Abstract

The integrated management of water resources is a requirement for environmental preservation and economic development, with the removal of nutrients being one of the main drawbacks. In this work, the efficiency of a bacterial consortium (Ecobacter WP) made up of eight bacterial strains of the genus Bacillus subtilis, Bacillus licheniformis, Bacillus megaterium, Bacillus cereus, Arthrobacter sp., Acinetobacter paraffineus, Corynebacterium sp., and Streptomyces globisporus was evaluated in the removal of nitrogen compounds in domestic wastewater in a plug flow system, in the extended aeration and bioaugmentation (FLAEBI). To promote the nitrification and denitrification processes, three doses were tested to establish the optimal concentration of the bacterial consortium on a laboratory scale and its subsequent application in an outdoor wastewater treatment plant (WWTP). The evaluation period was 15 days for each treatment in the laboratory and WWTP. The parameters monitored both at laboratory and outdoor were pH, temperature, dissolved oxygen, chemical oxygen demand (COD), biochemical oxygen demand (BOD5), ammonium, nitrites, and nitrates. The results indicated that the optimal concentration of the consortium was 30 mg L−1, with a removal of 92% of nitrate at the laboratory and 62% outdoor. Such a difference is attributed to the different operation residence times and the volume that caused different concentration gradients. The consortium studied can be used to promote nitrification and denitrification processes that intervene in the removal of nitrogenous compounds in plants with similar operating conditions, without investment in restructuring or design modification of the WWTP.

Graphical abstract

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Nitrogen compounds (CoN) can be found in water bodies either as products or by-products of anthropogenic activities: as a result of discharges from the consumption of water resources on a domestic, industrial, or agricultural scale or also from natural sources such as geological deposits, decomposition of organic matter, atmospheric deposition, and surface runoff (Cockburn et al., 2014; Dennis & Wilson, 2003). The discharge of these nitrogenous compounds has increased due to the intensification of agriculture, the increase in the levels of atmospheric deposition, and residual discharges due to the change in diet (Ramakrishnan, 2015).

Nitrogen compounds are frequently found in the form of ammonium (NH4+), nitrite (NO2−), and nitrate (NO3−) and are constantly transformed by microorganisms in the biogeochemical nitrogen cycle, and these nitrogen states are the most important, given their reactivity and presence in the environment (Eliašová et al., 2021; Li et al., 2017; Sotres et al., 2016).

Wastewater contaminated with nitrogen compounds is a problem for the wealth of water resources and ecosystems, due to its association with the problems of eutrophication and acidification of water bodies that lead to their deterioration (Camargo & Alonso, 2006; Cockburn et al., 2014; Sotres et al., 2016; Zou et al., 2018). For human beings, it can lead to physiological disorders such as nausea, diarrhea, gastroenteritis, muscle aches, and other various symptoms as dangerous as methemoglobinemia in babies (Dennis & Wilson, 2003; Fan, 2014, 2019). For this reason, efforts have been intensified in recent years to find treatments that eliminate nitrogen in effluents, since initially the projects of the effluent treatment stations were mainly focused on the removal of suspended solids, organic matter, and pathogenic microorganisms (Rathna & Nakkeeran, 2020). As a result of this, processes such as nitrification and denitrification in the elimination of nitrogen in wastewater have been commonly used in wastewater treatment (Sotres et al., 2016).

Nitrification is the process of biological oxidation of ammonium to nitrite, a reaction catalyzed by bacteria containing ammonia monooxygenase (amoA) enzymes, and then from nitrite to nitrate catalyzed by bacteria containing the enzyme nitrite oxidoreductase. This occurs by an anaerobic process and is carried out by ammonium oxidizing autotrophic bacteria, ammonium oxidizing archaea, and nitrite-oxidizing bacteria (Baumann et al., 1996; Sotres et al., 2016). Bacterial denitrification occurs by anaerobic respiration processes for various facultative bacteria and archaea and involves four reduction steps in which nitrate is transformed into dinitrogen, via nitrite, nitric oxide, and nitrous oxides (Baumann et al., 1996; Shapleigh, 2013; Sotres et al., 2016).

There are different types of treatments for the elimination of nitrogen in the water, from physical, physicochemical, and biological treatments, individually or in combination, which depend on multiple variables such as type of water, flow, temperature, and other variables typical of the effluent (Herrero and Stuckey, 2015; Sepehri et al., 2020; Yang et al., 2020). The methods widely used for the removal of CoN are mostly physicochemical and transfer the pollutant from one environment to another and not solve the root problem (Achak et al., 2009; Lee et al., 2003; Ramos et al., 2007).

There are several methods to treat the contaminated industrial wastewater, of which biological treatment methods are economical and environmentally friendly (Aragaw & Asmare, 2018). Biological processes are gaining more and more attention in several areas mainly due to the lower demand for chemical agents, cost-effectiveness, and environmentally friendly operating techniques. Through bioremediation methods of wastewater treatment that use bacteria, which are the most important microorganisms to promote the biodegradation, bioaugmentation, and biosorption of contaminants into innocuous or less toxic compounds, biological wastewater treatment proceeds with a complex biochemical reaction with the interaction between microorganisms and organic matters (Aragaw, 2020).

According to Igiri et al. (2018), microbial bioremediation can be affected because toxic organic contaminants such as pesticides, plastics, some azo dyes, and heavy metals are not biodegradable. The toxicity of contaminants can occur in the breakdown of fatal enzymatic functions, such as a redox catalyst during the production of reactive oxygen species, destabilize ions in the oxidation process, and directly toxify genetic materials and proteins (Igiri et al., 2018).

Although when we talk about bacterial consortium, which includes several species of bacteria, different microorganisms together can develop detoxification mechanisms to hostage the toxic effects of the contaminants. Microorganisms can develop various mechanisms of protection and resistance to toxic contaminants in their microbial cells. Among these mechanisms are the formation of extracellular barriers, extracellular sequestration and active transport of contaminants, and intracellular sequestration and the reduction and/or oxidation of elements with high molecular weights in lower valence states (Okoduwa et al., 2017).

To promote respiration in bioaugmentation, dissolved oxygen and different nutrients, sulfide or sulfate and nitrate, can be used as electron acceptors in aerobic, anaerobic, and anoxic systems (AFCEE, 2008). According to Samer (2015), the use of sulfide or sulfate is not desirable in wastewater treatment processes because sulfate or sulfide, a product of anaerobic respiration, generates unpleasant odors and can also be toxic to human health. Furthermore, the oxidation of sulfides generates sulfuric acid in the pipeline systems which is corrosive to the pipeline. Nevertheless the consortia of microorganisms, rich in species like the one used in the present study, attains a high biodegradation efficiency with different substrates, unlike the use of single species. Several bacterial species, have been extensively studied for heavy metal removal (Orellana et al., 2018).

Non-assimilative biological processes for the elimination of nitrogen can be an efficient alternative, based on the application of nitrifying and denitrifying bacteria of the ammonium-oxidant and nitrite-oxidant type that use inorganic carbon as a carbon source for cellular synthesis and inorganic nitrogen for obtaining energy (Ahn, 2006; Jia et al., 2019; Kallistova et al., 2016; Pérez-Uz et al., 2010; Ramos et al., 2007).

For biological treatment, a variety of configurations have been developed in activated sludge plants that increase the efficiency in the biological elimination of nitrogen (Ahn, 2006; Mažeikienė & Grubliauskas, 2021; Pérez-Uz et al., 2010). To accelerate these processes, bioaugmentation techniques are adopted (Jia et al., 2019). These treatments are focused on promoting the oxidation of ammonium (nitrification) and the elimination of nitrogen through the conversion of the oxidized forms to nitrogen gas (John et al., 2020; Yang et al., 2020; Zou et al., 2018).

As an innovation strategy in wastewater treatment systems, traditional systems were redesigned incorporating new stages (nitrification–denitrification) (Ekama, 2011). However, the first efforts, such as the Ludzack and Ettinger system (anoxic-aerobic), did not use mixed liquor recirculation, significantly wasting the biological oxygen demand (BOD) of the influent (Venegas, 2015). Later, this design was modified including an internal recirculation, which could use the BOD of the tributary for denitrification (Suárez, 2019). However, this research allowed evaluating the control of variables (pH, oxygen, temperature) in real time of the nitrogen removal process via nitrite at low cost, in addition to having as its main advantage the flexibility and ability to adapt to the characteristics of the tributary current and the state of the process (Venegas, 2015).

This study uses a bacterial consortium since it has more efficiency in the elimination of waste in the effluent water than the individual cultures. The assembled consortium is employed as a bioaugmentation agent to establish an eco-friendly practice for the remediation of nitrogenous ammonium and nitrite wastes wastewater (Herrero and Stuckey, 2015; John et al., 2020) and the operation of a treatment system with plug flow processes, extended aeration, and bioaugmentation (FLAEBI), for the removal of CoN (Jia et al., 2019; Peñafiel et al., 2016; Ruscalleda Beylier et al., 2011).

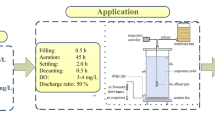

The FLAEBI technology is a type of advanced treatment and is made up of the combination of several techniques such as plug flow reactor, extended aeration, and bioaugmentation, generating a bioreaction based on the conversion and concentration of biomass. The wastewater in a plug flow reactor is transported throughout the reactor without mixing; therefore, the discharge emerges from the exit point of the reactor in the same sequence in which the wastewater enters. One of the main characteristics is that all the elements of the system travel at the same spee; there are no mixtures or longitudinal diffusions (Ipuz & Reyes, 2015; Jaibiba et al., 2020; Liu, 2017; Pal, 2017). The extended aeration process is the stage where the oxygen necessary to support the aerobic biological process is supplied by mechanical or diffuse aeration (EPA, 2000; Lucena et al., 2010; Pillai et al., 1971). Finally, bioaugmentation uses supplementary microorganisms with capacities to biodegrade pollutants or compounds in the wastewater in a faster way than native microorganisms of the wastewater (Herrero and Stuckey, 2015; Nzila et al., 2016; Raper et al., 2018). The set of all these technologies can result in a substantial improvement in the treatment, in addition to generating favorable conditions for the operation of the plant. Based on this and the CoN problem, the present investigation evaluates the efficiency of CoN removal through the application of the bioaugmentation technique in domestic wastewater, as well as the optimal concentration of the consortium understudy, which guarantees higher removal percentages in an outdoor wastewater treatment plant.

2 Material and Methods

2.1 Study Area

The wastewater used for this study was obtained from a wastewater treatment plant (WWTP) located in the north of Colombia, specifically in the municipality of Puerto Colombia. The average flow of this plant is 120 M3 day−1; the climatic conditions of the area reach maximum temperatures between 30 and 32 °C and minimum temperatures between 24 and 26 °C, with average ultraviolet radiation between 5 and 8 IUV (ultraviolet index) and daily average horizontal global irradiation between 5 and 6 kWh m−2 (IDEAM, 2019).

2.2 Consortium and Characterization Methods

Ecobacter was used as a bacterial consortium supplied by the company Ingeniería Medio Ambiente IMA S.A.S. This consortium is made up of eight strains, without genetic modifications and with different metabolic characteristics (aerobic, anaerobic, or facultative). The concentration used of the inoculum was calculated according to the manufacturer’s recommendations, multiplying the milligrams per liter of the consortium to be dosed by the flow of wastewater to be treated; the concentrations used were 20 mg L−1, 30 mg L−1, and 40 mg L−1. Consortium specifications are found in Table 1.

These concentrations were applied at two laboratory plants (Pe1, Pe2) and a blank (PeB) with the native bacterial flora of the wastewater under study. The efficiency of the concentration was evaluated for 15 days, where the first 5 correspond to the adaptation phase of the inoculum.

Ten samples of 80 L each were collected twice a week (Monday and Wednesday) for 6 weeks, guaranteeing the chain of custody for storage with refrigeration and transport in sterilized plastic containers (IDEAM, 2017). The examination techniques used on the samples were based on the Standard Methods for the Examination of Water and Wastewater (Baird & Bridgewater, 2017).

2.3 Laboratory Scale Design

The independent variables for the design of the laboratory plant were consortium concentration, sections of the treatment plant, hydraulic retention time (HRT), and flow rate (Q). The dependent variables were pH, temperature, dissolved oxygen (DO), nitrate, nitrite, ammonium, COD, and BOD5. The laboratory plant is a rectangular geometric shape in fiberglass, with a volume of 24 L and with five modules, where the first three are aerobic (nitrification) and the last two worked in an anoxic way (denitrification).

To create an aerobic system in the first three modules, a submersible pump is installed to recirculate 15% of the treated water flow, BF33 biofilters, and nine diffuser stones with a diameter of 30 mm to which an airflow was injected at 0.045 L min−1, supplied by two pumps with a capacity of 2.2 L min−1 each; after the aerobic zone, the flow is conducted to an anoxic zone. Ball valves (1/2″ in PVC) were installed for the discharge and sampling system. Once each test was finished, the biofilters and modules were washed and sterilized for the new test with the new concentration of inoculum.

The system operates by gravity since the energy used to move the fluid is the potential energy that the water has at its height. The communication between the modules is made by the height difference between the interns. Operational control was carried out manually.

2.4 Removal Efficiency

The efficiency of the treatment is obtained from the results of the monitoring of parameters carried out at the laboratory scale and outdoor system, both in the input and in the output (Table 2). Continuous 24-h cycles were used to analyze the physicochemical parameters, with a retention time of 3 days. The hydraulic residence time of 2 h was calculated, as a function of the flow rate and the volume of the laboratory plant (Eq. (1)).

where HRT is hydraulic retention time (h), V is the reaction volume (m3), and Q is the effluent flow (m3 h−1).

Sixty samples of wastewater treated by each procedure were taken for 15 days at 2-h intervals. The criteria to determine the optimal concentration were the highest CoN removal percentage. The best concentration obtained was applied in the outdoor wastewater treatment plant for 15 days, evaluating the same parameters analyzed in the laboratory plant.

2.5 Statistical Analysis

In the laboratory phase, it was considered the treatment (concentration (mg L−1) of the inoculum), replication (Pe control, Pe1, and Pe2), day (sample collection time and day), point (entry, exit, and sections from 1 to 4), hydraulic retention time per section and laboratory plant, and flow. For the field phase in the wastewater treatment plant, the data was organized by day (sample collection time and day), total volume, operating flow, the hydraulic retention time of the plant, and the point (input, output, and modules 1 to 4). Likewise, the input variable is inoculum concentration, and the output variables are COD, BOD5, and CoN removal percentages. This information allowed the analysis of the data using the Statgraphics Centurion XVI software, applying a generalized linear regression model, to determine if there is a relationship between the physicochemical variables evaluated with the results obtained with 95% confidence (p < 0.05). An analysis of multifactorial variance was carried out, ANOVA multifactorial, which allowed to establish a statistically significant relationship between the independent variables and the dependent variables, both on the laboratory scale and outdoor systems. Additionally, Fisher’s LSD (least significant difference) intervals are presented to compare the means of the groups of animals corresponding to the three treatments (StatPoint Technologies, 2010). In cases where the interaction of both independent variables (treatment concentration and module) was presented on the dependent variables, the interaction chart was added.

3 Results and Discussions

3.1 Initial Physicochemical Characterization of Wastewater

To determine the efficiency of the removal of the CoN, it is necessary to initially evaluate the parameters (COD, BOD5, nitrates, nitrites, ammonium, and pH) of the influent. Table 3 shows the initial concentrations of the water taken from the municipal WWTP pump station.

The values obtained in the characterization were compared with the typical compositions of domestic wastewater described in the literature (Metcalf et al., 2007; Niño Rodríguez and Martínez Medina, 2013). Table 3 shows the mean concentrations of COD and BOD5 from the initial characterization remain in a range of medium biodegradability (López-Vazquez et al., 2017). Nitrites and nitrates in wastewater normally range between 0.1 and 0.9 mg L−1 (Metcalf et al., 2007; Niño Rodríguez and Martínez Medina, 2013), but in this study, higher concentrations were found such as 7.89 NO2−-mg L−1 and 17.5 NO3−-mg L−1, which can be justified by industrial and domestic discharges. The ammonium concentration was relatively low (7.31 NH4+-mg L−1) compared to the normal values of domestic wastewater (Table 3). pH had a value of 7.43, a typical range of these waters. The high concentrations of the aforementioned parameters can lead to toxic problems in the environment and decrease the quality of the receiving water bodies (Atolia et al., 2020; López et al., 2017; Mytilinaios et al., 2015). The results of multifactorial ANOVA analysis showed a statistically significant difference (p ≥ 0.05), between the mean of the treatments (20, 30, and 40 mg L−1) for the parameters: pH, temperature, DO, COD, BOD5, and compounds nitrogenous (ammonium, nitrites, and nitrates).

3.1.1 pH and Temperature Parameters

These parameters can be influenced by microbial growth due to metabolic reactions associated with the cell duplication process, generating variations in pH and temperature (Ruscalleda Beylier et al., 2011).

The average pH values per concentration can be seen in Fig. 1; the highest average value was presented in the treatment with 30 mg L−1, where it increased to 8 pH units; the lowest value recorded was for the concentration of 40 mg L−1 with an average pH of 6.5. It can be diagnosed that the concentration of 30 mg L−1 maintains a balance between the bioaugmented biomass and the amount of organic carbon required for nitrification and denitrification because the consumption of organic carbon by biomass increases the alkalinity releasing carbon dioxide (CO2) in turn, increasing the pH to 8, in addition to compensating for the decrease in pH that occurred during nitrification; it allows to achieve adequate denitrification (López et al., 2017).

While for the concentrations of 20 and 40 mg L−1 and the control, the opposite occurred since the nitrification and denitrification processes were limited, leading to a decrease in pH 6.4 (Garrido et al., 2019). This is because the pH ranges were not within the range of 6.5 to 7.5 units established by the manufacturer nor in the range 7.5 to 8.5 units, reported by other studies as optimal for this type of biological nitrification treatment via nitrate (López et al., 2017; Zornoza et al., 2010). It is important to note that these are not the only conditions under which nitrification and denitrification processes can occur since the optimal ranges differ slightly for each type of treatment.

The highest average temperature was with the 30-mg L−1 treatment with a value of 28.1 °C, while for the other concentrations, the average range was below 27.5 °C (Fig. 2). The increase in temperature is because the microbial activity increases as the temperature of the system increase, especially for nitrifying agents (Zornoza et al., 2012).

Although the biological temperature is key in the processes, controlling this parameter on a real scale would affect the increase in the design and operating costs of the system, which would not be suitable for the adoption of the system in developing countries; though, not controlling this parameter would reduce bacterial growth if extreme changes in temperature were to occur or outside the working ranges. However, for this study, all treatments were within the temperature range recommended by the manufacturer (20 to 30 °C) and that recommended by other studies (≥ 20 °C) (López et al., 2017), becoming a fundamental factor in the success of the bacterial growth process.

The results of the multifactorial ANOVA indicated that the pH and temperature variables presented statistically significant differences (p < 0.05) concerning the treatment (20, 30, 40 mg L−1 and the control) (Fig. 3) and to the sections of the treatment (1, 2, 3, 4). For these two variables, the LSD Fisher graph shows that there is a statistically significant difference between the treatments and the blank for both parameters. In the case of pH and temperature, the treatment that presents the greatest difference from the blank (without bacterial consortium) is the 30-mg L−1 treatment (Fig. 3A, B).

For these two variables, the interaction shows that the four modules and the output reached pH units and higher temperatures in the 30-mg L−1 treatment, concerning the other treatments and the control, which is an indirect measure of microbial growth (Bedoya, 2012; Zornoza et al., 2010), and in the case of pH between neutrality and alkalinity, an indication of the reduction of nitrogen compounds (Fig. 4A, B). One of the advantages of this type of biotechnology (FLAEBI) lies in the use of the increase in alkalinity in the denitrification process, since, by recirculating the water at the entrance to the system, it is possible to compensate for the decrease in pH during nitrification, allowing a balance in the system and becoming a subject of interest for the development of another research.

3.2 DO and Temperature Parameters of Organic Matter

Figure 5 indicates the mean values of the DO concentration for each section of the laboratory scale plant, in the aerobic zones (1, 2, 3). The highest concentration occurred with the treatment of 30 and 40 mg L−1. It was observed that oxygen in the aerobic zone was favorable for nitrification, due to the increase in DO from 0.5 to 2.6 mg L−1 approximately. Likewise, it was found that Sects.4 and 5 gave an anoxic zone due to the drop in DO levels below 1 mg L−1 (Fig. 6). Additionally, a statistically significant correlation (p < 0.05) was obtained with the independent variables corresponding to not only the treatments (20, 30, and 40 mg L−1), the sections of the treatment system (1, 2, 3, 4), and the variable dependent dissolved oxygen evaluated, but also the treatment-section interaction had a relationship on the behavior of the mentioned variables (Fig. 6).

The behavior presented is following what was proposed by the manufacturer (2 to 4 mg L−1) and what was indicated by studies (López et al., 2017) that also used ammonium oxidizing bacteria for the elimination of CoN through nitrification and denitrification via nitrite demonstrating concentrations of 2 mg L−1 of DO favoring the nitrification process. Based on the initial physicochemical characterization, the low values at the beginning of the process possibly indicate a high organic load of the effluent, which led to a higher oxygen consumption for degradation by bioaugmented and autochthonous microorganisms in the wastewater. In the anoxic zone, the decrease in oxygen levels was favorable, since the absence of DO and the presence of oxidized nitrogen (nitrates and nitrites) favor the growth of facultative aerobic denitrifying bacteria, which reduce nitrates and nitrites to molecular nitrogen (Fig. 7) (Adolfo & Castillo, 2016; García, 2011; Gealt & Levin, 1993).

Table 4 shows the COD and BOD5 values, during the different operating stages of the laboratory plant and PeB. Considering the behavior of the pH, DO, and temperature conditions for the concentrations analyzed, it is established that the efficiencies in the removal of organic matter were consistent; 67% for the concentration of 40 mg L−1 and 73% for 30 mg L−1 in the COD; for BOD5 the removal efficiency was 54% for 40 mg L−1 and 55% for 30 mg L−1. The control presented the lowest removal percentage, COD of 17% and BOD5 of 20%, considering that it worked with the native strains of the affluent. This removal efficiency is attributed to the variables pH, DO, and temperature were target conditions throughout the study, to the bioaugmentation and recirculation, to the increase in the concentration of biomass within the reactor that accelerates the degradation process, and to the extended aeration that provides energy to microorganisms, metabolizing the organic substrate into carbon dioxide and water (Adolfo & Castillo, 2016; Peñafiel et al., 2016). Biofilters help the substrate removal performance because this is the biomass support medium, where they adhere, giving rise to new microorganisms and their development; therefore, with increasing the biofilm surface, an increase is achieved in the performance of substrate removal by microbial activity (Adolfo & Castillo, 2016).

The results of the multifactorial ANOVA indicated that the dependent variables BOD5 and COD present a statistically significant relationship (p < 0.05) with the independent variables (20, 30, and 40 mg L−1). These statistical results indicate that recirculation and DO favor the removal of matter because with recirculation, not only the load is diluted, but also adult bacteria are also recovered. One of the limitations of the present study was the short residence times, which did not allow the effluent to mix completely with the DO and the microbial mass through contact with the biofilters. Another important factor is the possible overpopulation of microorganisms in the submerged biofilters, although the aeration injected by the pumps could produce obstructions and at the same time anoxic zones in the laboratory plant, causing detachment of the biomass and loss of effluent quality (Zornoza et al., 2010).

3.3 Nitrification and Denitrification

Regarding nitrification, Table 5 presents the average values of ammonium, where the oxidation of ammonium to nitrites was carried out. For its part, the concentration of 40 mg L−1 reached the highest average input value with 1.0 mg L−1, while the concentration of 20 mg L−1 obtained the lowest value. Regarding the removal percentage, the 40-mg L−1 treatment achieved the highest removal with 98%, and in the control the lowest removal with 37%.

Different values of ammonium can be observed in the inputs, considering that the feeding of the laboratory plant was done on different days (1 day, 3 days, 8 days, and 10 days). The low levels of ammonium can be attributed to the transfer period of the wastewater sample, since the release of this compound occurs before reaching the laboratory, even though the samples were refrigerated during their transfer (Bedoya, 2012).

The transformation of the ammonium load as a function of the ammonium load to nitrites and its subsequent transformation to nitrates was reflected by the data obtained in Table 6, in which the maximum, minimum, and average results were obtained in entry and exit. Evidence in the mean removal values indicates that they remained similar for the 30-mg L−1 and 40-mg L−1 treatments with a percentage of 40 and 46%, respectively. The lowest percentages were presented in the 20-mg L−1 treatment with 16% followed by the control with 7%.

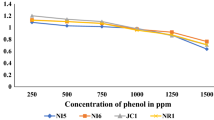

According to the results presented in Table 7, the behavior of nitrate is evidenced in each of the treatments, removal of 92% is observed for 30 mg L−1, 88% for 40 mg L−1, and 7% for 20 mg L−1, while for the PeB that worked with autochthonous bacteria, removal of 6% was obtained. A statistically significant relationship (p < 0.05) was obtained between the dependent variables ammonium, nitrite, and nitrate concerning the independent variables (20, 30, and 40 mg L−1), which indicated that the highest removal was achieved in the 30-mg L−1 treatment compared to the other treatments and blank. These results indicate a relationship between the target operational conditions and the applied treatment.

Ammonium was transformed by the microorganism reduction reactions, presenting a decrease at the end of the treatments, except for PeB where the bacterial consortium was not applied. Also, the nitrates and nitrites that worked as electron acceptors, and that are formed by oxidation, tended to decrease. Regarding nitrites, a removal difference could be observed between the 30- and 40-mg L−1 treatments concerning the 20-mg L−1 treatment and the control. However, the nitrites remained during the bioaugmentation process with low values at the effluent. The DO during the bioaugmentation process remained in a range of 1.0 to 1.5 mg L−1, even though it was worked with extended aeration; However, this nitrogen transformation did not affect the process, because there was the removal of this compound for the three treatments with respect to time. This decrease favored reduction processes, such as denitrification, where nitrate is used as an electron acceptor, causing a decrease in its concentration (Hong et al., 2020).

Table 8 shows the results obtained during the bioaugmentation of the bacterial consortium for the study time in the laboratory plant, which shows the working conditions and the percentage of removal in the COD, BOD5, and nitrogen compounds.

The 30-mg L−1 treatment achieved the operating parameters closest to those required, resulting in removals greater than 80%. Therefore, it was decided to implement a bioaugmentation strategy for a concentration of 30 mg L−1 in the wastewater treatment plant located in the municipality of Puerto Colombia to confirm the results.

3.4 Outdoor System Phase

3.4.1 Operational Conditions in the WWTP During Bioaugmentation

Based on the results obtained in Fig. 7, there were variations in the flow, reflecting as a trend a decrease in this with respect to time, where the maximum that occurred was 120 m3 day−1 and the minimum value that was obtained was 86 m3 day−1. In the same way, there was a decrease in the flow with respect to the outlet, due to pressure losses.

3.4.2 pH and Temperature

The pH values were higher than 7 with a tendency to neutrality, as can be seen in Fig. 8. The maximum value obtained was 7.62 on the third day; later, it decreased to 7.02, this being the minimum pH value. Following what was recommended by the manufacturer of the product (bacterial consortium) and what was cited by other authors in the laboratory scale stage, for this study, the range of values obtained did not present a significant relationship within the system, remaining within the working range, as noted above.

According to the results shown in Fig. 8, it was observed that the average temperature was 30.4 °C, being in the range of 30 to 33 °C. The lowest temperature was 22.5 °C, given on the first day of sampling, followed by an increase until reaching 32.9 °C on the last day of sampling. The results obtained in the present investigation were in accordance with what was stated by the manufacturer (20 to 30 °C) and by other mentioned authors.

3.4.3 Dissolved Oxygen and Biological Removal of Organic Matter

In Fig. 9, it is observed that the supply of O2 flow was given constantly from the inlet to Sect. 3, increasing the DO concentration, in which the maximum was reached in Sect. 2 with a value of 2.38 mg L−1. This process was carried out so that adequate nitrification was carried out. Likewise, for the denitrification process to take place, DO concentrations were decreased to minimum values, below 1 mg L−1. Regarding the nitrification process, the results were kept within the range recommended by the manufacturer (2 to 4 mg L−1), while very low DO values are recommended for denitrification (Cárdenas & Sánchez, 2013), complying with this range in the values obtained in this study.

The results shown in Table 9 indicate the variations of the organic load during the operation of the system, where a COD removal with a value of 76% could be seen, presenting an average value in the influent of 621 mg L−1. Regarding the effluent, an average value of 158.1 mg L−1 was evidenced. Based on the results obtained, it was possible to notice a good removal of this parameter for the imposed conditions. For BOD5, removal of 82% was reached, where average values of 325.8 mg L−1 were presented, while in effluent, there were average values of 57.8 mg L−1 of BOD5. Stability in terms of carbon removal was reflected, proving to be an efficient treatment and capable of adapting to the fluctuations of organic matter of the WWTP effluent (Hiren Trivedi, 1997), achieving the consumption of the organic substrate, metabolizing it into carbon dioxide and water (Bedoya, 2012).

3.4.4 Nitrification and Denitrification

Regarding nitrification, the removal of nitrogen in its ammonium form (NH4+) and its subsequent transformation to nitrites (NO2−) and nitrates (NO3−) were analyzed. In general, a trend towards greater removal of the ammonium load could be highlighted, as a function of the ammonium load (Table 10). In relation to the removal of nitrates, one of these compounds was presented from the maximum value reached of 28 mg L−1 NO3− in the effluent of day 3 to a minimum value of 4.7 mg L−1 NO3− in the effluent of day 9 of operation. According to the results obtained, the best conditions were evaluated for a target removal of this compound.

Once the results were obtained on an outdoor system and compared with the results on a laboratory scale, it could be determined that the removals occurred in the nitrification and denitrification processes with values greater than 50%, even though it was bio-increased for 10 days. Environmental conditions such as pH, temperature, and DO were kept within the ranges established by the manufacturer and by other studies. Likewise, it was shown that it is not necessary to carry out an external pH control for the start-up or during the operation of the system, taking into account the capacity of bacterial self-regulation, and the relationship between alkalinity and ammonium is sufficient to achieve nitrification (Adolfo & Castillo, 2016).

It has been shown that when studies that have been experimentally validated are followed, their practical application to engineering presents difficulties, since many phenomena are not considered, such as the difficulty of reproducing the same conditions on an experimental scale (Adolfo & Castillo, 2016). However, for the dosage of bacteria and residence time, the volume of the reactor and the flow rate were taken into account, so that the dosage of bacteria and residence time complied with the indicated scale and did not affect microbial growth and therefore the treatment efficiency. Another advantage of this type of technology is its low energy cost since the aeration system works temporarily. However, if it fails due to lack of energy, the removal efficiency decreases, but the process is still under development since bioaugmented microorganisms are optional.

Regarding the limitations of this study, the intermediate (metabolite) was not determined, this being critical in the biological treatment of wastewater to identify if the effluent contains toxic substances.

4 Conclusion

From the application of the Ecobacter bacterial consortium and the control sample (treatment without bioaugmentation), it is determined that there is a positive effect on bioaugmentation for the biological removal of nitrogen compounds, under the conditions of the present study, taking into account that the higher removal values were accompanied by optimal operating conditions both on a laboratory scale and on an outdoor system. Under optimal operating conditions, it was identified that the concentration of 30 mg L−1 is optimum for the removal of nitrogenous compounds. It should be noted that bacteria in a biological treatment are sensitive to many parameters, among them the high organic load and nutrients that make the bacteria in the system not sufficient, in the case of the concentration of 20 mg L−1, or little availability of organic load and nutrients that limit the growth of bacteria, in the case of the concentration of 40 mg L−1. Among the advantages of this type of biotechnology (FLAEBI) is the use of the increase in alkalinity for the denitrification process, due to the recirculation of water at the entrance of the system, which manages to compensate for the decrease in pH during nitrification, allowing a balance, becoming a topic of interest for the development of another research. This type of treatment turned out to be an efficient and economical alternative in the elimination of the generation of sludge and zero odors in the treatment of wastewater. The adoption of the bacterial consortium evaluated under the FLAEBI type model is easy to implement for the industrial, commercial, and municipal sectors, contributing to the sustainable development goal number six “Clean water and sanitation,” approved by the United Nations (UN) in 2015 in the 2030 agenda on sustainable development. Testing for the identification of toxic substances in the effluent is recommended in future studies.

Highlights

-

The applied treatment is effective in the removal of nitrogen compounds.

-

A concentration of 30 mg L−1 of the bacterial consortium is optimal for the denitrification process.

-

A removal of 92% of nitrate was obtained on a laboratory plant.

-

A removal of 62% of nitrate was obtained on an outdoor wastewater treatment plant.

Data Availability

The authors declare that all relevant data supporting the findings of this study are included in this article.

References

Achak, M., Mandi, L., & Ouazzani, N. (2009). Removal of organic pollutants and nutrients from olive mill wastewater by a sand filter. Journal of Environmental Management, 90, 2771–2779. https://doi.org/10.1016/j.jenvman.2009.03.012

Adolfo, G.,Castillo, S., (2016). Nutrient removal through biofilm treatments. https://doi.org/10.20868/UPM.thesis.39458.

AFCEE (2008) Technical protocol for enhanced anaerobic bioremediation using permeable mulch biowalls and bioreactors, Technical Directorate, Environmental Science Division. https://www.cluin.org/download/techfocus/prb/Final-Biowall-Protocol-05-08.pdf

AhnH, Y. (2006). Sustainable nitrogen elimination biotechnologies: A review. In Process Biochemistry, 41(8), 1709–1721. https://doi.org/10.1016/j.procbio.2006.03.033

Aragaw, T., (2020). Functions of various bacteria for specific pollutants degradation and their application in wastewater treatment: A review. In International Journal of Environmental Science and Technology. https://doi.org/10.1007/s13762-020-03022-2

Aragaw, T., Asmare, A., (2018). Phycoremediation of textile wastewater using indigenous microalgae. In Water Practice & Technology. 13, Issue 2, pp. 274–284. IWA Publishing. https://doi.org/10.2166/wpt.2018.037.

Atolia, E., Cesar, S., Arjes, H. A., Rajendram, M., Shi., H., Knapp, B. D., Khare, S., Aranda, A., Lenski, R. E., Huang, K.C., (2020). Environmental and physiological factors affecting high-throughput measurements of bacterial growth. Downloaded from. https://doi.org/10.1128/mBio

Baumann, B., Snozzi, M., Zehnder, A. J. B., Roelof, J., (1996). Dynamics of Denitrification activity of Paracoccus denitrificans in continuous culture during aerobic-anaerobic changes. In Journal of Bacteriology Vol. 178, Issue 15. http://jb.asm.org/

Bedoya, C., 2012. study of the nitrification and denitrification process via nitrite for the biological treatment of waste water currents with high ammonia nitrogen load. https://doi.org/10.4995/Thesis/10251/17653

Baird, R., & Bridgewater, L. (2017). Standard methods for the examination of water and wastewater (23rd ed.). American Public Health Association.

Camargo, J. A., Alonso, Á, (2006) Ecological and toxicological effects of inorganic nitrogen pollution in aquatic ecosystems: A global assessment. In Environment International. 32, Issue 6, pp. 831–849. Elsevier Ltd. https://doi.org/10.1016/j.envint.2006.05.002

Cárdenas, G., Sánchez, I., (2013) Nitrogen in wastewater: Origins, effects and removal mechanisms to preserve the environment and public health. 15, Issue 1.

Cervantes, F., Pérez, J., Gómez, J, (2000). Advances in the biological elimination of nitrogen from wastewater. Latin American Journal of Microbiology, 42, 73–82. https://www.medigraphic.com/pdfs/lamicro/mi-2000/mi002e.pdf

Cockburn, A., Heppner, W., Dorne, M., (2014). Environmental contaminants: Nitrate and nitrite. In Encyclopedia of Food Safety 2, pp. 332–336. Elsevier. https://doi.org/10.1016/B978-0-12-378612-8.00199-2

De Laia, G., Tosta dos Reis, J., Ferrei, A., and Silva, F., (2019). Methodology for minimum nitrogen compounds removal efficiencies estimation and wastewater treatment systems pre-selection: A watershed approach. Brazilian Journal of Water Resources.https://doi.org/10.1590/2318-0331.241920180173

Dennis, M. J., Wilson, L. A. 2003. Nitrates and nitrites. In Encyclopedia of food sciences and nutrition pp. 4136–4141. Elsevier. https://doi.org/10.1016/b0-12-227055-x/00830-0

Ekama, G. A. (2011). Biological nutrient removal. Treatise on Water Science, 4(August), 409–526. https://doi.org/10.1016/B978-0-444-53199-5.00094-4

Eliašová, A., Hrivnák, R., Štefánová, P., Svitok, M., Kochjarová, J., Oťaheľová, H., Novikmec, M., & Palove, P. (2021). Effects of ammonium levels on growth and accumulation of antioxidative flavones of the submerged macrophyte Ceratophyllum demersum. Aquatic Botany, 10, 33–76. https://doi.org/10.1016/j.aquabot.2021.103376

EPA. (2000). Wastewater technology fact sheet package plants. Packing plants. Washington DC: URL for the United States Environmental Protection Agency (EPA). https://www.epa.gov/npdes/pubs/package_plant.pdf

Fan, A. M. (2014). Nitrate. Encyclopedia of Toxicology. Elsevier., 3, 523–527. https://doi.org/10.1016/B978-0-12-386454-3.01067-8

Fan, A.M., (2019). Health, exposure and regulatory implications of nitrate and nitrite in drinking water. Encyclopedia of Environmental Health. Elsevier. 417-435. https://doi.org/10.1016/B978-0-12-409548-9.11837-8

García, S.C., (2011). Bacterias simbióticas fijadoras de nitrógeno. In CT. 3, 173–186. https://dialnet.unirioja.es/servle.t/articulo?codigo=3761553.

Garrido, J., Paredes, R., Alonso, B., (2019. Elimination of nitrogenous compounds in wastewater by nitrification and denitrification. https://hdl.handle.net/11673/48774.

Gealt, M.A., Levin, M.A., (1993). Biotreatment of industrial and hazardous waste. McGraw-Hill. //catalog.hathitrust.org/Record/002710706.

Herrero, M., & Stuckey, D. C. (2015). Bioaugmentation and its application in wastewater treatment: A review. Chemosphere, 140, 119–128. https://doi.org/10.1016/j.chemosphere.2014.10.033

Hiren, P.K., (1997). Ammonia reduction through bioaugmentation. http://www.labamerex.com/images/1997-Proteccion-ambiental-Triverdi-MSChE.pdf.

Hong, P., Wu, X., Shu, Y., Wang, C., Tian, C., Wu, H., Xiao, B., 2020.Bioaugmentation treatment of nitrogen-rich wastewater with a denitrifier with biofilm-formation and nitrogen-removal capacities in a sequencing batch biofilm reactor. Bioresource Technology. 303https://doi.org/10.1016/j.biortech.2020.122905

IDEAM. (2017). Ideam water monitoring protocol (N. Vargas, T. Tetaty, and A. Vesga, Eds.). http://documentacion.ideam.gov.co/openbiblio/bvirtual/023773/PROTOCOLO_MONITOREO_AGUA_IDEAM.pdf

IDEAM (2019). National water study 2018. Bogotá: Ideam: 452 pp. http://www.andi.com.co/Uploads/ENA_2018-comprimido.pdf

Igiri BE et al (2018) Toxicity and bioremediation of heavy metals contaminated ecosystem from tannery wastewater: A review. Journal of Toxicology.https://doi.org/10.1155/2018/2568038

Ipuz, A., and Reyes, M., (2015). Design, construction and start-up of an anaerobic piston flow reactor (RAP) with Guadua as a support medium, for the treatment of domestic wastewater from a workers' camp of a fish farm. https://ciencia.lasalle.edu.co/ing_ambiental_sanitaria.

Jaibiba, P., Naga, S., Hariharan, S., (2020). Working principle of typical bioreactors. Bioreactors. 145-173https://doi.org/10.1016/b978-0-12-821264-6.00010-3

Jia, L., Jiang, B., Huang, F., and Hu, X. (2019). Nitrogen removal mechanism and microbial community changes of bioaugmentation subsurface wastewater infiltration system. Bioresource Technology, 294https://doi.org/10.1016/j.biortech.2019.122140

John, E.M., Krishnapriya, K., Sankar, T.V., 2020.Treatment of ammonia and nitrite in aquaculture wastewater by an assembled bacterial consortium. Aquaculture. 526https://doi.org/10.1016/j.aquaculture.2020.735390

Kallistova, A. Y., Dorofeev, A. G., Nikolaev, Y. A., Kozlov, M. N., Kevbrina, M. V., & Pimenov, N. V. (2016). Role of anammox bacteria in removal of nitrogen compounds from wastewater. Microbiology Russian Federation., 85, 140–156. https://doi.org/10.1134/S0026261716020089

Lee, S. I., Weon, S. Y., Lee, C. W., & Koopman, B. (2003). Removal of nitrogen and phosphate from wastewater by addition of bittern. Chemosphere, 51, 265–271. https://doi.org/10.1016/S0045-6535(02)00807-X

Li, W., Cai, Z., Duo, Z. J., Lu, Y. F., Gao, K. X., Abbas, G., Zhang, M., & Zheng, P. (2017). Heterotrophic ammonia and nitrate bio-removal over nitrite (Hanbon): Performance and microflora. Chemosphere, 182, 532–538. https://doi.org/10.1016/j.chemosphere.2017.05.068

Liu, S., (2017). Ideal flow reactors. Bioprocess Engineering. 179-257.https://doi.org/10.1016/b978-0-444-63783-3.00005-8

López, C., Buitrón, G., García, H., Cervantes, F., 2017. Biological wastewater treatment: Principles, modeling and design. Cambridge University Press. https://doi.org/10.2166/9781780409146

Lucena, J., Schneider, J., & Leydens, J. A. (2010). Engineering and sustainable community development. Synthesis Lectures on Engineers, Technology, and Society, 11, 1–230. https://doi.org/10.2200/S00247ED1V01Y201001ETS011

Mažeikienė, A., Grubliauskas, R., (2021). Biotechnological wastewater treatment in small-scale wastewater treatment plants. Journal of Cleaner Production. 279.https://doi.org/10.1016/j.jclepro.2020.123750

Metcalf, E., Asano, T., Burton, F., Leverenz, H., 2007. Water reuse: Issues, technologies, and applications. McGraw-Hill Education. https://www.accessengineeringlibrary.com/content/book/9780071459273.

Mytilinaios, I., Bernigaud, I., Belot, V., & Lambert, R. J. (2015). Microbial growth parameters obtained from the analysis of time to detection data using a novel rearrangement of the Baranyi-Roberts model. Journal of Applied Microbiology., 118, 161–174. https://doi.org/10.1111/jam.12695

Niño, E.D., Martínez, N.C., (2013). Study of domestic gray water in three socioeconomic levels of the city of Bogotá. Pontifical Javeriana University. http://hdl.handle.net/10554/11139 .

Nzila, A., Razzak, S.A., Zhu, J., 2016. Bioaugmentation: An emerging strategy of industrial wastewater treatment for reuse and discharge. International Journal of Environmental Research and Public Health. 13.https://doi.org/10.3390/ijerph13090846

Okoduwa, S. I. R., et al. (2017). Tannery effluent treatment by yeast species isolates from watermelon. Toxics, 5, 6. https://doi.org/10.3390/toxics5010006

Orellana, R., et al. (2018). Living at the frontiers of life: Extremophiles in Chile and their potential for bioremediation. Frontiers in Microbiology, 9, 2309. https://doi.org/10.3389/fmicb.2018.02309

Pal, P., (2017).Biological treatment technology. Industrial Water Treatment Process Technology. 65-144.https://doi.org/10.1016/b978-0-12-810391-3.00003-5

Peñafiel, R. D., Moreno, C., Ochoa-Herrera, V. D. L. (2016). Eliminación de nitrógeno y contaminación orgánica de agua residual industrial pretratada en lagunas anaeróbicas mediante un biofiltro de arena. Avances En Ciencias e Ingeniería, -8–14. https://doi.org/10.18272/aci.v8i1.299

Pérez-Uz, B., Arregui, L., Calvo, P., Salvadó, H., Fernández, N., Rodríguez, E., Zornoza, A., & Serrano, S. (2010). Assessment of plausible bioindicators for plant performance in advanced wastewater treatment systems. Water Research, 17, 5059–5069. https://doi.org/10.1016/j.watres.2010.07.024

Pillai, N. N., Wheeler, W. C., and Prince, R. P. (1971). Design and operation of an extended aeration plant. Journal (Water Pollution Control Federation), 7, 1484–1498. http://www.jstor.org/stable/25037127

Ramakrishnan VV, G. A. 2015. Nitrogen sources and cycling in the ecosystem and its role in air, water and soil pollution: A critical review. Journal of Pollution Effects and Control, 02 https://doi.org/10.4172/2375-4397.1000136

Ramos, A. F., Gómez, M. A., Hontoria, E., & González-López, J. (2007). Biological nitrogen and phenol removal from saline industrial wastewater by submerged fixed-film reactor. Journal of Hazardous Materials, 142(1–2), 175–183. https://doi.org/10.1016/j.jhazmat.2006.08.079

Raper, E., Stephenson, T., Anderson, D. R., Fisher, R., Soares, A. (2018). Industrial wastewater treatment through bioaugmentation. In Process Safety and Environmental Protection (Vol. 118, pp. 178–187. Institution of Chemical Engineers. https://doi.org/10.1016/j.psep.2018.06.035

Rathna, R., Nakkeeran, E., (2020). The intertwined facets of membrane technology for industrial effluents. In Biovalorisation of Wastes to Renewable Chemicals and Biofuels pp. 133–147. Elsevier. https://doi.org/10.1016/b978-0-12-817951-2.00007-9

Ruscalleda, M., Balaguer, M.D., Colprim, J., Pellicer-Nàcher, C., Smets, S. P., (2011). Biological nitrogen removal from domestic wastewater. In Comprehensive biotechnology, second edition (Vol. 6, pp. 329–340. Elsevier Inc. https://doi.org/10.1016/B978-0-08-088504-9.00533-X

Samer M (2015) Biological and chemical wastewater treatment processes. In: Wastewater treatment engineering, InTech, pp 1–50.

Sepehri, A., Sarrafzadeh, M. H., Avateffazeli, M. (2020). Interaction between Chlorella vulgaris and nitrifying-enriched activated sludge in the treatment of wastewater with low C/N ratio. Journal of Cleaner Production, 247. https://doi.org/10.1016/j.jclepro.2019.119164

Shapleigh, J. P. (2013). Denitrifying prokaryotes. In E. Rosenberg, E. F. DeLong, S. Lory, E. Stackebrandt, and F. Thompson (Eds.), The prokaryotes: Prokaryotic physiology and biochemistry pp. 405–425. Springer Berlin Heidelberg. https://doi.org/10.1007/978-3-642-30141-4_71

Sotres, A., Cerrillo, M., Viñas, M., & Bonmatí, A. (2016). Nitrogen removal in a two-chambered microbial fuel cell: Establishment of a nitrifying-denitrifying microbial community on an intermittent aerated cathode. Chemical Engineering Journal, 284, 905–916. https://doi.org/10.1016/j.cej.2015.08.100

Suárez Oquedo Victor. (2019). Analysis of alternatives for the elimination of nutrients in the WWTP “La Poveda” (Rivas-VaciaMadrid, Madrid). Retrieved from https://pdfs.semanticscholar.org/def5/7d1f16f271995bfb5fdc085165b76d5a3677.pdf

Venegas, C. (2015). Biological removal of nutrients in high nitrogen ammoniacal wastewater using a biological sequencing reactor. Retrieved from URL: http://hdl.handle.net/10902/8451

Yang, N., Liu, H., Zhan, G. qiang, Li, D. ping. (2020). Sustainable ammonia-contaminated wastewater treatment in heterotrophic nitrifying/denitrifying microbial fuel cell. Journal of Cleaner Production, 245.https://doi.org/10.1016/j.jclepro.2019.118923

Zornoza, A., Avendaño, L., Aguado, D., Borrás, L., & Alonso, J. L. (2012). Analysis of the correlations between the abundance of nitrifying bacteria, operational and physicochemical parameters related to the biological process of nitrification in activated sludge.

Zornoza, A., Alonso-Molina, J. L., Serrano, S. (2010). New metagenomics and molecular based tools for European scale identification and control of emergent microbial contaminants in irrigation water. View project. https://www.researchgate.net/publication/234154599

Zou, S., Guan, L., Taylor, D. P., Kuhn, D., & He, Z. (2018). Nitrogen removal from water of recirculating aquaculture system by a microbial fuel cell. Aquaculture, 497, 74–81. https://doi.org/10.1016/j.aquaculture.2018.07.036

Funding

Open Access funding provided by Colombia Consortium

Author information

Authors and Affiliations

Contributions

Nubia Marquez: conceptualization, methodology. Wendy Morgado: data curation, visualization, investigation. Henry Maury: supervision. Andres Pulgar: writing — original draft preparation, validation. Claudete Gindri Ramos: writing — reviewing and editing. Alexander Parody: writing — reviewing and editing.

Corresponding author

Ethics declarations

Ethics Approval and Consent to Participate

This work did not report on or involved the use of any animal or human data or tissue.

Consent for Publication

This work did not contain data from any individual person.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Fontalvo, N.P.M., Gamero, W.B.M., Ardila, H.A.M. et al. Removal of Nitrogenous Compounds from Municipal Wastewater Using a Bacterial Consortium: an Opportunity for More Sustainable Water Treatments. Water Air Soil Pollut 233, 339 (2022). https://doi.org/10.1007/s11270-022-05754-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11270-022-05754-y