2003) Spall fracture. Springer, Berlin

Fox JA, Barr DN (1973) Laser-induced shock e.ects in Plexiglas and 6061-T6 aluminum. Appl Phys Lett 22(11):594

Eliezer S, Gilath I, Bar-Noy T (1990) Laser-induced spall in metals: Experiment and simulation. J Appl Phys 67(2):715

Gilath I, Eliezer S, Dariel M, Kornblit L (1988) Brittle-to-ductile transition in laser-induced spall at ultrahigh strain rate in 6061-T6 aluminum alloy. Appl Phys Lett 52(15):1207

Moshe E, Eliezer S, Dekel E, Ludmirsky A, Henis Z, Werdiger M, Goldberg I, Eliaz N, Eliezer D (1998) An increase of the spall strength in aluminum, copper, and Metglas at strain rates larger than 10 7 s- 1. J Appl Phys 83(8):4004

Cottet F, Boustie M (1989) Spallation studies in aluminum targets using shock waves induced by laser irradiation at various pulse durations. J Appl Phys 66(9):4067

Hu L, Miller P, Wang J (2009) High strain-rate spallation and fracture of tungsten by laserinduced stress waves. Mater Sci Eng A 504(1-2):73

Ripin BH, Decoste R, Obenschain SP, Bodner SE, McLean EA, Young FC, Whitlock RR, Armstrong CM, Grun J, Stamper JA, Gold SH, Nagel DJ, Lehmberg RH, McMahon JM (1980) Laser-Plasma Interaction and Ablative Acceleration of Thin Foils at 1012-1015 W/cm2. Phys Fluids 23(5):1012. https://doi.org/10.1063/1.863084

Obenschain SP, Whitlock RR, McLean EA, Ripin BH, Price RH, Phillion DW, Campbell EM, Rosen MD, Auerbach JM (1983) Uniform Ablative Acceleration of Targets by Laser Irradiation at 1014 W/cm22. Phys Rev Lett 50(1):44. https://doi.org/10.1103/PhysRevLett.50.44

Sheffield SA, Rogers JW, Castaneda JN (1986) Velocity measurements of laser-driven flyers backed by high impedance windows

Trott WM, Meeks KD (1990) Highpower Nd:glass laser transmission through optical fibers and its use in acceleration of thin foil targets. J Appl Phys 67(7):3296. https://doi.org/10.1063/1.345364

Paisley DL, Warnes RH, Kopp RA (1992) Proceedings of the APS 1991 Topical Conference on Shock Compression of Condensed Matter, 825–828. https://doi.org/10.1016/B978-0-444-89732-9.50189-8

Frank AM, Trott WM (1996) AIP Conference Proceedings- Shock Compression of Condensed Matter 370(1):1209. https://doi.org/10.1063/1.50698

Fujiwara H, Brown KE, Dlott DD (2009) AIP Conference Proceedings- Shock Compression of Condensed Matter 1195:1317. https://doi.org/10.1063/1.3295050

Fujiwara H, Brown KE, Dlott DD (2009) High-Energy Flat-top Beams for laser launching using a gaussian mirror. Appl Opt 49(19):3723. https://doi.org/10.1364/AO.49.003723

Fujiwara H, Brown KE, Dlott DD (2011) AIP Conference Proceedings- Shock COmpression of Condensed Matter 1426:382. https://doi.org/10.1063/1.3686298

Brown KE, Shaw WL, Zheng X, Dlott DD (2012) Simplified laser-driven flyer plates for shock compression science. Rev Sci Instrum 83(103901):1. https://doi.org/10.1063/1.4754717

Curtis AD, Banishev AA, Shaw WL, Dlott DD (2014) Laser-driven flyer plates for shock compression science: Launch and target impact probed by photon Doppler velocimetry. Rev Sci Instrum 85(043908):1. https://doi.org/10.1063/1.4871361

Banishev AA, Shaw WL, Bassett WP, Dlott DD (2016) High-speed laser-launched flyer impacts studied with ultrafast photography and velocimetry. J Dyn Behav Mater 2:194. https://doi.org/10.1007/s40870-016-0058-2

Paisley DL, Warnes RH, Kopp RA (1992) Proceedings of the APS 1991 Topical Conference on Shock Compression of Condensed Matter 825–828. https://doi.org/10.1016/B978-0-444-89732-9.50189-8

Vogler T, Alexander S, Thornhill T, Reinhart W (2011) Sandia Technical Report SAND2011-6700, pp SAND2011–6700

Chhabildas L, Sutherland H, Asay J (1979) A velocity interferometer technique to determine shearwave particle velocity in shock loaded solids. J Appl Phys 50(8):5196

Meyers M (2007) Dynamic behavior of materials. Wiley, New York

Warnes RH, Paisley DL, Tonks DL (1996) AIP Conference Proceedings- Shock COmpression of Condensed Matter, 1995 370(1):495. https://doi.org/10.1063/1.50645

Robbins DL, Gehr RJ, Harper RW, Rupp TD, SHeffield SA, STahl DB (2000) AIP Conference Proceedings- Shock COmpression of Condensed Matter, 1999 505(1):1199. https://doi.org/10.1063/1.1303676

Alexander DJ, Robbins DL, Sheffield SA (2000) Los Alamos National Lab. NM (US) LA-UR-00-3288:1

Paisley DL, Swift DC, Johnson RP, Kopp RA, Kyrala GA (2002) LaserLaunched flyer plates and direct laser shocks for dynamic material property measurements. AIP Conference Proceedings- Shock COmpression of Condensed Matter 2001:1343–1346. https://doi.org/10.1063/1.1483787

Swift DC, Niemczura JG, Paisley DL, Johnson RP, Luo S, IV TET (2005) Laserlaunched flyer plates for shock physics experiments. Rev Sci Instrum 093907(9):1. https://doi.org/10.1063/1.2052593

Paisley DL, Luo S, Greenfield S, Koskelo A (2008) Laser-launched flyer plate and confined laser ablation for shock wave loading: Validation and applications. Rev Sci Instrum 023902(2):1. https://doi.org/10.1063/1.2839399

de Resseguier T, He H, Berterretche P (2005) Use of laser-accelerated foils for impact study of dynamic material behaviour. Int J Impact Eng 31(8):945. https://doi.org/10.1016/j.ijimpeng.2004.07.003

Peralta P, DiGiacomo S, Hashemian S, Luo S, Paisley DL, Dickerson R, Loomis E, Byler D, McClellan KJ, D’Armas H (2009) Characterization of Incipient Spall Damage in Shocked Copper Multicrystals. Int J Damage Mech 18(4):393. https://doi.org/10.1177/1056789508097550

Wayne L, Krishnan K, DiGiacomo S, Kovvali N, Peralta P, Luo SN, Greenfield S, Byler D, Paisley DL, McClennan KJ, Koskelo A, Dickerson R (2010) Statistics of weak grain boundaries for spall damage in polycrystalline copper. Scr Mater 63(12):1065. https://doi.org/10.1016/j.scriptamat.2010.08.003

Wang H, Wang Y (2017) Laser-driven flyer application in thin film dissimilar materials welding and spalling. Opt Lasers Eng 97:1. https://doi.org/10.1016/j.optlaseng.2017.04.016

Farbaniec L, Williams CL, Kecskes L, Ramesh KT, Becker R (2016) Microstructural effects on the spall properties of ECAE-processed AZ31B magnesium alloy. Int J Impact Eng 98:34

Voelkel R, Weible KJ (2008) Optical Fabrication, Testing, and Metrology III, vol. 7102 (International Society for Optics and Photonics), vol. 7102, p. 71020J

Trott WM, Setchell RE, Castaneda JN, Berry DM (2001) Laser Beam Shaping II, vol. 4443 (International Society for Optics and Photonics, vol. 4443, p. 166–178

Kojima J, Nguyen QV (2002) . Appl Opt 41(30):6360

Mallick D, Shaeffer M, Dean S, Ramesh KT (2017) Laser pulse-stretching with multiple optical ring cavities. Procedia Eng 204:215

Strand O, Goosman D, Martinez C, Whitworth T, Kuhlow W (2006) Compact system for high-speed velocimetry using heterodyne techniques. Rev Sci Instr 77(8):08318:1

Klopp R, Clifton R, Shawki T (1985) Pressure-shear impact and the dynamic viscoplastic response of metals. Mech Mater 4(3): 375

Williams C, Farbaniec L, Kecskes L, Bradley J (2017) AIP Conference Proceedings, vol. 1793 (AIP Publishing), vol. 1793, p. 100011

Yu X, Li T, Li L, Liu S, Li Y (2017) Influence of initial texture on the shock property and spall behavior of magnesium alloy AZ31B. Mater Sci Eng A 700:25

Lässig T, Bagusat F, Pfändler S, Gulde M, Heunoske D, Osterholz J, Stein W, Nahme H, May M (2017) Investigations on the spall and delamination behavior of UHMWPE composites. Compos Struct 182:590

Hazell P, Appleby-Thomas G, Wielewski E, Stennett C, Siviour C (2012) The influence of microstructure on the shock and spall behaviour of the magnesium alloy, Elektron 675. Acta Materialia 60(17):6042

Mallick D, Zhao M, Bosworth B, Schuster B, Foster M, Ramesh KT (2018) A simple dual-beam time-multiplexed photon doppler velocimeter for pressure-shear plate impact experiments. Exp Mech:1–9

Dolan D (2010) Accuracy and precision in photonic doppler velocimetry. Rev Sci Instr 81:5

Kettenbeil C, Mello M, Bischann M, Ravichandran G (2018) Heterodyne transverse velocimetry for pressure-shear plate impact experiments. J Appl Phys 123:12

Moro EA, Briggs ME, Hull LM (2013) Defining parametric dependencies for the correct interpretation of speckle dynamics in photon Doppler velocimetry. Appl Opt 52(36):8661

Ao T, Dolan D (2010) Sandia Technical Report, pp SAND2010–3628

Luo J, Bai J, He P, Ying K (2004) IEEE Transactions on Ultrasonics, Ferroelectrics and Frequency Control 51(9)

Sagapuram D, Efe M, Moscoso W, Chandrasekar S, Trumble KP (2013) Controlling texture in magnesium alloy sheet by shear-based deformation processing. Acta Materialia 61(18):6843

Sagapuram D, Efe M, Trumble KP, Chandrasekar S (2016) Flow transitions and flow localization in large-strain deformation of magnesium alloy. Mater Sci Eng A 659:295. https://doi.org/10.1016/j.msea.2016.02.054

Garkushin G, Razorenov S, Krasnoveikin V, Kozulin A, Skripnyak V (2015) Effect of structural factors on mechanical properties of the magnesium alloy Ma2-1 under quasi-static and high strain rate deformation conditions. Phys Solid State 57(2):337

Cabral A, Rebordao J (2007) Accuracy of frequency-sweeping interferometry for absolute distance metrology. Opt Eng 46:7

Remington T, Hahn E, Zhao S, Flanagan R, Mertens J, Sabbaghianrad S, Langdon TG, Wehrenberg C, Maddox B, Swift D, et al. (2018) Spall strength dependence on grain size and strain rate in tantalum. Acta Materialia 158:313

Nichols A, Dawson D (2017) Livermore Technical Reports Tech. Rep LLNL-sm-726137

Steinberg D (1996) Equation of state and strength properties of selected materials, 1996, lawrence livermore national laboratory, Tech. rep. UCRL-MA-106439

Marsh SP (1980) LASL shock Hugoniot data, vol 5. Univ of California Press, California

Kanel’ G (2001) Distortion of the wave profiles in an elastoplastic body upon spalling. J Appl Mech Techn Phys 42:358

Chen DN, Yu YY, Yin ZH, Wang HR, Liu GQ (2005) On the validity of the traditional measurement of spall strength. Int J Impact Eng 31(7):811

Callaghan K, Becker R (2018) AIP Conference Proceedings, vol. 1979 (AIP Publishing), vol. 1979, p. 070010

Wilkerson J, Ramesh KT (2014) A dynamic void growth model governed by dislocation kinetics. J Mech Phys Solids 70:262

Wilkerson J (2017) On the micromechanics of void dynamics at extreme rates. Int J Plasticity 95:21

Wilkerson JW, Ramesh KT (2016) Unraveling the anomalous grain size dependence of cavitation. Phys Rev Lett 117(21):215503

Turneaure SJ, Renganathan P, Winey J, Gupta Y (2018) Twinning and dislocation evolution during shock compression and release of single crystals: real-time x-ray diffraction. Phys Rev Lett 120(26):265503

de Rességuier T, Hemery S, Lescoute E, Villechaise P, Kanel G, Razorenov S (2017) Spall fracture and twinning in laser shock-loaded single-crystal magnesium. J Appl Phys 121(16):165104

Acknowledgements

We thank the Dlott group at University of Illinois Urbana Champagne for their guidance in developing the apparatus based on their experiences pioneering their facility. We also thank Dr. Joseph Zaug for his mentorship of D.D.M. and general assistance with facility development. We thank Dr. Jeff Lloyd and Dr. Rich Becker for providing thought provoking conversations while analyzing these results and for assistance with the simulations. Finally, we thank the Hopkins Extreme Materials Institute for their support, specifically Dr. Amy Dagro, Matt Shaeffer, Dr. Andrew Leong, Hao Sheng, Steve Lavenstein, Dr. David Eastman and Dr. Ravi Shivaraman. This research was sponsored by the Army Research Laboratory and was accomplished under Cooperative Agreement Number W911NF-12-2-0022. The views and conclusions contained in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of the Army Research Laboratory or the U.S. Government. The U.S. Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation herein.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mallick, D.D., Zhao, M., Parker, J. et al. Laser-Driven Flyers and Nanosecond-Resolved Velocimetry for Spall Studies in Thin Metal Foils. Exp Mech 59, 611–628 (2019). https://doi.org/10.1007/s11340-019-00519-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-019-00519-x