Abstract

Conventional neutralization treatment for manganese (Mn)-bearing mine drainage provides a challenge of cost-efficiency, and new approaches should be explored for efficient removal of Mn. We focused on Mn neutralization sludge, a by-product of the Mn-bearing drainage treatment process, which was assumed to be useful as a water purification material. Mn and zinc (Zn) removal tests in simulated drainage were performed using Mn neutralization sludge, and the reaction mechanism was elucidated using geochemical modeling and X-ray absorption fine structure (XAFS) analysis. The results showed that the addition of sludge enabled to lower the Mn and Zn concentration below Japanese effluent standard (10 mg dm−3 for Mn; 2 mg dm−3 for Zn) within 1 h. Furthermore, heavy metal immobilization was achieved at neutral pH (7–8) with the sludge addition, while the conventional neutralization process without adding the sludge requires higher pH (>10) to lower Mn concentration. These removal behaviors were not explainable by considering only well-known phenomena: hydroxide precipitation, surface complexation reaction onto δ-MnO2, and autocatalytic Mn oxidation. Hence, we advanced the geochemical model for simulation, suggesting that a surface complexation reaction onto γ-MnOOH greatly contributed to the removal of Mn. Besides, Zn was calculated to be predominantly precipitated as ZnMn2O4. Solid residue analysis by XAFS measurement supported the result of above calculation, validating the reliability of the constructed geochemical model. Overall, we concluded that the advanced geochemical model would be useful in predicting the Mn and Zn behavior during mine drainage treatment with Mn neutralization sludge.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Manganese (Mn) is ubiquitous in the Earth’s surface in soil, rocks, ore deposits, and groundwater. Mn is essential for organisms; however, excessive intake can be harmful, causing toxicity to the nervous and respiratory systems (Dobson et al., 2004). There is various source of Mn-bearing water generated spontaneously or anthropogenically, and abandoned mines are one large source of drainage with a high concentration of Mn, which can exceed the Japanese effluent standard (10 mg dm−3; Ministry of the Environment, Government of Japan, n.d.). Hence, mine drainage needs to be properly treated to minimize its negative impact. Chemical neutralization is the most common way to treat mine drainage, where soluble heavy metals are immobilized as a hydroxide precipitation along with a pH increase (Johnson & Hallberg, 2005). However, this process is economically inefficient, especially for Mn removal, which requires a rather high pH (>10) for hydroxide precipitation. Furthermore, this alkalified drainage, exceeding the upper limit for pH set by the Japanese effluent standard (pH 8.6; Ministry of the Environment, Government of Japan, n.d.), needs to be re-neutralized, which result in an increase in treatment costs. Therefore, alternative methods have been investigated for achieving the cost-effective treatment of Mn-bearing mine drainage.

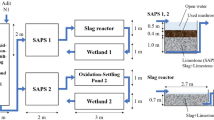

In recent decades, the use of Mn-oxidizing bacteria (MOB) was reported to be beneficial for Mn drainage remediation (Hallberg & Johnson, 2005), and a passive treatment system incorporating biological oxidation was implemented. The Motokura mine in Hokkaido, Japan, installed a 3-stage series channel: (i) a limestone tank for pre-neutralization of drainage, (ii) an oxic wetland for biological oxidation of dissolved Mn by MOB, and (iii) a subsurface limestone bed for precipitation of soluble heavy metals as hydroxides or carbonates via neutralization (Fuchida et al., 2020). In this system, Mn was entirely removed at pH 7–8, which is a much milder condition than the conventional neutralization process. Although treatment using MOB is likely promising in terms of cost-efficiency, the stability of the removal performance through biological oxidation is still challenging because of the necessity of providing an energy source for MOB and vulnerability to changes in the surrounding environment, such as pH and temperature. In this regards, abiotic oxidation is expected to be easier to control and stabilize the treatment performance.

While researchers have investigated abiotic oxidation methods for Mn-bearing drainage (Table 1), our research group has also reported that birnessite (δ-MnO2) shows outstanding performance as an oxidation reagent for Mn-bearing mine drainage remediation (Fuchida, Tajima, Nishimura, & Tokoro, 2022). Tetravalent Mn in δ-MnO2 exhibits a strong oxidative capability against Mn2+, known as “autocatalytic oxidation.” The reaction is divided into a series of elementary reaction (Stumm & Morgan, 1970): Mn2+ forms a surface complexation with the adsorption site on Mn oxide (≡MnOH; Eq. 1), and then transforms into MnOOH via a disproportionate reaction (Eq. 2), followed by aerobic oxidation of MnOOH to MnO2 (Eq. 3).

In a previous study using a column reactor to treat Mn-bearing mine drainage (Fuchida, Tajima, Nishimura, & Tokoro, 2022), autocatalytic oxidation by δ-MnO2 was determined to be the dominant mechanism for Mn removal. Furthermore, MnO2 is also known to be an extremely efficient scavenger for zinc (Zn; Tajima et al., 2022), cadmium (Cd; Suzuki et al., 2020; Wu et al., 2020), lead (Pb; O’Reilly & Hochella, 2003; Xu et al., 2013), arsenic (As; Thanabalasingam & Pckering, 1986; Oscarson et al., 1983); it shows great adsorption capacity and a high affinity for heavy metals, resulting from its two-dimensional layered structure (Tonkin et al., 2004) and low pH of the point of zero charge (pHPZC < 3; Gray et al., 1978). Therefore, δ-MnO2 is a promising material for stable treatment of Mn-bearing mine drainage, even though its procurement is a matter of concern.

The neutralization process for mine drainage produces a huge amount of sludge as a by-product, which is currently discarded as mining waste. This sludge is usually composed of residual chemical neutralizers such as limestone and slaked lime and precipitates of heavy metal. Notably, sludge produced from Mn-bearing mine drainage remediation (Mn neutralization sludge) was found to contain δ-MnO2 (Fuchida, Tajima, & Tokoro, 2022; Okibe et al., 2023). This suggests the possibility of using Mn neutralization sludge as a source of δ-MnO2 for mine drainage treatment. However, its effectiveness and the reaction mechanism have yet been understood because of its relatively complex constituents.

In this study, we evaluated the heavy metal removal capability of Mn neutralization sludge against Mn- and Zn-bearing mine drainage. Solution tests using Mn neutralization sludge were carried out to quantitatively assess its utility as material to remove heavy metals. On the basis of the experimental results of the test, we advanced the existing geochemical model, considering the kinetic, equilibrium, and surface complexation reactions to describe the mechanism in detail. XAFS analysis was also performed to identify the secondary minerals formed during metal removal, which validated the reliability of the advanced geochemical model.

2 Material and Methods

2.1 Targeted Mine Drainage and Sludge Preparation

Mine drainage discharged from X mine in Hokkaido, Japan, was used as the target wastewater. This drainage contained Mn and Zn concentrations (68.7 mg dm−3 and 5.39 mg dm−3, respectively; Table 2) that were above the Japanese effluent standard (Mn: 10 mg dm−3, Zn: 2 mg dm−3).

Mn neutralization sludge collected from X mine neutralization plant was freeze-dried for 24 h after filtration with a 0.45 μm mixed-cellulose ester membrane filter (ADVANTEC Japan Co. Ltd., Tokyo, Japan). Dried sludge was subjected to solid analysis to characterize its chemical properties. The chemical composition of Mn neutralization sludge was measured by X-ray fluorescence (XRF) analysis (VANTA, OLYMPUS Co., Tokyo, Japan). The Mn K-edge X-ray absorption fine structure (XAFS) spectra of Mn neutralization sludge and pure reference materials such as MnO, γ-MnOOH, and δ-MnO2 were measured (the detailed XAFS measurement is explained in Section 2.4). Linear combination fitting (LCF) to the Mn K-edge X-ray absorption near-edge structure (XANES) region was also performed to determine the Mn form existing in the neutralization sludge.

2.2 Heavy Metal Removal Experiment with Mn Neutralization Sludge

All metal removal experiments were conducted in ambient atmosphere at room temperature (25 °C). Analytical grade MnSO4·H2O (Alfa Aesar, Heysham, United Kingdom) and ZnSO4·6H2O (FUJIFILM Wako Pure Chemical Corp., Osaka, Japan) were dissolved in ultra-pure water to prepare 1000 mg dm−3 Mn and Zn stock solutions, respectively. Simulated X mine drainage containing 68.7 mg dm−3 Mn and 5.39 mg dm−3 Zn was prepared by mixing stock solutions with ultra-pure water. The ionic strength of the simulated drainage was adjusted to 0.05 mol dm−3 with 1 mol dm−3 H2SO4 and NaOH (FUJIFILM Wako Pure Chemical Corp., Osaka, Japan). The freeze-dried sludge was then added to 0.2 dm3 of simulated drainage at different molar ratios of (Mn in the added sludge)/(dissolved Mn in simulated drainage) = 5, 8. The mixture was stirred at 400 rpm for up to 3 h, with continuous pH adjustment with 1 mol dm−3 NaOH. After the reaction, the supernatant was filtered through a 0.45 μm polytetrafluoroethylene (PTFE) syringe filter (Membrane Solutions Limited, Seattle, United States), and the filtrate was acidified with 1 mol dm−3 H2SO4 (1 vol%) in a polypropylene bottle. Mn and Zn concentrations in the filtered samples were determined by inductively coupled plasma–optical emission spectrometer (ICP-OES, SPS-7800, Seiko Instruments Inc., Chiba, Japan).

2.3 Geochemical Modeling by PHREEQC

We employed the geochemical code PHREEQC ver.3 (USGS) to construct a geochemical model expressing Mn and Zn removal behavior in the presence of Mn neutralization sludge by considering the kinetic, equilibrium, and surface complexation reactions. Chemical equilibrium was calculated with the minteq.v4 database stored in the PHREEQC package. Kinetic Mn2+ oxidation in the presence of δ-MnO2 (Diem & Stumm, 1984) was installed in the geochemical model based on the following equation (Eq. 4)

where k1 and k2 are rate constants (k1 = 4 ×1012 M−3 day−1, k2 = 1018 M−4 day−1), [Mn2+] and [OH−] are the concentrations of each chemical species (M), and [MnOx] is the amount of oxidation agents in the system (M). Note that [MnOx] was calculated with the amount of δ-MnO2, and its reaction order (α) was determined through numerical fitting to the experimental results (Fuchida, Tajima, Nishimura, & Tokoro, 2022). The charge distribution multiple site complexation (CD-MUSIC) model was adopted to simulate the surface complexation reactions on the surface of δ-MnO2, and parameters used for this calculation are summarized in Table 3 (Li et al., 2020).

2.4 XAFS Analysis

XANES spectra of the Mn K-edge and Zn K-edge were measured at the BL5S1 and BL11S2 beamlines in the Aichi Synchrotron Radiation Center. The X-ray energy was controlled with a silica (111) monochromator, ranging from 6500 to 6700 eV for Mn and from 9600 to 9750 eV for Zn. The spectra were collected in transmission mode and then analyzed using the Athena software package provided by Demeter (Ravel & Newville, 2005). A good linear relationship exists between Mn valence and the white line position of the XAFS spectra (Foster et al., 2003); therefore, Mn valence can be estimated by regressing the white line position against a relationship between known valances and their white line positions. The spectra of standard samples were superimposed on the experimental spectra by LCF to estimate the Mn and Zn existence form.

3 Results and Discussion

3.1 Characterization of Mn Neutralization Sludge

Table 4 shows the chemical compositions of Mn neutralization sludge measured by XRF analysis. The sludge is composed of Mn (14.9 wt%), Zn (2.2 wt%), Fe, and Al (derived from drainage precipitates); and Ca, Si, and Mg (derived from residual neutralizer). Figure 1 shows the Mn K-edge XAFS spectra of reference materials and the original sludge, and LCF results are summarized in Table 5. Mn neutralization sludge mainly comprised γ-MnOOH (73.7%) and δ-MnO2 (26.3%).

3.2 Heavy Metal Removal by Mn Neutralization Sludge

Figure 2 shows the change in concentration of Mn and Zn in the simulated drainage with the addition of Mn neutralization sludge as a function of (i) reaction time and (ii) pH. In Fig. 2(i), the pH value was set at 8.5, which is sufficiently high for lowering Mn concentration below the Japanese effluent standard (pH 8.6). In the presence of Mn sludge, the soluble Mn concentration decreased gradually as the reaction proceeded; it was below the effluent standard after 1 h, and was completely removed after 3 h, while almost no decline in Mn concentration without sludge addition. Abiotic oxidation of Mn2+ at circumneutral pH is a slow kinetic process: 5 μM Mn2+ was halved by air oxidation in approximately 5 days at pH 8.8 (Diem & Stumm, 1984). This indicates that the presence of Mn sludge greatly promoted Mn2+ oxidation. The removability of chemical-synthesized δ-MnO2 has been examined with different MnO2/soluble-Mn molar ratios at pH 8 (Fuchida, Tajima, Nishimura, & Tokoro, 2022), in which Mn was completely removed within 30 min at a molar ratio of 10, while only 10% of Mn was removed at a molar ratio of 1. In contrast, in this experiment, the reaction proceeded sufficiently, although the molar ratio of MnO2/soluble-Mn was approximately 1.3. Notably, δ-MnO2 accounts for 26.3 mol% of Mn neutralization sludge, implying that components in Mn neutralization sludge other than δ-MnO2 may be involved in Mn removal. Soluble Zn was also completely removed at this pH via hydroxide formation. Figure 2(ii) shows that soluble Mn and Zn concentrations decreased as pH increased regardless of the molar ratios used in this study; soluble Mn gradually decreased at pH 7–9, while soluble Zn dropped at pH 6–7. On the basis of the conventional Mn and Zn removal mechanisms, three possible phenomena were assumed to occur here: (i) hydroxide formation, (ii) surface complexation onto δ-MnO2, and (iii) autocatalytic oxidation of Mn. As for the first phenomenon, Mn and Zn form hydroxides at pH 9–10 and pH 8–9, respectively (Fuchida, Tajima, & Tokoro, 2022; Kato et al., 2017). The second surface complexation reaction favors relatively acidic pH: pH < 3 for Mn (Li et al., 2020) and pH < 2 for Zn (Harding et al., 1986). The third phenomenon, Mn oxidation by MnO2 (autocatalytic oxidation), occurs at alkaline pH because the Mn oxidation rate is proportional to the square of the hydroxide ion concentration (Stumm & Morgan, 1970). Therefore, conventional removal mechanisms (i.e., hydroxide precipitation, surface complexation on MnO2, and autocatalytic oxidation) are insufficient to reproduce the behavior of soluble Mn and Zn, indicating that another underlying mechanism likely contributed to Mn and Zn removal in the presence of Mn neutralization sludge.

3.3 Mechanism of Heavy Metal Removal by Mn Neutralization Sludge Based on Geochemical Modeling and XAFS Analysis

In this section, the chemical mechanisms occurring in the presence of Mn neutralization sludge are quantitatively discussed by comparing the experimental results with the numerical calculations. We considered the contribution of a surface complexation reaction with γ-MnOOH, which is the major component of Mn neutralization sludge. A diffuse layered model (DLM; Dzombak & Morel, 1990) was used to simulate these reactions. The adsorption equilibrium constants (log K) for surface complexation reactions of Mn and Zn with γ-MnOOH (≡MnOH + Mn2+ [Zn2+] ⇆ ≡ MnOMn+ [Zn+] + H+) were determined to be −3.0 and −3.5, respectively, based on pH-edge adsorption experiments (Fig. S1). Note that we have confirmed that the conventional model was unsuitable to reproduce the experimental results without considering above-surface complexation.

3.3.1 Comparison Between the Geochemical Modeling and Experiment Results

Figure 3 shows the changes in experimental and calculation results with the developed geochemical model as a function of pH. On the basis of the model calculation, Mn was mainly removed by surface complexation reactions with δ-MnO2 (≡δ-MnO2) and γ-MnOOH (≡γ-MnOOH) and through precipitation of Mn(III)-bearing minerals such as γ-MnOOH and hetaerolite (ZnMn2O4). The surface complexation reaction on δ-MnO2 proceeded above pH 4, contributing to approximately 10 mg dm−3 of Mn removal. With increasing pH, autocatalytic reaction on δ-MnO2 surface was promoted, leading to the formation of γ-MnOOH. At circumneutral pH, a maximum of 20 mg dm−3 of dissolved Mn was removed by the surface complexation reaction on γ-MnOOH. Therefore, we revealed that both δ-MnO2 and γ-MnOOH play an important role in the removal of Mn from mine drainage.

A predominant removal mechanism for Zn was likely through the formation of hetaerolite (ZnMn2O4). Previous studies have reported the formation of ZnMn2O4 in the presence of Mn oxides and Zn ions via the successive substitution of Mn2+ in hausmannite (Mn3O4) by Zn2+ (Hem et al., 1987). In the numerical calculation, the formation of ZnMn2O4 was simulated as follows (Eq. 5):

Above pH 6, the solubility product of ZnMn2O4 was oversaturated, which might be because of the provision of Mn3+ from the gradual decomposition of the γ-MnOOH originally contained in the sludge. Therefore, γ-MnOOH was also shown to greatly contribute to Zn removal when Mn neutralization sludge was used.

3.3.2 Validation of the Geochemical Modeling with XAFS Analysis

Figure 4a shows the Mn K-edge spectra of the reference standards and the post-tested sludge taken from each pH reaction system. The white line position of each post-tested sample decreased as pH increased (Fig. 4a). The Mn valence of each sample was determined by the linear relationship between Mn valence and the white line position (Fig. 4b; Table 6). Mn valence decreased with increasing pH, likely because of the increasing development of Mn(III)-bearing secondary minerals. This is consistent with the simulated results from the geochemical model: Mn removal was proceeded by the formation of γ-MnIIIOOH and ZnMnIII2O4.

Figure 5 shows the Zn K-edge spectra of reference materials and sludge samples obtained from experiments under various pH conditions, and the LCF results against these spectra are summarized in Table 7. Results show that the largest fraction (approximately 60% for every sample) is ZnMn2O4 and the second-largest fraction (above 30% for every sample) is ZnCO3; however, the latter was not detected in the model calculation. Since carbonate ions are not involved in the experimental system, the original sludge was expected to have contained ZnCO3. This suggests that ZnMn2O4 predominantly contributed to the immobilization of Zn, which supports the reliability of the advanced geochemical model.

4 Conclusions

We evaluated the applicability of Mn neutralization sludge, normally recognized as a mining industrial waste, as a material for heavy metal remediation of Mn-bearing mine drainage. We demonstrated that Mn neutralization sludge promotes heavy metal immobilization at neutral pH (7–8) with a shorter reaction time than the conventional neutralization process. The reaction mechanisms were elucidated by comparing the empirical value and the calculated results from the advanced geochemical model. We revealed that, in addition to the conventionally known phenomena (autocatalytic oxidation and surface complexation reaction on δ-MnO2), surface complexation reaction on γ-MnOOH also greatly contributed to Mn removal. Zn was removed mainly by the precipitation of ZnMn2O4, which was facilitated by the presence of γ-MnOOH. XAFS analysis was in good agreement with the calculated results, which verified the reliability of the model.

In this study, we have found that the use of Mn neutralization sludge is beneficial in achieving the Mn and Zn removal at much milder pH than the conventional process, which contribute to reducing the cost for the consumption of chemicals. Furthermore, this process also promotes the volume reduction of Mn-neutralization sludge currently being discarded and landfilled. Therefore, we believed that this technique can be easily installed into the Mn-bearing wastewater treatment process.

The advanced model contributes to mechanism investigation and could also be used to predict the heavy metal removal behavior for treatment processes using Mn neutralization sludge under different configurations (e.g., different amount of sludge addition or the initial water chemistry of drainage). To improve the generality of the advanced model, further investigation is needed, for example, considering the effect of anions on the immobilization of heavy metal in mine drainage.

Data Availability

The datasets used and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- k1 :

-

Rate constant for Mn oxidation

- k2 :

-

Rate constant for autocatalytic oxidation

- [MnOx]:

-

Amount of oxidation agents in the system (M)

- Δz 0, Δz 1, Δz 2 :

-

Charge distribution coefficients for CD-MUSIC model

- C1 :

-

Inner-layer capacitance in the external surface

- C2 :

-

Outer-layer capacitance in the external surface

- C:

-

Capacitance in the internal surface

References

Diem, D., & Stumm, W. (1984). Is dissolved Mn2+ being oxidized by O2 in absence of Mn-bacteria or surface catalysis? Geochimica et Cosmochimica Acta, 48(7), 1571–1573. https://doi.org/10.1016/0016-7037(84)90413-7

Dobson, A. W., Erikson, K. M., & Aschner, M. (2004). Manganese neurotoxicity. Annals of the New York Academy of Sciences journal, 1012(1), 115–128. https://doi.org/10.1196/annals.1306.009

Dzombak, D. A., & Morel, F. M. M. (1990). Surface Complexation Modeling: Hydrous Ferric Oxide. John Wiley & Sons, Inc.

Foster, A. L., Brown, G. E., & Parks, G. A. (2003). X-ray absorption fine structure study of As(V) and Se(IV) sorption complexes on hydrous Mn oxides. Geochimica et Cosmochimica Acta, 67(11), 1937–1953. https://doi.org/10.1016/S0016-7037(02)01301-7

Freitas, R. M., Prilli, T. A. G., & Ladeira, A. C. Q. (2013). Oxidative Precipitation of Manganese from Acid Minde Drainage by Potassium Permanganate. Journal of Chemistry, 2013, 287257. https://doi.org/10.1155/2013/287257

Fuchida, S., Suzuki, K., Kato, T., Kadokura, M., & Tokoro, C. (2020). Understanding the biogeochemical mechanisms of metal removal from acid mine drainage with a subsurface limestone bed at the Motokura Mine, Japan. Scientific Reports, 10, 20889. https://doi.org/10.1038/s41598-020-78069-9

Fuchida, S., Tajima, S., Nishimura, T., & Tokoro, C. (2022). Kinetic modeling and mechanisms of manganese removal from alkaline mine water using a pilot scale column reactor. Minerals, 12(1), 99. https://doi.org/10.3390/min12010099

Fuchida, S., Tajima, S., & Tokoro, C. (2022). Investigation on effective neutralization process of acid mine drainage containing high amount of Mn and Zn by additions of δ-MnO2 adsorbent and oxidizing agent. Journal of MMIJ, 138(11), 160–169. https://doi.org/10.2473/journalofmmij.138.160

Gray, M. J., Malati, M. A., & Rophael, M. W. (1978). The point of zero charge of manganese dioxides. Journal of Electroanalytical Chemistry and Interfacial Electrochemistry, 89(1), 135–140. https://doi.org/10.1016/S0022-0728(78)80038-2

Hallberg, K. B., & Johnson, D. B. (2005). Biological manganese removal from acid mine drainage in constructed wetlands and prototype bioreactors. Science of the Total Environment, 338(1-2), 115–124. https://doi.org/10.1016/j.scitotenv.2004.09.011

Harding, J. G. C., Associates, L., Boulevard, R., & Langmuir, D. (1986). Adsorption of Cu, Pb and Zn by δ-MnO2: applicability of the site binding-surface complexation model. Applied Geochemistry, 1(2), 255–264. https://doi.org/10.1016/0883-2927(86)90010-7

Hem, J. D., Roberson, C. E., & Lind, C. J. (1987). Synthesis and stability of hetaerolite, ZnMn2O4 at 25°C. Geochimica et Cosmochimica Acta, 51(6), 1539–1547. https://doi.org/10.1016/0016-7037(87)90335-8

Johnson, D. B., & Hallberg, K. B. (2005). Acid mine drainage remediation options: A review. Science of the Total Environment, 338(1-2), 3–14. https://doi.org/10.1016/j.scitotenv.2004.09.002

Kato, T., Yagisawa, M., Matsuoka, M., Tokoro, C., Sakakibara, T., & Hayashi, K. (2017). Quantitative modeling incorporating surface complexation for the treatment of acid mine drainage. Kagaku Kogaku Ronbunshu, 43(4), 207–212. https://doi.org/10.1252/kakoronbunshu.43.207

Li, Y., Zhao, X., Wu, J., & Gu, X. (2020). Surface complexation modeling of divalent metal cation adsorption on birnessite. Chemical Geology, 551, 119774. https://doi.org/10.1016/j.chemgeo.2020.119774

Ministry of the Environment, Government of Japan. n.d. National Effluent Standards. Retrieved December 11, 2023, from https://www.env.go.jp/en/water/wq/nes.html

O’Reilly, S. E., & Hochella, M. F. (2003). Lead sorption efficiencies of natural and synthetic Mn and Fe-oxides. Geochimica et Cosmochimica Acta, 67(23), 4471–4487. https://doi.org/10.1016/S0016-7037(03)00413-7

Okibe, N., Nonaka, K., Kondo, T., Shimada, K., & Liu, P. (2023). Microbiological passive treatment of Mn/Zn-containing mine water. Hydrometallurgy, 219, 106084. https://doi.org/10.1016/j.hydromet.2023.106084

Oscarson, D. W., Huang, P. M., & Hammer, U. T. (1983). Oxidation and sorption of arsenite by manganese dioxide as influenced by surface coating of iron and aluminum oxides and calcium carbonate. Water, Air, & Soil Pollution, 20, 233–244.

Ravel, B., & Newville, M. (2005). ATHENA, ARTEMIS, HEPHAESTUS: Data analysis for X-ray absorption spectroscopy using IFEFFIT. Journal of Synchrotron Radiation, 12, 537–541. https://doi.org/10.1107/S0909049505012719

Shekarian, Y., Hassas, B. V., Rezaee, M., & Pisupati, S. V. (2022). Development of a chemical-free process utilizing ozone oxidative precipitation for the recovery of cobalt and manganese form acid mine drainage. Journal of Environmental Chemical Engineering, 10, 108533. https://doi.org/10.1016/j.jece.2022.108533

Stumm, W., & Morgan, J. (1970). Aquatic Chemistry -An Introduction Emphasizing Chemical Equilibria in Natural Waters. John Wiley & Sons, Inc.

Suzuki, K., Kato, T., Fuchida, S., & Tokoro, C. (2020). Removal mechanisms of cadmium by δ-MnO2 in adsorption and coprecipitation processes at pH 6. Chemical Geology, 550, 119744. https://doi.org/10.1016/j.chemgeo.2020.119744

Tajima, S., Fuchida, S., & Tokoro, C. (2022). Coprecipitation mechanisms of Zn by birnessite formation and its mineralogy under neutral pH conditions. Journal of Environmental Sciences, 121, 136–147. https://doi.org/10.1016/j.jes.2021.09.019

Thanabalasingam, P., & Pckering, W. F. (1986). Effect of pH on interaction between As(III) or As(V) and manganese (IV) oxide. Water, Air, & Soil Pollution, 29, 205–216.

Tonkin, J. W., Balistrieri, L. S., & Murray, J. W. (2004). Modeling sorption of divalent metal cations on hydrous manganese oxide using the diffuse double layer model. Applied Geochemistry, 19(1), 29–53. https://doi.org/10.1016/S0883-2927(03)00115-X

Wu, S., Xie, F., Chen, S., & Fu, B. (2020). The removal of Pb (II) and Cd (II) with hydrous manganese dioxide: mechanism on zeta potential and adsorption behavior. Environmental Technology, 41(24), 3219–3232. https://doi.org/10.1080/09593330.2019.1604814

Xu, M., Wang, H., Lei, D., Qu, D., Zhai, Y., & Wang, Y. (2013). Removal of Pb(II) from aqueous solution by hydrous manganese dioxide: Adsorption behavior and mechanism. Journal of Environmental Sciences, 25(3), 479–486. https://doi.org/10.1016/S1001-0742(12)60100-4

Zhang, W., Cheng, Y. C., & Pranolo, Y. (2010). Investigation of methods for removal and recovery of manganese in hydrometallurgical processes. Hydrometallurgy, 101, 58–63. https://doi.org/10.1016/j.hydromet.2009.11.018

Acknowledgements

Part of this work was performed at the Waseda Research Institute for Science and Research Organization for Open Innovation Strategy, Waseda University. XAFS analysis was performed using the BL5S1 and BL11S2 beamline at the Aichi Synchrotron Radiation Center, Aichi Science Center, Aichi Science & Technology Foundation, Aichi, Japan. We thank Tara Penner, MSc, from Edanz (https://jp.edanz.com/ac) for editing a draft of this manuscript.

Funding

Open Access funding provided by The University of Tokyo.

Author information

Authors and Affiliations

Contributions

Conceptualization: Keishi Oyama, Chiharu Tokoro; Methodology: Keishi Oyama, Shigeshi Fuchida; Formal analysis and investigation: Yusuke Furukori; Writing – original draft: Yusuke Furukori; Writing – review and editing: Keishi Oyama, Shigeshi Fuchida; Supervision: Chiharu Tokoro.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Supplementary file 1

(PNG 32 kb)

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Furukori, Y., Oyama, K., Fuchida, S. et al. Geochemical Evaluation of Manganese Neutralization Sludge for Mn-Containing Mine Drainage Treatment. Water Air Soil Pollut 235, 223 (2024). https://doi.org/10.1007/s11270-024-07031-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-024-07031-6