Abstract

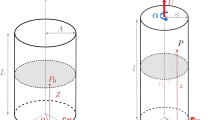

In this paper, we deal with the mechanical behavior of elastomeric materials subjected to high cyclic loading in cases of high strain. First, a methodology for material parameter identification is used for a constitutive visco-hyperelastic law with discontinuous damage, modeling the Mullins effect. Then a fatigue model characterized by a strain energy density-based criterion is proposed and implemented in the finite element code, Code-Aster [1]. Two kinds of elastomer are considered, an incompressible rubber and an expanded compressible polyurethane. Cyclic tensile tests were performed to identify material fatigue parameters. Finally, a numerical application using a finite element model is presented. This model is a plate perforated by a ∅6 mm hole for the first sample and a ∅10 mm hole for the second one. The results obtained from the finite element model are compared to experimental results.

Similar content being viewed by others

References

CODE-ASTER (2011) http://www.code-aster.org

Bouchart V, Brieu M, Kondo D, Nait-Abdelaziz M (2007) Macroscopic behavior of a reinforced elastomer: micromechanical modelling and validation. Méc Indust 8(3):199–205

Miehe C (1995) Discontinuous and continuous damage evolution in ogden-type large-strain elastic materials. Eur J Mech A Solid 14(5):697–720

Chagnon G, Verron E, Gornet L, Marckmann G, Charrier P (2004) On the relevance of continuum damage mechanics as applied to the mullins effect in elastomers. J Mech Phys Solid 52(7):1627–1650

Miehe C, Goektepe S, Lulei F (2004) A micro-macro approach to rubber-like materials part i the non-affine micro-sphere model of rubber elasticity. J Mech Phys Solid 52(11):2617–2660

Benkahla J, Baranger T, Issartel J (2012) Experimental and numerical simulation of elastomeric outsole bending. Exp Mech 52:1461–1473

Saintier N, Cailletaud G, Piques R (2006) Crack initiation and propagation under multiaxial fatigue in a natural rubber. Int J Fatig 28(1):61–72

Ayoub G (2010) Comportment en grandes déformations et fatigue des polymères : modélisation constitutive et prédiction de la durée de vie en fatigue. PhD thesis, Université Lille 1

Bennani A (2006) Elaboration, comportement et durée de vie en fatigue du caoutchouc naturel renforcé de silice. PhD thesis, Ecole des Mines de Paris

Mars WV (2001) Multiaxial fatigue of rubber. PhD thesis, The university of Toledo

Mars W, Fatemi A (2002) A literature survey on fatigue analysis approaches for rubber. Int J Fatig 24(9):949–961

Shigley JE (1972) Mechanical engineering design. McGraw-Hill, New-York

Bompas-Smith JH (1973) Mechanical survival: the use of reliability data. RHW Book, Maidenhead Berkshire-England

Lalanne C (1999) Vibrations et chocs mécaniques Tome 4: dommage par fatigue. Hermes, Paris

Raoult I (2005) Structure élastomère sous chargement cyclique. PhD thesis, Ecole Polytechnique

Kim W, Lee H, Kim J, Koh SK (2004) Fatigue life estimation of an engine rubber mount. Int J Fatig 26(5):553–560

Robisson A (2000) Mechanical bevavior of viscoelastic and damage induced elastomers (SBR and PU), fatigue lifetime prediction. PhD thesis, Ecole des Mines de Paris

Verron E, Andriyana A (2008) Definition of a new predictor for multiaxial fatigue crack nucleation in rubber. J Mech Phys Solid 56(2):417–443

Wang B, Lu H, Kim G-h (2002) A damage model for the fatigue life of elastomeric materials. Mech Mater 34(8):475–483

Cantournet S, Desmorat R (2003) Thermodynamics modelling of internal friction and hysteresis of elastomers. Comptes Rendus Mécanique 331(4):265–270

Lemaitre J, Chaboche J (2004) Mécanique des matériaux solides. Dunod, Paris

Diehl T (1995) Two-dimensional and three-dimensional analysis of nonlinear nip mechanics with hyperelastic material formulations. PhD thesis, University of Rochester

Schrodt M, Benderoth G, Khhorn A, Silber G (2005) Hyperelastic description of polymer soft foams at finite deformations. Tech Mech 25:3–4

Promma N, Raka B, Grdiac M, Toussaint E, Cam JBL, Balandraud X, Hild F (2009) Application of the virtual fields method to mechanical characterization of elastomeric materials. Int J Solid Struct 46(34):698–715

Guélon T, Toussaint E, Cam JBL, Promma N, Grédiac M (2009) A new characterisation method for rubber. Polymer Test 28(7):715–723

Palmieri G, Sasso M, Chiappini G, Amodio D (2011) Virtual fields method on planar tension tests for hyperelastic materials characterisation. Strain 47:196–209

Acknowledgments

This paper was written in the framework of a project called SN2C, Simulation Numérique Conception Chaussure, funded by the Rhone-Alpes Region and the DGCIS: Direction Générale de la Compétitivité de l’Industrie et des Services.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Benkahla, J., Baranger, T.N. & Issartel, J. Fatigue Life Estimation for an NBR Rubber and an Expanded Polyurethane. Exp Mech 53, 1383–1393 (2013). https://doi.org/10.1007/s11340-013-9749-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9749-y