Abstract

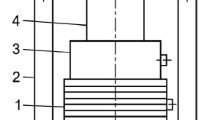

In this paper the design, the accuracy assessment and the calibration procedure of an innovative six axis load cell are presented. The load cell is able to measure the three forces and three moments and has been designed at the Politecnico di Milano (Technical University of Milan) as a result of 10 years of research in this field. The sensing structural element of the six-axis load cell is a three spoke structure constrained to the frame of the load cell by means of special joints conceived to avoid friction. Strain gauges are conveniently located on highly stressed areas. Mathematical models, both analytical and numerical, are implemented and presented in order to describe the behaviour of the load cell, to optimize its parameters and to theoretically assess its accuracy. A special device has been designed and constructed in order to accurately and quickly calibrate the load cell. Particular attention has been devoted to the processing of the strain gauges signals. An electronic DSP board, located inside the load cell, has been realized able to compute the six components of the generalized force from the strain gauge signals and return six voltage signals proportional to the measured forces. Software selectable filters and gains are implemented on the DSP board.

Similar content being viewed by others

Abbreviations

- F :

-

Vector of forces and moments acting at the load cell centre

- T1,T2,T3 :

-

Reaction forces (statically determined structure)

- E s :

-

Vector of the strains measured by the strain gauges

- Ε b :

-

Vector of the strain signals measured by the bridge ε i (i=1,..,6)

- C b :

-

Load cell force-deformation matrix

- ΔV :

-

Vector of the output voltages ΔVi (i=1,..,6) at the Wheatstone bridges

- V :

-

Excitation voltage at the Wheatstone bridges

- k :

-

Gauge factor

- L:

-

Total length of the spoke (from the spoke tip to the centre of the structure)

- H :

-

Elastic matrix for an isotropic material

- l/l joint :

-

Sensing element’s spoke length/sliding spherical joint’s spoke length

- a/ajoint :

-

Sensing element’s spoke height/sliding spherical joint’s spoke height

- b/bjoint :

-

Sensing element’s spoke width/sliding spherical joint’s spoke width

- ψ/ψjoint :

-

Angular error between the spokes of the sensing element/sliding spherical joint

- R/Rjoint :

-

Internal rigid ring radius (sensing element)/(sliding spherical joint)

- n:

-

Number of spokes of the sliding spherical joint

- xj,yj,zj :

-

Local coordinates related to spoke j

- ξ j :

-

Axial coordinate of the deformable part of spoke j

- A(ξ):

-

Cross section area of the spoke

- Δ R :

-

Compliance matrix (contribution of the deformation of the elastic spherical joints)

- Δ D :

-

Compliance matrix (contribution of the deformation of the spokes of the sensing element)

- Jx :

-

Moment of inertia of the spoke’s section around the x axis

- Jy :

-

Moment of inertia of the spoke’s section around the y axis

- JP :

-

Polar moment of inertia of the spoke’s section

- I :

-

Identity matrix

- Δ :

-

Compliance matrix

- M e :

-

Experimental calibration matrix

- M thp :

-

Calibration matrix (quasi-statically determined structure)

- \( \overline{\mathbf{M}} \) :

-

Inverse of calibration matrix

- k a :

-

Joint axial stiffness

- k rx /k ry :

-

Joint radial stiffnesses

- k t :

-

Joint torsional stiffness

- k bt /k b :

-

Joint bending stiffnesses

- k x /k y /k z :

-

Load cell interface stiffnesses

- S j :

-

Vector of the internal forces and moments acting at the j-th spoke root

- S :

-

Vector of the internal forces and moments acting at the spoke roots

- δ j :

-

Displacements and rotations at the j-th spoke root

- δ xj ,δ yj ,δ zj :

-

Displacement components at the centre of the structure related to spoke j

- ϕ xj ,ϕ yj ,ϕ zj :

-

Rotation components at the centre of the structure related to spoke j

- Σ i :

-

Matrix that relates stresses at each strain gauge location to the reactions at the centre

- σ ij :

-

Vector of stress components at each strain gauge location

- ε ij :

-

Vector of strain components at each strain gauge location

- εsg,ij :

-

Strain measured by each strain gauge

- nx,ny,nz :

-

Components of the direction of the reading sensor of the strain gauge

- q i :

-

Vector containing the functions of nx,ny,nz

- α :

-

Angle between two consecutive spokes

- R t (α) :

-

Rotation matrix

- σ VM :

-

Von Mises stress

- σ adm :

-

Admissible stress

- E:

-

Young’s modulus

- ν:

-

Poisson’s ratio

- G:

-

Shear modulus

- χ:

-

Shear factor

- β1:

-

Spoke taper angle in yz plane

- β2:

-

Spoke taper angle in xy plane

- A(ω) :

-

Inertance—transfer function acceleration/force

- ω :

-

Circular frequency

- f :

-

Frequency

- \( \overline{m} \) :

-

Mass of a single degree of freedom system

- \( \overline{k} \) :

-

Stiffness of a single degree of freedom system

- \( \overline{a} \) :

-

Acceleration

- \( \overline{F} \) :

-

Applied force

- DSP:

-

Digital signal processor

- BW:

-

Bandwidth

- x ij :

-

Error on positioning strain gauge i on spoke j (x direction, see Fig. 14)

- y ij :

-

Error on positioning strain gauge i on spoke j (y direction, see Fig. 14)

- z ij :

-

Error on positioning strain gauge i on spoke j (z direction, see Fig. 14)

- ϑ ij :

-

Error on positioning strain gauge i on spoke j (orientation angle error, see Fig. 14)

- cij :

-

Term of calibration matrix

- SI:

-

Sensitivity indices

- DI:

-

Disturbance indices (noise factors)

- F.S.:

-

Full scale

- u:

-

95 % relative uncertain with respect to full scale

- LB:

-

Lower bound

- UB:

-

Upper bound

- e k :

-

Vector of calibration errors for the k-th load combination

- F k :

-

Vector of calibration loads for the k-th load combination

- ΔV k :

-

Vector of output voltages at the Wheatstone bridges k-th load combination

- e cal :

-

Vector of calibration errors

- F cal :

-

Vector of calibration loads

- ΔV cal :

-

Vector of output voltages at the Wheatstone bridges measured during calibration procedure

- E :

-

Vector of square errors

References

Gobbi M, Mastinu G, Giorgetta F (2005) Sensors for measuring forces and moments with application to ground vehicle design and engineering. Proceedings ASME IMECE 2005 IMECE2005-81143

Mastinu G, Gobbi M (2006) Giunto elastico a cerniera sferica traslante e sensore di forze e momenti perfezionato con tale giunto. Italian Patent, ME.05.025.A, 22/05/2006

Mastinu G, Gobbi M (2010) Device and method for measuring forces and moments. United States Patent US 7 665 371 B2, 23 Feb 2010

Mastinu G, Gobbi M (2005) Device and method for measuring forces and moments. Patent WO2005015146, 17 Feb 2005

Mastinu G, Gobbi M (2007) Elastic joint with translating spherical hinge and force and moment sensor improved by means of the said joint. International Application number PCT/IB2007/001335, 16 May 2007

Cook et al (1999) Multi-axis wheel transducer with angular position detector. Advanced Mechanical Technology, Inc. Patent, US5886350

http://www.sendev.com/ Sensor Development Inc. (Model 77016 and 6 axis WFS), 5/2005

http://www.michsci.com/ Michigan Scientific Corporation (model LW 12.8), 5/2005

http://www.mts.com/ MTS Systems Corporation (SWIFT Wheel Force Transducer), 5/2005

http://www.kistler.com Kistler (RoaDyn Wheel Force Sensor), 5/2005

http://www.igel-ingenieure.de/ (IGel WFT Wheel Sensor), 5/2005

Giorgetta F, Gobbi M, Mastinu G (2007) On the testing of vibration performances of road vehicle suspensions. Exp Mech 47:485–495. doi:10.1007/s11340-006-9022-8

Gobbi M, Mastinu G (2004) Wheels with integrated sensors for measuring tyre forces and moments. Proc of the AVEC 04 Symposium, Arnhem, August 2004

Gobbi M, Mastinu G, Rocca G (2008) Design of a smart wheel. Proceedings of 2008 Design Engineering Technical Conference, New York City, August 2008

Gobbi M, Previati G, Mastinu G (2011) Refined design of a measuring wheel. Proceedings of the ASME Design Engineering Technical Conference IDETC/CIE 2011, Washington DC, USA, ISBN: 978-079185485-3

Gobbi M, Aiolfi M, Pennati M, Previati G, Levi F, Ribaldone M, Mastinu G (2005) Measurement of the forces and moments acting on farm tractor pneumatic tyres. Veh Syst Dyn 43:412–433. doi:10.1080/00423110500140963

Fischer U, Zimmermann C, Jörg W (2002) SG-balance 192-6I calibration report. RUAG Center Aerodynamics

University of Southampton (2012) http://www.windtunnel.soton.ac.uk/balance/balance_RJMitchell.html

Modern Machine & tool CO., INC (2012) Strain gage wind tunnel balances. http://www.mmtool.com/balances.html

RUAG Aerospace Defence Technology (2005) Strain gauge balances for wind tunnel measurements. http://www.ruag.com

Blakeborough A, Clément D, Williams MS, Woodward N (2002) Novel load cell for measuring axial force, shear force, and bending movement in large-scale structural experiments. Exp Mech 42:115–122

Jakovljevic Z, Petrovic PB, Hodolic J (2012) Contact states recognition in robotic part mating based on support vector machine. Int J Adv Manuf Technol 59:377–395. doi:10.1007/s00170-011-3501-5

Chen H, Wang J, Zhang B, Fuhlbrigge T (2011) Modeling and analysis of robotic wheel loading process in trim-and-final assembly. Ind Robot Int J 38:614–621

Carignan F et al (1985) Force measuring platform and load cell using strain gages to measure shear forces. Advanced Mechanical Technology, Inc., Patent US4493220

Spletzer B, Marron L (2000) Information package for the simplified six-axis load cell. sandia national laboratories, e-mail: blsplet @sandia.gov

Berme N (2002) Multi-component force and moment measuring platform and load transducer. Bertec Corporation, Patent US6354155

Engeler P et al (1995) Multicomponent force and moment measuring arrangement. K.K. Holding AG, US5402684

Meyer R et al (1998) Six axis load cell. MTS SYSTEMS CORPORATION, European Patent EP0632884B1

http://www.amti.biz/ Advanced Mechanical Technology, Inc, 2012

http://www.jr3.com/ Multi-Axis Load Cell Technologies, 2012

Yee AG, Akeel HA (1996) Six axis force sensor employing multiple shear strain gages. Fanuc USA Corporation (Elkgrove Village, IL), United States Patent 5490427

Meyer RA, Olson DJ (1994) Six axis load cell. MTS Systems Corporation (Eden Prairie, MN), United States Patent 5315882

Liu H, Willberg B, Meusel P (2005) Force moment sensor. Deutsches Zentrum fur Luft- und Raumfahrt e.V. (Koln, DE), United States Patent 6871552

Berme N (2002) Multi-component force and moment measuring platform and load transducer, Bertec Corporation (Worthington, OH), United States Patent 6354155

Meyer RA, Olson DJ (2005) Multi-axis load cell. MTS Systems Corporation (Eden Prairie, MN), United States Patent 6845675

Meyer RA, Kempainen AJ, Olson DJ (2004) Multi-axis load cell body. MTS Systems Corporation (Eden Priarie, MN), United States Patent 6769312

Lerat B (1989) Transducer for bending and twisting moments. Commissariat A L’Energie Atomique, Patent US4879913

Wensink H, de Boer MJ, Wiegerink RJ, Zwijze AF, Elwenspoek MC (1998) First micromachined silicon load cell for loads up to 1000 kg. Proc SPIE ‘98, vol 3514 Micromachined Devices and Components IV

Zwijze AF, Wiegerink RJ, Lammerink TSJ, Elwenspoek MC (1998) Low creep and hysteresis load cell based on a force to liquid pressure transformation. Proceedings of the Dutch National Sensor Conference, Enschede, March 2, 1998, pp 287–292

Byun Y et al (2002) Parallel type six-axes force moment measuring apparatus. Samsung Electronics Co., Ltd., Patent US6349604

http://www.ati-ia.com/ ATI Industrial Automation, (Series OMEGA and GAMMA), 5/2005

Gagliano C, Gobbi M, Mastinu G, Pennati M (2012) Indoor/outdoor testing of a passenger car suspension for vibration and harshness analysis. SAE Int J Passeng Cars Mech Syst 5:937–948

Dwarakanath TA, Bhutani G (2011) Beam type hexapod structure based six component force-torque sensor. Mechatronics 21:1279–1287

Hou Y, Zeng D, Yao J, Kang K, Lu L, Zhao Y (2009) Optimal design of a hyperstatic Stewart platform-based force/torque sensor with genetic algorithms. Mechatronics 19:199–204

Li Y et al (2012) Research on a novel parallel spoke piezoelectric 6-DOF heavy force/torque sensor. Mech Syst Signal Process. doi:10.1016/j.ymssp.2012.03.016

Liu W, Li Y, Jia Z, Zhang J, Quian M (2011) Research on parallel load sharing principle of piezoelectric six-dimensional heavy force/torque sensor. Mech Syst Signal Process 25:331–343

Jacq C, Luthi B, Maeder T, Lambercy O, Gassert R, Ryser P (2010) Thick-film multi-DOF force/torque sensor for wrist rehabilitation. Sensors Actuators A 162:361–366

Liang Q, Zhang D, Song Q, Ge Y, Cao H, Ge Y (2010) Design and fabrication of a six-dimensional wrist force/torque sensor based on E-type membranes compared to cross beams. Measurement 43:1702–1719

Mastinu G, Gobbi M, Previati G (2011) A new six-axis load cell. Part I: Design. Exp Mech 51:373–388

Gobbi M, Previati G, Guarneri P, Mastinu G (2011) A new six-axis load cell. Part II: error analysis, construction and experimental assessment of performances. Exp Mech 51:389–399

Robinson GM (1997) Finite element modelling of load cell hysteresis. Measurement 20:103–107

Gobbi M, Mastinu G, Pennati M (2007) Indoor testing of road vehicle suspensions. Meccanica 43:173–184. doi:10.1007/s11012-008-9119-5

Stanikov RB, Matusov JB (1995) Multicriteria optimization and engineering. Mechanical engineering: Industrial engineering, Chapman & Hall, New York

Mastinu G, Gobbi M, Miano C (2006) Optimal design of complex mechanical systems with application to vehicle engineering. Springer Verlag, Berlin

Gobbi M (2013) A k, k-ε optimality selection based multi objective genetic algorithm with applications to vehicle engineering. Optim Eng 14:345–360. doi:10.1007/s11081-011-9185-8

Wu B, Luo J, Shen F, Ren Y, Wu Z (2011) Optimum design method of multi-axis force sensor integrated in humanoid robot foot system. Measurement 44:1651–1660

Silva C, Murugan MS, Ganguli R (2011) Uncertainty quantification in helicopter performance using monte carlo simulations. J Aircraft 48(5) September-October 2011. doi:10.2514/1.C000288

Beretta S (2009) Affidabilità delle costruzioni meccaniche. Springer-Verlag Italia, Milano

Ewins DJ (2000) Modal testing: theory practice and application (2nd ed). Research Studies Press LTD., Baldock, Hertfordshire, England, 34–45

Cowper GR (1996) The shear coefficient in Timoshenko’s beam theory. J Appl Mech 1966:335–340

Gere J, Goodno BJ (2012) Mechanics of materials. Cengage Learning EMEA

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

Let us consider:

-

The vector S j of the six reactions in the central node of the structure for each spoke (a total of 18 reactions).

$$ {\mathbf{S}}_{j\left(j=1,2,3\right)}={\left[\begin{array}{cccccc}\hfill {S}_{xj}\hfill & \hfill {S}_{yj}\hfill & \hfill {S}_{zj}\hfill & \hfill {M}_{xj}\hfill & \hfill {M}_{yj}\hfill & \hfill {M}_{zj}\hfill \end{array}\right]}^T $$$$ \mathbf{S}={\left[\begin{array}{ccc}\hfill {\mathbf{S}}_1\hfill & \hfill {\mathbf{S}}_2\hfill & \hfill {\mathbf{S}}_3\hfill \end{array}\right]}^T $$ -

The vector δ j of the six components of displacement “δ” and rotation “φ” of each spoke at the central node of the structure.

$$ {\boldsymbol{\updelta}}_{j\left(j=1,2,3\right)}={\left[\begin{array}{cccccc}\hfill {\delta}_{xj}\hfill & \hfill {\delta}_{yj}\hfill & \hfill {\delta}_{zj}\hfill & \hfill {\varphi}_{xj}\hfill & \hfill {\varphi}_{yj}\hfill & \hfill {\varphi}_{zj}\hfill \end{array}\right]}^T $$$$ \boldsymbol{\updelta} ={\left[\begin{array}{ccc}\hfill {\boldsymbol{\updelta}}_1\hfill & \hfill {\boldsymbol{\updelta}}_2\hfill & \hfill {\boldsymbol{\updelta}}_3\hfill \end{array}\right]}^T $$ -

the rotation matrix R t (α) (α = ± 2/3π) defined as follows

$$ \begin{array}{l}{\boldsymbol{R}}_{\boldsymbol{t}}=\left(\alpha \right)=\left[\begin{array}{cc}\hfill \boldsymbol{R}\left(\alpha \right)\hfill & \hfill 0\hfill \\ {}\hfill 0\hfill & \hfill \boldsymbol{R}\left(\alpha \right)\hfill \end{array}\right]\hfill \\ {}\boldsymbol{R}\left(\alpha \right)=\left[\begin{array}{ccc}\hfill \cos \left(\alpha \right)\hfill & \hfill 0\hfill & \hfill \sin \left(\alpha \right)\hfill \\ {}\hfill 0\hfill & \hfill 1\hfill & \hfill 0\hfill \\ {}\hfill - \sin \left(\alpha \right)\hfill & \hfill 0\hfill & \hfill \cos \left(\alpha \right)\hfill \end{array}\right]\hfill \end{array} $$(19)

In order to compute the 18 components of the vector S, a 18 equation system has been written in the following form

The first equation refers to the force equilibrium at the central node (roots of the three spokes), while the other 2 equations refer to the displacement consistency at the central node between the spokes 1–2 and 1–3 respectively. The equation system can be written in a compact form:

Where Δ is a 6 × 6 matrix that links the generalized displacements vector δ j to the reactions vector S j of spoke j:

The matrix Δ derives from the sum of two different contributions: Δ R accounts for the elastic deformation of the sliding spherical joint at the spoke tip, and Δ D represents the elastic deformation of the spoke itself (Fig. 24).

Referring to the case of the deformation in the x direction due to a reaction force Sx in the same direction shown in Fig. 24, the contribution of the elastic deformation of the spoke and of the rigid motion due to the compliance of the joints of the generalized displacement δxj and of the generalized rotation φyj can be computed as follows. The total generalized rotation φyj reads

where the first term of equation (23) expresses a rigid rotation of the spoke

and the second term can be calculated by applying the virtual work principle

The generalized displacement δxj reads

where the first two terms of equation (26) account for the rigid motion associated to the joints elasticity

being φ Yj (K bt ) computed in equation (24). The third and fourth terms account for the elastic deformation of the spoke. In particular the third term can be obtained by applying the virtual work principle

where χ is the shear factor and A(ξ) is the cross-section area. For a rectangular section the shear factor χ reads [60]

The last term of equation (28) accounts for the shear contribution in the elastic deformation of the spoke [61]. The fourth term of equation (26) is given by considering the displacement of the rigid disk due to the rotation of the deformed spoke computed in equation (25).

All the displacements and rotations resulting at each spoke root can be computed by applying the same approach, and the matrix Δ reads

Where the coefficients I1–10 are summarized in Table 7

while the coefficients I11 and I12 have the following expression [61]

The coefficients reported in equation (30) quantify the effect of the shear force on the spoke elastic deformation.

Matrix Δ is numerically computed and it provides a linear relationship between the generalized displacements vector δ j and the reactions vector S j as stated in equation (22).

Numerical results show that the shear forces provide an average variation of 5 % on the computed stiffness values.

From equation (21), vector S can be computed. The linear relationship between S and the bridges outputs can be derived as follows.

Vector S can be divided into three vectors S j (j = 1,2,3), each one containing the 3 reaction forces and the 3 reaction moments applied at the tip of each spoke, and indicating with j the number of the spoke and with i the location of each of the 8 strain gauges on each spoke (i = 1a,1a′,1b,1b′,2a,2a′,2b,2b′, see Fig. 4), the stress components at each strain gauge location read

where Σ i is a 6 by 6 matrix that expresses the relationship between the reactions at the spoke tip and the stress components at each strain gauge location. Matrix Σ i is different for each of the 8 strain gauges on each spoke, but, being defined in a local reference frame, the 8 matrices Σ i are the same for all of the spokes.

By considering an elastic, isotropic material, the relationship between the stress and strain components at each strain gauge location is

being H the matrix of the stress–strain relationship (Hooke law), j refers to the spoke number and i to the location of the strain gauge.

Finally, to get the deformation read by the strain gauge, the taper angles of the spoke have to be considered, i.e. the strain gauge orientation is different from the orientation of the local reference system of the spoke (see Fig. 25). The strain measured by the strain gauge can be expressed by considering the rotation of the strain tensor

where nx,ny,nz are the components of the direction of the strain gauge. Being q i the vector containing the functions of nx,ny,nz, the relationship can be expressed in a more compact form:

By replacing equation (32) in equation (33), the relationships between the vectors S j and the corresponding strain gauge measures can be obtained:

where i refers to the strain gauge and j to the spoke. A total of 24 equations of the type of equation (34) can be written for the 24 strain gauges. By considering a full Wheatstone bridge connection, the equivalent strains measured by the six bridges due to the bending of the spokes read

that can be rearranged in a more compact notation

where \( \widehat{\mathbf{M}} \) is obtained by extracting the first six columns of the inverse of matrix A A of equation (21).

Finally, it is possible to compute the calibration matrix M thp

By simply inverting the terms in equation (36), the calibration matrix M thp can be derived

Rights and permissions

About this article

Cite this article

Ballo, F., Gobbi, M., Mastinu, G. et al. Advances in Force and Moments Measurements by an Innovative Six-axis Load Cell. Exp Mech 54, 571–592 (2014). https://doi.org/10.1007/s11340-013-9824-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9824-4