Abstract

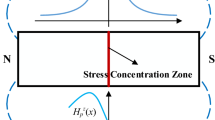

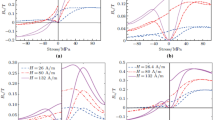

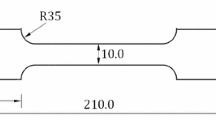

Metal magnetic memory (MMM) method is a novel, passive magnetic method for inspecting mechanical degradation of ferromagnetic components. To promote a further understanding of the relation between the magnetic characteristics and mechanical deformation, the normal spontaneous stray field component and its gradient of Q235-steel specimens were measured during uniaxial tensile and compressive loading processes. The results show that the normal spontaneous stray field component and its gradient are effective in capturing different deformation stages under tensions, but no detectable change can be found during the whole compressive loading processes. Compared with the amplitude of the normal spontaneous stray field component, the gradient is a more sensitive parameter. In addition, the result demonstrates that it is easy to differentiate macro-crack and plastic deformation because the differences among measured spontaneous stray field signals are obvious. Moreover, various factors affecting test results were also considered.

Similar content being viewed by others

References

Bozorth RM, Williams HJ (1945) Effect of small stress on magnetic. Properties Rev Mod Phys 17:72–80

Chikazumi S (1964) Physics of magnetism. Wiley, New York

ASTM international (1989) Nondestructive evaluation and quality control. Vol.17. ASM Handbook

Blitz J (1991) Electrical and magnetic methods of nondestructive testing. Adam Hilger IOP Publishing, Ltd., Bristol

Jiles D (1998) Introduction to magnetism and magnetic materials. 2nd edition. Chapman and Hall

Jagadish C, Clapham L, Atherton DL (1990) Influence of uniaxial elastic stress on power spectrum and pulse height distribution of surface Barkhausen noise in pipeline steel. IEEE Trans Magn 26(3):1160–1163

Lindgren M, Lepistö T (2003) Relation between residual stress and Barkhausen noise in a duplex steel. NDT&E Int 36:279–288

Sablik MJ, Augustyniak B (2000) Modeling the magnetic field dependence of magnetoacoustic emission. Mater Eval 58:655–660

Tomas I (2004) Non-destructive magnetic adaptive testing of ferromagnetic materials. J Magn Magn Mater 268:178–185

Doubov AA (1998) Screening of weld quality using the metal magnetic memory. Weld world 41:196–199

Doubov AA (1999) Diagnostics of metal items and equipment by means of metal magnetic memory, in: Proc of CHSNDT 7th Conference on NDT and International Research Symposium. Non-Destructive Testing Institution, CEMS, Shantou China, pp 181–187

Ren JL, Song K, Wu GH, Lin JM (2001) Mechanism study of metal magnetic memory testing, Proceedings of the 10th Asia-Pacific Conference on Non-Destructive Testing Brisbane, Australia, 17–21 September

Iordache VE, Hug E, Buiron N (2003) Magnetic behaviour versus tensile deformation mechanisms in a non-oriented Fe-(3 wt.%)Si steel. Mater Sci Eng A 359(1–2):62–74

Dong LH, Xu BS, Dong SY, Chen QZ, Wang YY, Zhang L (2005) Metal magnetic memory testing for early damage assessment in ferromagnetic materials. J Cent South Univ Technol 12(S2):102–106

Wang X, Chen M, Xu BS (2007) Change of magnetic memory signals during the tension–compression fatigue of 48MnV steel. China Mech Eng 18(15):1862–1864

Roskosz M, Gawrilenko P (2008) Analysis of changes in residual magnetic field in loaded notched samples. NDT&E Int 41:570–576

Doubov AA (2004) Principal features of metal magnetic memory method and inspection tools as compared to known magnetic NDT methods. Proceedings of the 16th Annual World Conference on Non-Destructive Testing. Montreal, Canada

Cullity BD (1972) Introduction to magnetic marerials. Addison-Wesley Publishing company, New York

Jiles DC, Atherton DL (1986) Theory of ferromagnetic hysteresis. J Magn Magn Mater 61:48–60

Sablik MJ, Burkhardt GL, Kwun H, Jiles DC (1988) A model for the effect of stress on the low frequency harmonic content of the magnetic induction in ferromagnetic materials. J Appl Phys 63:3930–3932

Kaminski DA, Jiles DC, Sablik MJ (1992) Angular dependence of the magnetic properties of polycrystalline iron under the action of uniaxial stress. J Magn Magn Mater 104:382–384

Richard HM, Harvey R, Robert JS (1971) Magnetostrictive phenomena in metallic materials and some of their device applications. IEEE Trans Mag 7(1):29–48

Gatelier-Rothea C, Chicois J, Fougeres R, Fleischmann P (1998) Characterization of pure iron and (130 P.P.M.) carbon–iron binary alloy by Barkhausen noise measurements: study of the influence of stress and microstructure. Acta Mater 46(14):4873–4882

Stefanita CG, Atherton DL, Clapham L (2000) Plastic versus elastic deformation effects on magnetic Barkhausen noise in steel. Acta Mater 48:3545–3551

Wang ZD, Deng B, Yao K Physical model of plastic deformation on magnetization in ferromagnetic materials. J Appl Phys D (accepted)

Doubov AA, Vstovsky GV (2000) Physical base of the method of metal magnetic memory. Moscow

Dong LH, Xu BS, Dong SY, Chen QZ, Wang YY, Zhang L (2009) Stress dependence of the spontaneous stray field signals of ferromagnetic steel. NDT & E Int 42:323–327

Leng JC, Xu MQ, Xu MX, Zhang JZ (2009) Magnetic field variation induced by cyclic bending stress. NDT&E International 42:410–414

Shi CL, Dong SY, Xu BS, He P (2010) Metal magnetic memory effect caused by static tension load in a case-hardened steel. J Magn Magn Mater 322(4):413–416

Shi CL, Dong SY, Xu BS, He P (2010) Stress concentration degree affects spontaneous magnetic signals of ferromagnetic steel under dynamic tension load. NDT&E Int 43(1):8–12

Wang ZD, Yao K, Ding KQ (2010) Theoretical studies of metal magnetic memory technique on magnetic flux leakage signals. NDT&E Int 43(4):354–359

Wang ZD, Yao K, Ding KQ (2010) Quantitative study of metal magnetic memory signal versus local stress concentration. NDT&E Int 43(6):513–518

Birss RR, Faunce CA, Isaac ED (1971) Magnetomechanical effects in iron and iron-carbon alloys. J Phys D 4:1040–1048

Banks PJ (1975) The effects of some complex systems of stress on dynamic magnetostriction in oriented silicon iron. Ph.D. dissertation, Liverpool Polytechnic, England, pp 81–92

Acknowledgements

This work was funded by Natural Science Foundations of China (No 11072027, 10872025), the Fundamental Research Funds for the Central Universities and Ministry of Education of the People’s Republic of China (NECT).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yao, K., Wang, Z.D., Deng, B. et al. Experimental Research on Metal Magnetic Memory Method. Exp Mech 52, 305–314 (2012). https://doi.org/10.1007/s11340-011-9490-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-011-9490-3