Abstract

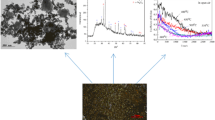

In this study, the Fe3O4@PEG nanocomposites with core–shell structure were fabricated by a co-precipitation method and characterized by scanning electron microscopy, transmission electron microscopy, Fourier transform infrared spectroscopy, X-ray diffractometer and thermal gravimetric. The physicochemical and tribological properties of the Fe3O4@PEG nanocomposites in aqueous glycerol were systematically evaluated on steel/steel contact for the first time. The aqueous glycerol solution added with 1.0 wt% Fe3O4@PEG showed no obvious precipitation after standing for 72 h and had good dispersion stability. Compared with the base aqueous glycerol, the Fe3O4@PEG nanocomposites exhibited excellent friction-reducing and anti-wear properties at an optimal concentration of 1.0 wt%, with a 41.4% decrease in friction coefficient and a 24.1% reduction in wear volume. Also, the Fe3O4@PEG nanocomposites in aqueous glycerol exhibited superior lubricating performance than unmodified Fe3O4. The boundary lubrication films formed on the surface were attributed to be the main factor in reducing friction and wear, and a possible lubrication mechanism was suggested.

Similar content being viewed by others

References

Martini, A., Ramasamy, U.S., Len, M.: Review of viscosity modifier lubricant additives. Tribol. Lett. 66, 1–14 (2018). https://doi.org/10.1007/s11249-018-1007-0

Lee, S., Muller, M.: Boundary lubrication of oxide surfaces by Poly(L-lysine)-g-poly(ethylene glycol) (PLL-g-PEG) in aqueous media. Tribol. Lett. 15, 231–239 (2003). https://doi.org/10.1023/a:1024861119372

Drobek, T., Spencer, N.D.: Nanotribology of surface-grafted PEG layers in an aqueous environment. Langmuir 24, 1484–1488 (2008). https://doi.org/10.1021/la702289n

Arcifa, A., Rossi, A.: Lubrication of Si-based tribopairs with a hydrophobic ionic liquid: the multiscale influence of water. J Phys. Chem. C. 122, 7331–7343 (2018). https://doi.org/10.1021/acs.jpcc.8b01671

Ju, C., Zheng, D.: Tribological properties of green ILs containing MoS2 quantum dots with one-step preparation. Tribol. Lett. 68, 1–9 (2020). https://doi.org/10.1007/s11249-020-01314-9

Zheng, D., Zhao, Q.: The interaction of two anticorrosive ionic liquid additives on the friction properties of water lubricants. Tribol. Int. 141, 237–249 (2020). https://doi.org/10.1016/j.triboint.2019.105948

Zheng, D., Wang, X.: Anticorrosion and lubricating properties of a fully green lubricant. Tribol. Int. 130, 324–333 (2019). https://doi.org/10.1016/j.triboint.2018.08.014

Zheng, G., Zhang, G.: Tribological properties and surface interaction of novel water-soluble ionic liquid in water-glycol. Tribol. Int. 116, 440–448 (2017). https://doi.org/10.1016/j.triboint.2017.08.001

Bondarev, A.V., Fraile, A.: Mechanisms of friction and wear reduction by h-BN nanosheet and spherical W nanoparticle additives to base oil: experimental study and molecular dynamics simulation. Tribol. Int. (2020). https://doi.org/10.1016/j.triboint.2020.106493

Ren, B., Gao, L.: Tribological properties and anti-wear mechanism of ZnO@graphene core-shell nanoparticles as lubricant additives. Tribol. Int. 144, 106–114 (2020). https://doi.org/10.1016/j.triboint.2019.106114

Wu, X., Zhao, G.: Investigating the tribological performance of nanosized MoS2 on graphene dispersion in perfluoropolyether under high vacuum. RSC Adv. 6, 98606–98610 (2016). https://doi.org/10.1039/c6ra22863a

Yao, Y., Wang, X.: Tribological property of onion-like fullerenes as lubricant additive. Mater. Lett. 62, 2524–2527 (2008). https://doi.org/10.1016/j.matlet.2007.12.056

Chen, L., Xu, H.: Preparation of Cu–Ni bimetallic nanoparticles surface-capped with dodecanethiol and their tribological properties as lubricant additive. Particuology 34, 89–96 (2017). https://doi.org/10.1016/j.partic.2016.12.006

Huang, W., Wang, X.: Study on the synthesis and tribological property of Fe3O4 based magnetic fluids. Tribol. Lett. 33, 187–192 (2009). https://doi.org/10.1007/s11249-008-9407-1

Wang, N., Wang, H.: High-efficient and environmental-friendly PTFE@SiO2 core-shell additive with excellent AW/EP properties in PAO6. Tribol. Int. 158, 106–121 (2021). https://doi.org/10.1016/j.triboint.2021.106930

Lu, Z., Cao, Z.: Preparation and tribological properties of WS2 and WS2/TiO2 nanoparticles. Tribol. Int. 130, 308–316 (2019). https://doi.org/10.1016/j.triboint.2018.09.030

Johnson, D., Hils, J.: Phosphate esters, thiophosphate esters and metal thiophosphates as lubricant additives. Lubricants 1, 132–148 (2013). https://doi.org/10.3390/lubricants1040132

Zhang, X., Sun, W.: Investigation of the tribological properties of two different layered sodium silicates utilized as solid lubrication additives in lithium grease. Ind. Eng. Chem. Res. 53, 182–188 (2013). https://doi.org/10.1021/ie402481u

Ye, C., Liu, W.: Room-temperature ionic liquids: a novel versatile lubricant. Chem .Commun. (Camb). (2001). https://doi.org/10.1039/b106935g

Mello, V.S., Trajano, M.F.: Comparison between the action of nano-oxides and Conventional EP additives in boundary lubrication. Lubricants 8, 5–54 (2020). https://doi.org/10.3390/lubricants8050054

Pham, S.T., Tieu, A.K.: Smart-Responsive Colloidal Capsules as an Emerging Tool to Design a Multifunctional Lubricant Additive. ACS Appl Mater Interfaces. 13, 7714–7724 (2021). https://doi.org/10.1021/acsami.0c20759

Wu, X., Gong, K.: MoS2/WS2 quantum dots as high-performance lubricant additive in polyalkylene glycol for steel/steel contact at elevated temperature. Adv. Mater. Interfaces (2018). https://doi.org/10.1002/admi.201700859

Lee, J., Cho, S.: Enhancement of lubrication properties of nano-oil by controlling the amount of fullerene nanoparticle additives. Tribol. Lett. 28, 203–208 (2007). https://doi.org/10.1007/s11249-007-9265-2

Song, X., Qiu, Z.: Submicron-lubricant based on crystallized fe3o4 spheres for enhanced tribology performance. Chem. Mater. 26, 5113–5119 (2014). https://doi.org/10.1021/cm502426y

Zhou, G., Zhu, Y.: Sliding tribological properties of 0.45% carbon steel lubricated with Fe3O4 magnetic nano-particle additives in baseoil. Wear 301, 753–757 (2013). https://doi.org/10.1016/j.wear.2013.01.027

Liu, L., Jiao, S.: A green design for lubrication: multifunctional system containing Fe3O4@MoS2 nanohybrid. ACS. Sustain. Chem. Eng. 6, 7372–7379 (2018). https://doi.org/10.1021/acssuschemeng.7b04801

Yan, W., Ramakrishna, S.N.: Brushes, graft copolymers, or bottlebrushes? the effect of polymer architecture on the nanotribological properties of grafted-from assemblies. Langmuir 35, 11255–11264 (2019). https://doi.org/10.1021/acs.langmuir.9b01265

Xu, Y., Geng, J.: Lubricating mechanism of Fe3O4@MoS2 core-shell nanocomposites as oil additives for steel/steel contact. Tribol. Int. 121, 241–251 (2018). https://doi.org/10.1016/j.triboint.2018.01.051

Huang, J., Li, Y.: Preparation and tribological properties of core-shell Fe3O4@C microspheres. Tribol. Int. 129, 427–435 (2019). https://doi.org/10.1016/j.triboint.2018.08.036

Zhang, Q., Wu, B.: Preparation, characterization and tribological properties of polyalphaolefin with magnetic reduced graphene oxide/Fe3O4. Tribol. Int. 141, 105952 (2020). https://doi.org/10.1016/j.triboint.2019.105952

Huo, L., Zeng, X.: Enhanced removal of As (V) from aqueous solution using modified hydrous ferric oxide nanoparticles. Sci Rep. 7, 40765 (2017). https://doi.org/10.1038/srep40765

Karimi, S., Namazi, H.: Fe3O4@PEG-coated dendrimer modified graphene oxide nanocomposite as a pH-sensitive drug carrier for targeted delivery of doxorubicin. J. Alloys Compd. 879, 160426 (2021). https://doi.org/10.1016/j.jallcom.2021.160426

Totolin, V., Goecerler, H.: The role of ferric oxide nanoparticles in improving lubricity and tribo-electrochemical performance during chemicalmechanical polishing. Tribol. Lett. 65, 1–12 (2017). https://doi.org/10.1007/s11249-016-0806-4

Acknowledgements

This work was supported by National Key R&D Program of China (2018YFB2000601) and National Natural Science Foundation of China (NSFC 51875553).

Funding

Funding was supported by National Key R&D Program of China, (Grant No. 2018YFB2000601), Natural Science Foundation of China, (Grant No. 51875553).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no competing financial interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, T., Zhao, Q., Hu, M. et al. Tribological Behavior of Novel Core–Shell Fe3O4@PEG Nano-Additives. Tribol Lett 70, 116 (2022). https://doi.org/10.1007/s11249-022-01656-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-022-01656-6