Abstract

Municipal solid waste incineration (MSWI) bottom ash contains economically significant levels of silver and gold. Bottom ashes from incinerators at Amsterdam and Ludwigshafen were sampled, processed, and analyzed to determine the composition, size, and mass distribution of the precious metals. In order to establish accurate statistics of the gold particles, a sample of heavy non-ferrous metals produced from 15 tons of wet processed Amsterdam ash was analyzed by a new technology called magnetic density separation (MDS). Amsterdam’s bottom ash contains approximately 10 ppm of silver and 0.4 ppm of gold, which was found in particulate form in all size fractions below 20 mm. The sample from Ludwigshafen was too small to give accurate values on the gold content, but the silver content was found to be identical to the value measured for the Amsterdam ash. Precious metal value in particles smaller than 2 mm seems to derive mainly from waste of electrical and electronic equipment (WEEE), whereas larger precious metal particles are from jewelry and constitute the major part of the economic value. Economical analysis shows that separation of precious metals from the ash may be viable with the presently high prices of non-ferrous metals. In order to recover the precious metals, bottom ash must first be classified into different size fractions. Then, the heavy non-ferrous (HNF) metals should be concentrated by physical separation (eddy current separation, density separation, etc.). Finally, MDS can separate gold from the other HNF metals (copper, zinc). Gold-enriched concentrates can be sold to the precious metal smelter and the copper-zinc fraction to a brass or copper smelter.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

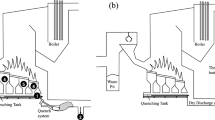

Municipal solid waste incineration (MSWI) bottom ash is commonly separated by dry physical methods into valuable ferrous and non-ferrous metals and building products, such as aggregate and sand (Muchova 2007a). Dry treatment processes do not recover the fine heavy non-ferrous fraction of MSWI bottom ash efficiently; however, and this is the fraction that contains most of the valuable precious metals (Bakker 2007; Chimenos 1999). The implementation of a new wet treatment process at the incinerator of Amsterdam (Rem 2004; Muchova 2006, 2007b) produced bulk amounts of heavy non-ferrous metals from bottom ash in three different size fractions, down to 300 µm. The Amsterdam pilot plant separates dry pretreated bottom ash into metals and building products by wet screening, cyclones, eddy current separation, kinetic gravity separation (Van Kooy 2004), and jigging. The resulting fractions of interest for this study are the coarse non-ferrous (6–20 mm), fine heavy non-ferrous (2–6 mm), and very fine heavy non-ferrous (<2 mm) products (see Fig. 1). The development of the wet process created an incentive to characterize bottom ash in terms of its precious metal content, and it produced statistically significant amounts of fine non-ferrous product for precious metal analysis. These results improve on previous studies which reported strongly varying and unrealistic levels of precious metals in fly ash and bottom ash (Wiles 1999; Schmelzer 1996), probably because of small sample sizes. Precious metal composition can be determined relatively easily by smelting the metal scrap and analyzing the smelt (Muchova 2006). However, data about the size distribution and other physical properties of precious metal-containing particles is lost in the smelt. For this reason, Bakker (2007) proposed a system called magnetic density separation (MDS) to further concentrate the precious metal particles, so that they can be studied individually. MDS can separate heavy non-ferrous metal (HNF) products into a light fraction with the residual glass and stone, a copper–zinc concentrate and a lead and precious metal concentrate. The MDS process may also be applicable for bulk industrial recovery of precious metals from bottom ash. Separating the HNF fraction into a precious metal concentrate, which can be sold to the precious metal smelter, and a copper–zinc product to be sold to the copper or brass smelter may make bottom ash treatment economically more attractive. The results of the characterization study are therefore used as input for an economical analysis of this option.

2 Materials and Methods

The samples of bottom ash investigated during this research were obtained from the incinerator of Amsterdam and from the incinerator of Ludwigshafen. The Amsterdam bottom ash was separated partly by a wet pilot plant at the site of the incinerator and partly in the laboratory, resulting in three heavy non-ferrous concentrates: <2, 2–6, and 6–20 mm. Two of the concentrates, <2 and 2–6 mm, were analyzed for precious metal content. The 6–20 mm HNF fraction was handpicked, but the number of precious metal particles found was too small to give statistically significant results. The raw bottom ash sample from Ludwigshafen was treated completely in the laboratory, using a process that closely mimics the process executed on the Amsterdam sample. For this sample, only the 2–6 mm HNF concentrate was analyzed.

At an early phase of the wet process development, two batches of 2–6 mm HNF concentrate, together about 1,600 kg, were smelted, and the metal product was analyzed by X-ray fluorescence spectroscopy (XRF). Based on these preliminary experiments, it was expected to find one or two 2–6 mm gold-containing particles per ton of bottom ash (Bakker 2007). In order to reliably characterize the gold in this fraction of the Amsterdam bottom ash, 15 tons was wet screened and concentrated for heavy metals by kinetic gravity separation and eddy current separation, resulting in 75 kg of 2–6 mm HNF concentrate. The 2–6 mm HNF concentrate contains 20–30% of large pieces of glass and stone, while the rest is made up of copper, zinc, and lead with traces of iron, tin, silver, and gold. The 2–6 mm fraction contains about 4.5 kg of heavy non-ferrous metal per ton of dry bottom ash.

Statistical analysis, using Gy’s formula (Gy 1999), shows that if the gold concentration of the <2 mm fraction is comparable to that of the 2–6 mm fraction, less than 500 kg of bottom ash is needed for the same relative accuracy. On this basis, the heavy non-ferrous in 145 dry kg of the <2 mm fraction of bottom ash, obtained by wet screening and cyclones, was concentrated by jigging. The HNF concentrate produced after jigging had a poor non-ferrous grade, so it was upgraded by removing the steel and coarse sand by LIMS magnetic separation and tabling/sink–float in a heavy liquid. The resulting mixture of heavy non-ferrous metals was smelted, producing 0.6 kg of solid HNF metal. This smelt was analyzed by XRF and microprobe. The <2 mm fraction yields about 1.4 kg of heavy non-ferrous metal per ton of dry bottom ash. The amount of bottom ash collected from the incinerator of Ludwigshafen was only 57 kg, resulting in 0.23 kg of 2–6 mm heavy non-ferrous metal after wet physical separation. Since the sample was too small to get a reliable value for gold, only the silver content was measured.

The batch of 75 kg of the 2–6 mm HNF concentrate was separated by MDS at a cut-density of approximately 10,000 kg/m3. The light and heavy products of this separation were each further processed to obtain fractions that could be smelted and analyzed. The heavy MDS fraction (6.3 kg) was first separated magnetically to remove the steel (1.05 kg), and then, the remaining nonmagnetic heavy material was treated with HCl to change the color of the brass particles from yellow to red. Finally, the nonmagnetic heavy fraction was handpicked to separate the yellow gold-containing alloys from the copper–alloys and the lead and silver. Each of the potential gold particles was analyzed by XRF to determine the alloy and gold mass. The rest of the sample was smelted and analyzed by instrumental neutron activation analysis. MDS tests on a parallel sample of the 0–2 mm HNF concentrate with the aim to further concentrate the precious metals were not very successful, indicating that most of the precious metal in this fraction is not made up of solid gold–alloys but of material with a density below or equal to that of copper.

3 Magnetic Density Separation

The basic principle of magnetic density separation is to use magnetic liquids as the separation medium. Such liquids have a material density which is comparable to that of water, but in a gradient magnetic field, the force on the volume of the liquid is the sum of gravity and the magnetic force. By a clever arrangement of the magnetic induction, it is possible to make the liquid artificially light or heavy.

Many designs of magnetic density separators are known from the literature (Kaiser 1969; Reimers 1974; Vlasov 1988; Svoboda 1998). The most regular type of separator consists of a cavity between two curved polar pieces of an electromagnet, in which the field lines run mainly horizontal and the concentration of field lines (the magnetic induction) increases toward the bottom of the cavity. If the induction could be made to depend perfectly linear in the vertical direction, and the magnetization of the magnetic liquid is a constant (which is nearly so for ferrofluids), the effective density of the medium would be the same in the entire cavity. In reality, Maxwell’s equations do not allow this, and therefore, the density is not entirely homogeneous in the cavity. The particles will converge to the middle of the cavity, and this will lower the capacity. Another important point is the relatively complex geometry of the cavity. Iron particles are present in most waste streams, and such iron will be collected at the surface of the magnet. With the geometry of the cavity, it is difficult to remove any iron present at the surface of the magnet. The complex geometry makes it also difficult to scale the separator to an industrial size.

The MDS approach to magnetic density separation is to create a medium with an artificial density that varies exponentially in the vertical direction. For a magnetic induction that varies exponentially in the vertical direction, the effective medium density varies in this direction as well. This is visualized in Fig. 2. The density is constant in the horizontal plane.

A series of alternating magnetic poles in a plane geometry can create such a field. The MDS separator segregates the feed into layers of different materials, with each material floating on a distance from the magnet according to its density and the apparent density of the liquid.

Figure 3 shows the principle of the separation. Because of the simple geometry of the MDS, in contrast with existing magnetic density separators, it is easy to get rid of any iron by using a conveyer belt. The MDS can be easily built on an industrial scale because, in the horizontal plane, there are no size limitations.

4 Precious Metals in Bottom Ash

The smelt obtained from the HNF metal in the 145 kg of the <2 mm bottom ash fraction was drilled vertically (in triple), and the drillings were milled to a powder and analyzed by XRF. The result for the corresponding average amounts of non-ferrous and precious metals per ton of bottom ash is shown in Table 1.

A small number of microprobe analyses on a polished section of a similar smelt indicate significant levels of platinum and palladium as well as silver and gold (Table 2).

The data therefore suggest that some of the precious metals in the 0–2 mm fraction are derived from electronics. This hypothesis fits well with the reconstructed mass balance of an MSWI in the Western European context. A recent study by Janz (2007) showed that German household waste contains 1.4% to 2.8% of small WEEE (shavers, hair-dryers, cell phones, etc.). Such numbers are consistent with a UK study by Darby (2005), who found that UK WEEE is 4% of household waste and that 23–60% of UK citizens respond to questionnaires saying that they put small WEEE in household waste. The maximum precious metal content in the 0–2 mm non-ferrous metal fraction resulting from WEEE can therefore be computed as:

Here, Y precious is the concentration of precious metals in the Printed Circuit Boards (PCB’s) of small WEEE, which is 110 ppm of gold and 280 ppm of silver (Cui 2005), F PCB is the mass fraction of PCBs in small WEEE (measured by Cui as 3%), F WEEE is the mass fraction of small WEEE in household waste (taken as 1.4% to 2.8%), F ash is the mass ratio of household waste to the resulting dry bottom ash, which is known to be about 3 for the Amsterdam incinerator (AEB incinerates waste with about 60% household waste), and F NF0–2 is the mass ratio of dry bottom ash to the 0–2 mm non-ferrous metal, which is about 700. The resulting equation is:

The precious metal concentrations found with XRF in the 0–2 mm HNF was 80 ppm of gold and 1,500 ppm of silver. According to the previous calculation based on average levels of precious metals found in PCBs of small WEEE, expected gold levels from WEEE ranges are between 100 and 200 ppm and silver between 300 and 600 ppm. In fact, the smelt level for gold is of the right order of magnitude, whereas the number for silver shows that WEEE is one of the important contributors.

At an early phase of the wet process development, two batches of the 2–6 mm heavy non-ferrous concentrate (about 1,600 kg in total) were smelted, and the metal product was analyzed by XRF. The results are shown in Table 3. A sample of the same fraction from a German incinerator was also smelted and analyzed for comparison. Samples of such small sizes do not show a consistent gold content, so only the silver content is given in Table 3. The results suggest that German bottom ash has a similar heavy non-ferrous and precious metal content as Dutch bottom ash.

A batch of 75 kg of the 2–6 mm heavy non-ferrous concentrate was separated by MDS to further investigate the source of the gold particles. Table 4 shows the XRF analysis of the gold particles. The alloy compositions show that most of the particles originate from jewelry. In some cases, this is also apparent from the shapes of the particles. A minor amount of gold is present as a thin coating on copper alloy particles (Table 4 shows five of such particles).

The 19 solid gold particles obtained from the separation were combined with four solid gold particles found in earlier tests of the MDS separation on smaller samples of several kilograms of 2–6 mm heavy non-ferrous concentrate each. In total, the 23 particles have a gold mass of 5.04 g and represent 68.5 kg of 2–6 mm heavy non-ferrous metal, corresponding to a level of 74 ppm. Since one of the particles out of the set of 23 has almost 1 g of gold, and particles containing up to 4 g of gold have been observed in the 2–6 mm fraction, this result has a significant statistical error. In order to reduce the error, the cumulative distribution of the gold mass of the particles was compared and fitted with the lognormal distribution (Fig. 4). The maximum deviation of the fit to the data in terms of cumulative probability is 0.07, which is well below the deviation that would be expected from the Kolmogorov–Smirnov theory. According to the best fit, the logarithm of the gold content of the solid gold–alloy particles is normally distributed with mean μ = −1.926 and SD σ = 1.077. Assuming that the gold mass of the solid gold–alloy particles in bottom ash is indeed distributed in this way, the gold mass of N of these particles is expected to be

or 0.26 g of gold per solid gold–alloy particle. According to this distribution, the probabilities that a solid gold–alloy particle contains less than 30 mg of gold (which would be typical for a particle with a size less than 2 mm) or more than 1 g (which would be typical for a particle with a size larger than 6 mm) are both less than 3%. This means that the fact that such particles may be (partially) missing from the 2–6 mm data set does not significantly affect the parameters of the lognormal fit. The expected gold mass of a 2- to 6-mm particle may be somewhat lower, however:

The upper threshold of 2 g of gold for the 2–6 mm fraction implies that about 10% of the gold in the form of solid gold–alloy particles ends up in the 6- to 20-mm fraction at the AEB wet treatment plant.

The overall analysis of the light and heavy MDS products is given in Table 5. The recovery of the various nonmagnetic materials into the heavy MDS product is strictly increasing with the material density, as expected. Nevertheless, the recovery of silver and lead is less than satisfactory. This indicates that the cut-density of the experiment was slightly too high. Analysis of the relation between material recovery and material density shows that by lowering the cut-point by about 800 kg/m3, the recoveries of silver and lead would increase to about 26% and 45%, respectively, at the expense of losing 10% of the copper to the heavy MDS product. The recovery value for gold in Table 5 was calculated on the basis of the gold mass of the 24 recovered pieces of Table 2 and the known gold content of the large smelts (Table 1). However, sampling theory shows that the limited sample mass of the MDS experiment results in an uncertainty of about 18% in the gold recovery value.

5 Economical Evaluation

The economical analysis focuses on the 2–6 mm HNF for which two economic options are compared. One option is to sell the original 2–6 mm HNF fraction to a precious metal smelter. A precious metals smelter pays for the gold (minimum 5 g of Au in 1 ton), silver (minimum 100 g of Ag in 1 ton), and the copper content. Table 6 shows the estimated price for one ton of 2–6 mm HNF when it is sold to a precious metals smelter without the MDS. The smelter pays 2,108 euro including charges and penalties. The metal prices are averages based on London metal exchange (LME) of the second half of 2007.

The second option is to separate the fraction into three products: a stone–glass fraction, a copper–zinc concentrate for the copper or brass smelter, and a precious metal concentrate for the precious metals smelter (Table 7). The copper–zinc concentrate can be either sold to a brass smelter or to a copper smelter. Therefore, a copper smelter from Germany and a brass smelter from the Netherlands were contacted to bid on the light product. The copper smelter pays for the copper content and the offered price for one ton of the 2–6 mm light fraction was between 455–637 Euro. The route of the copper smelter was not considered as an interesting option. The brass smelter uses a different pricing strategy which is based on the current market prices for their metals of interest as well as for the market situation of their final product. The prices offered by the smelter were between 80% and 96% of the LME value including charges and penalties. The value at this moment for the fraction shown in Table 5 is between 1,806 and 2,167 euro/ton assuming there is 25% of stone in the light 2–6 mm fraction. At current LME prices, the value per ton of the original HNF fraction has the value between 2,357 and 2,686 euro/ton when selling it to a precious metal smelter and to a brass smelter. The cost of the MDS process is calculated on the basis of an installation for a large incinerator (e.g., incinerator in Amsterdam) which produces 300,000 tons of bottom ash, or about 1,500 tons of the 2–6 mm HNF fraction per year. The cost of the process is a combination of investment cost (estimated at 67 euro/ton) and operation cost (123 euro/ton).

The bottom ash from the incinerator of Amsterdam is first separated by the pilot plant for wet physical separation of bottom ash. Therefore, Tables 8 and 9 show the estimated cost and returns of the pilot plant with and without the MDS. The highest prices offered by the brass smelter (2,167 euro/ton) were taken into account for the total economic calculation (Table 9).

The profit of the pilot plant without the MDS is approximately 3 euro/ton and, with the MDS, 5 euro/ton of bottom ash. The MDS step increased the value of bottom ash by approximately 2 euro/ton.

6 Conclusion

Two HNF fractions from Amsterdam’s bottom ash were analyzed for the precious metals content; 0–2 mm HNF and 2–6 mm HNF. Each fraction contains approximately 100 ppm of gold and 1,500–4,000 ppm of silver. The source of the gold in the 0- to 2-mm fraction is probably from waste electrical and electronic equipment (WEEE). The separation of this fine fraction is technically very difficult, and it needs further research. The source of the gold in the 2–6 mm HNF fraction is from jewelry. The statistics of the gold particles show that 10% of gold from the jewelry will be found in the fraction >6 mm. The separation experiment with the 2–6 mm HNF fraction using the MDS system shows that 88% of the gold can be recovered in a precious metal concentrate, while 94% of the copper can be recovered in the copper–zinc fraction. The recoveries of silver and lead should be improved by lowering the density of the magnetic fluid. By improving the MDS settings, the recovery of silver and lead in the precious metals fraction will increase.

New technology based on magneto-hydrostatic separation is suitable from the economical point of view to recover precious metals from the HNF fraction >2 mm of MSWI bottom ash. The system of separation is simple and economically feasible. Economical analysis was performed for the case of a large incinerator producing about 1,500 tons of this fraction per year, but the additional value of precious metals like platinum and palladium was left out of the calculation. The MDS separates the fraction into a copper–zinc concentrate for the copper or brass smelter and a precious metal concentrate for the precious metal smelter. The price of the 2–6 mm HNF fraction increased from 2,108 euro/ton (price without the MDS) up to 2,357–2,686 euro/ton (price with the MDS).The value of MSWI bottom ash by using the MDS and separating precious metals increased the value by 2 euro/ton.

References

Bakker, E. J., Muchova, L., & Rem, P. C. (2007). Separation of precious metals from MSWI bottom ash. Conference proceeding from 6th international industrial mineral symposium, 1–3 February, Izmir, Turkey, pp.6.

Cui, J. (2005). Mechanical recycling of consumer electronic scrap, Ph.D. thesis 2005:36 ISSN: 1402–1757, Lulea University of Technology.

Darby, L., & Obara, L. (2005). Household recycling behavior and attitudes towards the disposal of small electrical and electronic equipment. Resources, Conservation and Recycling, 44(1), 17–35.

Gy, P. (1999). Sampling for analytical purposes. John Wiley & Sons, ISBN 0-471 97956-2.

Janz, A., & Bilitewski, B. (2007). The contribution of small electric and electronic devices to the content of hazardous substances and recyclables in residual household waste. Proceedings of the International Conference on Environmental Management, Engineering, Planning and Economics, Skiathos, June 24–28, 2007. Pages:1576.

Chimenos, J. M., Segarra, M., Fernandez, M. A., & Espiell, F. (1999). Characterization of the bottom ash in municipal solid waste incinerator. Journal of Hazardous Materials, 64, 211–222.

Kaiser, R. (1969). Patent US 3,483,968.

Muchová, L., & Rem, P. C. (2006). Metal content and recovery of MSWI bottom ash in Amsterdam. Proceedings Waste Management and the Environment, III, 211–216.

Muchová, L., & Rem, P. C. (2007a). Wet or dry separation; management of bottom ash in Europe. Waste Management World Nov-Dec, 46–49.

Muchova, L., Rem, P., & Van Berlo, M. (2007b). Innovative Technology for the Treatment of Bottom Ash. Conference proceeding from ISWA/NVRD World Congress 2007, Amsterdam, The Netherlands. 24–27 September 2007.

Reimers, G. W., Rholl, S. A., & Khallafalla, S. A. (1974). Patent US 3,788,465.

Rem, P. C., de Vries, C., van Kooy, L. A., Bevilacqua, P., & Reuter, M. A. (2004). The Amsterdam pilot on bottom ash. Mining Engineering, 17, 363–365.

Schmelzer, G., Wolf, S., & Hoberg, H. (1996). New wet treatment for components of incineration slag. AT Aufbereitungs Technik, 37, 1996.

Svoboda, J. (1998). Patent EP 0 839 577.

Van Kooy, L., Mooij, M., & Rem, P. (2004). Kinetic gravity separation. Physical Separation in Science and Engineering, 13, 25–32.

Vlasov, V. N., Gubarevich, V. N., Zaskevich, M. V., Kravchenko, N. D., Zelenchuk, V. A., & Alipov, A. I. (1988). Patent EP 0 362 380.

Wiles, C., & Shepher, P. (1999). Beneficial use and recycling of municipal waste, Combustion Residues—a comprehensive resource document. National Renewable Energy Laboratory, Golden Coloradom, BK-570–25841.

Acknowledgement

The research in this project is funded in part by the LIFE program of the European Union.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

Muchova, L., Bakker, E. & Rem, P. Precious Metals in Municipal Solid Waste Incineration Bottom Ash. Water Air Soil Pollut: Focus 9, 107–116 (2009). https://doi.org/10.1007/s11267-008-9191-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11267-008-9191-9