Abstract

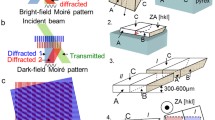

The electron-beam moiré method uses a high frequency grating to measure microscopic deformation. Increasingly fine gratings are being developed to achieve increasingly high resolutions in microscopic stress analysis. In this study, we improve the electron grid fabricating technique by using a common scanning electron microscope (SEM). An error analysis for the multi-scanning grating was performed by a sampling moiré method. The grating manufacturing parameters strongly affect the superfine grating quality. A high accelerating voltage or a short working distance yield better results generally. A set of optimal parameters is suggested based on a minimum-error criterion. A cross-line grid with a frequency of 10,000 lines/mm and a parallel grating with a frequency of 13,000 lines/mm were successfully fabricated.

Similar content being viewed by others

References

Kishimoto S, Egashira M, Shinya N, Carolan RA (1991) Local micro-deformation analysis by means of micro-grid and electron beam moiré fringe method. Proceedings of the 6th International Conference on the Mechanical Behavior of Materials. Jono M, Inoue T (ed). 4: 661–666

Read DT, Dally JW (1994) Electron-beam moiré study of fracture of a glass fiber reinforced plastic composite. J Appl Mech 61(2):402–409

Dally JW, Read DT (1993) Electron-Beam Moire. Exp Mech 33(4):270–277

Post D, Han B, Ifju P (1994) High sensitivity moiré. Springer, New York, pp 85–134

Durelli AJ, Daniel IM (1961) A nondestructive three-dimensional strain analysis method. J Appl Mech 28(1):83–96

Kishimoto S, Shinya N (1997) Application of electron beam lithography to study microcreep deformation and grain boundary sliding. J Mater Sci 32:3411–3497

Lee OS, Read DT (1995) Micro-strain distribution around a crack-tip by electron-beam moire methods. KSME Int J 9(3):298–311

Lee OS (1997) Residual stress interference by two micro-Vickers indentations. KSME Int J 11(4):379–385

Berger JR, Drexler ES, Read DT (1998) Error analysis and thermal expansion measurement with electron-beam moire. Exp Mech 38(3):167–171

Drexler ES (1999) Reliability of a flip-chip package thermally loaded between 55 °C and 125 °C. J Electron Mater 28(11):1150–115

Drexler ES, Berger JR (1999) Mechanical deformation in conductive adhesives as measured with electron-beam moire. J Electron Pack 121(2):69–74

Drexler ES (2000) Plastic strain in thermally cycled flip-clip PBGA solder bumps. IEEE Trans Adv Pack 23(4):646–651

Kishimoto S, Xie HM, Shinya N (2000) Electron moiré method and its application to micro-deformation measurement. Opt Laser Eng 34(1):1–14

Xing YM, Kishimoto S, Tanaka Y, Shinya N (2004) A novel method for determining interfacial residual stress in fiber reinforced composites. J Compos Mater 38(2):137–148

Xie HM, Shang HX, Dai FL et al (2004) Phase shifting SEM moiré method. Opt Laser Techno 36(4):291–297

Xie HM, Kishimoto S, Shinya N (2000) Fabrication of high-frequency electron beam moire grating using multi-deposited layer techniques. Opt Laser Techno 32(5):361–367

Xing YM, Kishimoto S, Zhao YR (2006) An electron moiré method for a common SEM. Acta Mech Sin 22:595–602

Xing YM, Kishimoto S, Shinya N (2004) Multiscanning method for fabricating electron moiré grating. Exp Mech 44(12):562–566

Ri S, Fujigaki M, Morimoto Y (2010) Sampling moiré method for accurate small deformation distribution measurement. Exp Mech 50:501–508

Lambert MS, Mariam TT, Susan FH (2010) Scanning Electron Microscope. Betascript Publishing pp 56–62

Fraser DA (2006) Probability and statistics. Duxbury Press, Boston, pp 116–117

Acknowledgments

The authors are grateful for support from the National Natural Science Foundation of China (Nos. 10972097 and 11062007), the Natural Science Foundation of Inner Mongolia of China (No. 010MS0703) and the Research Fund for the Doctoral Program of Higher Education of China (No.20101514120005).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, Y.R., Lei, Z.K., Xing, Y.M. et al. Fabricating Parameters Optimization of High Frequency Grating by Multi-scanning Electron Beam Method. Exp Mech 54, 45–55 (2014). https://doi.org/10.1007/s11340-013-9742-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-013-9742-5