Abstract

An experimental approach for determining the effect of machining the gage section of specimens for quasi-static, biaxial tension/shear testing of sheet steels is described. This method is demonstrated by comparing the results found by an existing testing method with a reduced thickness (Mohr and Oswald Exp Mech 48:65–77, 2008) to that of full-thickness specimens. Finally, the same results are compared to a specimen in which half of the thickness is removed. These tests are performed on DP780, a first generation advanced high-strength steel. Analysis of the full-thickness and one of the reduced thickness specimens shows that some second-order effects in measuring stress occur from these procedures, but these effects are small. Direct comparison of the engineering stress versus strain curves for the tested conditions shows that for the steel under consideration, there is little dependence on full-thickness, partial thickness, or through-thickness sampling location for continuum-level anisotropic plasticity properties in multi-axial loading for the material investigated and the methods used in manufacturing the specimens.

Similar content being viewed by others

References

ASTM Standard Test Methods for tension testing of metallic materials [Metric], ASTM International E 8M-04

Zavattieri PD, Savic V, Hector LG, Fekete JR, Tong W, Xuan Y (2009) Spatio-temporal characteristics of the Portevin-Le Chatelier effect in austenitic steel with twinning induced plasticity. Int J Plast 25:2298–2330

Tong W, Tao H, Jiang X, Zhang N, Marya MP, Hector LG, Gayden XQ (2005) Deformation and fracture of miniature tensile bars with resistance-spot-weld microstructures. Metall Mater Trans A 36A:2005–2651

Tao H, Zavattieri PD, Hector LG, Tong W (2010) Mode I fracture at spot welds in dual-phase steel: an application of reverse digital image correlation. Exp Mech:1199–1212

Savic V, Hector L, Snavely K, Coryell J (2010) Tensile deformation and fracture of TRIP590 steel from digital image correlation. SAE Int:246–254

Savic V, Hector LG, Fekete JR (2010) Digital image correlation study of plastic deformation and fracture in fully martensitic steels. Exp Mech 50:99–110

Savic V, Hector LG (2007) Tensile deformation and fracture of press hardened boron steel using digital image correlation. Paper 2007-01-0790. p 28/30

Foecke T, Banovic SW, Fields RJ (2001) Sheet metal formability studies at the National Institute of Standards and Technology. J Metals:27–30

Hosford WF, Duncan JL (1999) Sheet metal forming: a review. J Mater:39–44

Nakazima K, Kikuma T, Hasuka K (1971) Study on the formability of steel sheets. Yawat Tech Rep No 284:678–680

Hasek V (1973) On the strain and stress states in drawing of large unregular sheet metal components (in German), Berichte aus dem Institute fuer Umformtechnik, Universitaet Stuttgart, Nr. 25, Essen, Girardet

Hasek V (1978) Untersuchung und theoretische Beschribung wichtiger Einflussgroessen auf das Grenzformaenderungsschaubild [Research and theoretical description concerning the influences on the FLDs (In German)], Blech Rohre Profile 25:213–220, 285–292, 493–399, 617–627

Abu-Farha F, Hector LG, Khraisheh M (2009) Cruciform-shaped specimens for elevated temperature biaxial testing of lightweight materials. JOM a TMS Publ 61:48–56

Abu-Farha F, Hector L, Nazzal M (2010) On the development of viable cruciform-shaped specimens: towards accurate elevated temperature biaxial testing of lightweight materials. Key Eng Mater 433:93–101

Banabic D, Barlat F, Cazacu O, Kuwabara T (2010) Advances in anisotropy and formability. Int J Form 3:165–189

Makinde A, Thibodeau L, Neale KW (1992) Development of an apparatus for biaxial testing using cruciform specimens. Exp Mech:138–144

Müller W, Pöhlandt K (1996) New experiments for determining yield loci of sheet metal. J Mater Process Technol 60:643–648

Green DE, Neale KW, MacEwen SR, Makinde A, Perrin R (2004) Experimental investigation of the biaxial behavior of an aluminum sheet. Int J Plast:1677–1706

Geiger M, Hussnätter W, Merklein M (2005) Specimen for a novel concept of the biaxial tension test. J Mater Process Technol 167:177–183

Arcan M, Hashin Z, Voloshin A (1978) A method to produce uniform plane-stress states with applications to fiber-reinforced materials. Exp Mech:141–146. p 29/30

Tao H, Tong W, Hector LG, Zavattieri PD (2008) Uniaxial tensile and simple shear behavior of resistance spot-welded dual-phase steel joints. J Mater Eng Perform 17:517–534

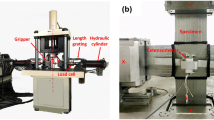

Mohr D, Oswald M (2008) A new experimental technique for the multi-axial testing of advanced high strength steels. Exp Mech 48:65–77

Han S-H, Choi S-H, Choi J-H, Seong H-G, Kim I-B (2010) Effect of hot-rolling processing on texture and rvalue of annealed dual-phase steels. Mater Sci Eng A:1686–1694

Kamikawa N, Tsuji N, Minamino Y (2004) Microstructure and texture through thickness of ultralow carbon IF steel sheet severely deformed by accumulative roll-bonding. Sci Technol Adv Mater 5:163–172

Xu P, Yin F, Nagai K (2004) The thickness gradient of microstructure and mechanical property in an as-cast thin steel slab. Mater Trans 45:2456–2462

Mishra SK, Tiwari SM, Kumar AM, Hector LG (2012) Effect of strain and strain path on texture and twin development in austenitic steel with twinning-induced plasticity. Metall Mater Trans A 43A:1598–1609

Bleys P, Kruth J-P, Lauwers B, Schacht B, Balasubramanian V, Froyen L, Humbeeck JV (2006) Surface and sub-surface quality of steel after EDM. Adv Eng Mater 8:15–25

Outeiro JC, Umbrello D, M’Saoubi R (2006) Experimental and FEM analysis of cutting sequence on residual stresses in machined layers of AISI 316L steel. Mater Sci Forum 542–525:179–184

Huh J, Huh H, Lee CS (2013) Effect of strain rate on plastic anisotropy of advanced high strength steel sheets. Int J Plast In Press

Wu X, Bahmanpour H, Schmid K (2012) Characterization of mechanically sheared edges of dual phase steels. J Mater Process Technol 212:1209–1224

Lee JY, Lee JW, Lee MG, Barlat F (2012) An application of homogenous anisotropic hardening to springback predication in pre-strained U-draw/bending. Int J Solids Struct 49:3562–3572

Samei J, Green DE, Golovashchenko S, Hassannejadasl A (2012) Quantitative microstructure analysis of formability enhancement in dual phase steels subject to electrohydraulic forrming. J Mater Eng Perform:30/30

Sung JH, Kim JH, Wagoner RH (2010) A plastic constitutive equation incorporating strain, strain-rate, and temperature. Int J Plast 26:1746–1771

Sutton M, Jose Orteu J, Schreier H (2009) Image correlation for shape, motion and deformation measurements: basic concepts, theory and applications. Springer, ISBN 0387787461

Voloshin A, Arcan M (1980) Failure of unidirectional fiber-reinforced materaisl – new methodology and results. Exp Mech:280–284

Banks-Sills L, Arcan M (1983) An edge-cracked mode II fracture specimen. Exp Mech:357–261

McClintock FA, Zheng ZM (1993) Ductile fracture in sheets under transverse strain gradients. Int J Fract 64:321–337

Hill R (1950) The mathematical theory of plasticity. Oxford University Press

Barlat F, Lian J (1989) Plastic behavior and stretchability of sheet metals. Part I: a yield function for orthotropic sheets under plane stress conditions. Int J Plast 5:51–66

Mohr D, Henn S (2007) Calibration of stress-triaxiality dependent crack formation criteria: a new hybrid experimetnal-numberical method. Exp Mech 47:805–820

Acknowledgments

The support of the Joint MIT/Industry AHSS Fracture Consortium is gratefully acknowledged. US Steel is thanked for providing the material. Professors Wierzbicki and Mohr are thanked for their editorial review. Professor Dirk Mohr is also thanked for valuable discussions and for some automation of the calibration process.

Author information

Authors and Affiliations

Corresponding author

Additional information

Work performed at Impact and Crashworthiness Laboratory, Department of Mechanical Engineering.

Rights and permissions

About this article

Cite this article

Walters, C.L. The Effect of Machining the Gage Section on Biaxial Tension/Shear Plasticity Experiments of DP780 Sheet Steel. Exp Mech 53, 1647–1659 (2013). https://doi.org/10.1007/s11340-013-9754-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9754-1