Abstract

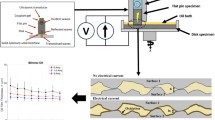

The material properties of an oxygen-free high thermal conductivity (OFHC) film with a thickness of 0.1 mm were evaluated at strain rates ranging from 10−3/s to 103/s using a high-speed material micro-testing machine (HSMMTM). The high strain-rate material properties of thin films are important especially for an evaluation of the structural reliability of micro-formed parts and MEMS products. The high strain-rate material testing methods of thin films, however, have yet to be established to the point that the testing methods of larger specimens for electronics, auto-body, train, ship, and ocean structures are. For evaluation, a new type of HSMMTM was developed to conduct high-speed tensile tests of thin films. This machine is capable of testing at a sufficiently high tensile speed with an electromagnetic actuator, a novel gripping mechanism, and an accurate load measurement system. The OFHC copper film shows high strain-rate sensitivity in terms of the flow stress, fracture elongation, and strain hardening. These measures increase as the tensile strain rate increases. The rate-dependent material properties of an OFHC copper film are also compared with those of a bulk OFHC copper sheet with a thickness of 1 mm. The flow stress of an OFHC copper film is relatively low compared to that of a bulk OFHC copper sheet in the entire range of strain rates, while the fracture elongation of an OFHC copper film is much larger than that of a bulk OFHC copper sheet. A quantitative comparison would provide material data at high strain rates for the design and analysis of micro-appliances and different types of micro-equipment.

Similar content being viewed by others

References

Vollertsen F, Hu Z, Niehoff HS, Theiler C (2004) State of the art in micro forming and investigations into micro deep drawing. J Mater Process Technol 151:70–79

Engel U, Eckstein R (2002) Microforming—from basic research to its realization. J Mater Process Technol 125:35–44

Sharpe WN Jr (2003) Murray lecture—tensile testing at the micrometer scale: opportunities in experimental mechanics. Exp Mech 43:228–237

Oosterkamp LD, Ivankovic A, Venizelos G (2000) High strain rate properties of selected aluminium alloys. Mater Sci Eng A—Structural Materials Properties Microstructure and Processing 278:225–235

Miura K, Takagi S, Obara T, Tanimura S (1998) High strain rate deformation of high strength sheet steels for automotive parts. SAE Paper No. 980952

Huh H, Lim JH, Park SH (2009) High speed tensile test of steel sheets for the stress–strain curve at the intermediate strain rate. Int J Automot Technol 10:195–204

Kolsky H (1963) Stress waves in solids. Dover, New York, pp 41–98

Sharpe WN, Yuan B, Edwards RL (1997) A new technique for measuring the mechanical properties of thin films. J Microelectromech Syst 6:193–199

Sharpe WN, Pulskamp J, Gianola DS, Eberl C, Polcawich RG, Thompson RJ (2007) Strain measurements of silicon dioxide microspecimens by digital imaging processing. Exp Mech 47:649–658

Lee SJ, Han SW, Hyun SM, Lee HJ, Kim JH, Kim YI (2009) Measurement of Young’s modulus and Poisson’s ratio for thin Au films using a visual image tracing system. Curr Appl Phys 9:S75–S78

Emery RD, Povirk GL (2003) Tensile behavior of free-standing gold films. Part I. Coarse-grained films. Acta Mater 51:2067–2078

Huh YH, Kim DL, Kim DJ, Park P, Kee CD, Park JH (2004) Application of micro-ESPI technique for measurement of micro-tensile properties. Advances in Nondestructive Evaluation, Pt 1–3,270–273: 744–749

Huh YH, Kim DL, Kee CD (2005) Measurement of continuous micro-tensile strain using micro-ESPI technique. Advances in Fracture and Strength, Pts 1–4,297–300: 53–58

Cheng S, Ma E, Wang YM, Kecskes LJ, Youssef KM, Koch CC et al (2005) Tensile properties of in situ consolidated nanocrystalline Cu. Acta Mater 53:1521–1533

Schwaiger R, Moser B, Dao M, Chollacoop N, Suresh S (2003) Some critical experiments on the strain-rate sensitivity of nanocrystalline nickel. Acta Mater 51:5159–5172

Gu CD, Lian JS, Jiang Q, Zheng WT (2007) Experimental and modelling investigations on strain rate sensitivity of an electrodeposited 20 nm grain sized Ni. J Phys D Appl Phys 40:7440–7446

Dalla Torre F, Van Swygenhoven H, Victoria M (2002) Nanocrystalline electrodeposited Ni: microstructure and tensile properties. Acta Mater 50:3957–3970

Jiang ZH, Liu XL, Li GY, Jiang Q, Lian JS (2006) Strain rate sensitivity of a nanocrystalline Cu synthesized by electric brush plating. Appl Phys Lett 88:143115

Lou J, Allameh S, Buccheit T, Soboyejo WO (2003) An investigation of the effects of thickness on mechanical properties of LIGA nickel MEMS structures. J Mater Sci 38:4129–4135

Wang YM, Wang K, Pan D, Lu K, Hemker KJ, Ma E (2003) Microsample tensile testing of nanocrystalline copper. Scr Mater 48:1581–1586

Huh H, Kang WJ, Han SS (2002) A tension split Hopkinson bar for investigating the dynamic behavior of sheet metals. Exp Mech 42:8–17

Kim JS, Huh H, Lee KW, Ha DY, Yeo TJ, Park SJ (2006) Evaluation of dynamic tensile characteristics of polypropylene with temperature variation. Int J Automot Technol 7:571–577

Meyers MA, Andrade UR, Chokshi AH (1995) The effect of grain-size on the high-strain, high-strain-rate behavior of copper. Metall Mater Trans, A Phys Metall Mater Sci 26:2881–2893

Wang W, Makarov G, Shenoi RA (2005) An analytical model for assessing strain rate sensitivity of unidirectional composite laminates. Compos Struct 69:45–54

Follansbee PS, Kocks UF (1988) A constitutive description of the deformation of copper based on the use of the mechanical threshold stress as an internal state variable. Acta Metall 36:81–93

Tong W, Clifton RJ, Huang S (1992) Pressure-shear impact investigation of strain rate history effects in oxygen-free high-conductivity copper. J Mech Phys Solids 40:1251–1294

Huh H, Kim SB, Song JH, Lim JH (2008) Dynamic tensile characteristics of TRIP-type and DP-type steel sheets for an auto-body. Int J Mech Sci 50:918–931

Peixinho N, Pinho A (2005) Dynamic material properties of dual-phase and TRIP steels and constitutive equation. Proc EURODYN 3:1767–1771

Choi ID, Son DM, Kim SJ, Matlock DK, Speer JG (2006) Strain rate effects on mechanical stability of retained austenite in TRIP sheet steels. SAE paper No. 2006-01-1434

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, J.S., Huh, H. Evaluation of the Material Properties of an OFHC Copper Film at High Strain Rates Using a Micro-Testing Machine. Exp Mech 51, 845–855 (2011). https://doi.org/10.1007/s11340-010-9395-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-010-9395-6