Abstract

Microplastic pollution is a growing concern for the earth’s terrestrial and marine environments. Synthetic fibers from textiles are one source of microplastic pollution as fibers may be released from garments during use and especially during laundering, whereby they may enter the aquatic environment via wastewater systems. Wool is a natural fiber, but it is often given treatments to enhance its performance, such as to make it resistant to shrinkage caused by machine washing. Treatments of this type might influence the fiber’s inherent biodegradability. We sought to understand the aquatic biodegradation behavior of wool (in its unmodified form, and chlorine-Hercosett shrink-resist treated) and a range of synthetic fibers that are used in similar clothing applications. The biodegradation test was carried out in a simulated marine environment using a natural seawater inoculant according to the ASTM D6691 method with some modifications. Biodegraded wool residues were characterized by Fourier transform infrared and energy dispersive X-ray spectroscopies. The extent of fiber damage was observed by scanning electron microscopy. Both types of wool biodegraded readily under these conditions and machine-washable wool biodegraded to a greater extent than untreated wool. Regenerated cellulosic fiber (viscose rayon) also degraded readily, but all three synthetic fibers (polyester, nylon and polypropylene) showed virtually no biodegradation. Analysis of solid and liquid residues generated by the biodegraded wool showed no evidence that the chlorine-Hercosett-treated wool generated any non-degraded residues. Based on these findings we believe that, unlike synthetics, wool fibers are very unlikely to lead to microplastic pollution in the aquatic environment.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Microplastic pollution is a serious and growing issue that affects our aquatic environment, as microscopic particles of discarded plastic could be potentially harmful to aquatic organisms (Andrady, 2011; Gunaalan et al., 2020). Pollution of the environment by microscopic fragments of plastic has been a growing environmental concern for well over a decade (Browne et al., 2011; Gavigan et al., 2020), and a substantial proportion of these materials originate from textile fibers (Sanchez-Vidal et al., 2018). One aspect of this is pollution of freshwater bodies and the ocean, and this so called ‘microfiber’ pollution has been detected across a wide range of environments globally, from deep sea sediments (Peng et al., 2018; Sanchez-Vidal et al., 2018) to the polar regions (Greenpeace, 2018; Obbard et al., 2014). Microfiber contamination has been found in drinking water and even in beer, (Kosuth et al., 2018) and in seafood (Santillo et al., 2017). The extent to which these materials are harmful to organisms is still being elucidated (Hu et al., 2020; Jabeen et al., 2018; Rebelein et al., 2021) but compared to non-fibrous microplastic fragments, fibers have a high aspect ratio, which means they may have a greater ability to become entangled in microscopic structures in aquatic organisms (Rebelein et al., 2021).

It is likely that fibers enter the environment from a multitude of sources (Gavigan et al., 2020) but one that has received particular attention is laundering of clothing. Many studies have shown how the type and structure of the textile and the type of washing conditions influence fiber loss (De Falco et al., 2019; Lant et al., 2020; Napper & Thompson, 2016). These indicate that possible approaches to mitigating the problem are via changes to textile structures to make fibers more secure in the material structure or by capturing fibers before they can escape into the wastewater system. The former can be achieved via textile manufacturing parameters such as the twist level used to make yarns, or the tightness of fabric structures. These will often compromise attributes of the textile that are desirable to the consumer, such as softness. Indeed, one of the fabric types that is thought to shed the most fiber during laundering is synthetic fleece fabric (Carney Almroth et al., 2018), which is liked by consumers for its softness and warmth. Cutting and sewing techniques also influence fiber loss in laundering (Cai et al., 2020; Dalla Fontana et al., 2021). The fibers lost during laundering of garments could be captured through the addition of filters to washing machines. This would be relatively straightforward to achieve for new machines but retrofitting filters to existing machines would be inconvenient for consumers who are not ready to replace their current appliance. They would also need to follow appropriate procedures for cleaning the filter to avoid simply releasing those trapped fibers to the environment by another route (e.g., if the filter was rinsed clean at a sink or shaken outside). Clearly it is going to be difficult to eliminate microfiber pollution from the environment by these approaches alone, so to reach that goal it will be necessary to increase the use of biodegradable materials in textiles, just as it is for other products, such as packaging.

All types of fibers, both natural and synthetic, have been detected in terrestrial, aquatic and atmospheric environments (Dris et al., 2016; Sanchez-Vidal et al., 2018; Stanton et al., 2019), although the length of time the fibers were present in that environment is not easy to ascertain. Wool is a natural keratin protein fiber used in apparel, floor coverings, and technical applications due to its various qualities and attributes, such as moisture absorption, mechanical resilience and wrinkle-resistance (Johnson et al., 2003). The biodegradation behavior of wool is well authenticated for certain terrestrial environments, such as soil burial (Broda et al., 2016; Hodgson et al., 2014; McNeil et al., 2007), but little has been reported about the biodegradation behavior of wool in aquatic environments. It must degrade readily in the environment, as one can simply observe that keratin-based hair from water-dwelling mammals and feathers from sea birds do not accumulate long-term in the aquatic environment. Nevertheless, it is important to understand the biodegradation behavior of fibers that come from manufactured products as they can undergo processes that may have modified them from their natural state. In particular, in order to impart resistance to shrinkage due to machine washing, wool fibers are treated with various synthetic polymeric resins, most commonly Hercosett, a fiber-reactive polyamide resin (Hassan & Carr, 2019). It is important to know if this kind of treatment affects the biodegradability of wool but so far, no systematic studies have been carried out to investigate this aspect.

The limited amount of literature related to aquatic biodegradation of wool includes a study by Brown (Brown, 1994) which showed that wool ‘knops’ (intended for use as oil sorbents in the ocean) biodegraded in the natural marine environment (Lyttelton Harbor, New Zealand), but this work was largely qualitative rather than quantitative, and did not compare with other fiber types. However, it demonstrated clearly that there are microorganisms in the ocean that readily biodegrade wool keratin. In a more recent study the biodegradation of wool, polylactide (PLA) and cotton fibers was assessed in an aqueous environment at elevated temperature (35°C), with light excluded and with aeration, for a period of 42 days (Sun et al., 2013). Biodegradation was assessed by weight loss and strength reduction, and they found that wool and cotton biodegraded faster than PLA. In another study, Anselmi et al also found that recycled wool fibers (from reprocessed wool textiles) biodegraded in aquatic conditions, which were simulated in mesocosms comprising natural seawater inoculated with marine bacteria (Anselmi et al., 2023). By comparison, in water-logged archaeological deposits human hair and wool textiles can be relatively well preserved because microbial activity is reduced (Solazzo et al., 2013). However, these conditions are not at all typical of aquatic environments such as lakes, rivers and oceans, as light and oxygen are reduced or excluded. Clearly there is more to be learned about the biodegradation of natural fibers in aquatic environments.

In this work we report the marine biodegradation of wool and other fiber types, via an accepted method for assessing the biodegradation of plastics, including, for the first time, the marine biodegradation behavior of wool that has been modified by chlorine-Hercosett treatment to make it resistant to shrinkage during machine washing. In previous work we established the viability of this biodegradation assessment method for fibrous materials in an investigation into the biodegradation behavior of fibers derived from five floorcoverings and two apparel fabrics (Collie et al., 2019). Here, the extent of biodegradation was established, and fiber residues were collected at the completion of the biodegradation period for analysis by scanning electron microscope (SEM) and Fourier-transform infrared (FTIR) spectroscopy.

2 Materials and Methods

2.1 Fabrics

A series of five single-jersey knitted apparel fabrics were supplied by The Woolmark Company (Shanghai, China). These were constructed from untreated wool, chlorine-Hercosett treated machine-washable wool, polyester, polyamide (nylon) and polypropylene and were manufactured to be well matched in their structural properties. They were all fabrics intended for use as a ‘next-to-skin’ or base layer. Effectively they only differed in the type of fiber used in their construction. As next-to-skin fabrics, they are good examples of the fabrics used in garments that are subject to frequent washing. All fabrics were finished commercially and had been dyed pale-blue, with the exception of the polypropylene which was undyed. An additional fabric made from viscose rayon (regenerated cellulose) was included as a bio-based comparison. This was in a lightweight woven structure (sourced from a local fabric retailer, dyed to a beige color), so was different to the others, however the fabrics were deconstructed before testing to minimize fabric structure effects (see following section). In all, the biodegradation behavior of a total of six fibre types was evaluated, as shown in Table 1 (the nominal carbon content is provided as this is used to determine the sample size for the biodegradation test).

2.2 Fabric Preparation

For each fabric type a quantity sufficient for testing was removed from the bulk and given laundering treatments designed to impart a level of wear corresponding to them being well into their intended lifespan. The laundering treatments were carried out using a Wascator laboratory washing machine, applying two standard wash cycles using the Woolmark ‘5A’ protocol on all fabrics except the untreated wool fabric. For this we used two Woolmark ‘7A’ cycles, because the 5A cycles are too severe and would have caused an unacceptably high level of felting that would not be encountered in real life. The 7A cycle is intended for fabrics that should be handwashed (Woolmark, 2016), so is less severe. This washing regime corresponds to the physical deterioration caused by about 20 domestic washing cycles (Smith, 1990), but an additional two 7A cycles were applied in order to expose the fabrics to increased detergent-related damage. A standard detergent for textile testing was used (ECE Phosphate Reference Detergent ‘B’ (SDC Enterprises, 2021).

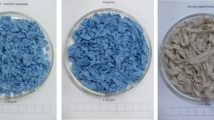

We subjected the fabrics to the biodegradation test in the same physical form, so that any differences in physical structure would not confound the experimental results. We used a reproducible deconstruction process to do this by shredding them twice in a heavy-duty paper shredder. The second shredding was done at a 90-degree angle to the first and this yielded small pieces of fabric of the order of millimeters to centimeters in size, along with yarn and fiber fragments, as illustrated for three of the fabrics in Fig. 1. Between processing of each fabric type the shredder was carefully cleaned to prevent cross-contamination between fiber types.

2.3 Biodegradation Method

The biodegradation test was carried out according to ASTM Test Method D6691-17: Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials in the Marine Environment by a Defined Microbial Consortium or Natural Sea Water Inoculum (ASTM International, 2017) with some modifications. One notable variance to the standard method was the use of a larger sample size, providing 10 g of carbon (see Table 1), in a 1.5 L seawater inoculum. This was to suit the design of the biodegradation test apparatus, but also for improved accuracy of CO2 detection.

This test method is used to measure the amount and rate of marine biodegradation of plastic materials in either natural or ‘simulated’ seawater, under aerobic conditions. In the method, biodegradation occurs in a controlled laboratory environment in bioreactor vessels filled with seawater. We used a natural seawater inoculum, collected outside the tidal influence zone in the Bay of Plenty, New Zealand. The principle of the test is to measure the CO2 evolved by the samples as they biodegrade, i.e., as the material’s carbon (wool or other fiber polymer) is converted into CO2 by decomposition. The test was carried out over a 90-day duration with the required quantity of fabric sample equivalent to 10 g carbon placed in the bioreactor vessels in a water bath maintained at 30±2°C. Three replicates were tested for each fabric and the position of the vessels in the water bath was randomized. As well as the positive control (see below), three ‘blanks’ with just seawater and no sample were included. The only agitation of the samples was weekly shaking of the vessels, and therefore conditions were generally static. To ensure non-limiting biodegradation conditions, 0.5 g/L ammonium chloride (NH4Cl) and 0.1 g/L monopotassium hydrogen phosphate (KH2PO4) were added to the seawater at the start of the biodegradation trial. The averages of the three replicates are reported here.

2.4 Selection of Control Material

Based on the experience of a preliminary biodegradation trial reported previously (Collie et al., 2019), we selected kraft paper pulp as the positive control in this trial. In the preliminary trial, microcrystalline cellulose was used, but this gave highly variable biodegradation behavior, as it tended to not remain suspended in the seawater in the bioreactor. Several options, namely cellulose, chitin and kraft paper pulp, are suggested in the standard method so we were able to select kraft paper pulp for this trial. It is a fibrous material and appeared to remain very well suspended in the vessels, which gave us confidence that it would demonstrate consistent behavior. The viscose rayon fabric acted as a second, textile-derived, positive control.

2.5 Analysis Methods

After the biodegradation test, the solid residues of all fabric types were collected and examined using a scanning electron microscope (SEM) to identify the extent the fibers were degraded and in the case of machine-washable wool to detect the presence or absence of Hercosett coating on the wool fiber. The residues were examined using a Hitachi SEM (Model: TM 3030 Plus, Hitachi Corporation, Tokyo, Japan). To identify any chemical change of the fibers caused by biodegradation, the surface of wool fibers was characterized by Fourier-Transform Infrared (FTIR) and energy dispersive X-ray (EDX) spectroscopies. The FTIR spectra of various biodegraded wool fibers were recorded on a Perkin Elmer FTIR (Model: System 2000, Perkin Elmer Corporation, USA). Elemental analysis of the wool fiber surface was carried out by EDX using the Hitachi SEM described above equipped with a Quantax75 energy dispersive X-ray attachment.

3 Results and Discussion

3.1 Biodegradation Behavior

The extent of biodegradation of each type of fabric sample (conversion of carbon in the material to CO2 as measured by the respirometry system) after 90 days is provided in Table 2. The average of three replicates is provided along with the standard error, and the relative biodegradation is provided, i.e., the biodegradation of each as a percentage of that shown by the positive control. Figure 2 shows the progression of biodegradation of selected fabrics.

The positive control showed a high level of biodegradation, confirming that the test conditions, including the seawater inoculant collected, were suitable for biodegradation studies. The other cellulose specimen (viscose rayon) also showed high biodegradation. The machine-washable wool showed high biodegradation, even higher than that of viscose rayon. The untreated wool had considerably lower biodegradation than the machine-washable wool. The chlorine-Hercosett treatment used in the machine-washable finish had the very consistent effect of increasing the overall biodegradability of the fiber. A possible reason is that the untreated wool fiber cuticle has a hydrophobic 18-methyleicosanoic acid layer bound to it through thioester linkages, which probably hindered microbial attack, at least in the early stages of the test, slowing the biodegradation process. As part of the chlorine-Hercosett treatment the thioester linkages are broken, increasing the hydrophilicity of wool fibre surface (Hassan & Leighs, 2017) and the attachment of the thin layer of polyamide Hercosett resin further enhances its hydrophilicity. When the machine-washable wool fiber is immersed in water, the surface Hercosett layer absorbs water and becomes swollen (Hassan & Carr, 2019). During prolonged water immersion over the 90-day biodegradation test duration, this fragile, swollen layer could detach from the fiber surface, further compromising its integrity and exposing the fiber surface to microbial attack. Therefore, machine-washable wool showed considerably higher biodegradation compared to the untreated wool.

As expected, polypropylene and nylon showed virtually no biodegradation. Surprisingly, polyester seemed to show some level of biodegradation, but it was extremely low, and it appears to be the result of a single replicate of the three showing an abnormally high biodegradation (see Fig. 2, top right, blue line), for an unknown reason. In our experience, with low levels of biodegradation, the relative error can sometimes be high, which is perhaps not unexpected for a biological system. Indeed, it appears that the results for untreated wool (Fig. 2, top left) and viscose (Fig. 2 bottom left) also show an outlier, in these cases a low value (green and blue lines respectively).

Although untreated wool biodegraded more slowly, it still biodegraded to a far greater extent than all the synthetic fibers. It is important to note that under terrestrial conditions of biodegradation, such as soil burial, where the Hercosett resin is not always swollen by absorbed moisture, it might present a greater barrier to initial microbial attack resulting in slower biodegradation overall (Hodgson et al., 2023).

The regenerated cellulose fiber, viscose rayon, biodegraded readily, in a similar manner to machine-washable wool. This seems to contradict the apparent prevalence in marine environments, where regenerated cellulosic fibers are often found as a high proportion of the fiber detected (Sanchez-Vidal et al., 2018), suggesting limited biodegradation in the marine environment. However, this might be more an indication of their widespread use in disposable products such as wipes, cleaning cloths and sanitary products (Allison et al., 2023), resulting in higher volumes entering the environment than via the garment laundering route. If fibers from paper products (such as toilet paper) are also considered, then the potential for cellulosic fibers directly entering the marine environment is huge. Cellulose also has a higher density than other fibers (Kajiwara & Ohta., 2009), meaning that these fibers might sink more rapidly after entering a water body, reducing their exposure to mechanisms of physical and chemical degradation such as light, UV and oxygen compared to other fiber types. This might ultimately manifest in a reduced rate of biological degradation.

3.2 Scanning Electron Microscopy

Figures 3 and 4 are representative scanning electron microscope images of the two wool types (Fig. 3) and polyester (Fig. 4). These are provided here as they are of most interest considering the biodegradation results. The other synthetics are excluded here as they show virtually no change from the original state, consistent with their lack of biodegradation.

For the untreated wool (Fig. 3 top) degradation of the fibers is clearly apparent, including areas where the cuticle has been degraded exposing the cortical cells. There are also regions where fiber ends have fibrillated, and fully separated cortical cells. There are particles apparent on some fibers, which could be microbial colonies as observed by others (Broda et al., 2016), fiber fragments or possibly other residues from the seawater. Consistent with the biodegradation results for the machine-washable wool, the SEM images in Fig. 3 (bottom) show more degradation overall than the untreated wool, with the fiber surfaces generally less intact and cortex more exposed. There are irregular cracks on the fiber surfaces, for most of the fibers the edges of scales were completely degraded, and the surface of scales was heavily damaged. The Hercosett resin layer seems completely eroded from the wool fiber surface. Spot EDX scans were carried out on various items of debris produced by biodegradation of machine-washable wool fibers (see section 3.5) but none of them resembled Hercosett, rather they resembled wool fiber. There are still some intact fibers visible, even at this level of biodegradation, so it is clear that the degradation is non-uniform, i.e., different fibers degrade at different rates within a given sample.

In Fig. 4 we can see that the polyester fibers show no apparent degradation (despite the small amount of biodegradation measured). The deformation of the fiber ends in the image on the right is probably due to the shredding process used during sample preparation. There is some surface debris, probably residues from seawater. Overall, these results support the biodegradation results, with the level of observed degradation corresponding to the extent of biodegradation (Table 2).

3.3 Analysis of Residual Seawater

Analysis of the residual seawater at the completion of the trial is a routine part of carrying out a marine biodegradation assessment according to the standard method (ASTM International, 2017). These data (the mean of three replicates, plus/minus one standard deviation in parentheses) are provided in Table 3. Data for the blank control are also included.

Considering first the pH results, it is apparent that the pH of the residual seawater for synthetic fiber samples (5.1 to 5.4) did not change from that of the blank control (5.4), consistent with these being essentially biologically inert in the system. The reason for all of these being slightly acidic is the presence of the nutrient supplement added to the vessels at the start of the trial (see Section 2.3). The pH for both of the cellulosic materials (the positive control and viscose fabric) decreased to an average of 3.2, whereas the pH for the wool fabric solutions (averages of 6.6 and 7.8), is closer to that of the original seawater (measured before the trial and found to be 8.1) and appears to correlate with the extent of biodegradation. This suggests that the biodegradation products of cellulose and wool are quite different, with the former encouraging acidic conditions and the latter encouraging neutral-alkaline conditions. It should be noted that if this was the real-world situation of biodegradation of microfiber pollution, the dilution level would be vastly greater than that used in this test, so this observation is more of background interest than it is relevant to any effect on the environment.

The dissolved carbon values (DIC and DOC) relate to carbon compounds that are soluble in water and have not yet broken down to release CO2. They represent an intermediate state between the solid residue and the CO2 gas that is measured to indicate the extent of biodegradation. The three synthetic fibers have levels only marginally higher than the blank control, while the levels for the wool fabrics again seem to correspond to the level of biodegradation. This indicates that there are biodegradation products present after 90 days that range from somewhat intact fibers through high molecular weight species, to small molecules and ultimately CO2 gas.

The nitrogen in the residual seawater (NH4-N) is also potentially an indication of biodegradation. As noted in Section 2.3, nitrogen was added in the form of NH4Cl, as a microbial nutrient, so even the blank control has nitrogen present at the conclusion of the trial. If we compare each of the fibers with the blank control, we can group them into three sets:

Group 1: Less nitrogen present at the end of the trial than the blank control. This was the two cellulose materials i.e., kraft pulp and viscose.

Group 2: Approximately the same nitrogen present at the end of the trial as the blank control. This was all three synthetic fibers.

Group 3: More nitrogen present at the end of the trial than the blank control. This was the untreated wool and the machine-washable wool.

Group 2 were fabrics that showed little or no biodegradation, so it follows that they would not differ from the blank control. As was the case for the pH data, we see that the two types of biodegradable materials showed different behavior, with cellulose reducing nitrogen levels and wool increasing them. The latter is likely to be nitrogen liberated from the wool as it breaks down. The machine-washable wool has substantially more nitrogen present than the untreated wool, which may simply be indicative of its greater biodegradation, but it is also interesting to consider if some of this has resulted from the polyamide Hercosett treatment; if so, it would indicate biodegradation of that material.

To explore the feasibility of this further, consider that the machine-washable wool showed about three times the biodegradation of the untreated wool (in terms of quantity of CO2 liberated). If we consider the nitrogen levels of these two materials after subtracting the base level that the blank control produced, we have 33.1 mg/L for the untreated wool and 141.0 mg/L for the machine-washable wool. The machine-washable wool’s residual nitrogen level (after allowing for the level generated in the blank control) is about four times that of the untreated wool, rather than only three times as would be expected if it was only the wool’s biodegradation that liberated nitrogen. In other words, it seems that the machine-washable wool produces disproportionately more nitrogen when it biodegrades than the untreated wool, when the different biodegradation levels are allowed for. This might indicate biodegradation of the polyamide.

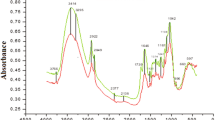

3.4 Fourier-Transform Infrared Spectroscopy (FTIR)

The FTIR spectrum of undegraded untreated wool fabric shows major IR bands at 1236, 1540, and 1650 cm-1 that could be associated with the amide III, amide II, and amide I groups of the wool fiber, respectively (Fig. 5). It also shows a broad hydroxyl band at 3100-3700 cm-1 due to the water absorbed by the wool fiber (Hassan & Leighs, 2017). The spectrum of undegraded machine-washable wool also shows the same IR bands but the intensity of amide and hydroxyl bands increased due to the deposition of the Hercosett layer on the surface of wool fibers. Hercosett is a polyamide resin having azetidinium reactive groups, some of which may be hydrolyzed to hydroxyl groups and thus increase the hydroxyl band intensity of the machine-washable wool (Hassan & Leighs, 2017). The degraded machine-washable wool also shows similar IR bands, but the intensity of the amide II and amide I bands considerably decreased suggesting breakdown of these amide bands. The hydroxyl band also became broad suggesting very high degradation of machine washable wool fiber after the 90-day test.

3.5 Energy Dispersive X-ray Spectroscopy (EDX)

In this investigation we examined the same three fabric types as for the FTIR work, plus several of the microscopic fragments present after biodegradation of the machine-washable wool sample. The fragments were selected under SEM because they most resembled microplastic fragments that could be from the physical breakdown of non-biodegradable materials (such as a polyamide resin coating). These results are presented in Table 4.

The C, S, O, and N content of untreated wool is 50.18, 3.71, 26.24 and 19.87% respectively, which is slightly inconsistent with the published data (Hassan, 2020), especially the S content which is comparatively high. This is probably due to the presence of acid dyes used to dye the fabric, which have sulfonate groups. In the case of machine-washable wool, the S content was lower and N content was higher because of the surface coating of fibers with the polyamide Hercosett resin, which does not have any S but is rich in N. In the case of degraded machine-washable wool, the S and O content increased due to the removal of Hercosett and also due to the degradation of wool fibers that produced hydrophilic carboxyl and hydroxyl groups consistent with FTIR analysis. In the SEM images of degraded machine-washable wool (Fig. 6), the fragments for which EDX spot elemental analysis was carried out are indicated with arrows and the results are also presented in Table 4. All of them showed high S content indicating they are not fragments of Hercosett but fragments of wool fiber, as S is absent from the Hercosett layer. This suggests substantial removal and biodegradation of the Hercosett.

4 Conclusions

This work has demonstrated the biodegradation behavior of commercially finished wool fabrics in a marine environment. The marine biodegradation test revealed that chlorine-Hercosett treated machine-washable wool biodegraded more readily compared to untreated wool. Rather than retarding its biodegradation, this treatment actually accelerated its biodegradation. The regenerated cellulose fiber, viscose rayon, biodegraded to a similar degree to machine-washable wool but analysis of the residual seawater after biodegradation (section 3.3) showed that biodegradation products of cellulose fibers (viscose rayon and kraft paper pulp) and wool are very different. Machine-washable wool appeared to produce disproportionately more nitrogen during biodegradation than untreated wool. A potential source of this nitrogen is the polyamide Hercosett resin, implying its biodegradation.

FTIR analysis was unable to clearly distinguish between amide peaks associated with non-degraded machine-washable and untreated wool because the polyamide resin layer is extremely thin. The spectrum of machine-washable wool showed a considerable decrease in amide band intensity after biodegradation, which could indicate removal of the polyamide resin from the fiber and also extensive degradation of wool fiber. EDX was also revealing: the surface of untreated wool and machine-washable wool (undegraded) had substantially different sulfur content, and biodegraded machine-washable wool had a sulfur content close to that of untreated non-degraded wool. This also suggests removal of the polyamide resin coating from the surface. This removal would be concerning if it resulted in microplastic fragments. However, EDX analysis of fragments that had the appearance of microplastics showed they had the same composition as biodegraded wool, including sulfur levels consistent with wool. They were clearly not polyamide resin, which does not contain sulfur.

The findings show that wool fibers degrade in the marine environment, but the untreated wool degrades more slowly compared to machine-washable wool. Nevertheless, their biodegradation behavior rules out the formation of persistent fibrous fragments of wool in the environment.

In principle, life-cycle assessment for products should include the impacts of their ‘in-use’ and ‘end-of-life’ phases. The research described here is relevant to both of these aspects, i.e., the environmental impact of microfiber pollution as a result of product laundering and eventual disposal. The true environmental impact of different fiber types will be different depending on whether these factors are taken in into account.

Data Availability

Data sets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Allison, T., Ward, B. D., Harbottle, M., & Durance, I. (2023). Do flushed biodegradable wet wipes really degrade? Science of the Total Environment, 894, 164912. https://doi.org/10.1016/j.scitotenv.2023.164912

Andrady, A. L. (2011). Microplastics in the marine environment. Marine Pollution Bulletin, 62(8), 1596–1605. https://doi.org/10.1016/j.marpolbul.2011.05.030

Anselmi, S., Provenza, F., Bentivoglio, T., Picerno, G., Cavallo, A., & Renzi, M. (2023). Marine Biodegradability and Ecotoxicity of MWool Recycled Wool Fibers: A Circular-Economy-Based Material. Oceans, 4(1), 114–131 https://www.mdpi.com/2673-1924/4/1/9

ASTM International. (2017). ASTM D6691-17 Standard Test Method for Determining Aerobic Biodegradation of Plastic Materials in the Marine Environment by a Defined Microbial Consortium or Natural Sea Water Inoculum.

Broda, J., Przybyło, S., Kobiela-Mendrek, K., Biniaś, D., Rom, M., Grzybowska-Pietras, J., & Laszczak, R. (2016). Biodegradation of sheep wool geotextiles. International Biodeterioration and Biodegradation, 115, 31–38. https://doi.org/10.1016/j.ibiod.2016.07.012

Brown, R. (1994). The Microbial Degradation of Wool in the Marine Environment. University of Canterbury.

Browne, M. A., Crump, P., Niven, S. J., Teuten, E., Tonkin, A., Galloway, T., & Thompson, R. (2011). Accumulation of Microplastic on Shorelines Woldwide: Sources and Sinks. Environmental Science & Technology, 45(21), 9175–9179. https://doi.org/10.1021/es201811s

Cai, Y., Yang, T., Mitrano, D., Heuberger, M., Hufenus, R., & Nowack, B. (2020). Systematic Study of Microplastic Fiber Release from 12 Different Polyester Textiles during Washing. Environmental Science & Technology, 54, 4847–4855. https://doi.org/10.1021/acs.est.9b07395

Carney Almroth, B. M., Åström, L., Roslund, S., Petersson, H., Johansson, M., & Persson, N.-K. (2018). Quantifying shedding of synthetic fibers from textiles; a source of microplastics released into the environment. Environmental Science and Pollution Research, 25(2), 1191–1199. https://doi.org/10.1007/s11356-017-0528-7

Collie, S. R., Ranford, S., Fowler, I., & Brorens, P. (2019). 4A3_0151_ Microfibre Pollution - What's the Story for Wool? Proceedings of the 19th World Textile Conference-Autex 2019, Ghent.

Dalla Fontana, G., Mossotti, R., & Montarsolo, A. (2021). Influence of Sewing on Microplastic Release from Textiles During Washing. Water, Air, & Soil Pollution, 232, 50. https://doi.org/10.1007/s11270-021-04995-7

De Falco, F., Di Pace, E., Cocca, M., & Avella, M. (2019). The contribution of washing processes of synthetic clothes to microplastic pollution. Scientific Reports, 9(1), 6633. https://doi.org/10.1038/s41598-019-43023-x

Dris, R., Gasperi, J., Saad, M., Mirande, C., & Tassin, B. (2016). Synthetic fibers in atmospheric fallout: A source of microplastics in the environment? Marine Pollution Bulletin, 104(1), 290–293. https://doi.org/10.1016/j.marpolbul.2016.01.006

Gavigan, J., Kefela, T., Macadam-Somer, I., Suh, S., & Geyer, R. (2020). Synthetic microfiber emissions to land rival those to waterbodies and are growing. PLOS ONE, 15(9), e0237839. https://doi.org/10.1371/journal.pone.0237839

Greenpeace. (2018). Microplastics and persistent fluorinated chemicals in the Antarctic. https://www.greenpeace.org/static/planet4-international-stateless/2018/06/4f99ea57-microplastic-antarctic-report-final.pdf

Gunaalan, K., Fabbri, E., & Capolupo, M. (2020). The hidden threat of plastic leachates: A critical review on their impacts on aquatic organisms. Water Research, 184, 116170. https://doi.org/10.1016/j.watres.2020.116170

Hassan, M. M. (2020). Enhanced thermal stability, hydrophobicity, UV radiation resistance, and antibacterial properties of wool fabric treated with: P -aminobenzenesulphonic acid. RSC Advances, 10(30), 17515–17523. https://doi.org/10.1039/d0ra02267e

Hassan, M. M., & Carr, C. M. (2019). A review of the sustainable methods in imparting shrink resistance to wool fabrics. Journal of Advanced Research, 18, 39–60. https://doi.org/10.1016/j.jare.2019.01.014

Hassan, M. M., & Leighs, S. J. (2017). Effect of surface treatments on physicomechanical, stain-resist, and UV protection properties of wool fabrics. Applied Surface Science, 419, 348–356. https://doi.org/10.1016/j.apsusc.2017.05.046

Hodgson, A., Barker, R., van Koten, C., & Collie, S. (2014). Wool: A Compostable Substrate? 43rd Textile Research Symposium, Christchurch.

Hodgson, A., Leighs, S. J., & van Koten, C. (2023). Compostability of wool textiles by soil burial. Textile Research Journal, 93(15-16), 3692–3702. https://doi.org/10.1177/00405175231163590

Hu, L., Chernick, M., Lewis, A. M., Ferguson, P. L., & Hinton, D. E. (2020). Chronic microfiber exposure in adult Japanese medaka (Oryzias latipes). PLOS ONE, 15(3), e0229962. https://doi.org/10.1371/journal.pone.0229962

Jabeen, K., Li, B., Chen, Q., Su, L., Wu, C., Hollert, H., & Shi, H. (2018). Effects of virgin microplastics on goldfish (Carassius auratus). Chemosphere, 213, 323–332. https://doi.org/10.1016/j.chemosphere.2018.09.031

Johnson, N. A. G., Wood, E. J., Ingham, P. E., McNeil, S. J., & McFarlane, I. D. (2003). Wool as a technical fibre. Journal of the Textile Institute, 94(3-4), 26–41. https://doi.org/10.1080/00405000308630626

Kajiwara, K. O., & Y. (2009). Synthetic textile fibers: structure, characteristics and identification. In M. M. Houck (Ed.), Identification of Textile Fibers (pp. 70–71). Woodhead Publishing.

Kosuth, M., Mason, S. A., & Wattenberg, E. V. (2018). Anthropogenic contamination of tap water, beer, and sea salt. PLOS ONE, 13(4), e0194970. https://doi.org/10.1371/journal.pone.0194970

Lant, N. J., Hayward, A. S., Peththawadu, M. M. D., Sheridan, K. J., & Dean, J. R. (2020). Microfiber release from real soiled consumer laundry and the impact of fabric care products and washing conditions. PLOS ONE, 15(6), e0233332. https://doi.org/10.1371/journal.pone.0233332

McNeil, S. J., Sunderland, M. R., & Zaitseva, L. I. (2007). Closed-loop wool carpet recycling. Resources, Conservation and Recycling, 51(1), 220–224. https://doi.org/10.1016/j.resconrec.2006.09.006

Napper, I. E., & Thompson, R. C. (2016). Release of synthetic microplastic plastic fibres from domestic washing machines: Effects of fabric type and washing conditions. Marine Pollution Bulletin, 112(1), 39–45. https://doi.org/10.1016/j.marpolbul.2016.09.025

Obbard, R. W., Sadri, S., Wong, Y. Q., Khitun, A. A., Baker, I., & Thompson, R. C. (2014). Global warming releases microplastic legacy frozen in Arctic Sea ice. Earth's Future, 2(6), 315–320. https://doi.org/10.1002/2014EF000240

Peng, X., Chen, M., Chen, S., Dasgupta, S., Xu, H., Ta, K., Du, M., Li, J., Guo, Z., & Bai, S. (2018). Microplastics contaminate the deepest part of the world’s ocean. Geochemical Perspectives Letters, 9, 1–5. https://doi.org/10.7185/geochemlet.1829

Rebelein, A., Int-Veen, I., Kammann, U., & Scharsack, J. P. (2021). Microplastic fibers — Underestimated threat to aquatic organisms? Science of the Total Environment, 777, 146045. https://doi.org/10.1016/j.scitotenv.2021.146045

Sanchez-Vidal, A., Thompson, R. C., Canals, M., & de Haan, W. P. (2018). The imprint of microfibres in southern European deep seas. PLOS ONE, 13(11), e0207033. https://doi.org/10.1371/journal.pone.0207033

Santillo, D., Miller, K., & Johnston, P. (2017). Microplastics as contaminants in commercially important seafood species. Integrated Environmental Assessment and Management, 13(3), 516–521. https://doi.org/10.1002/ieam.1909

SDC Enterprises. (2021). ECE Phosphate Reference Detergent 'B'. Retrieved 22nd March from https://www.sdcenterprises.co.uk/products/sdce-ece-b-phosphate-sdce-type-3/

Smith, P. J. (1990). Dimensional Stability in Domestic Laundering. 8th International Wool Textile Research Conference Christchurch.

Solazzo, C., Dyer, J. M., Clerens, S., Plowman, J., Peacock, E. E., & Collins, M. J. (2013). Proteomic evaluation of the biodegradation of wool fabrics in experimental burials. International Biodeterioration and Biodegradation, 80, 48–59. https://doi.org/10.1016/j.ibiod.2012.11.013

Stanton, T., Johnson, M., Nathanail, P., MacNaughtan, W., & Gomes, R. L. (2019). Freshwater and airborne textile fibre populations are dominated by ‘natural’, not microplastic, fibres. Science of the Total Environment, 666, 377–389. https://doi.org/10.1016/j.scitotenv.2019.02.278

Sun, Y., Luo, J., Ni, A. Q., Bi, Y. Y., & Yu, W. D. (2013). Study on Biodegradability of Wool and PLA Fibers in Natural Soil and Aqueous Medium. Advanced Materials Research, 641-642, 82–86. https://doi.org/10.4028/www.scientific.net/AMR.641-642.82

Woolmark. (2016). TM31 Dimensional Stability. In Woomark Specification AK-1.

Acknowledgements

We are grateful to Steve Ranford and Andy Cooper for their valuable discussions and assistance with reviewing this work.

Funding

Open Access funding enabled and organized by CAUL and its Member Institutions. This work was funded by Australian Wool Innovation Limited, contract number 4500012232.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing Interests

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

•Wool biodegrades readily in the marine environment, unlike synthetic fibers

•Machine-washable wool biodegrades more quickly than untreated wool

•Wool does not appear to produce non-degradable fiber fragments, unlike synthetic fibers

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Collie, S., Brorens, P., Hassan, M.M. et al. Marine Biodegradation Behavior of Wool and Other Textile Fibers. Water Air Soil Pollut 235, 283 (2024). https://doi.org/10.1007/s11270-024-07093-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-024-07093-6