Abstract

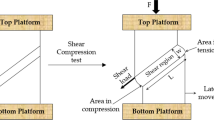

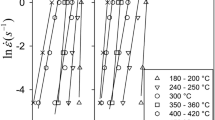

In the present work, shear-compression specimen was successfully employed to study the shear flow behavior of AZ31 magnesium alloy at high temperatures and in quasi-static regime. The loading process of shear-compression testing was simulated using ABAQUS software. This was carried out in the temperature range of 250–450°C and displacement rates of 1.5, 15 and 150 mm/min. In addition, to validate the numerical simulation results, the shear compression specimens were also compressed experimentally at the same conditions of numerical ones. Equivalent stress–strain curves obtained from numerical simulation results along with microstructural observations were utilized to investigate the effect of loading conditions on deformation behavior of the experimental alloy. The results indicated a homogenous distribution of shear strains within the gage and the high applicability of shear-compression specimen to study shear flow behavior of materials at hot deformation conditions.

Similar content being viewed by others

References

Andrade U, Meyers MA, Vecchio KS, Chokshi AH (1994) Dynamic recrystallization in high-strain, high-strain rate plastic deformation of copper. Acta Metall Mater 42:3183–3195

Hartmann KH, Kunze HD, Meyer LW (1981) In: Meyers MA, Murr LE (eds) Shock Wave and High-Strain-Rate Phenomena in Metals. New York, Plenum

Shih-Chieh L, Duffy J (1998) Adiabatic shear bands in a Ti–6Al–4V titanium alloy. J Mech Phys Sol 46:2201–2231

Xue Q, Nesterenko VF, Meyers MA (2003) Evaluation of the collapsing thick-walled cylinder technique for shear-band spacing. Intl J Impact Eng 28:257–280

Rittel D, Lee S, Ravichandran G (2002) A shear-compression specimen for large strain testing. Exp Mech 42(1):58–64

Rittel D, Ravichandran G, Lee S (2002) Large strain constitutive behavior of OFHC copper over a wide range of strain rates using the shear compression specimen. Mech Mater 34:627–642

Dorogoy A, Rittel D (2005) Numerical validation of the shear compression specimen part I: quasi-static large strain testing. Exp Mech 45(2):167–177

Rittel D, Landau P, Venkert A (2008) Dynamic Recrystallization as a Potential Cause for Adiabatic Shear Failure. Phys Rev Lett 101:165501

Rittel D, Wang ZG, Dorogoy A (2008) Geometrical imperfection and adiabatic shear banding. Intl J Impact Eng 35:1280–1292

Vural M, Rittel D, Ravichandran G (2003) Large Strain Mechanical Behavior of 1018 Cold-Rolled Steel over a Wide Range of Strain Rates. Met Mater Trans 34A:2873–2885

Rittel D, Wang ZG (2008) Thermo-mechanical aspects of adiabatic shear failure of AM50 and Ti6Al4V alloys. Mech Mater 40:629–635

Zhao J, Knauss WG, Ravichandran G (2009) A New Shear-Compression-Specimen for Determining Quasi-static and Dynamic Polymer Properties. Exp Mech 49(3):427–436

Rittel D, Ravichandran G, Venkert A (2006) The mechanical response of pure iron at high strain rates under dominant shear. Mater Sci Eng A 432:191–201

Keshavarz Z, Barnett MR (2006) EBSD analysis of deformation modes in Mg–3Al–1Zn. Scr Mater 55:915–918

Fatemi-Varzaneh SM, Zarei-Hanzaki A, Cabrera JM (2011) J Alloy Compd 509:3806–3810

Roostaei A, Zarei-Hanzaki A, Parsa MH, Fatemi-Varzaneh SM (2010) An analysis to plastic deformation behavior of AZ31 alloys during accumulative roll bonding process. J Mater Sci 45:4494–4500

Fatemi-Varzaneh SM, Zarei-Hanzaki A, Beladi A (2007) Dynamic recrystallization in AZ31 magnesium alloy. Mater Sci Eng A 456:52–57

Choi SH, Shin EJ, Seong BS (2007) Simulation of deformation twins and deformation texture in an AZ31 Mg alloy under uniaxial compression. Acta Mater 55:4181–4192

Máthis K, Trojanová Z, Lukáč P, Cáceres CH, Lendvai J (2004) Modeling of hardening and softening processes in Mg alloys. J Alloy Compd 378:176–179

Barnett MR (2001) Influence of deformation conditions and texture on the high temperature flow stress of magnesium AZ31. J Light Met 1:167–177

Nave MD, Barnett MR (2004) Microstructures and textures of pure magnesium deformed in plain-strain compress. Scr Mater 5:881–885

Choi SH, Kim DH, Lee HW, Seong BS, Piao K, Wagoner R (2009) Evolution of the deformation texture and yield locus shape in an AZ31 Mg alloy sheet under uniaxial loading. Mater Sci Eng A 526:38–49

Al-Samman T, Gottstein G (2008) Dynamic recrystallization during high temperature deformation of magnesium. Mater Sci Eng A 490:411–420

Acknowledgment

The authors would like to appreciate AIRIC for manufacturing of Shear Compression Specimens.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Moemeni, S., Zarei-Hanzaki, A., Abedi, H.R. et al. The Application of Shear Compression Specimen to Study Shear Deformation Behavior of AZ31 Mg Alloy at High Temperatures and Quasi-Static Regime. Exp Mech 52, 629–636 (2012). https://doi.org/10.1007/s11340-011-9525-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-011-9525-9