Abstract

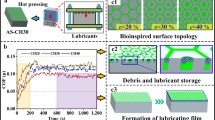

This paper proposes a new strategy to design the copper–graphite self-lubricating composites (CGSCs) for dynamic sealing applications. The relationships among structural parameters, mechanical and tribological properties of CGSCs were investigated. Results showed that the composites with a 3D network structure presented superior comprehensive mechanical performance; the bending strength, fracture toughness and impact toughness can reach 352 MPa, 9.6 MPa m1/2 and 9.2 J cm−2, respectively, which are 1.4, 1.7 and 5.8 higher than conventional Cu663–graphite composite. This new strategy was based on a combination of the large plastic deformation of the copper 3D network, and considerable crack deflection includes by spherical graphite particles in fracture. Meanwhile, this novel design shows the perfect combination of the mechanical reliability and self-lubricated ability. The 3D-CGSCs exhibit more excellent tribological properties when sliding against AISI 52100 bearing steel under dry condition at room temperature. The friction coefficient and wear rate are stable and with low value under a wide range of loads and reciprocating frequencies, and it possesses good anti-friction capability over a long sliding distance (3 km).

Similar content being viewed by others

References

Chen, J.K., Huang, I.S.: Thermal properties of aluminum–graphite composites by powder metallurgy. Compos. B Eng. 44(1), 698–703 (2013). https://doi.org/10.1016/j.compositesb.2012.01.083

Grandin, M., Wiklund, U.: Wear phenomena and tribofilm formation of copper/copper–graphite sliding electrical contact materials. Wear. 398, 227–235 (2018). https://doi.org/10.1016/j.wear.2017.12.012

Grandin, M., Wiklund, U.: Influence of mechanical and electrical load on a copper/copper–graphite sliding electrical contact. Tribol. Int. 121, 1–9 (2018). https://doi.org/10.1016/j.triboint.2018.01.004

Rohatgi, P.K., Ray, S., Liu, Y.: Tribological properties of metal matrix graphite particle composites. Int. Mater. Rev. 37(3), 129–149 (1992). https://doi.org/10.1179/imr.1992.37.1.129

Ma, W.L., Lu, J.J.: Effect of sliding speed on surface modification and tribological behavior of copper–graphite composite. Tribol. Lett. 41(2), 363–370 (2011). https://doi.org/10.1007/s11249-010-9718-x

He, D.H., Manory, R.: A novel electrical contact material with improved self–lubrication for railway current collectors. Wear. 249(7), 626–636 (2001). https://doi.org/10.1016/s0043-1648(01)00700-1

Su, Y.F., Zhang, Y.S., Song, J.J., Hu, L.T.: Tribological behavior and lubrication mechanism of self–lubricating ceramic/metal composites: the effect of matrix type on the friction and wear properties. Wear. 372, 130–138 (2017). https://doi.org/10.1016/j.wear.2016.12.005

Moustafa, S.F., ElBadry, S.A., Sanad, A.M.: Effect of graphite with and without copper coating on consolidation behaviour and sintering of copper–graphite composite. Powder Metall. 40(3), 201–206 (1997). https://doi.org/10.1179/pom.1997.40.3.201

Kadkhodapour, J., Montazerian, H., Samadi, M., Schmauder, S., Mehrizi, A.A.: Plastic deformation and compressive mechanical properties of hollow sphere aluminum foams produced by space holder technique. Mater. Des. 83, 352–362 (2015). https://doi.org/10.1016/j.matdes.2015.05.086

Ji, K.J., Shan, W.G., Xia, Y.Q., Dai, Z.D.: The tribological behaviors of self-lubricating composites as filler in copper foam. Tribol. Trans. 55(1), 20–31 (2012). https://doi.org/10.1080/10402004.2011.622069

Davies, G.J., Zhen, S.: Metallic foams-their production, properties and applications. J. Mater. Sci. 18(7), 1899–1911 (1983). https://doi.org/10.1007/bf00554981

Fan, Z., Zhang, B., Gao, Y., Guan, X., Xu, P.: Deformation mechanisms of spherical cell porous aluminum under quasi-static compression. Scripta Mater. 142, 32–35 (2018). https://doi.org/10.1016/j.scriptamat.2017.08.019

Yang, W.L., Zhou, L.P., Peng, K., Zhu, J.J., Wan, L.: Effect of tungsten addition on thermal conductivity of graphite/copper composites. Compos. B Eng. 55, 1–4 (2013). https://doi.org/10.1016/j.compositesb.2013.05.023

Kato, H., Takama, M., Iwai, Y., Washida, K., Sasaki, Y.: Wear and mechanical properties of sintered copper–tin composites containing graphite or molybdenum disulfide. Wear. 255, 573–578 (2003). https://doi.org/10.1016/s0043-1648(03)00072-3

Joyce, M.R., Reed, P.A.S., Syngellakis, S.: Numerical modelling of crack shielding and deflection in a multi-layered material system. Mat. Sci. Eng. A. 342(1–2), 11–22 (2003). https://doi.org/10.1016/s0921-5093(02)00279-4

Hofmann, D.C., Suh, J.Y., Wiest, A., Duan, G., Lind, M.L., Demetriou, M.D., Johnson, W.L.: Designing metallic glass matrix composites with high toughness and tensile ductility. Nature. 451(7182), 1085–1089 (2008). https://doi.org/10.1038/nature06598

Song, J.J., Su, Y.F., Fan, H.Z., Zhang, Y.S., Hu, L.T.: A novel design to produce high-strength and high-toughness alumina self-lubricated composites with enhanced thermal-shock resistance—Part I: mechanical properties and thermal shock behavior of Al2O3/Mo–Al2O3 laminated composites. J. Eur. Ceram. Soc. 37(1), 213–221 (2017). https://doi.org/10.1016/j.jeurceramsoc.2016.08.016

Purcek, G., Saray, O., Karaman, I., Kucukomeroglu, T.: Effect of severe plastic deformation on tensile properties and impact toughness of two-phase Zn–40Al alloy. Mat. Sci. Eng. A. 490(1–2), 403–410 (2008). https://doi.org/10.1016/j.msea.2008.01.080

Mirone, G.: A new model for the elastoplastic characterization and the stress–strain determination on the necking section of a tensile specimen. Int. J. Solids Struct. 41(13), 3545–3564 (2004). https://doi.org/10.1016/j.ijsolstr.2004.02.011

Onck, P., Van Merkerk, R., Raaijmakers, A., De Hosson, J.T.M.: Fracture of open-and closed-cell metal foams. J. Mater. Sci. 40(22), 5821–5828 (2005). https://doi.org/10.1007/s10853-005-4996-7

Zhang, B.Y., Lin, Y.F., Li, S., Zhai, D.X., Wu, G.H.: Quasi-static and high strain rates compressive behavior of aluminum matrix syntactic foams. Compos. B Eng. 98, 288–296 (2016). https://doi.org/10.1016/j.compositesb.2016.05.034

Gupta, P.K., Iqbal, M.A., Mohammad, Z.: Energy dissipation in plastic deformation of thin aluminum targets subjected to projectile impact. Int. J. Impact Eng. 110, 85–96 (2017). https://doi.org/10.1016/j.ijimpeng.2017.05.008

Zhao, H.J., Liu, L., Wu, Y.T., Hu, W.B.: Investigation on wear and corrosion behavior of Cu–graphite composites prepared by electroforming. Compos. Sci. Tech. 67(6), 1210–1217 (2007). https://doi.org/10.1016/j.compscitech.2006.05.013

Cui, G.J., Niu, M.Y., Zhu, S.Y., Yang, J., Bi, Q.L.: Dry-sliding tribological properties of bronze–graphite composites. Tribol. Lett. 48(2), 111–122 (2012). https://doi.org/10.1007/s11249-012-0007-8

Moustafa, S.F., El-Badry, S.A., Sanad, A.M., Kieback, B.: Friction and wear of copper–graphite composites made with Cu-coated and uncoated graphite powders. Wear. 253(7–8), 699–710 (2002). https://doi.org/10.1016/s0043-1648(02)00038-8

Liu, Y.B., Lim, S.C., Ray, S., Rohatgi, P.K.: Friction and wear of aluminum–graphite composites—the smearing process of graphite during sliding. Wear. 159(2), 201–205 (1992). https://doi.org/10.1016/0043-1648(92)90303-p

Riahi, A.R., Alpas, A.T.: The role of tribo-layers on the sliding wear behavior of graphitic aluminum matrix composites. Wear. 251, 1396–1407 (2001). https://doi.org/10.1016/s0043-1648(01)00796-7

Zhao, J.H., Li, P., Tang, Q., Zhang, Y.Q., He, J.S., He, K.: Influence of metal-coated graphite powders on microstructure and properties of the bronze-matrix/graphite composites. J. Mater. Eng. Perform. 26(2), 792–801 (2017). https://doi.org/10.1007/s11665-016-2495-4

Lim, S.C., Ashby, M.F.: Wear-mechanism maps. Acta Metall. 35(1), 1–24 (1987). https://doi.org/10.1016/0001-6160(87)90209-4

Amanov, A., Cho, I.S., Pyoun, Y.S., Lee, C.S., Park, I.G.: Micro-dimpled surface by ultrasonic nanocrystal surface modification and its tribological effects. Wear. 286, 136–144 (2012). https://doi.org/10.1016/j.wear.2011.06.001

Amanov, A., Sasaki, S.: A study on the tribological characteristics of duplex-treated Ti–6Al–4V alloy under oil-lubricated sliding conditions. Tribol. Int. 64, 155–163 (2013). https://doi.org/10.1016/j.triboint.2013.03.015

Langhorn, J., Borjali, A., Hippensteel, E., Nelson, W., Raeymaekers, B.: Microtextured CoCrMo alloy for use in metal-on-polyethylene prosthetic joint bearings: multi-directional wear and corrosion measurements. Tribol. Int. 124, 178–183 (2018). https://doi.org/10.1016/j.triboint.2018.04.007

Acknowledgements

The authors gratefully acknowledge the financial support of the National Natural Science Foundation of China (51775534) and the Youth Innovation Promotion Association CAS (2013272). Thanks are also due to Hengzhong Fan (State Key Laboratory of Solid Lubrication, Lanzhou Institute of Chemical Physics, Chinese Academy of Sciences, Lanzhou, China) for the assistance during friction testing and the improvement in mechanism diagram.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jiang, X., Song, J., Su, Y. et al. Novel Design of Copper–Graphite Self-Lubricating Composites for Reliability Improvement Based on 3D Network Structures of Copper Matrix. Tribol Lett 66, 143 (2018). https://doi.org/10.1007/s11249-018-1098-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-018-1098-7