Abstract

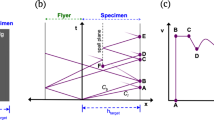

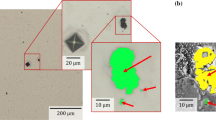

We examine the statistical distribution of critical nucleation pressures necessary to dynamically grow voids during the spall failure of an AZ31B magnesium alloy. The approach uses laser-driven micro-flyers to generate spall over times of the order of tens of nanoseconds, allowing us to focus on void nucleation processes rather than void coalescence processes. Our methodology combines quantitative postmortem characterization of void mediated failure with time-resolved interferometry of the failure event, and reveals the dynamics of the failure process. We infer the distribution of the underlying nucleation pressures and explore the associated strain rate dependence of spall strength in these alloys.

Similar content being viewed by others

References

Antoun T, Seaman L, Curran DR, Kanel GI, Razorenov SV, Utkin AV (2003) Spall fracture. Springer, New York

Rinehart JS (1951) Some quantitative data bearing on the scabbing of metals under explosive attack. J Appl Phys 22(5):555–560

Wu XY, Ramesh KT, Wright TW (2003) The dynamic growth of a single void in a viscoplastic material under transient hydrostatic loading. J Mech Phys Solids 51(1):1–26

Molinari A, Wright TW (2005) A physical model for nucleation and early growth of voids in ductile materials under dynamic loading. J Mech Phys Solids 53(7):1476–1504

Paisley DL, Warnes RH, Kopp RA (1992) laser-driven flat plate impacts to 100 GPa with sub nanosecond pulse duration and resolution for material property studies. In: Proceedings of the APS 1991 Topical Conference on Shock Compression of Condensed Matter, pp 825–828. https://doi.org/10.1016/B978-0-444-89732-9.50189-8

Warnes RH, Paisley DL, Tonks DL (1996) Hugoniot and spall data from the laser-driven miniflyer. AIP Conf Proc Shock Compress Cond Matter 370(1):495–498. https://doi.org/10.1063/1.50645

Paisley DL, Swift DC, Johnson RP, Kopp RA, Kyrala GA (2002) Laser-launched flyer plates and direct laser shocks for dynamic material property measurements. AIP Conf Proc Shock Compress Cond Matter 2001:1343–1346. https://doi.org/10.1063/1.1483787

de Resseguier T, He H, Berterretche P (2005) Use of laser-accelerated foils for impact study of dynamic material behaviour. Int J Impact Eng 31(8):945–956. https://doi.org/10.1016/j.ijimpeng.2004.07.003

Swift DC, Niemczura JG, Paisley DL, Johnson RP, Luo S, Tierney IV TE (2005) Laser-launched flyer plates for shock physics experiments. Rev Sci Instrum 76(9):093907:1–9. https://doi.org/10.1063/1.2052593

Paisley DL, Luo S, Greenfield SR, Koskelo AC (2008) Laser-launched flyer plate and confined laser ablation for shock wave loading: validation and applications. Rev Sci Instrum 79(2):023902:1–8. https://doi.org/10.1063/1.2839399

Peralta P, DiGiacomo S, Hashemian S, Luo S, Paisley DL, Dickerson R, Loomis E, Byler D, McClellan KJ, D’Armas H (2009) Characterization of incipient spall damage in shocked copper multicrystals. Int J Damage Mech 18(4):393–413. https://doi.org/10.1177/1056789508097550

Wayne L, Krishnan K, DiGiacomo S, Kovvali N, Peralta P, Luo SN, Greenfield S, Byler D, Paisley DL, McClennan KJ, Koskelo A, Dickerson R (2010) Statistics of weak grain boundaries for spall damage in polycrystalline copper. Scripta Mater 63(12):1065–1068. https://doi.org/10.1016/j.scriptamat.2010.08.003

Brown AD, Wayne L, Pham Q, Krishnan K, Peralta P, Luo S, Patterson BM, Greenfield S, Byler D, McClellan KJ et al (2015a) Microstructural effects on damage nucleation in shock-loaded polycrystalline copper. Metall Mater Trans A 46(10):4539–4547

Brown AD, Pham Q, Peralta P, Luo SN, Patterson BM, Byler D, Koskelo A, Xiao X (2015) Correlations between spall damage mode preference and microstructure in shocked polycrystalline copper: a 3-d X-ray tomography study. J Dyn Behav Mater 1(4):388–396

Brown AD, Pham Q, Fortin EV, Peralta P, Patterson BM, Escobedo JP, Cerreta EK, Luo SN, Dennis-Koller D, Byler D et al (2017) Correlations among void shape distributions, dynamic damage mode, and loading kinetics. JOM 69(2):198–206

Remington TP, Hahn EN, Zhao S, Flanagan R, Mertens JCE, Sabbaghianrad S, Langdon TG, Wehrenberg CE, Maddox BR, Swift DC et al (2018) Spall strength dependence on grain size and strain rate in tantalum. Acta Mater 158:313–329

Krishnan K, Brown A, Wayne L, Vo J, Opie S, Lim H, Peralta P, Luo SN, Byler D, McClellan KJ, Koskelo A (2015) Three-dimensional characterization and modeling of microstructural weak links for spall damage in fcc metals. Metall Mater Trans A 46(10):4527–4538

Nguyen T, Luscher DJ, Wilkerson JW (2019) The role of elastic and plastic anisotropy in intergranular spall failure. Acta Mater 168:1–12

Grady D (2020) Statistics of energy dissipation in the hypervelocity impact shock failure transition. Int J Impact Eng 137:103435

Vogler TJ, Reinhart WD, Chhabildas LC (2004) Dynamic behavior of boron carbide. J Appl Phys 95(8):4173–4183

Mallick DD, Zhao M, Parker J, Kannan V, Bosworth BT, Sagapuram D, Foster MA, Ramesh KT (2019a) Laser-driven flyers and nanosecond-resolved velocimetry for spall studies in thin films. Exp Mech 59:611–628

Mallick DD, Williams CL, Wilkerson JW (2020) A brief review of spall failure in pure and alloyed magnesium. Dyn Behav Mater 46(10):4539–4547

Jones TL, DeLorme RD, Burkins MS, Gooch WA (2007) Ballistic evaluation of magnesium alloy az31b. Technical report, ARMY RESEARCH LAB ABERDEEN PROVING GROUND MD

Sagapuram D, Efe M, Moscoso W, Chandrasekar S, Trumble KP (2013) Controlling texture in magnesium alloy sheet by shear-based deformation processing. Acta Mater 61(18):6843–6856

Mallick DD, Zhao M, Bosworth BT, Schuster BE, Foster MA, Ramesh KT (2019b) A simple dual-beam time-multiplexed photon doppler velocimeter for pressure-shear plate impact experiments. Exp Mech 59(1):41–49

Mallick DD (2019) Shock-induced failure of protection materials using laser-driven micro-flyers. PhD thesis, Johns Hopkins University

Bassett WP, Johnson BP, Salvati III L, Nissen EJ, Bhowmick M, Dlott DD (2020) Shock initiation microscopy with high time and space resolution. Propellants Explos Pyrotech 45(2):223–235

Shazly M, Prakash V (2008) Shock response of a gamma titanium aluminide. J Appl Phys 104(8):083513

Ek DR, Asay JR (1986) The stress and strain-rate dependence of spall strength in two aluminum alloys. Shock waves in condensed matter. Springer, New York, pp 413–418

Bless SJ (1981) Spall criteria for several metals. Technical report, DAYTON UNIV OH RESEARCH INST

Appleby-Thomas GJ, Hazell PJ (2010) A study on the strength of an armour-grade aluminum under high strain-rate loading. J Appl Phys 107(12):123508

Selvarajou B, Joshi SP, Benzerga AA (2019) Void growth and coalescence in hexagonal close packed crystals. J Mech Phys Solids 125:198–224

Patterson BM, Escobedo-Diaz JP, Dennis-Koller D, Cerreta E (2012) Dimensional quantification of embedded voids or objects in three dimensions using X-ray tomography. Microsc Microanal 18(2):390–398

Huang Y, Hutchinson JW, Tvergaard V (1991) Cavitation instabilities in elastic-plastic solids. J Mech Phys Solids 39(2):223–241

Ghosh S, Cheng J (2018) Adaptive multi-time-domain subcycling for crystal plasticity fe modeling of discrete twin evolution. Comput Mech 61(1–2):33–54

Wright TW, Ramesh KT (2008) Dynamic void nucleation and growth in solids: a self-consistent statistical theory. J Mech Phys Solids 56(2):336–359

Wilkerson JW, Ramesh KT (2014) A dynamic void growth model governed by dislocation kinetics. J Mech Phys Solids 70:262–280

Wilkerson JW (2017) On the micromechanics of void dynamics at extreme rates. Int J Plast 95:21–42

Wang Y, Choo H (2014) Influence of texture on hall-petch relationships in an mg alloy. Acta Mater 81:83–97

Lloyd JT, Williams CL, Clayton JD (2020) Dynamic strength of az31b-4e and amx602 magnesium alloys under shock loading. J Dyn Behav Mater 1:11. https://doi.org/10.1007/s40870-019-00230-x

Farbaniec L, Williams CL, Kecskes L, Ramesh KT, Becker R (2016) Microstructural effects on the spall properties of ecae-processed az31b magnesium alloy. Int J Impact Eng 98:34–41

Wilkerson JW, Ramesh KT (2016) Unraveling the anomalous grain size dependence of cavitation. Phys Rev Lett 117(21):215503

Marsh SP (1980) LASL shock Hugoniot data, vol 5. University of California Press, Berkeley

Trojanová Z, Lukáč P, Podrábskỳ T, Pešička J (2011) High strain rate behaviour of an az31+ 0.5 ca magnesium alloy. Materials Engineering-Materiálové inžinierstvo (MEMI) 19(1):12–17

Xia Y, Li T, Li L, Liu S, Li Y (2017) Influence of initial texture on the shock property and spall behavior of magnesium alloy az31b. Mater Sci Eng A 700:259–268

Garkushin GV, Razorenov SV, Krasnoveikin VA, Kozulin AA, Skripnyak VA (2015) Effect of structural factors on mechanical properties of the magnesium alloy ma2-1 under quasi-static and high strain rate deformation conditions. Phys Solid State 57(2):337–343

Thao Nguyen, Luscher DJ, Wilkerson JW (2020) A physics-based model and simple scaling law to predict the pressure dependence of single crystal spall strength. J Mech Phys Solids 137:103875

Czarnota C, Jacques N, Mercier S, Molinari A (2008) Modelling of dynamic ductile fracture and application to the simulation of plate impact tests on tantalum. J Mech Phys Solids 56(4):1624–1650

Acknowledgements

We thank the Dlott group at University of Illinois Urbana Champagne for their guidance in developing the laser-driven flyer apparatus used in this study, with special thanks to Dr. William Shaw, Dr. William Bassett, and Erin Nissen. We thank the Sagapuram group at Texas A&M University for providing the AZ31B target foils. Finally, we thank the Hopkins Extreme Materials Institute for their support, specifically Dr. Meng Zhao for his discussions regarding the subject matter and Dr. Amy Dagro, Matt Shaeffer, and Hao Sheng for their help with procuring materials and proofreading. This research was sponsored by the Army Research Laboratory and was accomplished under Cooperative Agreement Number W911NF-12-2-0022. The views and conclusions contained in this document are those of the authors and should not be interpreted as representing the official policies, either expressed or implied, of the Army Research Laboratory or the U.S. Government. The U.S. Government is authorized to reproduce and distribute reprints for Government purposes notwithstanding any copyright notation herein.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mallick, D.D., Parker, J., Wilkerson, J.W. et al. Estimating Void Nucleation Statistics in Laser-Driven Spall. J. dynamic behavior mater. 6, 268–277 (2020). https://doi.org/10.1007/s40870-020-00248-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40870-020-00248-6