Abstract

Open channels are one of the most used water conveyance systems for delivering water for different purposes. Existing models for the design of open channels mainly assume uniform flow, focus on cross-section sizing, and generally decouple cross-section sizing from the selection of channel alignment and profile. In this study, we developed an optimization model for a comprehensive design of transmission channels. The model minimizes the sum of costs for earthwork, lining, water losses, and land acquisition; accounts for non-uniform, mixed-regime flow; and considers multiple geometric and hydraulic constraints. The model was validated using several idealized scenarios. The model potential in minimizing the cost of real open channel projects was demonstrated through application to an existing irrigation water transmission canal in Egypt (the Sheikh Zayed Canal). The results of validation scenarios matched the anticipated outcomes for channel profile and alignment and reproduced analytical solutions given in the literature for channel cross-section design. Application of the model to the Sheikh Zayed Canal gave a more optimal design; the OCCD model produced a design alternative with ~27% less cost than the constructed alternative.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

While artificial open channels have existed for several millennia (Swamee and Chahar 2013), they are still the most widely used water conveyance systems (Aksoy and Altan-Sakarya 2006). Open channels may extend over a few kilometers to several hundreds of kilometers (e.g., Indira Gandhi Canal and Central Arizona Aqueduct). As open channel construction cost constitutes a major part of the cost of flood protection and water supply projects, optimization of open channel design is important for cost reduction and for achieving project economic feasibility, particularly for long-distance, large-capacity open channels. Furthermore, optimizing the design of open channels may aid in saving water lost by evaporation and seepage, which is particularly important for water supply projects in regions suffering from water scarcity (El Baradei and Al Sadeq 2019).

The traditional design of open channels is a multi-stage process, which starts by selecting the channel alignment, then the channel profile, and finally the channel cross-section dimensions. For transmission channels with no intermediate water supply or abstraction, the selection of the channel alignment mainly aims to achieve the shortest path between the water source and destination locations provided that topography along the shortest path is favorable and no obstructions exist. The selection of channel profile primarily depends on the topography; channel bed slopes are usually selected to match ground slope with mild slopes used in flat regions. Although flow in open channels is generally non-uniform, channel cross-section is typically designed based on flow resistance equations applied under uniform flow conditions (Swamee et al. 2000a; Akan 2006; Chahar et al. 2007; Monadi et al. 2019).

Extensive research has been done on optimizing the channel cross-section, particularly for channels with rigid boundary (i.e., lined channels). As erosion control is not a major concern in these channels, the primary design goal was typically to reduce the cross-section area and/or perimeter (Swamee et al. 2000b). King et al. (1949) and Chow (1959) derived the dimensions for the so-called best hydraulic section (BHS) which gives both minimum area and perimeter. The derivation was performed for different cross-section shapes and neglected freeboard. Monadjemi (1994) proposed a more general approach for deriving BHS dimensions using Lagrange’s Method of Undetermined Multipliers. Froehlich (1994) accounted for depth and top-width constraints while determining BHS dimensions for trapezoidal canals. By considering freeboard, Guo and Hughes (1984) showed that the section with minimum total area differed from the section with the minimum total perimeter. Given this difference, subsequent studies aimed to optimize the cross-section by explicitly minimizing the total area and/or perimeter (i.e., lining and/or excavation costs) (Das 2000; Swamee et al. 2000c; Jain et al. 2004; Bhattacharjya 2005).

Trout (1982) ignored the excavation cost and focused on minimizing the lining cost with different unit prices for channel bed and sides. Das (2000) included the excavation cost with the lining cost while accounting for differences in unit price and roughness. Jain et al. (2004) considered both lining and excavation costs and added a maximum permissible velocity constraint. Bhattacharjya (2005) added the freeboard as a design variable to accommodate the depth fluctuation corresponding to a specified change in specific energy. Neglecting the differences in the lining material, Han et al. (2019) added the land acquisition cost to the lining and excavation costs and derived a general equation for the most economic section.

Discarding freeboard and based on the resistance equation formulated by Swamee (1994) and Swamee et al. (2000c) considered a depth-dependent excavation cost with the lining cost, which made the optimal cross-section tend to be wider and shallower. Further improvement in cross-section optimization was attained by Swamee et al. (2000b) who combined the costs of water losses due to seepage and evaporation with lining and depth-dependent excavation costs. Later, Chahar (2006) proposed channel division into segments with different cross-sections to account for the decrease in discharge due to water losses along the channel.

More recent studies examined the applicability of various deterministic and heuristic optimization techniques in optimizing the channel cross-section. Adarsh and Sahana (2013) used the Probabilistic Global Search Lausanne algorithm, Tabari et al. (2014), Tabari and Mari (2016) used the Direct Search algorithm, Niazkar and Afzali (2015) used the Honey Bee Mating Optimization algorithm, and El-Ghandour et al. (2020) used the Particle Swarm Optimization (PSO) algorithm. More recently, Farzin and Anaraki (2020) applied a hybrid PSO-bat algorithm, Roushangar et al. (2021) applied the Grey Wolf Optimization algorithm, and Pourbakhshian and Pouraminian (2021) applied the Simultaneous Perturbation Stochastic Approximation algorithm. Furthermore, Niazkar (2020) showed that artificial intelligence can be used to optimize the lined channels by comparing the results to explicit equations given by Swamee et al. (2000c), Aksoy and Altan-Sakarya (2006), and Niazkar and Afzali (2015).

Despite the considerable attention paid to the optimization of channel cross-section, few studies addressed the optimization of open channel alignment. Swamee and Chahar (2013) proposed the concept of balancing the cutting depth by equating the volume of excavation and embankment along individual segments of trapezoidal channels. Basu and Chahar (2013) applied the previous concept on channels with parabolic sections and introduced the concept of balancing the cutting depth along a certain length of the channel alignment. Swamee and Chahar (2015) reapplied the latter concept to channels with trapezoidal sections to allow for feasible haulage length.

Most of the studies indicated earlier addressed the optimal channel cross-section as a separate problem from that of determining the optimal channel alignment and profile. Similarly, the few studies that examined optimal channel alignment decoupled it from the optimal cross-section design. Hence, these studies did not necessarily guarantee the optimal overall channel design. Furthermore, no automated optimization framework was developed in the studies that focused on alignment optimization; a manual trial approach was adopted.

To overcome the above limitations, this study proposes an innovative comprehensive model that combines the currently separate open channel design stages and applies an automated optimization algorithm for simultaneous design of channel alignment, profile, and cross-section. To achieve more optimal design than the traditional models, the model developed in this study allows for variation in profile and cross-section along channel reaches while accounting for the non-uniform flow and possibly mixed-flow regime resulting from these changes. To handle the extensive parameter space due to the large number of design parameters, the developed model employs an optimization algorithm based on the widely used genetic algorithm which is capable of efficiently searching large domains for the optimal feasible solutions (Sarker et al. 2003).

In summary, the main objective of this paper is to develop an automated optimization model for the design of transmission open channels. The developed model, referred to as the Optimal Comprehensive Channel Design (OCCD) model, minimizes selected or combined cost components including the cost of earthwork, lining, land acquisition, and water losses. In addition, the OCCD model accounts for several geometric and hydraulic constraints including restricted zones, flow depth, flow velocity, and cross-section width constraints. The results of the OCCD model were validated using several idealized scenarios and the model performance was assessed through application to an irrigation water transmission channel in Egypt, the Sheikh Zayed Canal (SZC).

This paper is structured as follows. The next section presents the OCCD model formulation and modules. The following section describes the model validation scenarios and the SZC case study. Afterwards, the results of model application to the validation scenarios and the SZC case study are presented. Finally, the model capabilities, performance, limitations, and possible future improvements are summarized.

2 Model Formulation

2.1 Modeling Framework

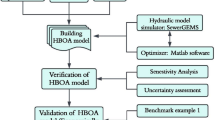

The OCCD model consists of three main modules which include the Optimization Controller (OC) module, the Hydraulic Simulation (HS) module, and the Quantity and Cost (QC) module (Fig. 1). The OC module generates an initial set of channel design alternatives. For each alternative, the HS module simulates the flow depth and velocity along the entire channel. The QC module then estimates the needed freeboard; bank level; excavation, fill and lining quantities; land acquisition extent; and water losses. The total cost for each alternative is subsequently calculated by the QC module and sent back to the OC module. With the total cost of all design alternatives, optimization operators are applied to the population to produce the next generation with more optimal design alternatives. The model proceeds with repeating this cycle until stopping criteria are satisfied and the optimal design alternative is identified.

2.2 Design Variables

The OCCD model divides the channel to be designed into multiple straight reaches with trapezoidal cross-sections. Bed width, side slope, and longitudinal slope are kept constant along each reach but can vary between reaches. Transitions in cross-section dimensions, slope, horizontal alignment, and bed level occur at the intermediate junctions connecting the reaches. The length of the transitions between reaches is neglected compared to reach lengths. However, the energy loss and the change in water surface elevation at the transitions are accounted for in the OCCD model.

For each reach \(i=1, 2,...,{n}_{r}\), the design variables are the reach bed width \(\left({b}_{i}\right)\), side slope \(\left({t}_{i}\right)\), and upstream bed elevation \(\left({Z}_{i}\right)\). For each intermediate junction \(j=1, 2,...,{n}_{r}-1\), the design variables are the junction coordinates \(\left({X}_{j},{Y}_{j}\right)\) and the bed drop or rise \({d}_{j}\) at the junction (where \({d}_{j}>0\) represents a drop). The last design variable is the downstream bed elevation of the last reach \(\left({Z}_{e}\right)\); i.e., bed elevation at the destination point. For the reaches other than the last reach, the downstream bed elevation of a reach \(i\) is calculated by adding the bed drop/rise at the intermediate junction \({d}_{j=i}\) to the upstream bed elevation of the subsequent reach \({Z}_{i+1}\). The full set of design variables and their count are summarized in Table 1.

Increasing the number of reaches \({n}_{r}\) gives the OCCD model the flexibility to form more complex channel alignment (Fig. 2). Also, using more reaches allows the model to select the channel profile and cross-sections that better adapt to the topography. However, using more reaches increases the complexity of the optimization process; the total number of design variables \({n}_{v}\) increases linearly with the number of reaches according to Eq. (1).

Illustration of the possibility of forming more complex channel alignments by using a higher number of reaches. The black line shows a channel alignment with two reaches \(\left({n}_{r}=2\right)\). The blue line shows a more sinuous channel with four reaches \(\left({n}_{r}=4\right)\). The red marker indicates the starting point of the channel (i.e., the source). The blue marker indicates the channel end point (i.e., the destination). Color shading represents ground elevation with red and green colors corresponding to higher and lower elevations, respectively

In general, the value of \({n}_{r}\) should be selected using an iterative approach starting with a small value (e.g., \({n}_{r}=4\)), applying the OCCD model, and increasing \({n}_{r}\) incrementally until no further significant difference in the total cost is observed. This scheme will be demonstrated later through model application to a validation scenario in Sect. 4.1.

2.3 Optimization Controller Module

2.3.1 Objective Function and Constraints

The OCCD model applies an optimization scheme to minimize the overall cost of the open channel that is being designed. The objective function of the optimization scheme can be represented mathematically as:

where \({C}_{tot}\) is the total channel cost, \({C}_{E}\) is the earthwork cost including excavation cost \({C}_{x}\) and fill cost \({C}_{f}\), \({C}_{L}\) is the lining cost, \({C}_{W}\) is the cost incurred by water loss from the channel, and \({C}_{A}\) is the land acquisition cost. In Eq. (2), \({f}_{k}\) with \(k=1\) to 4 is a binary factor that can be set to 0 to exclude specific cost items.

To determine the optimal values of the design variables, the OCCD model applies the objective function given by Eq. (2) subject to the following geometric and hydraulic constraints that ensure the feasibility of the results,

where \(V\) is flow velocity along the channel, \({V}_{max}\) is the maximum permissible velocity, \(y\) is flow depth along the channel, \({y}_{max}\) is maximum allowable depth, \({F}_{r}\) is the Froude number along the channel, \(\Delta {F}_{rc}\) is the minimum allowable departure from critical flow (e.g., 0.2), \({\gamma }_{e}\ge 1\) is the maximum expansion ratio, and \({\gamma }_{c}\le 1\) is the minimum contraction ratio for bed width. The bounds in Eqs. (3) and (4) limit the flow velocity and depth to user-specified thresholds. The constraint in Eq. (5) prevents undesirable near-critical flow regime (Akan 2006). The constraints in Eqs. (6) and (7) prevent adverse slopes while the constraint in Eq. (8) enforces an upper limit on the ratio of bed widths for successive reaches to avoid excessive expansions and contractions in cross-sections. Additional constraints are also imposed to prevent undesirable channel geometries that may be generated during the application of the optimization scheme; e.g., self-intersecting alignments and passage through restricted zones.

The OCCD model implements the above constraints at different stages. During generation of design alternatives, the OCCD model produces only feasible alternatives that satisfy the longitudinal slope and bed width constraints. Within the optimization process, the OCCD model eliminates the design alternatives that violate near-critical flow, self-intersection, and restricted zone constraints. During calculation of the objective function, the model applies a cost penalty to the design alternatives violating the maximum flow depth and/or velocity constraints.

Besides the above constraints, the OCCD model enforces lower and upper bounds for all design variables. Furthermore, for efficiency, the optimization scheme uses integer instead of real-valued variables. For the case study of the Sheikh Zayed Canal which will be discussed later, a unit step was mapped to a discrete change of 10 m for junction coordinates, 0.25 m for bed width, 0.1 for side slope, and 0.1 m for bed drop/rise at junctions.

2.3.2 Optimization Scheme

The genetic algorithm (GA) was selected as the optimization scheme for the OCCD model due to its ability to solve complicated non-linear problems and its extensive use in water transport systems optimization (Simpson et al. 1994; Jain et al. 2004; Bhattacharjya 2005; Kentli and Mercan 2014; Tofiq and Guven 2015). As an evolutionary algorithm, the main advantage of the GA is that it does not require objective function derivatives and can handle the optimization of non-smooth objective functions (Haupt and Haupt 2003; Kramer 2017).

The OCCD model utilizes the Matlab Global Optimization Toolbox (Mathworks 2014). The GA implementation in the OCCD model starts by semi-randomly generating multiple sets of design variables (i.e., a population of design alternatives) satisfying specified bounds and constraints. The GA subsequently calls the Hydraulic Simulation (HS) and Quantity and Cost (QC) modules to calculate the fitness value of each individual design alternative then sends this value back to the GA to produce a new generation. The GA applies selection, crossover, and mutation operators to produce the next generation of design alternatives. The selection operator draws the most fit individuals (i.e., parents) from the current population and directly passes a limited number representing the most elite individuals to the next generation. The remaining parents are paired and combined by the crossover operator to generate new individuals. To increase the diversity and avoid quickly getting trapped in local minima, the mutation operator then randomly alters some of the parents’ genes. The process is repeated and new generations are produced until the average relative change in the fitness values remains below a set threshold for a specified number of generations (known as stalled generations).

As indicated earlier, the GA semi-randomly generates the initial population. While reach bed width and side slope are randomly generated (subject to the previously mentioned bounds and constraints), a deterministic scheme is used to define coordinates and elevations of junctions between reaches for the design alternatives of the initial population. This scheme uniformly locates junction coordinates along paths given by polynomial functions that cover a large swath surrounding the channel end points. Bed elevations at junctions are then determined based on the average slope between the channel end points. This deterministic definition of junctions avoids the generation of infeasible self-intersecting alignments and ensures that the entire search domain is properly sampled. For subsequent generations, self-intersecting alignments may be formed by the GA cross-over and mutation operators. A sub-module of the OCCD model identifies the self-intersections and eliminates the corresponding alternatives. Similarly, alternatives passing through restricted zones as well as alternatives with near-critical slopes are identified and eliminated before the application of the Hydraulic Simulation module which is described next.

2.4 Hydraulic Simulation Module

For each feasible design alternative, the Hydraulic Simulation (HS) module determines the water surface elevation along the channel based on steady, one-dimensional, gradually varied flow analysis given by Eq. (9) (King et al. 1949),

where \(\frac{dy}{dx}\) is the rate of change of water depth \(y\) with distance \(x\) along the channel reach, \({S}_{o}\) is the reach bed slope, and \({S}_{f}\) is the friction slope.

The OCCD model applies a finite difference scheme to solve Eq. (9). Discretization of each reach of length \(L\) is based on a geometric series scheme that produces variable computational intervals \(\Delta l\) ranging between specified minimum \(\left(\Delta {l}_{min}\right)\) and maximum \(\left(\Delta {l}_{max}\right)\) values. This discretization scheme provides better accuracy for possible near-critical flow at the start and end of the channel reaches without significant increases in the computational time needed for applying small uniform intervals along the entire reach.

The HS module performs mixed flow regime analysis. First, a sub-critical flow is simulated starting with the normal depth as a boundary condition at the downstream end of the channel. The solution proceeds in the upstream direction. Energy conservation is applied at transitions between reaches to estimate the flow depth at the downstream ends of upstream reaches. Energy losses due to expansion/contraction at reach transitions are estimated using (HEC 2016),

where \({V}_{1}\) and \({V}_{2}\) are the flow velocities upstream and downstream of the transition, respectively, and \({K}_{l}\) is the head loss coefficient which is set to 0.1 for contraction \(\left({V}_{2}>{V}_{1}\right)\) and 0.3 for expansion \(\left({V}_{2}<{V}_{1}\right)\).

During the sub-critical flow simulation, computational nodes with near-critical depth are flagged for further analysis. After the sub-critical simulation concludes, a super-critical flow simulation starts from the first upstream node that was flagged during the sub-critical simulation and continues in the downstream direction. The super-critical simulation is interrupted when a valid sub-critical flow depth with higher specific force is found, and a hydraulic jump (with a negligible length) is assumed to occur between the super-critical and sub-critical depths. The super-critical flow simulation resumes at the next flagged nodes if any.

The HS module was implemented in Matlab for efficient integration with the Optimization Controller module. Hydraulic simulation results were validated for different flow conditions through comparison to results from HEC-RAS simulations (an example is illustrated in Fig. 3).

Comparison of along-channel water surface elevation simulated with the OCCD HS module and HEC-RAS for a channel with (a) a mild-sloped reach connected to a reach with milder slope, (b) a steep reach connected to a mild-sloped reach, (c) a mild-sloped reach ending with a critical slope and (d) a mild-sloped reach ending with a contraction and milder slope

2.5 Quantity and Cost Module

Based on the hydraulic simulation results along with the alignment, profile, and cross-section for each reach, the Quantity and Cost (QC) module computes the water surface elevation with respect to the ground level. For a specified freeboard \(\left({F}_{b}\right)\), the QC module then calculates the earthwork (i.e., excavation and fill), lining, and land acquisition quantities. Each of these quantities is calculated at uniformly-spaced sampling nodes after interpolating the HS module results obtained at the computational nodes. The quantities are then summed over the reaches and multiplied by the unit price of each cost item to give total costs as follows,

where \(\Delta x\) is the interval between the sampling nodes, \(i=1, 2\dots {n}_{r}\) is the reach index, \(k=1, 2,\dots {m}_{i}\) is the sampling node index; \({U}_{X}\) is the unit cost of excavation at ground level; \({U}_{D}\) is the excavation cost increment per unit depth; \({U}_{F}\), \({U}_{L}\), \({U}_{A}\), and \({U}_{W}\) are the unit costs for fill, lining, land acquisition, and water losses, respectively; \({A}_{x}\) and \({A}_{f}\) are the excavation and fill areas, respectively; \(\ell\) is lining length within channel cross-section; \({q}_{s}\) and \({q}_{v}\) are the amounts of water lost due to seepage and evaporation per unit length of the channel, respectively; \(\overline{Y }\) is the depth from the ground surface to the centroid of the excavated area; \(T\) is the total channel width including banks; and \(N\) is the useful lifetime of the channel.

3 Model Validation and Application

3.1 Validation Scenarios

Seven validation scenarios VS 1 to VS 7 were conducted to confirm the ability of the OCCD model to identify optimal channel design parameters (Table 2). In scenario VS 1, the objective was to optimize the cross-section to achieve the minimum lining cost subject to a maximum flow depth constraint as presented by Froehlich (1994). In the second validation scenario VS 2, the objective was to optimize the cross-section considering lining and depth-dependent excavation costs. Results were compared to the regression equations obtained by Niazkar and Afzali (2015) using the Honey Bee Mating Optimization algorithm. For the next scenario VS 3, the cross-section was optimized to minimize lining, excavation, and land acquisition costs considering freeboard. The results were compared to the analytical solution derived by Han et al. (2019) for different values of side slope.

Validation scenario VS 4 aimed to identify the channel alignment and profile that minimize the excavation cost as well as to examine the effect of changing the number of reaches \({n}_{r}\) on model results. For the latter purpose, three reaches were used in VS 4.1 and eight reaches were used in VS 4.2. In scenario VS 5, the objective was to determine the channel alignment that minimizes lining and land acquisition costs. To achieve this objective, scenario VS 5 used a region with a binary low/high land cost (Fig. 4a). Two cases were considered with different high-to-low land cost ratios (VS 5.1 and VS 5.2).

Similar to VS 5, scenario VS 6 had the same objective but with the addition of restricted zones (Fig. 4b). Scenario VS 6 also examined the effect of the number of reaches \({n}_{r}\) on the identified optimal channel alignment and the corresponding cost. The model was run repeatedly for VS 6 while increasing the number of reaches incrementally from 6 to 15. Finally, the objective of scenario VS 7 was to optimize all the design parameters to achieve the minimum lining and earthwork costs subject to a maximum velocity constraint \({V}_{max}\) (Table 2). Three cases were considered VS 7.1, VS 7.2, and VS 7.3 with no constraint on flow velocity, with \({V}_{max}=\) 3 m/s, and with \({V}_{max}=\) 2 m/s, respectively.

The hypothetical terrain in scenarios VS 2 and VS 3 represented a straight valley with a uniform longitudinal slope of 10 cm/km with valley sides rising to the edge of the search domain with a slope of 5 m/km (Fig. 5a). The terrain in scenario VS 4 consisted of a winding valley with variable longitudinal slopes ranging from 1 cm/km to 9 cm/km (Fig. 5b). The topography in VS 7 was a relatively steep terrain with a uniform, unidirectional slope of 1.3 m/km (Fig. 5c). For scenarios VS 1, VS 5, and VS 6, the topography does not influence the results as the earthwork cost was excluded from these scenarios.

Topography for validation scenarios (a) VS 2 and VS 3, (b) VS 4, and (c) VS 7. Green shading indicates higher ground while brown shading indicates lower ground. Solid lines represent elevation contours with 0.25 m intervals. The red triangle denotes the source and the blue dot denotes the destination

Validation scenarios VS 4 to VS 7 were conducted using a Manning roughness coefficient \(n=0.013\) and a volumetric flow rate \(Q=80\) m3/s. The OCCD model results for scenarios VS 1, VS 2, and VS 3 were summarized using the parameters \(\lambda\), \(\alpha\), \(\beta\), \({U}_{L}^{*}\), and \({U}_{D}^{*}\). The parameter \(\lambda ={\left(nQ\text{/}\sqrt{{S}_{o}}\right)}^{3/8}\) is a length scale that represents the size of the required cross-section where \({S}_{o}\) is the longitudinal slope. The dimensionless parameters \(\beta =b/y\) and \(\alpha =F/y\) represent the bed width to depth ratio and the freeboard to depth ratio, respectively. Finally, the parameters \({U}_{L}^{*}={U}_{L}/{U}_{X}\lambda\) and \({U}_{D}^{*}={U}_{D}\lambda /{U}_{X}\) represent the normalized cost of lining and normalized cost of excavation with depth, respectively. The ratio \({U}_{D}^{*}/{U}_{L}^{*}\) gives the relative costs of depth-dependent excavation and lining. Higher values of \({U}_{D}^{*}/{U}_{L}^{*}\) indicate greater importance for the increase of excavation cost with depth relative to the lining cost.

To compare the OCCD model results for VS 1 to VS 3 to the literature, the widely used Nash–Sutcliffe efficiency coefficient (NSE) was used (McCuen et al. 2006). The NSE was calculated using,

where \({y}_{{m}_{i}}\) represents the OCCD model results, \({y}_{{a}_{i}}\) represents the analytical solution from the literature, and \(\bar{{y }_{{a}_{i}}}\) is the mean of the \({y}_{{a}_{i}}\) values. The NSE ranges from \(-\infty\) to 1, where 1 indicates a perfect match between the OCCD model results and the analytical solution given in the literature.

For VS 4 to VS 7, the OCCD model performance was assessed through comparison to the anticipated outcomes. For VS 4, the model should produce an alignment along the valley floor with a profile that follows the valley slope. For VS 5, the model should give the shortest alignment within the area of low-cost land. For VS 6, the model results should correspond to the shortest alignment that passes through the area of low-cost land and does not cross restricted zones. Finally, by imposing smaller \({V}_{max}\) in VS 7, the model should select milder slopes, widen the cross-section, and possibly create bed drops.

3.2 Model Application

To demonstrate the OCCD model potential in minimizing the total cost of real projects, the model was applied to an irrigation water conveyance channel in Egypt, the Sheikh Zayed Canal (SZC). This section describes SZC and the implementation of the OCCD model to SZC.

3.2.1 Canal Characteristics

SZC delivers irrigation water to 540,000 feddan in the western desert of Egypt and is the main component of the Toshka Agricultural Development Project which started in 1998 (Wahby 2002). The SZC is located \(250\hspace{0.25em}\mathrm{km}\) south of Aswan and is supplied by water from Lake Nasser via the Mubarak Pumping Station (Fig. 6). The SZC extends for about 50 km and runs mostly parallel to the Toshka Bay at a distance ranging from about \(2.4\) to \(5.5\hspace{0.25em}\mathrm{km}\) from the Bay boundary (Fig. 6). The first segment of the canal is a transitional vertical-walled canal with a length of approximately \(2.7\hspace{0.25em}\mathrm{km}\). The rest of SZC is the main stem and is the focus of this study. SZC consists of 23 reaches connected by curves with radii ranging between \(400\) and \(1600\hspace{0.25em}\mathrm{m}\). The main stem has a trapezoidal cross-section with a bed width of \(30\hspace{0.25em}\mathrm{m}\), a side slope \(t=2\), and a bed slope of \(10\hspace{0.25em}\mathrm{cm/km}\) (Wahby 2002). The canal has a design capacity of \(334\hspace{0.25em}\mathrm{{m}^3/s}\) with a maximum water depth of \(6\hspace{0.25em}\mathrm{m}\) and a freeboard of \(1\hspace{0.25em}\mathrm{m}\) (El Baradei and Al Sadeq 2019). To reduce seepage losses, the SZC was lined with a \(0.2\hspace{0.25em}\mathrm{m}\) concrete layer placed on top of \(1\hspace{0.25em}\mathrm{mm}\) thick polyethylene sheets which were in turn laid on top of a \(0.2\hspace{0.25em}\mathrm{m}\) thick compacted and stabilized soil.

Pre-construction satellite imagery for the SZC domain revealed no distinct land use in the region except for some scattered roads. Accordingly, land acquisition cost was excluded from the OCCD model by applying the objective function in Eq. (2) with the binary variable \({f}_{4}=0\). The other cost components were retained in the objective function to investigate the optimal design of SZC based on earthwork, lining, and water loss costs.

3.2.2 Surrounding Topography

Topographic survey data for the SZC region were not available for this study. Instead, the ALOS digital elevation model (DEM) was used. Similar to other freely available DEMs (SRTM and ASTER), the ALOS DEM has a horizontal resolution of \(30\hspace{0.17em}\mathrm{m}\times 30\hspace{0.17em}\mathrm{m}\) (Takaku et al. 2018). However, the ALOS DEM likely has higher vertical accuracy (Zhang et al. 2019). It was released in mid-2016, is based on the data collected after the construction of the SZC, and accordingly represents post-construction topography. To approximate the pre-construction topography along the SZC, the DEM data was adjusted by interpolation of ground elevations within a swath extending over the canal width and length (Fig. 7).

3.2.3 Evaporation and Seepage Losses

The SZC is in a hyper-arid region and evaporation losses from the canal are expected to be high. For the application of the OCCD model, the annual average evaporation rate was set to \(E=7.5\hspace{0.25em}\mathrm{mm/d}\) (El Baradei and Al Sadeq 2019). The model estimated daily evaporation flux per unit length of SZC \(\left({q}_{v}\right)\) using,

where B is the top channel width obtained from the Hydraulic Simulation module. Similar to other lined channels, the lining in SZC cannot completely prevent seepage. Even with good maintenance and little imperfections, lining reduces seepage by only 30 to 40% compared to seepage from unlined channels (Swamee and Chahar 2015). To estimate seepage losses from SZC, the seepage rate with no lining was first quantified and was then adjusted by a factor of 0.65 to account for the lining. The final seepage rate per unit length of SZC \(\left({q}_{s}\right)\) was calculated using (Swamee and Chahar 2015),

where \(k\) is the hydraulic conductivity of the underlying soil, \(y\) is the simulated water depth, and the factor \({F}_{s}\) is given by,

in which the exponents \({p}_{1}=\frac{0.77+0.462\hspace{0.17em}t}{1.3+0.6\hspace{0.17em}t}\), \({p}_{2}=\frac{1+0.6\hspace{0.17em}t}{1.3+0.6\hspace{0.17em}t}\), and \({p}_{3}=\frac{1.3+0.6\hspace{0.17em}t}{1+0.6\hspace{0.17em}t}\). For SZC, the underlying soil is classified as clay loam (FAO et al. 2012). The hydraulic conductivity for this soil was taken as \(0.22\hspace{0.25em}\mathrm{m/d}\) (Tapiador 2008).

3.2.4 Cost Calculations

Indicative values for the unit cost of excavation at the ground surface; cost increment per unit depth of excavation; and unit costs for fill, lining, and water losses were adapted from IWD (2018) and Ren et al. (2018). To simplify the analysis and presentation of results, the unit costs were normalized by the excavation unit cost (e.g., the unit cost of excavation was taken as unity). The normalized unit costs for fill, lining, and water loss were set to \({U}_{F}/{U}_{X}=1.4\), \({U}_{L}/{U}_{X}=10\hspace{0.25em}\mathrm{m}\), and \({U}_{W}/{U}_{X}=0.02\) m3(water)/m3(soil), respectively. The increase in excavation cost per unit depth was set to \(12{\%}\) of \({U}_{X}\).

The cost of water losses was calculated for 25 years which was assumed to be the duration until major rehabilitation of the canal would be performed. Conversion to present worth was not needed; the unit cost for water loss was assumed to increase by the same percentage as the interest rate.

For calculation of earthwork and lining costs, the berm level was set based on the higher freeboard obtained from the following equations (JICA and OIDA 2014),

where \(y\) is the flow depth, \(V\) is the flow velocity, \({h}_{v}\) is the velocity head, and \({h}_{s}\) is the water surface oscillation range (taken as 0.1 m).

3.2.5 Modelling Scenarios

The hydraulic analysis was first conducted for the existing canal design to calculate its cost, which was then compared to the cost of the design alternatives determined by the OCCD model. Three different scenarios were examined with the model. The objective of the first scenario (SZS-1) was to identify the optimal design variables that achieve the minimum total cost. The second scenario (SZS-2) aimed to produce the optimal design variables while neglecting water losses. Finally, the third scenario (SZS-3) was used to demonstrate how the model can be applied to justify canal lining. In this scenario, the optimal design for the minimum cost of earthwork and water loss was compared with the optimal design from SZS-1.

To keep the number of design variables in the OCCD model reasonable, 14 reaches were applied in all scenarios instead of the 23 reaches making up the existing canal alignment. The Manning coefficient for scenarios SZS-1 and SZS-2 was set to 0.02 as per the existing design and was set to 0.03 in SZS-3. The geometric constraints included a restricted zone extending over the Toshka Bay (Fig. 6). Maximum contraction and enlargement in bed width were limited to 20%. Hydraulic constraints included limiting the maximum flow depth to 8 m for all scenarios and limiting the maximum flow velocity to \(2.5\hspace{0.25em}\mathrm{m/s}\) for SZS-1 and SZS-2 and to \(1\hspace{0.25em}\mathrm{m/s}\) in SZS-3.

4 Results

4.1 Validation Scenarios

Results of scenario VS 1 show that for a cross-section scale \(\lambda\), the bed width \(b\) giving minimal lining cost decreased with the increase of the maximum imposed depth \({y}_{max}\) up to \({y}_{max}=0.968\hspace{0.17em}\lambda\) (Fig. 8a). For higher values of \({y}_{max}\), the optimal bed width remained constant and the depth corresponded to \({y}_{max}\). The side slope \(t\) oscillated around \(1/\sqrt{3}\) for small values of \({y}_{max}/\lambda\) with the magnitude of the oscillations becoming smaller with the increase in \({y}_{max}/\lambda\). For \({y}_{max}/\lambda \gtrsim 0.8\), the side slope attained a constant value of \(t=1/\sqrt{3}\) (Fig. 8b). The model results for the VS 1 scenario matched the analytical solution by Froehlich (1994) with a high NSE of 0.999 for bed width (Fig. 8).

OCCD model results for scenario VS 1 versus analytical solution by Froehlich (1994). Shown are the (a) bed width and (b) side slope for minimum lining cost

For scenario VS 2, the OCCD model shows that with a higher relative cost for depth-dependent excavation \(\left({U}_{D}^{*}/{U}_{L}^{*}\right)\), a cross-section of scale \(\lambda\) required larger bed width to depth ratio \(\beta\) (i.e., larger bed width with shallower depth) and steeper side slope to have minimal lining and excavation costs (Fig. 9a–c). These trends are the same as those revealed by the regression equations given by Niazkar and Afzali (2015) over the equations’ range of applicability \(0<{U}_{D}^{*}/{U}_{L}^{*}<2\). However, compared to the regression equations, the OCCD model results show less dependence on \({U}_{D}^{*}/{U}_{L}^{*}\) when its value approaches 2 (Fig. 9a, b). For flow depth, the results of the OCCD model are more accurate than the regression equations; the latter give depths that deviate from the values obtained with the Manning equation using the bed widths and side slopes from the regression equations (Fig. 9c). This deviation leads to inaccurate total cost estimation. Correction of the depth and the total cost from the equations by Niazkar and Afzali (2015) shows that the OCCD model produces more optimal solutions with up to 1.1% lower cost (Fig. 9d).

OCCD model results (markers) for scenario VS 2 versus values from regression equations by Niazkar and Afzali (2015) (solid lines). Shown are the (a) bed width to depth ratio β, (b) side slope, and (c) depth for minimum lining and depth-dependent excavation costs. Also shown in panel (d) is the total cost normalized by the cost when excavation cost is independent of depth (i.e., \(U_D=0\))

The results of VS 3 show that for any value of side slope, the bed width to depth ratio \(\beta\) increased with the increase of \(\lambda\) for \(\alpha =0\), and decreased when \(\alpha \ge 0.1\) (Fig. 10). Also, the results show that the change of \(\beta\) with \(\lambda\) decreased (i.e., became less sensitive) with the increase of the side slope \(\left(t\right)\) (Fig. 10). The VS 3 results matched the analytical equations produced by Han et al. (2019), with an average NSE of 0.95, 0.85 and 0.52 for \(t=0.5\), \(t=1\) and \(t=1.5\), respectively.

OCCD model results (markers) for scenario VS 3 versus analytical solution by Han et al. (2019) (solid lines). Shown is the variation of the optimal bed width to depth ratio β with the cross-section scale λ for the side slopes (a) t = 0.5, (b) t = 1, and (c) t = 1.5. Solid lines represent different freeboard-to-depth ratios α. Values of β correspond to the minimum lining, excavation, and land acquisition costs for the unit costs \(U_L/U_X = 2\;\mathrm{m}\;\mathrm{and}\;U_A/U_X = 0.5\;\mathrm{m}\)

In VS 4.1 with 3 reaches, the OCCD model generated a non-straight alignment to minimize the excavation through the terrain (Fig. 11a), and to reduce the cost by 78% compared to the straight alignment. Increasing the number of reaches to 8 in VS 4.2 gave the OCCD model more flexibility to produce an alignment that closely followed the path of the winding valley (Fig. 11a), and reduced the cost by 14% than VS 4.1. For VS 4.2, the profile coincided with the ground (Fig. 11c) with less excavation than VS 4.1 (Fig. 11b). These results confirmed the OCCD model ability to determine the optimum alignment and profile that minimize the excavation cost.

In VS 5, the OCCD model successfully handled the spatial variation of the land acquisition cost. For VS 5.1 with a high-to-low (HL) land cost ratio of 3.0, the lining cost dominated over land acquisition cost leading to an alignment that partly crossed through the high-cost land (Fig. 12a). This alignment produced a total cost 38% lower than the straight alignment. By increasing the HL land cost ratio from 3 to 100 in VS 5.2, the land acquisition cost became much more significant than the lining cost. The corresponding alignment followed a longer path completely within the low-cost land (Fig. 12a). This alignment produced a total cost 94% lower than the straight alignment.

In VS 6, the OCCD model properly identified the location of restricted zones and selected the shortest alignment within the low-cost land without crossing the restricted zones (Fig. 12b). Also, using a higher number of reaches, the OCCD model was able to form a more complex alignment with lower cost. As the number of reaches was increased from 6 to 8, the cost decreased rapidly by 18.3%. Further increase in the number of reaches yielded marginal reduction in cost; applying the model with 11 reaches instead of 8 reaches produced a design with 6.6% less cost and using 15 reaches instead of 11 reaches gave a further cost reduction of only 5.5%.

In VS 7, the optimum alignment produced by the OCCD model was the shortest path connecting the source and the destination for all three sub-scenarios VS 7.1, VS 7.2, and VS 7.3 (Fig. 13a). However, the optimum profile and cross-section varied based on the maximum velocity \(\left({V}_{max}\right)\). With no velocity constraint in VS 7.1, the OCCD model minimized the cost by producing a profile with successively increasing bed slope (Fig. 13a). This allowed the flow to accelerate, velocity to increase, and cross-section area to decrease. The velocity at the downstream reached \(4.5\) m/s, which can damage the filler in the joints between the lining panels. By limiting the maximum velocity in VS 7.2 to \(3\) m/s, the OCCD model produced an almost constant bed slope, which induced an approximately uniform flow (Fig. 13b). Also, a wider cross-section was produced to accommodate the flow, with a total cost ~20% higher than VS 7.1.

Lowering the velocity to \(2\) m/s in VS 7.3, the OCCD model produced a profile with a bed drop of \(0.2\) m (Fig. 13c). A wider cross-section was produced and the cost increased by 56% beyond the cost in VS 7.1. Table 3 summaries the results of all three sub-scenarios, listing the allowable velocities, the optimum profile and cross-section dimensions, and the percentages of cost increment relative to VS 7.1.

4.2 Case Study Results

4.2.1 Cost of Existing Canal Design

The hydraulic simulation of the existing SZC design showed that the flow is sub-critical with a Froude number of 0.2, a depth of \(6\hspace{0.25em}\mathrm{m}\), and a flow velocity of \(1.34\hspace{0.25em}\mathrm{m/s}\). The rate of water losses amounts to \(5.9\hspace{0.25em}\mathrm{{m}^3/s}\) for seepage and \(0.2\hspace{0.25em}\mathrm{{m}^3/s}\) for evaporation, which combined represents about \(1.8{\%}\) of the design discharge. The \(1\hspace{0.25em}\mathrm{m}\) freeboard can accommodate an additional discharge of \(100\hspace{0.25em}\mathrm{{m}^3/s}\); SZC can carry a flow of up to \(444\hspace{0.25em}\mathrm{{m}^3/s}\) without flooding). The existing canal profile shows that the canal passes through different high and low terrain, with maximum excavation and fill depths of \(27\hspace{0.25em}\mathrm{m}\) and \(16\hspace{0.25em}\mathrm{m}\), respectively (Fig. 14a).

The normalized present cost (NPC) of the existing canal design amounted to \(1.54\times {10}^{8}\). The water loss cost due to seepage represented \(\sim\!56{\%}\) of the total cost whereas the evaporation losses cost represented only \(\sim\!2{\%}\) (Fig. 15). The excavation cost was more than five times the fill cost as the canal alignment passes through relatively high terrain, whereas the applied \(12{\%}\) increment in excavation cost accounted for \(\sim\!40{\%}\) of the overall excavation cost. Finally, the lining cost was \(\sim\!20{\%}\) less than the earthwork cost.

4.2.2 Minimum Total Cost Scenario

The OCCD model results for SZS-1 showed that the model respected the geometric constraint and avoided crossing the Toshka Bay (Fig. 16). The canal alignment produced by the OCCD model had a length of \(45\hspace{0.25em}\mathrm{km}\), shorter by \(5{\%}\) than the existing canal (\(47.3\hspace{0.25em}\mathrm{km}\)). The alignment from the model was almost identical to the existing canal alignment at its downstream end. Along the rest of the path, the alignment from the model wiggled around and deviated from the existing alignment by up to \(2.8\hspace{0.25em}\mathrm{km}\) (Fig. 16).

The OCCD model produced a profile with reaches of variable longitudinal slope ranging from flat (i.e., horizontal) to \(186\hspace{0.25em}\mathrm{cm/km}\) (Fig. 14b and Table 4). The model generated a cross-section with a uniform side slope of 0.5 which matched the lower limit specified to the model. The canal bed width ranged between \(23.5\hspace{0.25em}\mathrm{m}\) at the canal upstream end and \(33.5\hspace{0.25em}\mathrm{m}\) at the downstream end with an average width of \(26.8\hspace{0.25em}\mathrm{m}\). Including the freeboard, the total canal depth ranged between \(5.3\hspace{0.25em}\mathrm{m}\) and \(8.7\hspace{0.25em}\mathrm{m}\). The maximum excavation and fill depths were \(23.5\hspace{0.25em}\mathrm{m}\) and \(14.2\hspace{0.25em}\mathrm{m}\), respectively. Compared to the maximum excavation and fill depths for the existing canal, the maximum depths for the SZS-1 design alternative were less by about \(13.5{\%}\), making this alternative easier and safer to construct.

The OCCD model respected the specified hydraulic constraints. The simulated reach-average flow velocity ranged between \(1.3\hspace{0.25em}\mathrm{m/s}\) and \(2.2\hspace{0.25em}\mathrm{m/s}\), lower than the maximum allowable velocity of \(2.5\hspace{0.25em}\mathrm{m/s}\) (Table 4). The simulated reach-average flow depth ranged between \(7.8\hspace{0.25em}\mathrm{m}\) and \(4.6\hspace{0.25em}\mathrm{m}\), below the maximum threshold of \(8\hspace{0.25em}\mathrm{m}\) (Fig. 14b). If the bed width in the downstream-most reach had been \(30\hspace{0.25em}\mathrm{m}\) instead of \(33.5\hspace{0.25em}\mathrm{m}\) to maintain a uniform width, the maximum allowable depth constraint would be violated by \(0.015\hspace{0.25em}\mathrm{m}\) in the first \(155\hspace{0.25em}\mathrm{m}\) of the reach, which explains why the OCCD model selected the bed width of \(33.5\hspace{0.25em}\mathrm{m}\). The calculated freeboard by the OCCD model ranged from \(0.66\hspace{0.25em}\mathrm{m}\) to \(0.8\hspace{0.25em}\mathrm{m}\). The minimum freeboard can accommodate an additional \(56\hspace{0.25em}\mathrm{{m}^{3}/s}\) of water, allowing the canal to carry up to \(390\hspace{0.25em}\mathrm{{m}^{3}/s}\) without flooding (if water surface fluctuation was neglected). If a uniform freeboard of \(1\hspace{0.25em}\mathrm{m}\) was considered, the total cost of the OCCD design would increase by \(0.8{\%}\).

The NPC of SZS-1 design alternative which was produced by the OCCD model was equal to \(1.17\times {10}^{8}\), with a significant reduction of \(24{\%}\) compared to the cost of the existing canal design (Fig. 15). The largest percentage of cost reduction was in the excavation cost, which decreased by approximately half. In contrast, the fill cost increased by \(\sim\!109{\%}\). A maximum cost difference of \(1.78\times {10}^{7}\) was achieved in the seepage losses cost, with a reduction percentage of \(\sim\!21{\%}\). Considering the capital costs only (i.e., neglecting the water losses cost), the cost of the design alternative produced by the OCCD model would be \(\sim\!27\%\) less than the cost of the existing canal design.

4.2.3 Minimum Earthwork and Lining Costs Scenario

Similar to SZS-1, the OCCD model avoided crossing Toshka Bay in SZS-2 (Fig. 16). The produced canal alignment had a length of \(46.6\hspace{0.25em}\mathrm{km}\), longer by \(3.5{\%}\) than the SZS-1 alignment (\(45\hspace{0.25em}\mathrm{km}\)) but shorter by \(1.5{\%}\) than the existing canal alignment (\(47.3\hspace{0.25em}\mathrm{km}\)). The SZS-2 alignment is similar to the existing canal alignment except near the middle of the canal where it was shifted by \(3\hspace{0.25em}\mathrm{km}\) southward (Fig. 16).

Similar to SZS-1, the OCCD model selected a uniform side slope of 0.5 for scenario SZS-2. However, as the cost of water losses was not included in scenario SZS-2, the OCCD model did not tend to limit the flow width and depth to reduce seepage and evaporation losses. Compared to SZS-1, the model selected wider canal beds with larger flow depths for SZS-2 (Table 5). The canal bed width for SZS-2 ranged between \(24.75\hspace{0.25em}\mathrm{m}\) and \(36.25\hspace{0.25em}\mathrm{m}\) with an average of \(28.6\hspace{0.25em}\mathrm{m}\) which is \(\sim 7\) % wider than for SZS-1. The reach-average flow depth for SZS-2 ranged between \(5.0\hspace{0.25em}\mathrm{m}\) and \(8.0\hspace{0.25em}\mathrm{m}\) with a mean value that is \(\sim\!6{\%}\) deeper than for SZS-1. To obtain larger flow depth and wider bed width for SZS-2, the model selected milder longitudinal slopes of no more than \(34\hspace{0.25em}\mathrm{cm/km}\) (Table 5 and Fig. 14c). These milder slopes allowed for lower flow velocities in the range \(1.32\hspace{0.25em}\mathrm{m/s}\) to \(1.91\hspace{0.25em}\mathrm{m/s}\).

The OCCD model respected the constraints of maximum allowable depth and velocity along the canal. Flow depth along the canal was less than 8 m and flow velocity was less than 2.5 m/s (Table 5). The calculated freeboard by the OCCD model ranged between \(0.66\hspace{0.25em}\mathrm{m}\) and \(0.76\hspace{0.25em}\mathrm{m}\). The minimum freeboard can accommodate an additional \(54\hspace{0.25em}\mathrm{{m}^{3}/s}\) of water, leading to a total flow of \(388\hspace{0.25em}\mathrm{{m}^{3}/s}\). If a uniform freeboard of \(1\hspace{0.25em}\mathrm{m}\) was considered, the total cost of the OCCD design would increase by \(1.9{\%}\). Considering the freeboard, the canal depth ranged between \(6\hspace{0.25em}\mathrm{m}\) and \(9\hspace{0.25em}\mathrm{m}\). The maximum excavation depth was \(24.2\hspace{0.25em}\mathrm{m}\), slightly higher than in scenario SZS-1, whereas the maximum fill depth was \(13.8\hspace{0.25em}\mathrm{m}\), slightly lower than in SZS-1.

With the exclusion of water losses cost, the NPC of the SZS-2 design alternative was \(4.46\times {10}^{7}\) compared to \(6.50\times {10}^{7}\) for the existing canal design. The cost reduction achieved by the SZS-2 alternative amounts to \(\sim\!31{\%}\) (Fig. 15). The largest percentage of cost reduction was in the excavation, which was \(\sim\!61{\%}\) less in SZS-2. In contrast, the fill cost increased by about \(\sim\!104{\%}\) (Fig. 15). Furthermore, the NPC of SZS-2 design alternative was \(\sim\!5{\%}\) less than the cost of SZS-1 if water losses is excluded.

Including the cost of water losses, the NPC of SZS-2 design alternative was \(\sim\!23{\%}\) less than the cost of the existing canal design, and \(\sim\!2{\%}\) more than the cost of SZS-1. The water losses cost was reduced by \(\sim\!17{\%}\) compared to the existing canal design but increased by \(5{\%}\) compared to SZS-1.

4.2.4 Minimum Earthwork and Water Losses Cost Scenario

Similar to the previous two scenarios, the OCCD model avoided crossing the Toshka Bay in scenario SZS-3 (Fig. 16). The produced canal alignment had a length of \(43.25\hspace{0.25em}\mathrm{km}\), shorter by \(3.8{\%}\) than SZS-1 (\(45\hspace{0.25em}\mathrm{km}\)). In this scenario, the OCCD model tried to shorten the length of the canal alignment despite the existence of very high terrain along the chosen alignment (Fig. 16). This indicates the dominance of the water losses cost along the canal lifetime over the earthwork cost.

Similar to the previous two scenarios, the OCCD model application to scenario SZS-3 produced a cross-section with a uniform side slope along the canal. The selected side slope of 2 corresponded to the lower limit specified in the model. This lower limit was higher than for the other scenarios (where the limit was 0.5) to maintain side slope stability given that no lining was used in SZS-3.

Compared to scenarios SZS-1 and SZS-2, the SZS-3 profile was relatively more uniform (Fig. 14d). The longitudinal slopes for the SZS-3 canal reaches ranged between \(3\) and \(25\hspace{0.25em}\mathrm{cm/km}\). The slopes were milder than in other scenarios to allow for lower flow velocities that would minimize erosion of the unlined canal bed in SZS-3. With a specified maximum allowable velocity of 1 m/s for SZS-3, the model produced reach-average flow velocities ranging between \(0.88\hspace{0.25em}\mathrm{m/s}\) and \(0.98\hspace{0.25em}\mathrm{m/s}\). Besides using milder longitudinal slopes, the model selected relatively wide bed widths to attain lower velocities. The canal bed width ranged between \(26.5\hspace{0.25em}\mathrm{m}\) and \(36.6\hspace{0.25em}\mathrm{m}\) with an average of \(31\hspace{0.25em}\mathrm{m}\).

Along the flow direction, the reach-average depth decreased from 8 to 7 m; while the freeboard was almost constant at \(0.66\hspace{0.17em}\mathrm{m}\) (Table 6). The maximum excavation depth for SZS-3 reached \(40.5\hspace{0.25em}\mathrm{m}\), higher than in the other scenarios. Similarly, the maximum fill depth reached \(19.5\hspace{0.25em}\mathrm{m}\), higher than the other scenarios. The calculated freeboard by the OCCD model can accommodate an additional \(57\hspace{0.25em}\mathrm{{m}^{3}/s}\) of water; allowing the canal to carry up to \(391\hspace{0.25em}\mathrm{{m}^{3}/s}\). If a uniform freeboard of \(1\hspace{0.25em}\mathrm{m}\) was considered, the total cost of the OCCD design would increase by \(0.4{\%}\).

With the cost of water losses included, the NPC of the unlined canal from scenario SZS-3 was \(2.09\times {10}^{8}\), which is \(\sim\!79{\%}\) higher than the cost of the lined canal from scenario SZS-1 (Fig. 15). Passing through high terrain to shorten the canal length caused the excavation cost for SZS-3 to increase by \(\sim\!248{\%}\), whereas the fill cost slightly decreased by \(\sim\!2{\%}\). Even though the SZS-3 alignment is shorter, the cost of water losses due to seepage increased significantly by \(\sim\!107{\%}\) due to the absence of lining, whereas the evaporation losses cost increased by \(\sim\!75{\%}\) as the canal became wider. SZS-3 results support the decision made to line the canal with a concrete lining, as a lower total cost was achieved in SZS-1 compared to SZS-3.

5 Conclusions and Recommendations

In this study, an optimization model, referred to as the OCCD model, was developed to aid in the design of open channels taking into account the interdependence between the design parameters and efficiently searching through the massive number of design alternatives. Unlike traditional design methodologies, the OCCD model is capable of concurrently optimizing the channel design parameters as opposed to separating the design process into de-linked stages. The developed OCCD model is robust, automated, and comprehensive as it accounts for various costs and considers geometric and hydraulic constraints. Furthermore, the OCCD model is compact and efficient as it includes its own hydraulic simulation module and requires no link to external hydraulic models.

The performance of the OCCD model was thoroughly evaluated by applying it to seven validation scenarios. The first three scenarios focused on the optimization of the channel cross-section, whereas the other four scenarios were used to confirm the ability of the OCCD model to optimize the channel profile and alignment. The results of the first three validation scenarios matched the analytical/regression equations found in the literature. Similarly, the other four scenarios produced anticipated rational outcomes. These results confirmed that the model can determine the optimal channel design parameters (e.g., channel alignment, profile, and cross-section). Also, it proved that the OCCD model can handle the specified geometric and hydraulic constraints.

The model performance was further assessed by applying it to a case study; the existing Sheikh Zayed Canal in Egypt. The model was first applied to conduct a hydraulic simulation and cost analysis for the existing channel design. The model was then applied to identify the optimal design for multiple scenarios. The OCCD model produced more optimal design alternatives, with considerable cost reduction and water savings compared to the existing canal design. In one of the scenarios, the OCCD model was used to determine the feasibility of lining the SZC; model results supported the decision to line the canal and reduce seepage losses.

In summary, the OCCD model represents a useful tool that engineers can utilize in designing transmission channels as part of new water conveyance projects. The model facilitates the design process, saves time, enables efficient examination of effects of cost uncertainties, and produces more optimal designs than those possible with the traditional manual design. The model also incorporates seepage water losses in the design process and can accordingly be used to quickly answer questions related to the feasibility of canal lining.

The methodology used in the formulation of the OCCD model (Sect. 2) makes the model suitable for the design of transmission open channels that convey constant discharge. Nonetheless, there are multiple possibilities for improving the OCCD model in future work. From a hydraulic point of view, it can be generalized to consider the possible variation of discharge along the channel to be suitable for designing irrigation distribution channels. This will also enable the OCCD model to account for water lost along the channel length, providing for a more optimal design. Furthermore, the model may be improved by including the spatial variation of hydraulic conductivity and climatic conditions for better estimation of seepage and evaporation losses. From an optimization point of view, the model can be improved by accounting for more detailed earthwork costs including haulage, soil import, and disposal as well as by accounting for the variation of ground level along the transverse direction of the channel alignment. In addition, the cost of inter-reach transition, as well as operation and maintenance costs, can be considered to accurately represent the overall cost. Finally, other evolutionary optimization techniques may be tested to increase the efficiency and reliability of the OCCD model.

Availability of Data and Materials

All data that support the results are available upon request.

Notes

Irrigation and Hydraulics Department, Faculty of Engineering, Cairo University, Giza, Egypt

Construction Research Institute, National Water Research Center, Qalyubia, Egypt

References

Adarsh S, Sahana AS (2013) Minimum cost design of irrigation canals using probabilistic global search Lausanne. Arab J Sci Eng 38(10):2631–2637. https://doi.org/10.1007/s13369-012-0493-x

Akan O (2006) Open Channel Hydraulics. https://doi.org/10.1016/B978-0-7506-6857-6.X5000-0

Aksoy B, Altan-Sakarya AB (2006) Optimal lined channel design. Can J Civ Eng 33:535–545. https://doi.org/10.1139/L06-008

Basu S, Chahar BR (2013) Optimal cutting and filling height for canal length. In: World Environmental and Water Resources Congress 2013, May, pp 2227–2236. https://doi.org/10.1061/9780784412947.219

Bhattacharjya RK (2005) Optimal design of open channel section considering freeboard. ISH J Hydraul Eng 11(3):141–151. https://doi.org/10.1080/09715010.2005.10514808

Chahar BR (2006) Simplified design method of a transmission canal. In: Joint International Conference on Computing and Decision Making in Civil and Building Engineering, pp 436–445

Chahar BR, Novman A, Godara R (2007) Optimal parabolic section with freeboard. J Indian Water Works Assoc (March) 43–48

Chow VT (1959) Open Channel Hydraulics, 1st edn. McGRAW-HILL, New York, N.Y.

Das A (2000) Optimal channel cross section with composite roughness. J Irrig Drain Eng 126(1):68–72. https://doi.org/10.1061/(asce)0733-9437(2000)126:1(68)

El Baradei SA, Al Sadeq M (2019) Optimum coverage of irrigation canals to minimize evaporation and maximize dissolved oxygen concentration: Case study of Toshka, Egypt. Int J Environ Sci Technol 16(8):4223–4230. https://doi.org/10.1007/s13762-018-2010-6

El-Ghandour HA, Elbeltagi E, Gabr ME (2020) Design of irrigation canals with minimum overall cost using particle swarm optimization - case study: El-Sheikh Gaber canal, north Sinai Peninsula, Egypt. J Hydroinf 22(5):1258–1269. https://doi.org/10.2166/hydro.2020.199

FAO, IIASA, ISRIC, ISSCAS, JRC (2012) Harmonized world soil database (version 1.2). FAO, Rome, Italy and IIASA, Laxenburg, Austria. http://webarchive.iiasa.ac.at/Research/LUC/External-World-soil-database/HTML/index.html?sb=1

Farzin S, Anaraki MV (2021) Optimal construction of an open channel by considering different conditions and uncertainty: Application of evolutionary methods. Eng Optim 53(7):1173–1191. https://doi.org/10.1080/0305215X.2020.1775825

Froehlich DC (1994) Width and depth-constrained best trapezoidal section. J Irrig Drain Eng 120(4):828–835. https://doi.org/10.1061/(ASCE)0733-9437(1994)120:4(828)

Guo CY, Hughes WC (1984) Optimal channel cross section with freeboard. J Irrig Drain Eng 110(3):304–314. https://doi.org/10.1061/(ASCE)0733-9437(1984)110:3(304)

Han YC, Easa SM, Gao XP (2019) General explicit solutions of most economic sections and applications for trapezoidal and parabolic channels. J Hydrodyn 31(5):1034–1042. https://doi.org/10.1007/s42241-018-0155-x

Haupt RL, Haupt SE (2003) Practical genetic algorithms. John Wiley & Sons. https://doi.org/10.1002/0471671746

Hydrologic Engineering Center (2016) HEC-RAS Reference Manual. Institute of Water Resources, U.S. Army of Corps of Engineers. https://hec.usace.army.mil/software/hec-ras/

Irrigation & Waterways Department (2018) Unified Schedule of Rates. Technical report by Government of Karnataka. https://kbjnl.karnataka.gov.in/storage/pdffiles/Schedule%20of%20Rates%202018-19%20(1).pdf

Jain A, Bhattacharjya RK, Sanaga S (2004) Optimal design of composite channels using genetic algorithm. J Irrig Drain Eng 130(4):286–295. https://doi.org/10.1061/(ASCE)0733-9437(2004)130:4(286)

JICA, OIDA (2014) Technical Guideline for Design of Headworks. Technical Report, Japan International Cooperation Agency, Oromia Irrigation Development Authority

Kentli A, Mercan O (2014) Application of different algorithms to optimal design of canal sections. J Appl Res Technol 12(4):762–768. https://doi.org/10.1016/S1665-6423(14)70092-6

King HW, Brater EF, Lindell JE, Wei CY (1949) Handbook of hydraulics. Civil Engineering, McGraw-Hill Education. https://books.google.com/books?id=R41UAAAAMAAJ

Kramer O (2017) Genetic algorithm essentials. Studies in Computational Intelligence, Springer Cham. https://doi.org/10.1007/978-3-319-52156-5

Mathworks (2014) Optimization toolbox user’s guide R2014b. https://mathworks.com/help/pdf_doc/optim/optim.pdf

McCuen RH, Knight Z, Cutter AG (2006) Evaluation of the Nash-Sutcliffe efficiency index. J Hydrol Eng 11(6):597–602. https://doi.org/10.1061/(asce)1084-0699(2006)11:6(597)

Monadi M, Mohammadi M, Taghizadeh H (2019) Optimal design of open channel sections using PSO. Iran J Optim 11(2):207–215

Monadjemi P (1994) General formulation of best hydraulic channel section. J Irrig Drain Eng 120(1):27–35

Niazkar M (2020) Assessment of artificial intelligence models for calculating optimum properties of lined channels. J Hydroinf 22(5):1410–1423. https://doi.org/10.2166/hydro.2020.050

Niazkar M, Afzali SH (2015) Optimum design of lined channel sections. Water Resour Manage 29(6):1921–1932. https://doi.org/10.1007/s11269-015-0919-9

Pourbakhshian S, Pouraminian M (2021) Analytical models for optimal design of a trapezoidal composite channel cross-section. Civil Environ Eng Rep 31(1):118–138. https://doi.org/10.2478/ceer-2021-0009

Ren Y, Wei S, Cheng K, Fu Q (2018) Valuation and pricing of agricultural irrigation water based on macro and micro scales. Water (switzerland) 10(8):1–13. https://doi.org/10.3390/w10081044

Roushangar K, Nouri A, Shahnazi S, Azamathulla HM (2021) Towards design of compound channels with minimum overall cost through grey wolf optimization algorithm. J Hydroinf 23(5):985–999. https://doi.org/10.2166/hydro.2021.050

Sarker R, Kamruzzaman J, Newton C (2003) Evolutionary optimization (Evopt): a brief review and analysis. Int J Comput Intell Appl 03(04):311–330. https://doi.org/10.1142/s1469026803001051

Simpson AR, Dandy GC, Murphy LJ (1994) Genetic algorithms compared to other techniques for pipe optimization. J Water Resour Plan Manag 120(4):423–443. https://doi.org/10.1061/(asce)0733-9496(1994)120:4(423)

Swamee PK (1994) Normal-depth equations for irrigation canals. J Irrig Drain Eng 120(5):942–946. https://doi.org/10.1061/(ASCE)0733-9437(1994)120:5(942)

Swamee PK, Chahar BR (2013) Optimal alignment of a canal route. Proc Inst Civil Eng Water Manage 166(8):422–431. https://doi.org/10.1680/wama.11.00097

Swamee PK, Chahar BR (2015) Design of canals. Springer Transactions in Civil and Environmental Engineering, Springer New Delhi. https://doi.org/10.1007/978-81-322-2322-1

Swamee PK, Mishra GC, Chahar BR (2000a) Design of minimum seepage loss canal sections. J Irrig Drain Eng 126:28–32. https://doi.org/10.1061/(ASCE)0733-9437(2000)126:1(28)

Swamee PK, Mishra GC, Chahar BR (2000b) Comprehensive design of minimum cost irrigation canal sections. J Irrig Drain Eng 126(5):322–327

Swamee PK, Mishra GC, Chahar BR (2000c) Minimum cost design of lined canal sections. Water Resour Manage 14:1–12. https://doi.org/10.1023/A:1008198602337

Tabari MM, Mari M (2016) The integrated approach of simulation and optimization in determining the optimum dimensions of canal for seepage control. Water Resour Manage 30(3):1271–1292. https://doi.org/10.1007/s11269-016-1225-x

Tabari MM, Tavakoli S, Mari M (2014) Optimal design of concrete canal section for minimizing costs of water loss, lining and earthworks. Water Resour Manage 28(10):3019–3034. https://doi.org/10.1007/s11269-014-0652-9

Takaku J, Tadono T, Tsutsui K, Ichikawa M (2018) Quality improvements of ’AW3D’ global DSM derived from ALOS PRISM. In: International Geoscience and Remote Sensing Symposium (IGARSS), IEEE. https://doi.org/10.1109/IGARSS.2018.8518360

Tapiador FJ (2008) Rural analysis and management: an earth science approach to rural science. Springer- Verlag, Berlin Heidelberg

Tofiq FA, Guven A (2015) Optimal design of trapezoidal lined channel with least cost: Semi-theoretical approach powered by genetic programming. Water SA 41(4):483–489. https://doi.org/10.4314/wsa.v41i4.07

Trout TJ (1982) Channel design to minimize lining material costs. J Irrig Drain Div 108:242–294

Wahby WS (2002) The Toshka project of Egypt: a multidisciplinary engineering education case study. In: ASEE Annual Conference Proceedings, pp 4671–4682

Zhang K, Gann D, Ross M, Robertson Q, Sarmiento J, Santana S, Rhome J, Fritz C (2019) Accuracy assessment of ASTER, SRTM, ALOS, and TDX DEMs for hispaniola and implications for mapping vulnerability to coastal flooding. Remote Sens Environ 225:290–306. https://doi.org/10.1016/j.rse.2019.02.02

Acknowledgements

The first author is grateful to Prof. Reda M. El-DamakFootnote 1 and Dr. Ashraf A. Al-ashaalFootnote 2 for providing important information and sharing some data for the Sheikh Zayed Canal.

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). All authors declare that no funds or other support were received for this research.

Author information

Authors and Affiliations

Contributions

Aly K. Salem: Conceptualized, coded, tested and analyzed the OCCD model results and wrote the manuscript. Yehya E. Imam: Assisted in conceptualizing, coding and analyzing the results, reviewed and edited the manuscript. Ashraf H. Ghanem and Abdallah S. Bazaraa: Reviewed the manuscript and gave constructive suggestions.

Corresponding author

Ethics declarations

Consent to Participate

All authors give their consent to participate.

Consent to Publish

All authors give their consent to publish.

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Salem, A.K., Imam, Y.E., Ghanem, A.H. et al. Genetic Algorithm Based Model for Optimal Selection of Open Channel Design Parameters. Water Resour Manage 36, 5867–5896 (2022). https://doi.org/10.1007/s11269-022-03323-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11269-022-03323-w