Abstract

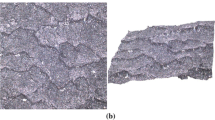

Due to the complexity of the rubber wear process, the research work of the wear mechanism is limited to normal temperature, and the mechanism of high temperature wear has not been established. The temperature has great influence on the appearance of wear and the change of the surface characteristics of wear. This paper presents the wear surface morphology of rubber materials at different temperatures. The two-dimensional gray level images of the rubber surface are captured by a 3D measuring laser microscope and are converted to black-and-white binary images. Then, the quantitative analysis of the wear surface is processed using fractal dimension and the multifractal spectrum method. Results show that the wear rubber surface is fractal. Additionally, the roughness and the spectral width values increases with increase in temperature. Furthermore, the fractal dimensions shrink and the homogeneity of the rubber surface worsens. As temperature increases, the corresponding Δα and Δf(α) increase, resulting in rough wear surface with lower height homogeneity and higher complexity. Δα is equal to 0.238, 0.281 and 0.283 at the temperature of 25, 60 and 80 °C, respectively. Δf(α) is equal to 0.027, 0.035 and 0.039 at the temperature of 25, 60 and 80 °C, respectively. In conclusion, fractal theory can be used to describe and evaluate the surface morphology and wear characteristics of rubber materials.

Similar content being viewed by others

References

Dong, C., Yuan, C., Bai, X., et al. (2014). Study on wear behaviour and wear model of nitrile butadiene rubber under water lubricated conditions. Rsc Advances, 4(36), 19034–19042.

Wu, Y. P., Zhou, Y., & Li, J. L. (2016). A comparative study on wear behavior and mechanism of styrene butadiene rubber under dry and wet conditions. Wear, 356–357, 1–8.

Vieira, T., Ferreira, R. P., & Kuchiishi, A. K. (2015). Evaluation of friction mechanisms and wear rates on rubber tire materials by low-cost laboratory tests. Wear, 328–329, 556–562.

Shen, M. X., Dong, F., & Zhang, Z. X. (2016). Effect of abrasive size on friction and wear characteristics of nitrile butadiene rubber (NBR) in two-body abrasion. Tribology International, 103, 1–11.

Wu, Y., Zhou, Y., & Li, J. (2016). Influence of fillers dispersion on friction and wear performance of solution styrene butadiene rubber composites. Journal of Applied Polymer Science, 133(26), 43589.

Grosch, K. A. (2007). Rubber friction and its relation to tire traction. Rubber Chemistry and Technology, 80(3), 379–411.

Heinz, M., & Grosch, K. A. (2007). A laboratory method to comprehensively evaluate abrasion, traction and rolling resistance of tire tread compounds. Rubber Chemistry and Technology, 80(4), 580–607.

Gent, A. N., & Walter, J. D. (2005). The pneumatic tire. Washington DC: NHTSA.

Grosch, K. A., & Heinz, M. (2003). The use of laboratory tester 100 for the evaluation of tire tread properties. In Third european conference on constitutive models for rubber (pp. 15–17). London, Great Britain.

Du, G. X., & Ning, X. X. (2008). Multifractal properties of Chinese stock market in Shanghai. Physica A, 387(1), 261–269.

Ge, S. R., & Zhu, H. (2005). Fractal of tribology. Beijing: Machinery Industry Press.

Quan Shuhai. (2002). Research on fractal character of machined surface topography based on surface grayscale image. WuHan University of Technology.

Zhu, H., & Ji, C. C. (2011). Fractal theory and its application. Science Press.

Li, P., Hu, K. L., & Wang, B. H. (2004). Design and application about computing program of material multifractal spectrum[J]. Journal of Nanjing University of Aeronautics and Astronautics, 36(1), 77–81.

Acknowledgements

This research is funded by Research Award Fund for Outstanding Young Scientists in Shandong province (BS2012CL014), the center open issue for Green tire and Rubber collaborative innovation (2014GTR0013).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Z., Hu, S., Miao, Z. et al. Application of Multifractal Spectrum Calculation Program in Rubber Wear Under High Temperature. Wireless Pers Commun 103, 1–9 (2018). https://doi.org/10.1007/s11277-018-5419-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11277-018-5419-9