Abstract

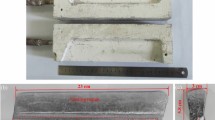

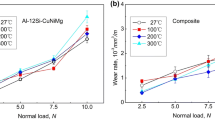

The effect of Ti3AlC2 content on electrical friction and wear behaviors of Cu–Ti3AlC2 composites is investigated. Composites with different volume ratios of Ti3AlC2 are prepared by the hot-pressing method, and experiments are performed on a block-on-ring sliding electrical wear tester. The results demonstrate that with increasing Ti3AlC2 content, the contact voltage drops of the Cu–Ti3AlC2 composites increase, the friction coefficient decreases, and the wear rate initially decreases and then increases. A lubricating film forms on the worn surface during the process of electrical sliding wear, which improves the wear resistance of the material. Raman spectroscopy and X-ray photoelectron spectroscopy spectra of the worn surface show that the lubricating film comprises Ti3AlC2, CuO, TiO2 and Al2O3, where the TiO2 and Al2O3 result from decomposition of Ti3AlC2.

Similar content being viewed by others

References

Ding, T., Chen, G.X., Li, Y.M., He, Q.D., Xuan, W.J.: Friction and wear behavior of pantograph strips sliding against copper contact wire with electric current. AASRI Procedia 2, 288–292 (2012)

Bucca, G., Collina, A.: A procedure for the wear prediction of collector strip and contact wire in pantograph–catenary system. Wear 266, 46–59 (2009)

Huang, S., Feng, Y., Liu, H., Ding, K., Qian, G.: Electrical sliding friction and wear properties of Cu–MoS2–graphite–WS2 nanotubes composites in air and vacuum conditions. Mater. Sci. Eng. A 560, 685–692 (2013)

Yi, F., Zhang, M., Xu, Y.: Effect of the electric current on the friction and wear properties of the CNT–Ag–G composites. Carbon 43, 2685–2692 (2005)

Zhao, H., Barber, G.C., Liu, J.: Friction and wear in high speed sliding with and without electrical current. Wear 249, 409–414 (2001)

Wang, Y.A., Li, J.X., Yan, Y., Qiao, L.J.: Effect of electrical current on tribological behavior of copper-impregnated metallized carbon against a Cu–Cr–Zr alloy. Tribol. Int. 50, 26–34 (2012)

Su, L., Gao, F., Han, X., Fu, R., Zhang, E.: Tribological behavior of copper–graphite powder third body on copper-based friction materials. Tribol. Lett. 60, 30 (2015)

Hu, Z.L., Chen, Z.H., Xia, J.T., Ding, G.Y.: Effect of pv factor on the wear of carbon brushes for micromotors. Wear 265, 336–340 (2008)

Hu, Z.L., Chen, Z.H., Xia, J.T.: Study on surface film in the wear of electrographite brushes against copper commutators for variable current and humidity. Wear 264, 11–17 (2008)

Hu, Z.L., Chen, Z.H., Xia, J.T., Ding, G.Y.: Wear property of high-resistivity carbon brushes made with and without MoS2 in variable humidity. Trans. Nonferrous Met. Soc. China 18, 340–345 (2008)

Qian, G., Feng, Y., Chen, Y.M., Mo, F., Wang, Y.Q., Liu, W.H.: Effect of WS2 addition on electrical sliding wear behaviors of Cu–graphite–WS2 composites. Trans. Nonferrous Met. Soc. China 25, 1986–1994 (2015)

Yasar, I., Canakci, A., Arslan, F.: The effect of brush spring pressure on the wear behavior of copper–graphite brushes with electrical current. Tribol. Int. 40, 1381–1386 (2007)

Kaczmar, J.W., Pietrzak, K., Włosińskic, W.: The production and application of metal matrix composite materials. J. Mater. Process. Technol. 106, 58–67 (2000)

Wang, J., Yi, F., Shu, L., Shen, L.: Influence of graphite content on sliding wear characteristics of CNTs-Ag-G electrical contact materials. Trans. Nonferrous Met. Soc. China 19, 113–118 (2009)

He, D.H., Manory, R.: A novel electrical contact material with improved self-lubrication for railway current collectors. Wear 249, 626–636 (2001)

Qian, G., Feng, Y., Chen, F.Y., Liu, W.H., Zhang, X.B., Liu, Y.F.: Effect of current polarity on electrical sliding wear behavior of Cu-WS2-graphite-WS2 nanotube composites in air and vacuum conditions. Sci. China Technol. Sci. 56, 2839–2846 (2013)

Qian, G., Feng, Y., Li, B., Huang, S.Y., Liu, H.J., Ding, K.W.: Effect of electrical current on the tribological behavior of the Cu-WS2-G composites in air and vacuum. Chin. J. Mech. Eng. 26, 384–392 (2013)

Mo, F., Feng, Y., Chen, Y.M., Wang, Y.Q., Qian, G., Dou, Y.K., Zhang, X.B.: Effect of La2O3 on electrical friction and wear properties of Cu-graphite composites. J. Rare Earths 33, 327–333 (2015)

Peng, T., Yan, Q., Li, G., Zhang, X., Wen, Z., Jin, X.: The braking behaviors of cu-based metallic brake pad for high-speed train under different initial braking speed. Tribol. Lett. 65, 135 (2017)

Barsoum, M.W.: The MN+1AXN phases: a new class of solids; thermodynamically stable nanolaminates. Prog. Solid State Chem. 28, 201–281 (2000)

Tzenov, N.V., Barsoum, M.W.: Synthesis and characterization of Ti3AlC2. J. Am. Ceram. Soc. 83, 825–832 (2010)

Sun, Z.M.: Progress in research and development on MAX phases: a family of layered ternary compounds. Int. Mater. Rev. 56, 143–166 (2011)

Ai, T.T.: High-temperature oxidation behavior of un-dense Ti3AlC2 material at 1000 C in air. Ceram. Int. 38, 2537–2541 (2012)

Bao, Y.W., Zhou, Y.C.: Evaluating high-temperature modulus and elastic recovery of Ti3SiC2 and Ti3AlC2 ceramics. Mater. Lett. 57, 4018–4022 (2003)

Zhou, Y.C., Wang, X.H., Sun, Z.M., Chen, S.Q.: Electronic and structural properties of the layered ternary carbide Ti3AlC2. J. Mater. Chem. 11, 2335–2339 (2001)

Huang, X.C., Feng, Y., Dou, Y.K., Tang, H., Ding, D.D., Tian, P., Xia, M., Qian, G., Wang, Y.Q., Zhang, X.B.: Effect of electron irradiation on Ti3AlC2. Scr. Mater. 113, 114–117 (2016)

Huang, X.C., Feng, Y., Qian, G., Zhao, H., Zhang, J.C., Zhang, X.B.: Physical, mechanical, and ablation properties of Cu-Ti3AlC2 composites with various Ti3AlC2 contents. Mater. Sci. Technol. 34, 757–762 (2018)

Huang, X.C., Feng, Y., Qian, G., Zhang, J.C., Zhang, X.B.: Influence of breakdown voltages on arc erosion of a Ti3AlC2 cathode in an air atmosphere. Ceram. Int. 43, 10601–10605 (2017)

Swamy, V.: Size-dependent modifications of the first-order Raman spectra of nanostructured rutile TiO2. Phys. Rev. B 77, 998–1002 (2008)

Presser, V., Naguib, M., Chaput, L., Togo, A., Hug, G., Barsoum, M.W.: First-order Raman scattering of the MAX phases: Ti2AlN, Ti2AlC0.5N0.5, Ti2AlC, (Ti0.5V0.5)2AlC, V2AlC, Ti3AlC2, and Ti3GeC2. J. Raman Spectrosc. 43, 168–172 (2012)

Porto, S.P.S., Krishnan, R.S.: Raman effect of corundum. J. Chem. Phys. 47, 1009–1012 (1967)

Myhra, S., Crossley, J.A.A., Barsoum, M.W.: Crystal-chemistry of the Ti3AlC2 and Ti4AlN3 layered carbide/nitride phases-characterization by XPS. J. Phys. Chem. Solids 62, 811–817 (2001)

Diebold, U.: TiO2 by XPS. Surf. Sci. Spectra 4, 227–231 (1996)

Harju, M., Areva, S., Rosenholm, J.B., Mäntylä, T.: Characterization of water exposed plasma sprayed oxide coating materials using XPS. Appl. Surf. Sci. 254, 5981–5989 (2008)

Rotole, J.A.: Corrundum (α-Al2O3) by XPS. Surf. Sci. Spectra 5, 11–17 (1998)

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51571078, 51871085), and the Natural Science Foundation of Anhui Province (1808085 ME122, 1908085 QE218).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhao, H., Feng, Y., Qian, G. et al. Effect of Ti3AlC2 Content on Electrical Friction and Wear Behaviors of Cu–Ti3AlC2 Composites. Tribol Lett 67, 96 (2019). https://doi.org/10.1007/s11249-019-1211-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-019-1211-6